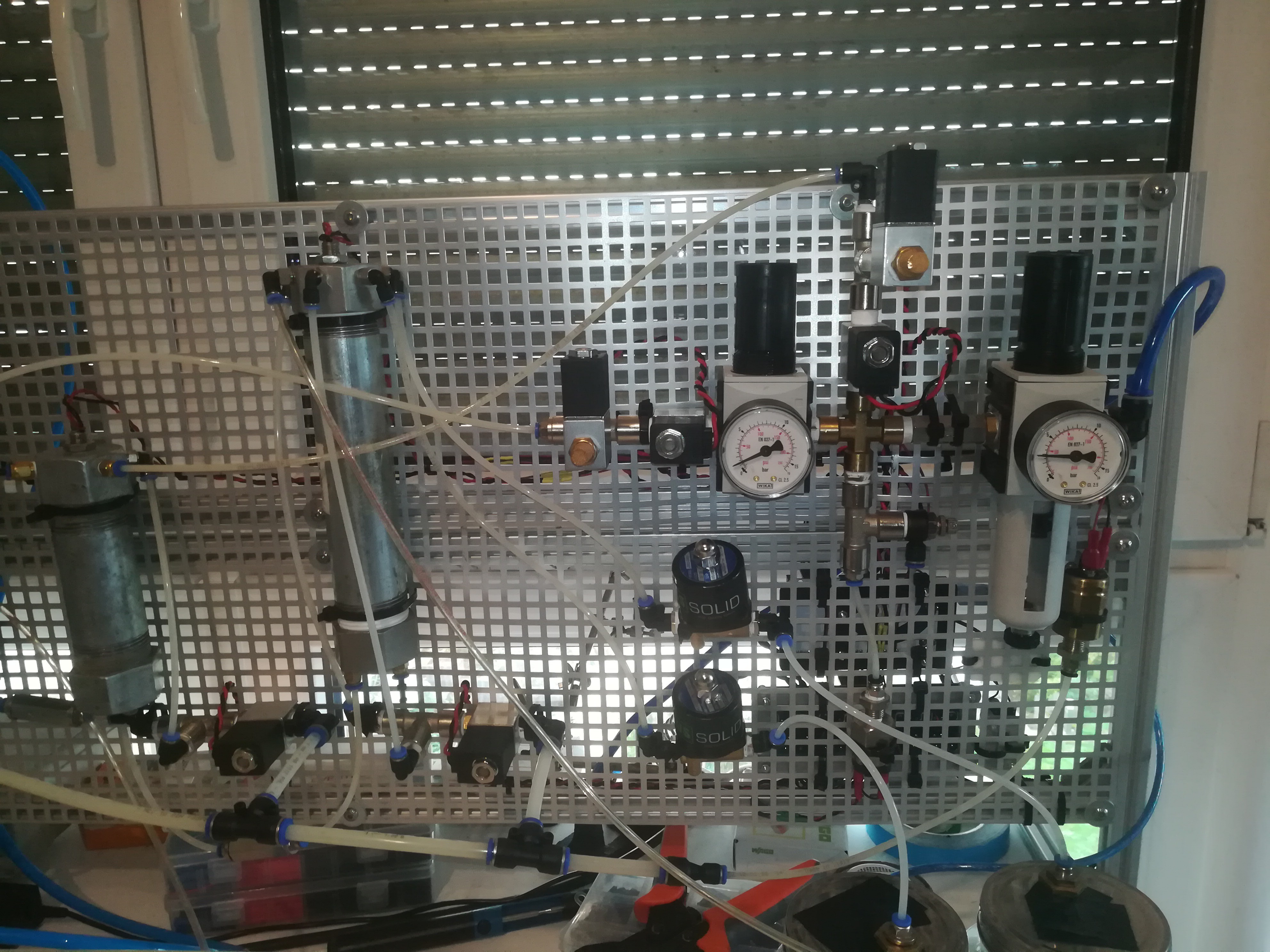

I replaced the 5/2 way solenoid valve for the ink pressure with two 2/2 way solenoid valves - one for switching the pressure and one for venting - so that all valves that switch air are from the same type. I also added mufflers to the venting valves for ink and pump pressure. Both the ink and pump pressure function switch a relay that has two valves connected to it - one for switching the pressure when the function gets activated and one for venting the lines when the function gets deactivated.

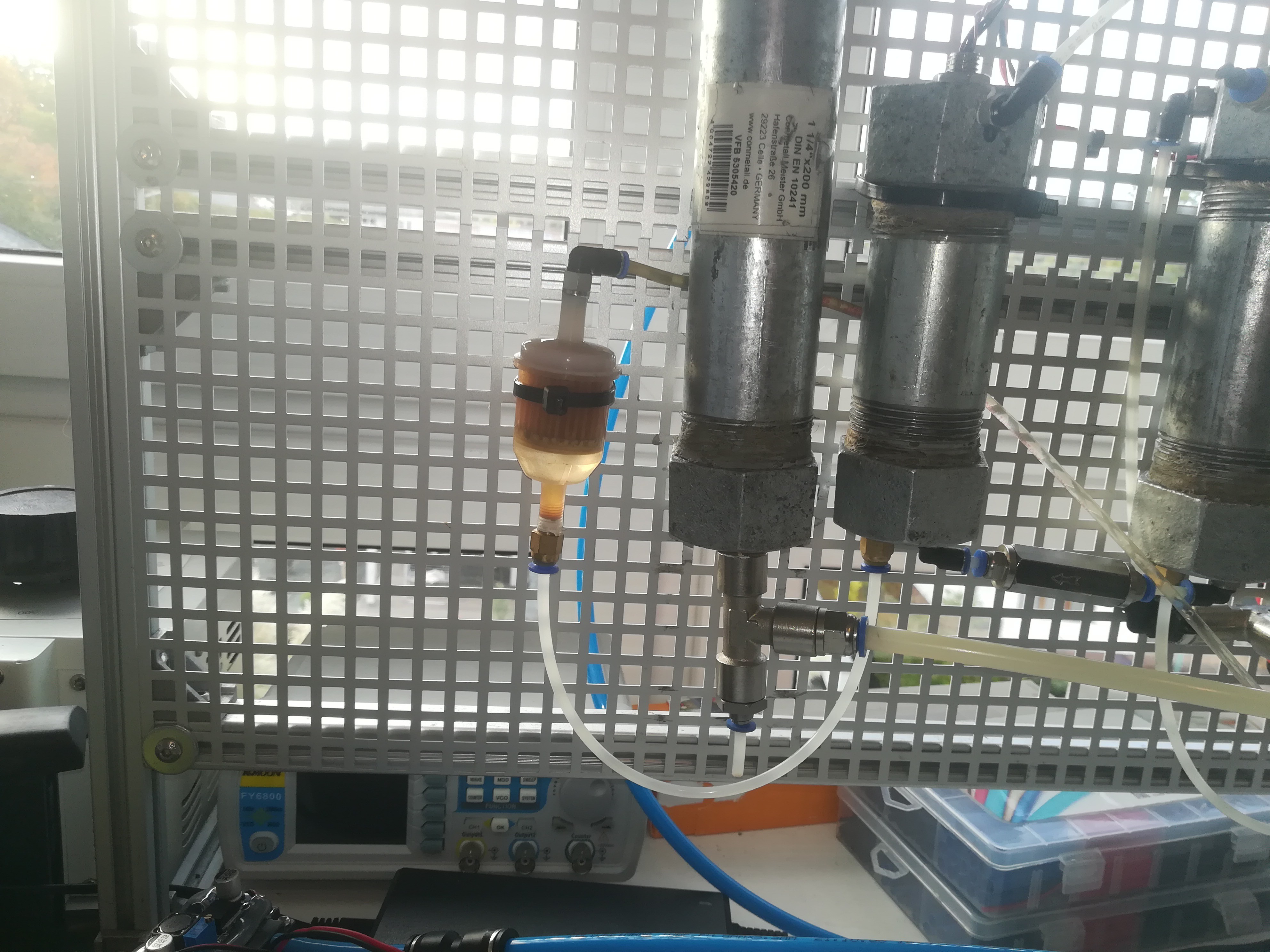

The ink filter is now mounted on the frame again.

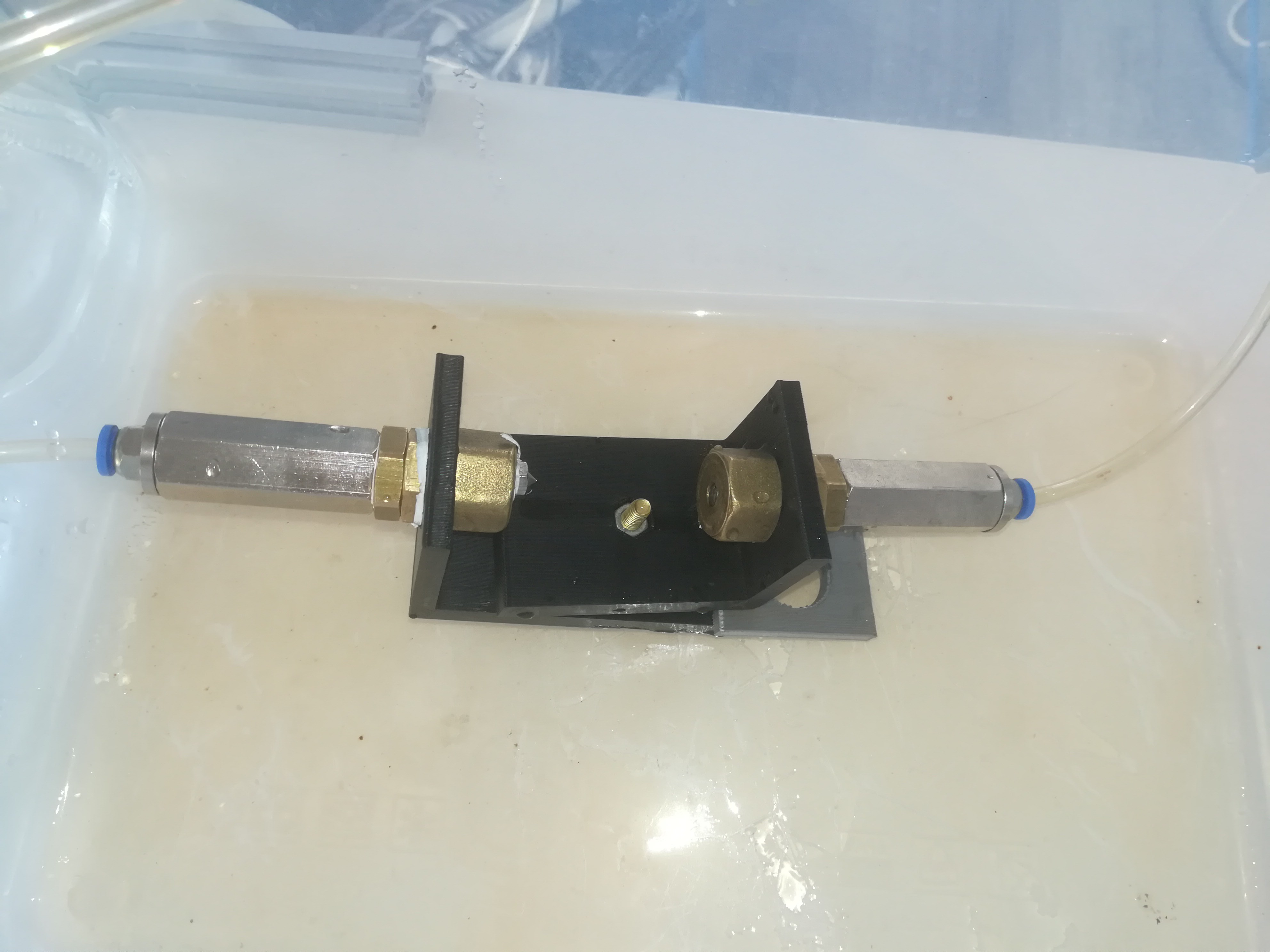

And the check valves are now directly connected to the nozzle and return port.

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.