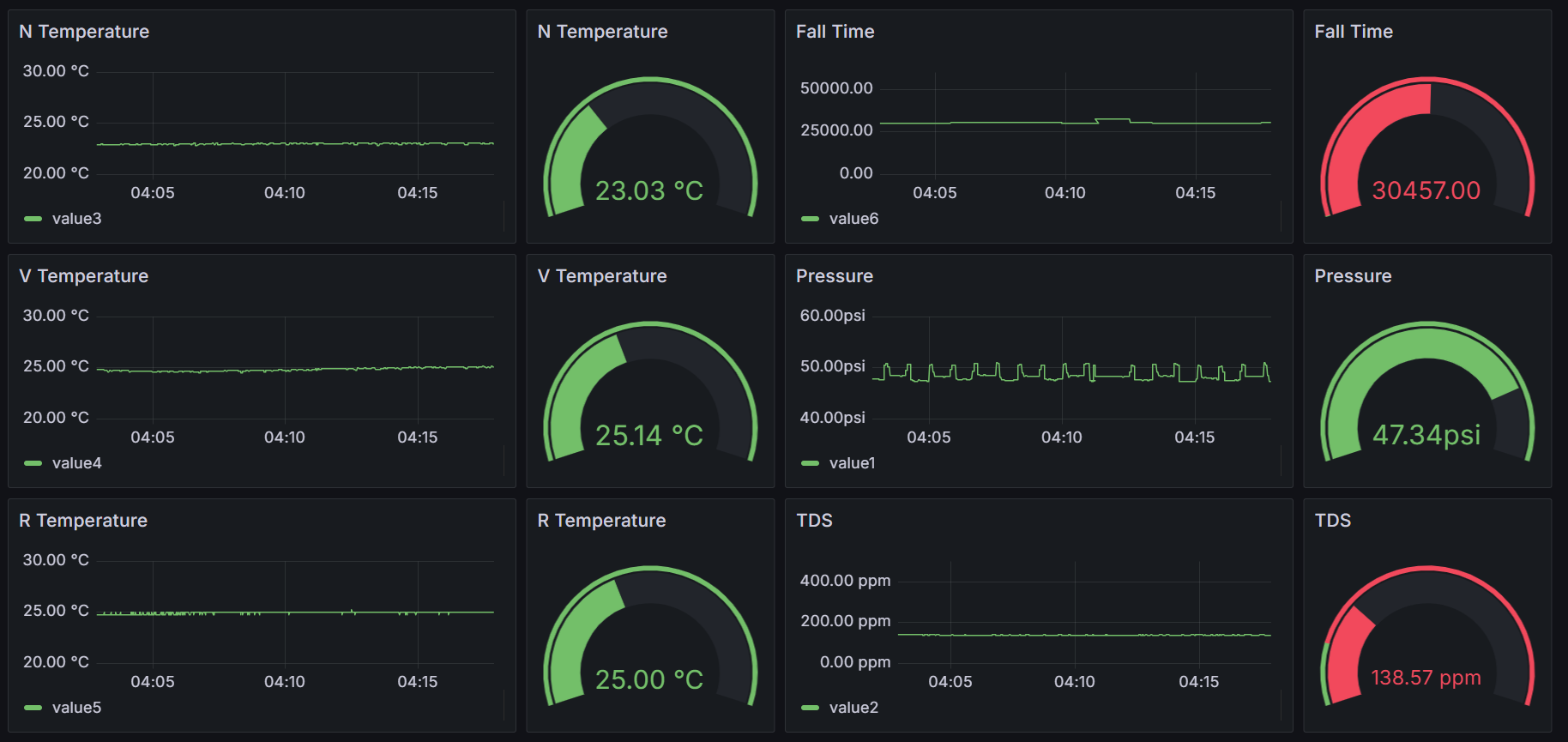

For the last month, I tried out different ways to log and monitor the data that the sensors on the machine collect to get a graphical way to watch the operation of the machine over time.

This way it is possible to verify that everything is working as expected and to find problems that would be otherwise hard to detect.

It's also just nice to see your machine's sensor readings on a dashboard :)

I tried out:

- saving the data on my router's FTP server

- saving the data on Google Sheets

- saving the data on InfluxDB

Finally, I ended up saving the data on a MYSQL database that I set up on a Raspberry Pi, which appeared to me as the most independent/universal solution.

In addition to that I installed Grafana on the Raspberry Pi to get a nice way to display the sensor data.

In the current picture, all values besides the pressure are as expected, so I still have to find a way to get a stable pressure.

The readings I currently get from the machine are:

- The room temperature

- The nozzle temperature

- The viscosimeter temperature

- The conductivity

- The fall time (the time an 8mm steel ball needs to drop around 100mm in a 10mm PC tube at 25⁰C - equal to the current dynamic viscosity)

- The pressure

Update:

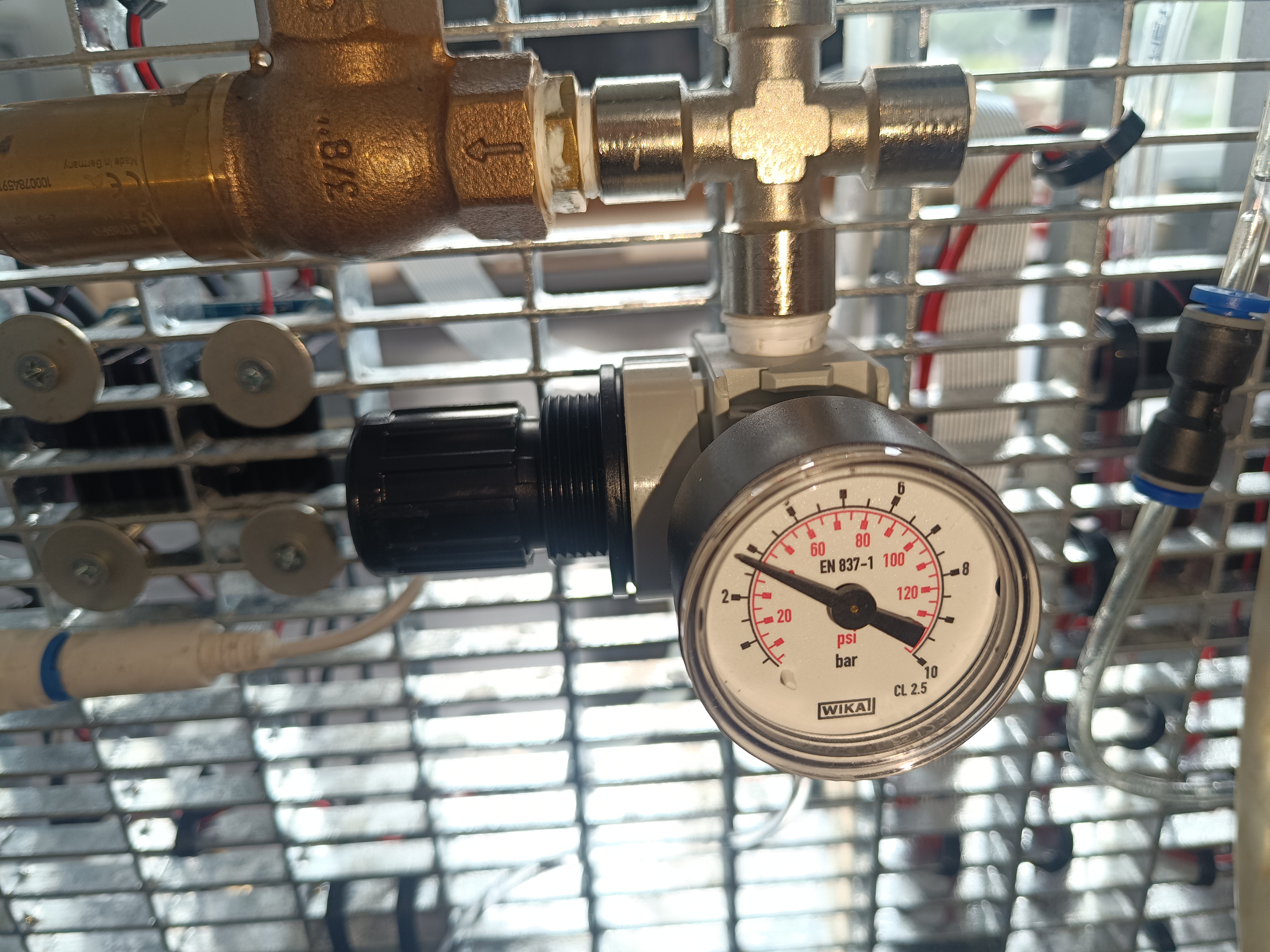

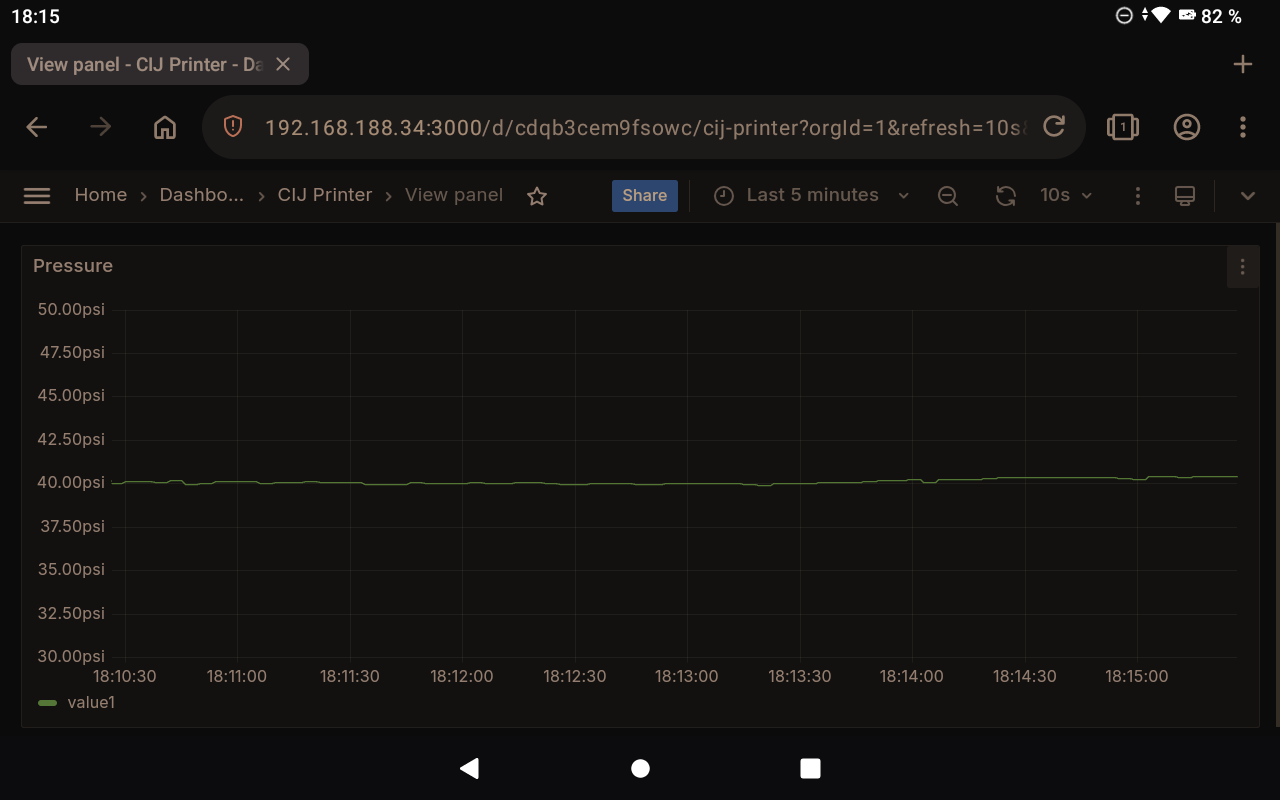

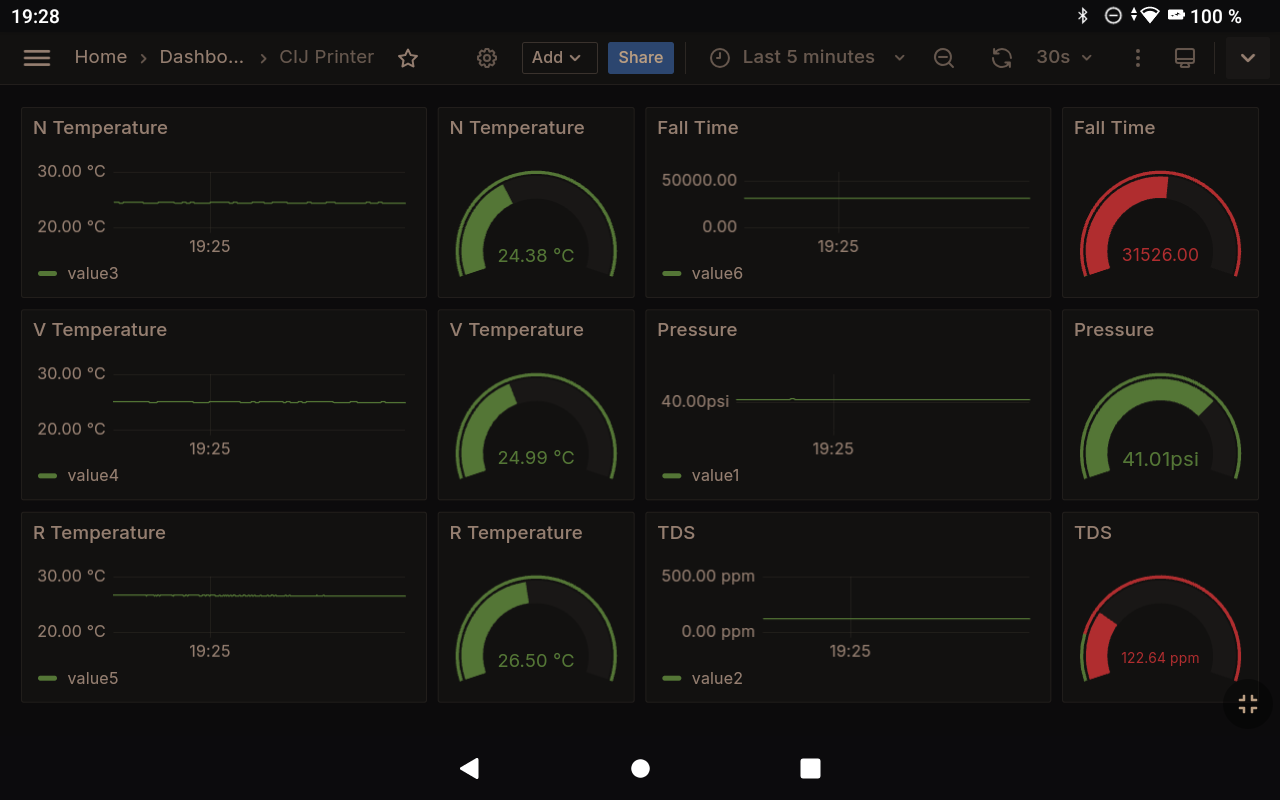

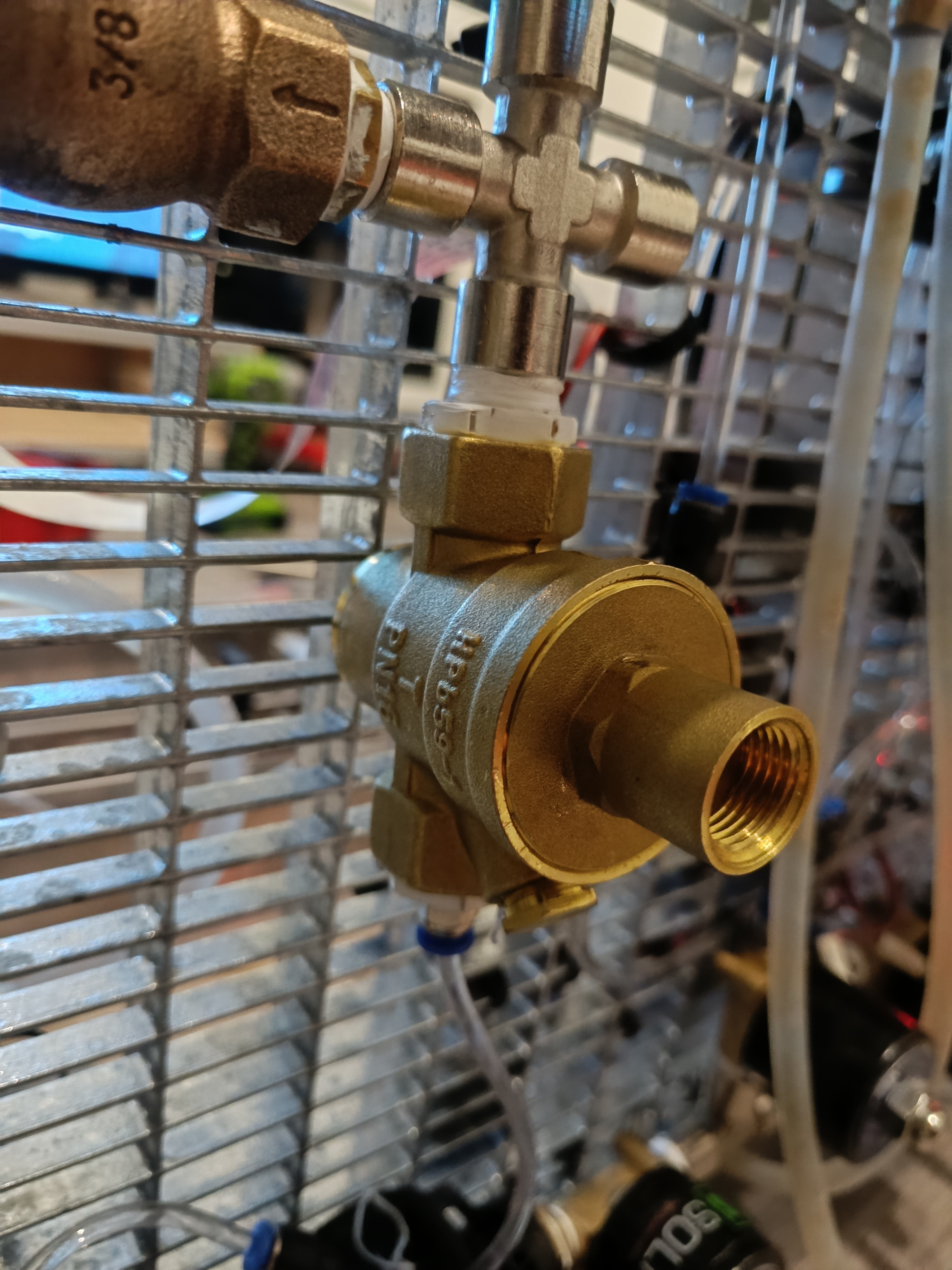

Today, I installed a new pressure regulator which finally outputs a stable pressure.

It's also visible in the readings:

Now, that all sensor readings are stable the work on the fluid management system is finished until new problems appear and I can finally continue working on the printhead design.

Update:

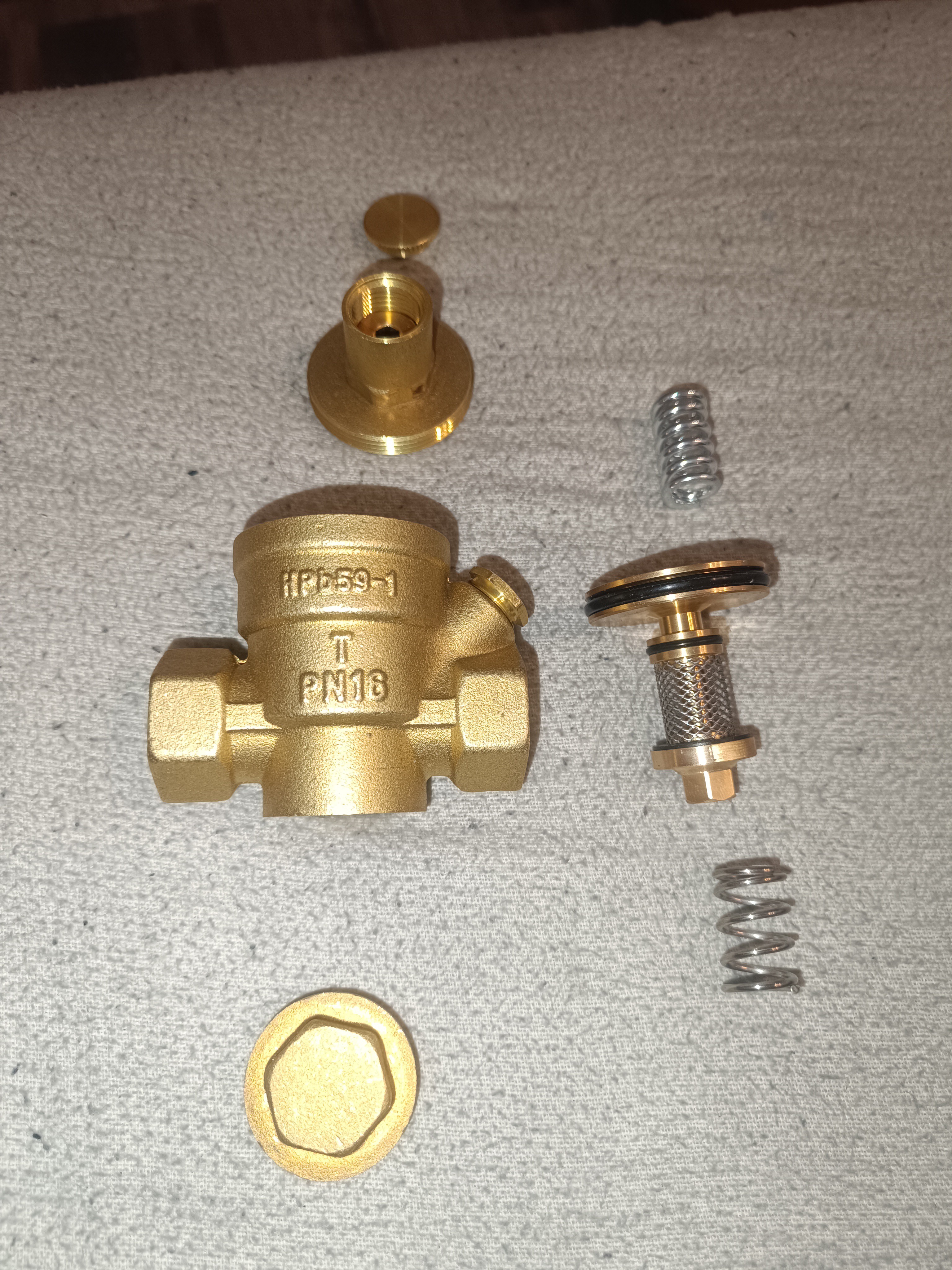

I just found out what caused the pressure regulator to fail:

The pin inside the pressure regulator got stuck, because the used PVB/Ethanol mix is quite sticky. Maybe in the future I can find a pressure regulator with a different design that also works for adhesives or sticky fluids. At least it's no general problem of the system. Until then it's needed to clean and "unstick" the pin of the pressure regulator before running the system.

Another Update:

I switched to using another type of pressure regulator which also has a spring at the bottom for closing the seal so that doesn't get stuck open that easily.

The next thing I want to do is learn more about things like electrostatic induction and conduction and how to measure the charge on droplets.

For this, I'm planning to build a test stand for charging single water drops with variable voltage, detecting when the drops hit a copper mesh, and measuring their charge to learn how to do these things and which factors are important for a successful charge induction and measurement.

Thank you for your interest in my project :)

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.