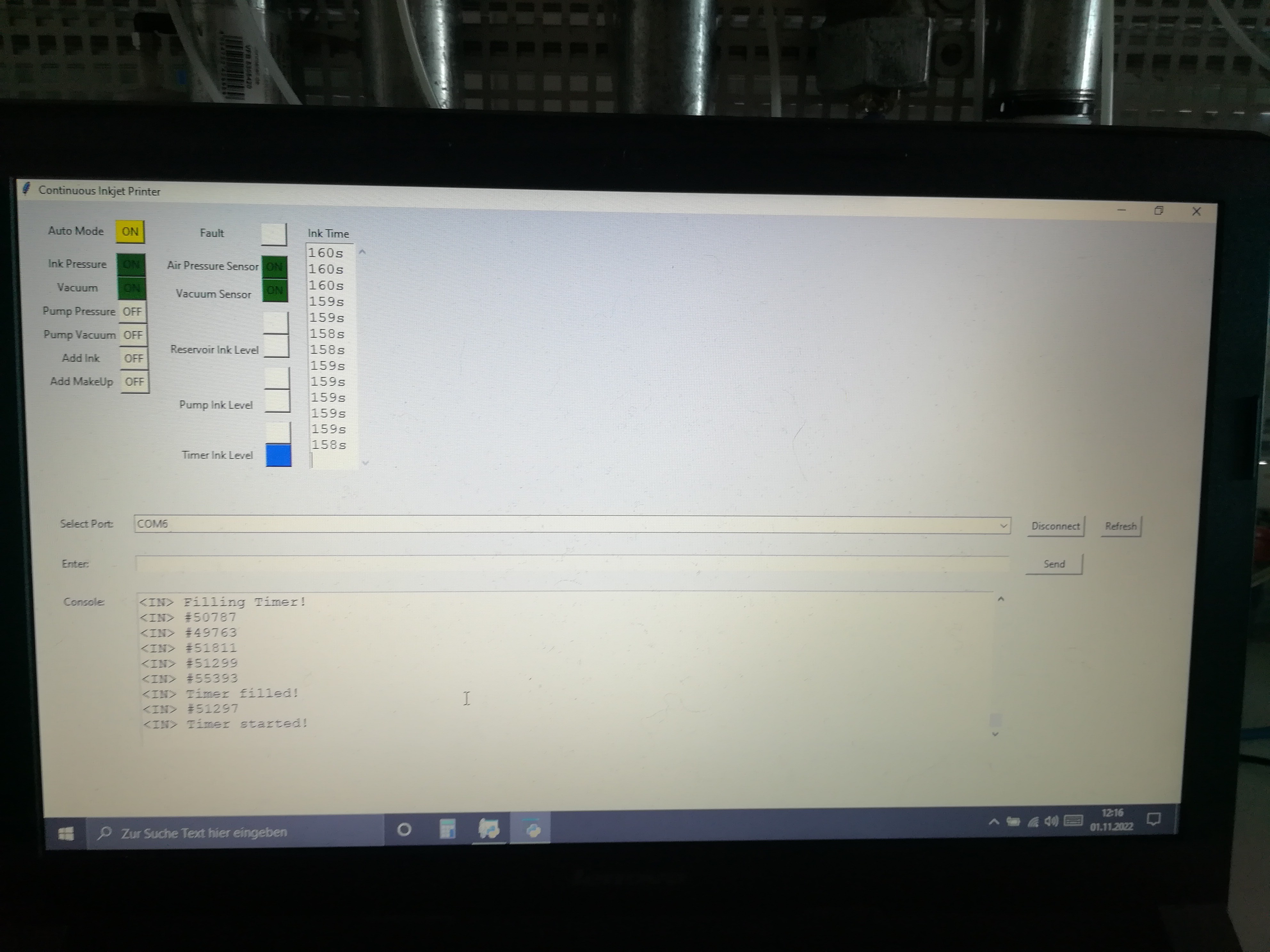

I added an automatic mode to the code so that the printer can now run on its own without user interaction.

When the auto mode is turned on the printer turns on ink pressure and vacuum, and waits for the ink level of the timer to drop below its lower sensor.

When the ink level of the timer drops below its lower sensor the printer checks the ink level of the reservoir.

If the reservoir's ink level is below its lower sensor the printer adds ink. I will later add more code to either add ink or makeup or nothing to adjust the viscosity to a set value, but for now, it only adds ink.

When the ink level of the reservoir rises above its lower sensor, the printer stops adding ink and checks the ink level of the pump.

If the pump's ink level is below its upper sensor the printer closes the vacuum valve of the reservoir and opens the vacuum valve of the pump to fill up the pump.

When the ink level of the pump rises above its upper sensor the printer closes the vacuum valve of the pump, opens the vacuum valve of the reservoir, and checks the ink level of the timer.

If the timer's ink level is below its upper sensor the printer adds pressure to the pump to fill up the timer.

When the ink level of the timer rises above its upper sensor the printer turns off pump pressure and waits until the ink level drops below its upper sensor.

When the ink level of the timer drops below its upper sensor the printer starts counting the time until the ink level drops below its lower sensor. When that happens it prints the counted time to serial and repeats the cycle.

Here is the Code that I'm using for it:

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.