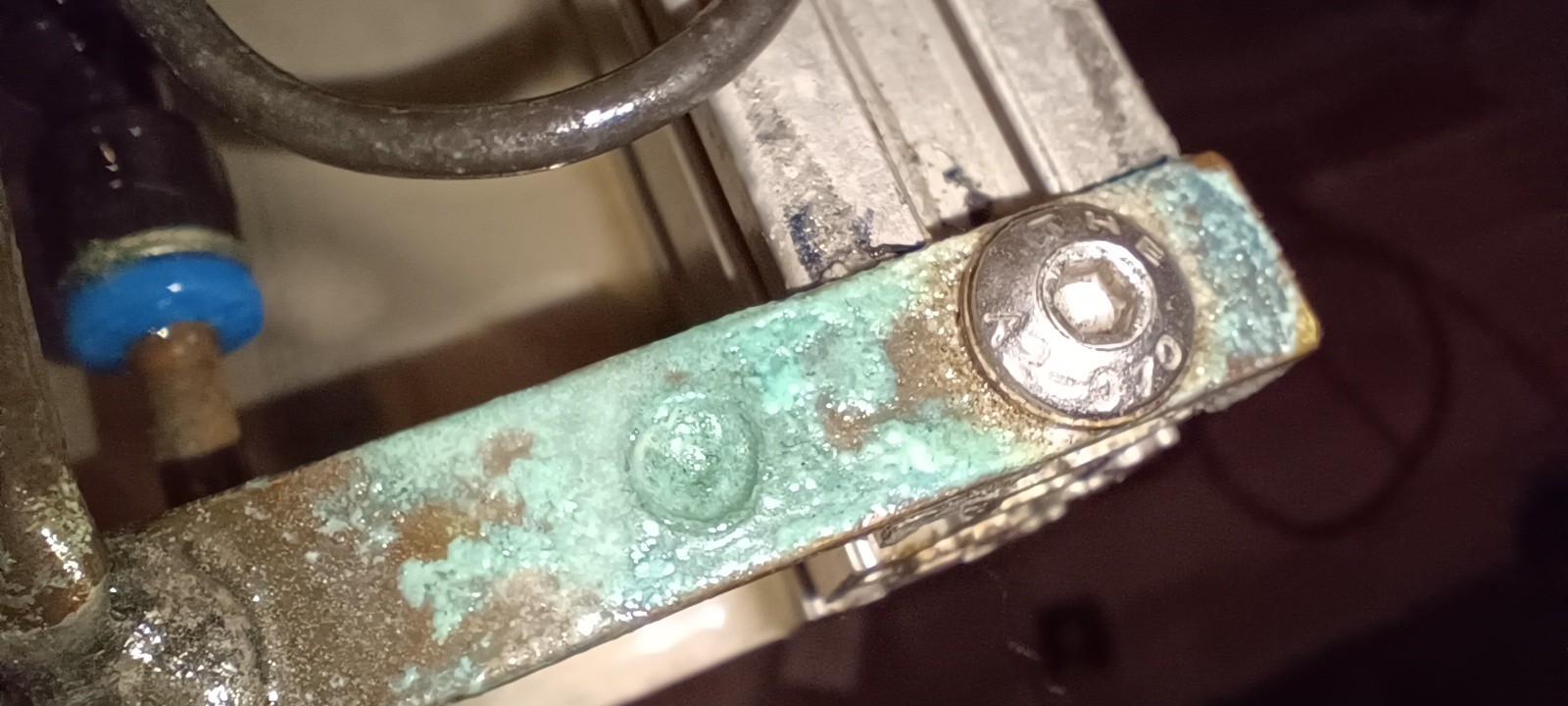

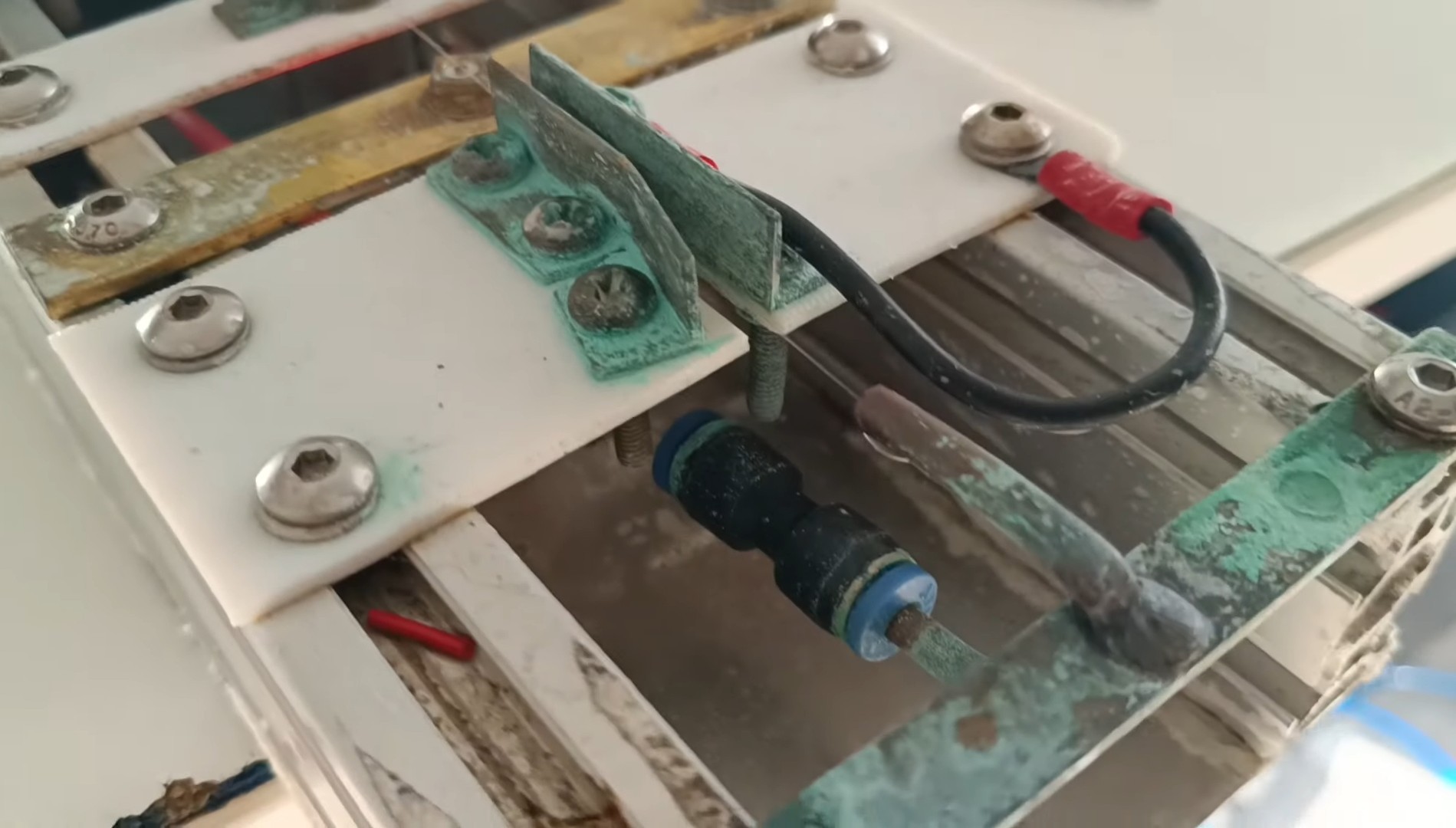

While testing I realized that the ink that I used caused a lot of corrosion on steel, copper, aluminum, and brass parts:

I assume this is caused by the sodium propionate that I used for increasing the conductivity of the ink.

Since the ink has to be conductive for the CIJ printing process, it needs to contain something that makes it this way and since all salts that I know so far can cause corrosion on metals like steel, copper, aluminum, and brass, these materials have to be replaced by other corrosion resistant materials like stainless steel, rubber, and plastic to prevent corrosion of the printer and also contamination of the ink.

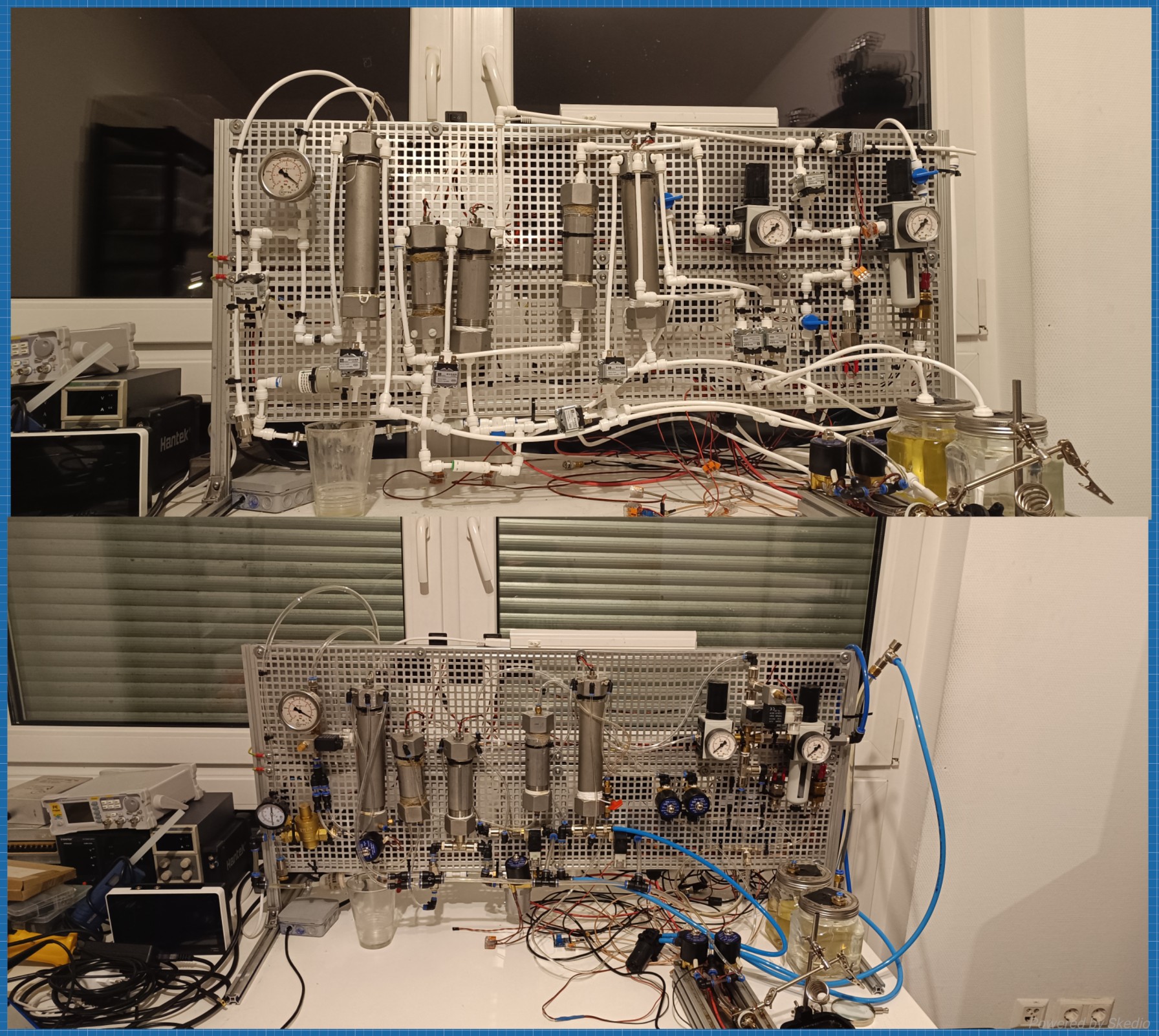

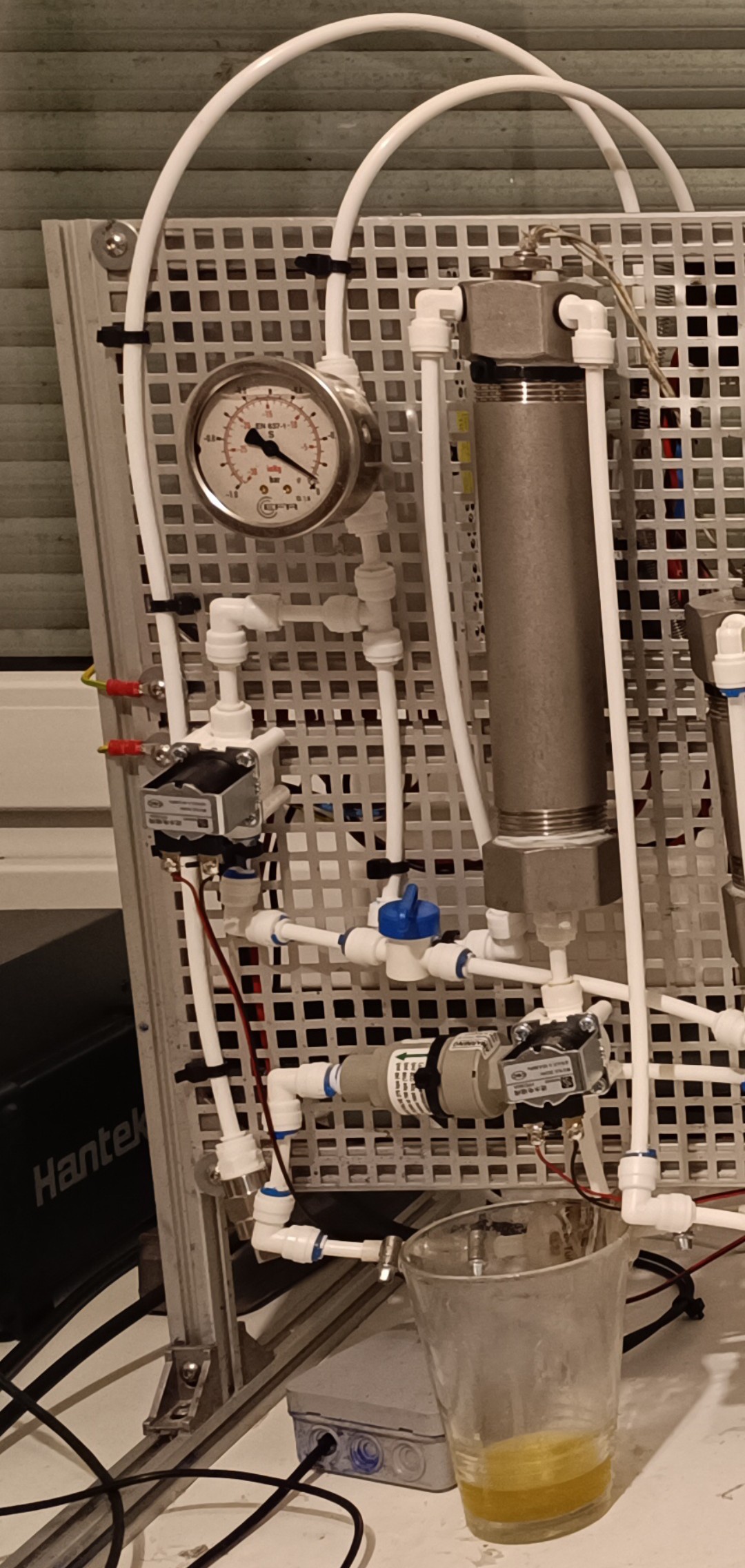

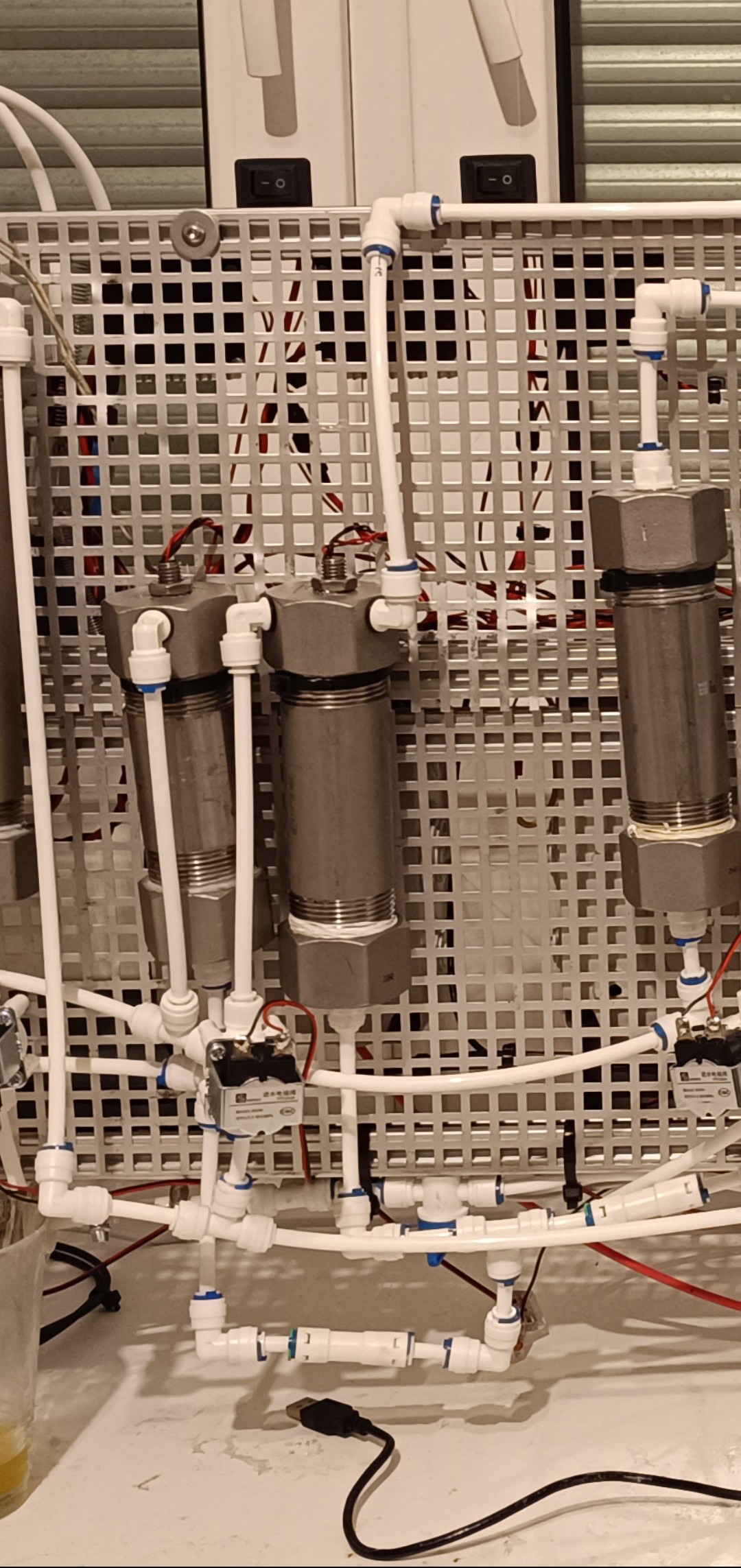

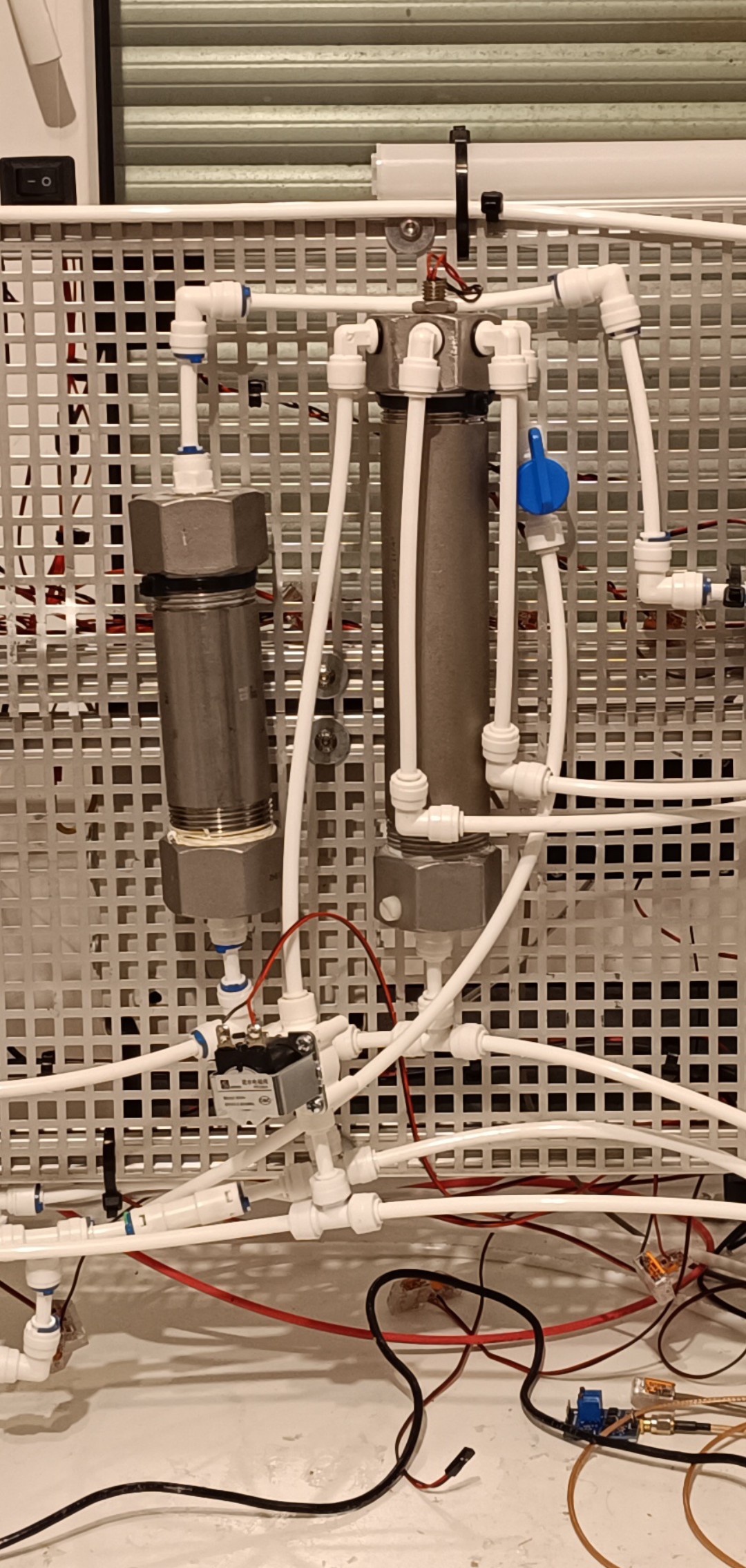

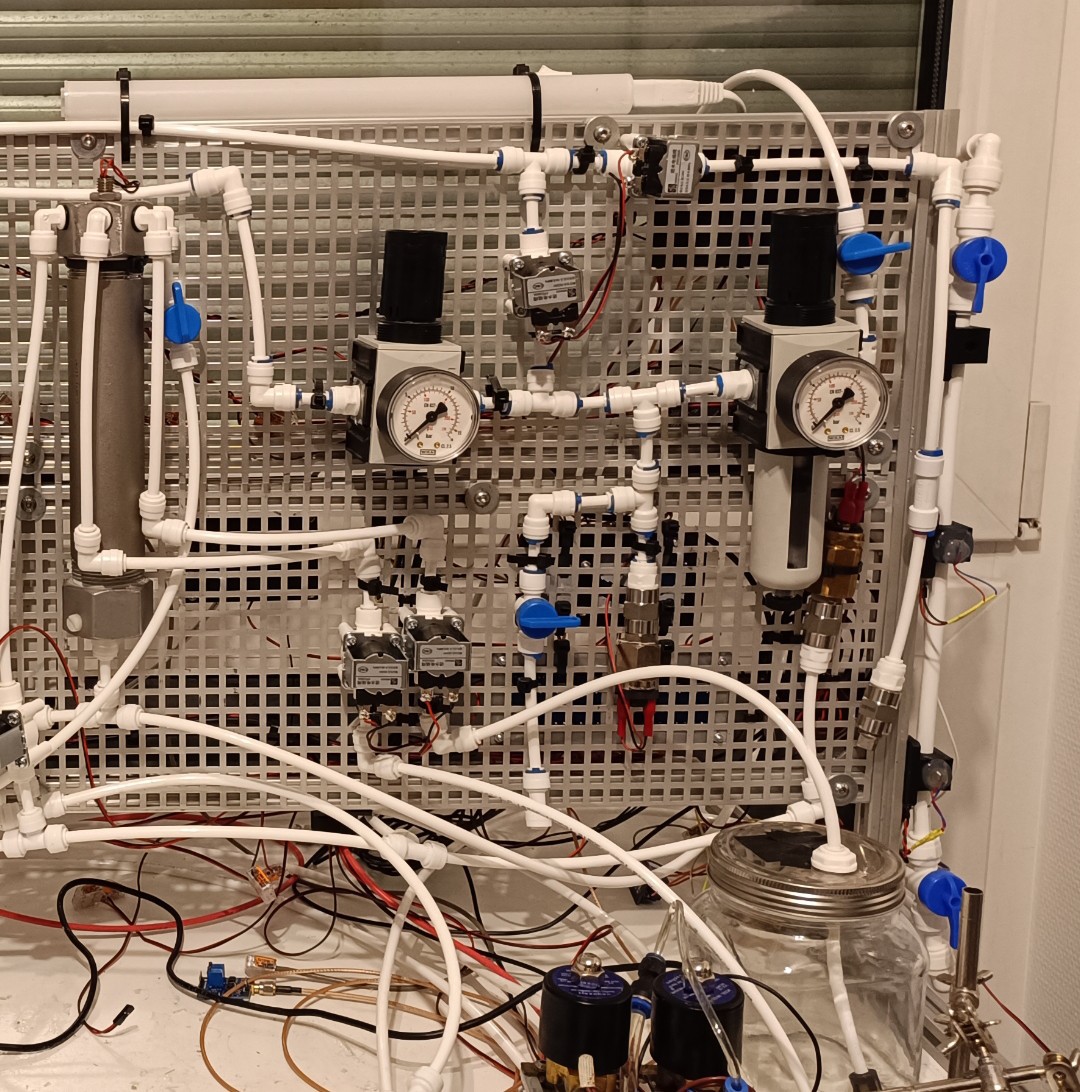

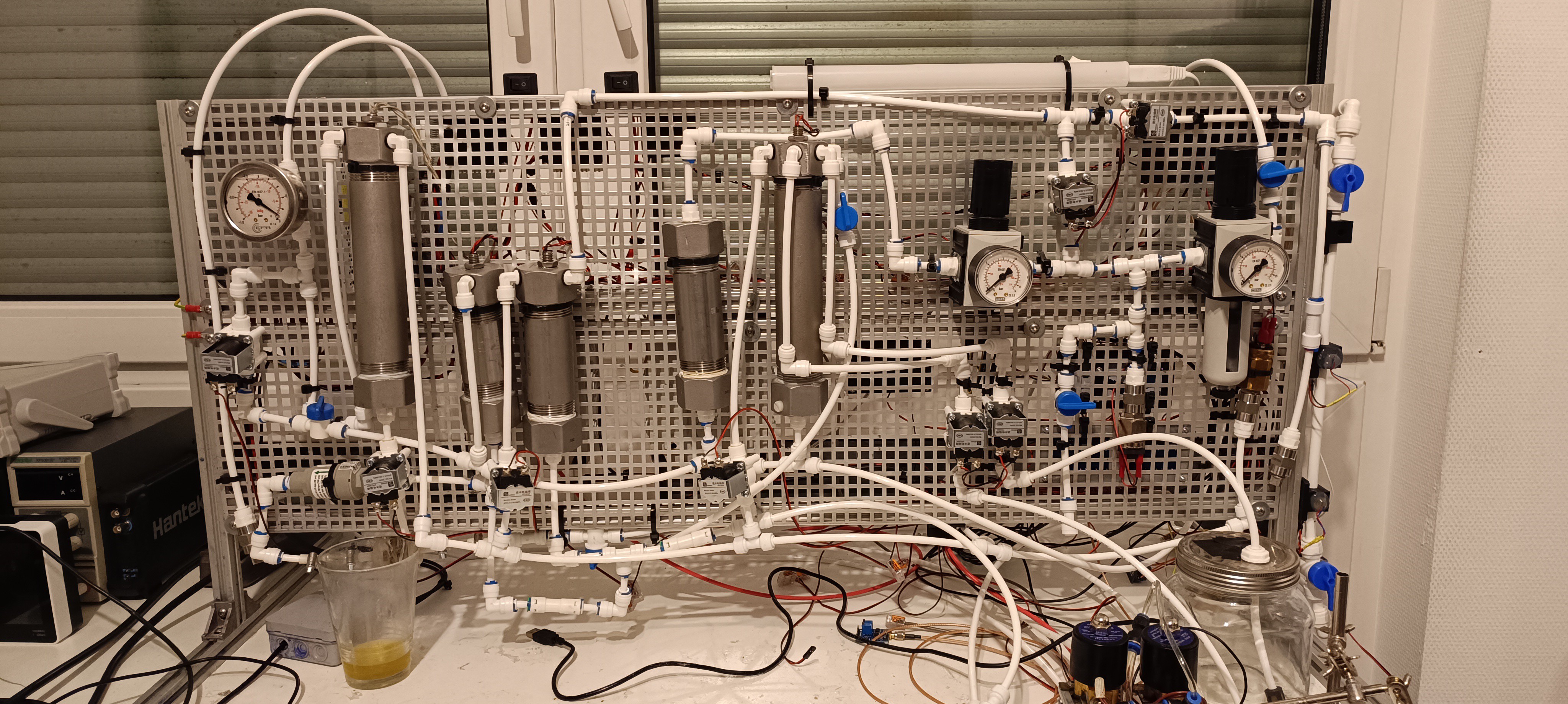

So, I searched for corrosion-resistant fittings to replace all the brass fittings and ultimately stumbled across the Reverse Osmosis plumbing system of white fittings of all sorts + white 1/4 inch and 3/8 inch PE tubing.

I think with all brass parts replaced by plastic or stainless steel the printer should now no longer have problems with corrosion caused by a small amount of salt in the ink.

While the printer hydraulics should be fine now, the printhead is still made out of brass, copper, and aluminum and will also need an upgrade to withstand corrosion.

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Maybe you should consider electroplating some of the things that cant be replaced by plastic with something more corrosion resistant, or add sacrificial anodes to them. Also, ensuring that there is only one metal (except for any sacrificial anodes) helps prevent galvanic corrosion. Up here in Canada, some people have electronic protection to help prevent rust on their vehicles from salt, but how well these work I'm not sure, additionally the charge pumping of these rust preventers might be a problem for this particular system.

Are you sure? yes | no

Good idea, over the last days I could replace almost every metal part with stainless steel and switched to a less corrosive salt.

Maybe I can electroplate the remaining parts like the feedback antenna and piezo ring.

Are you sure? yes | no