Hi,

sorry for posting no updates in a while.

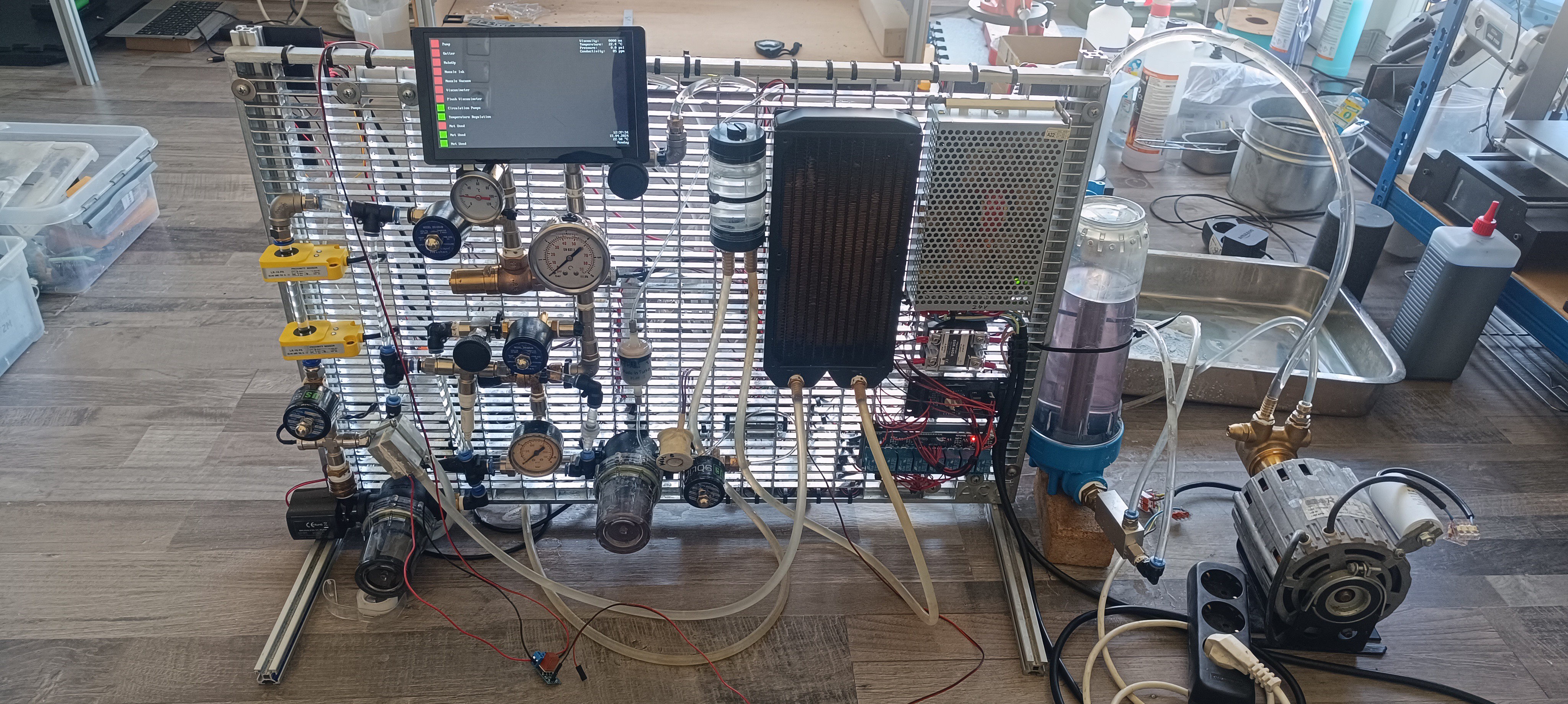

I'm still working on the project and over the last months I added an ESP32 powered 7-inch touch panel to the machine and changed the code so that a PC is no longer needed for running the machine.

I also built a new viscosimeter that features a thermistor, Peltier cooler, and circulation pump for keeping the temperature, always the same while measuring, even if the room temperature changes.

Before, I couldn't get a reliable reading of the ink's viscosity since it changed from day to day depending on the room temperature. On some days when the sun was heating the room all day long the ball drop time reduced by it's half just by the rising of the temperature during the day.

When the ink gets pumped around it also heats up, so that without cooling the viscosity would continuously drop until the temperature reaches its highest point which is also dependent on the room temperature.

The good thing about ink heating is, that with it the ink in the viscosimeter and the rest of the printer heats up on its own so that only cooling is necessary to keep the ink temperature stable.

Currently, I only finished the Peltier cooler of the viscosimeter, but I will also add a cooler to the printhead to keep the ink that exits the nozzle at the same temperature as the ink sample in the viscosimeter so that the measured viscosity equals the viscosity of the ink stream.

While I haven't seen a cooling system on any CIJ printer so far, I have seen designs that feature a temperature sensor on the viscosimeter and on the nozzle.

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Up to the last paragraph I was wondering about calculating viscosity from fall time & temp. Then you answered that.

Your cooler gives you more liberty to experiment with ink without having to determine new temp-viscosity curves. Nice :)

Are you sure? yes | no