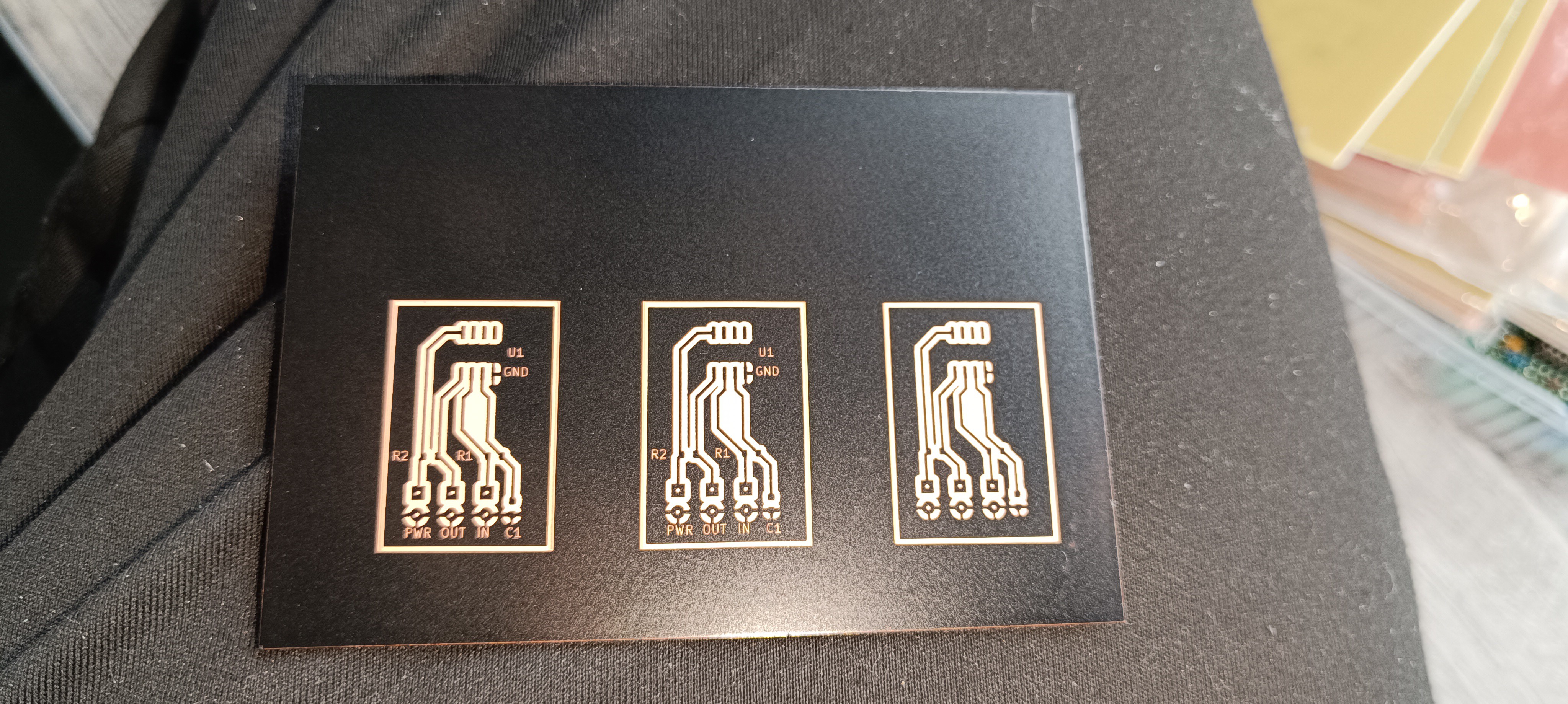

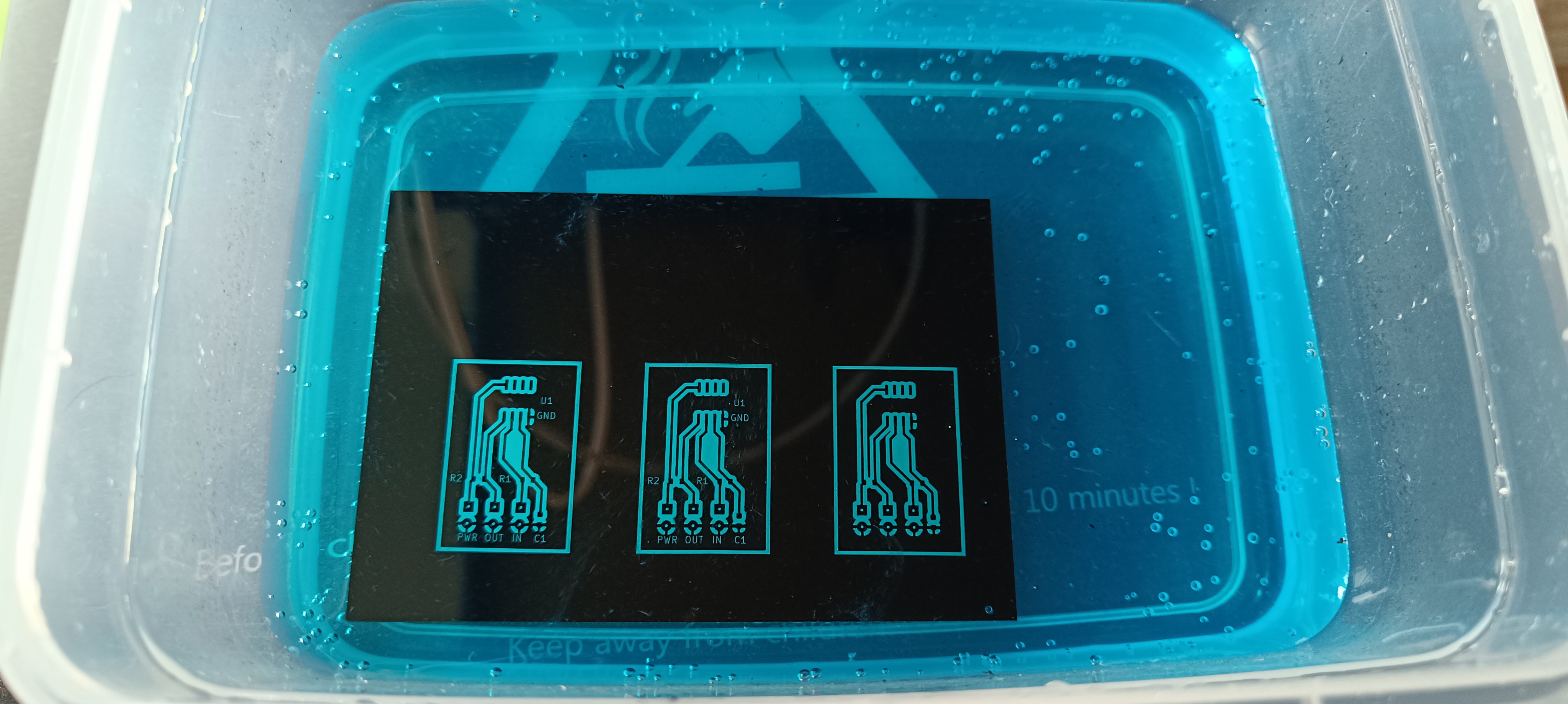

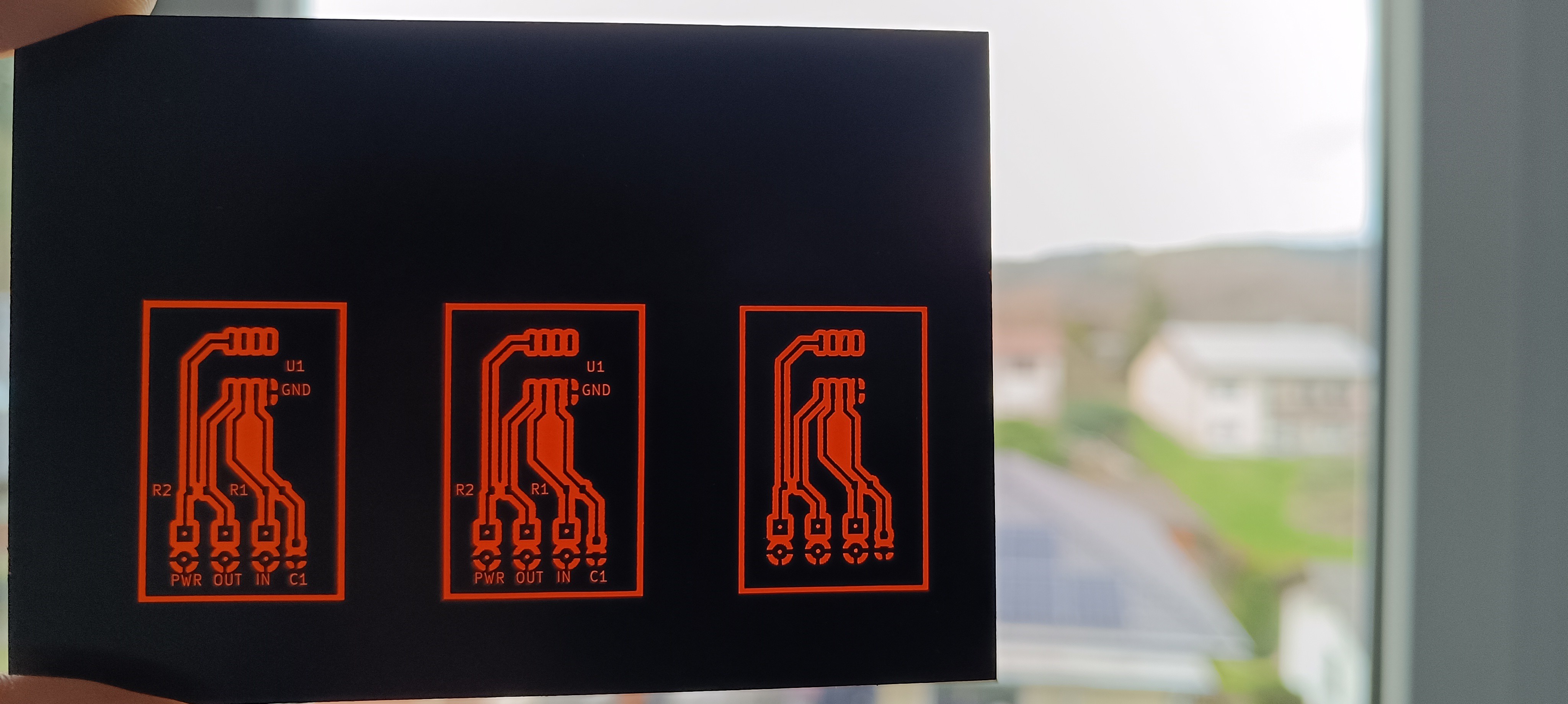

Some time ago, I bought a pulsed 1064nm IR laser (Sculpfun IR2) for metal engraving and I recently figured out that this laser is the perfect tool for removing spray paint from copper PCBs without any residue.

A year ago I tried the same with a common 450nm laser, but this laser rather burned the paint off while leaving a lot of residue on the PCB.

My guess would be that the pulsed operation mode of the new laser is the decisive factor here, which causes the paint to chip off or evaporate when hit with the laser instead of just getting burned away.

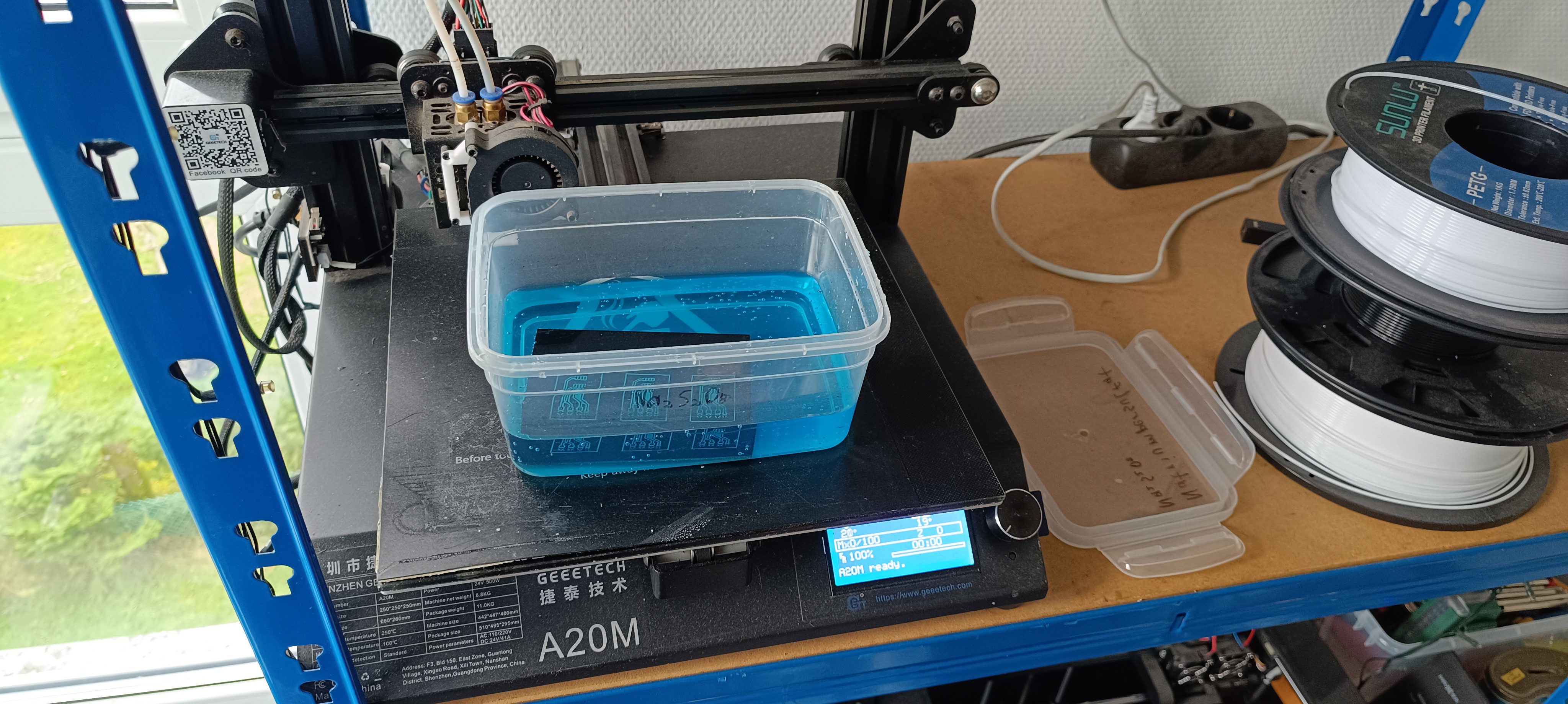

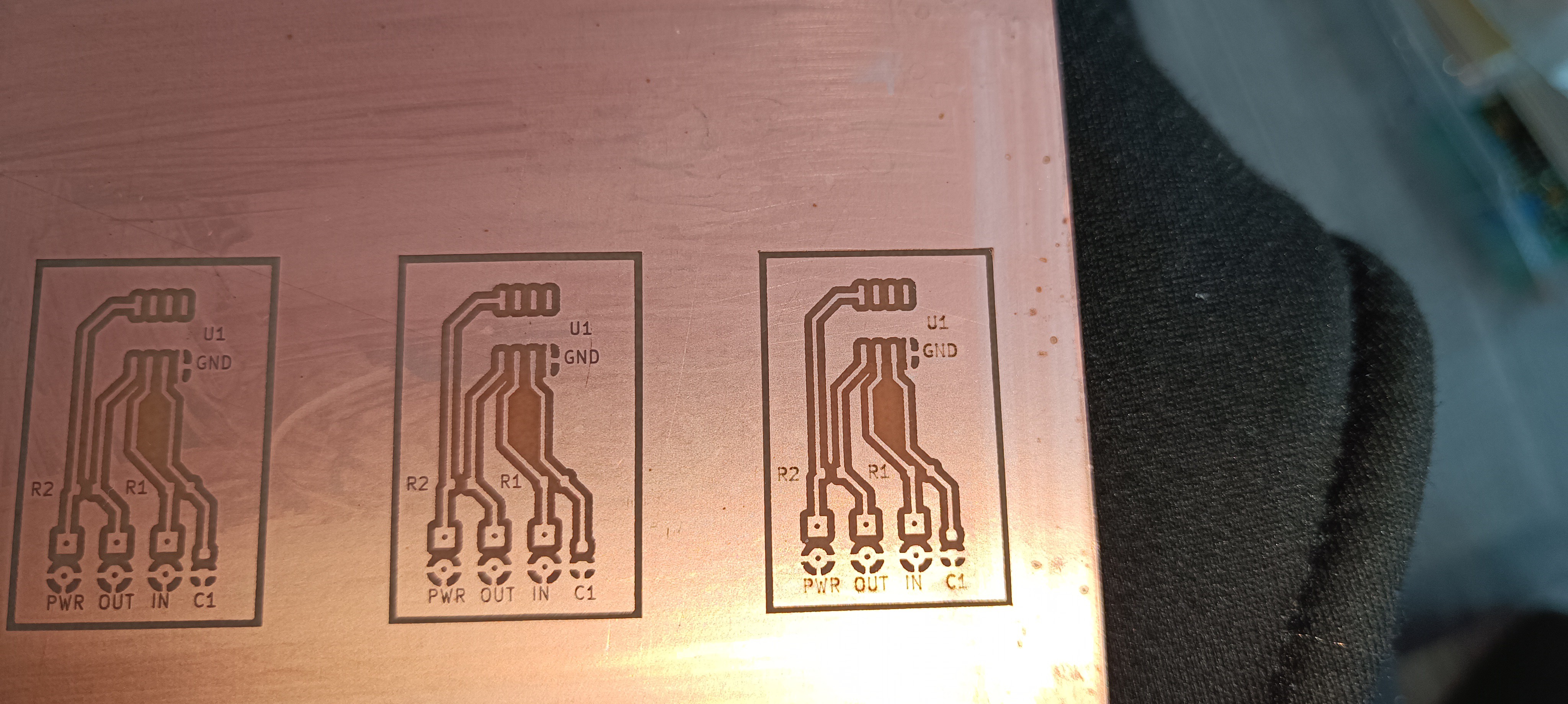

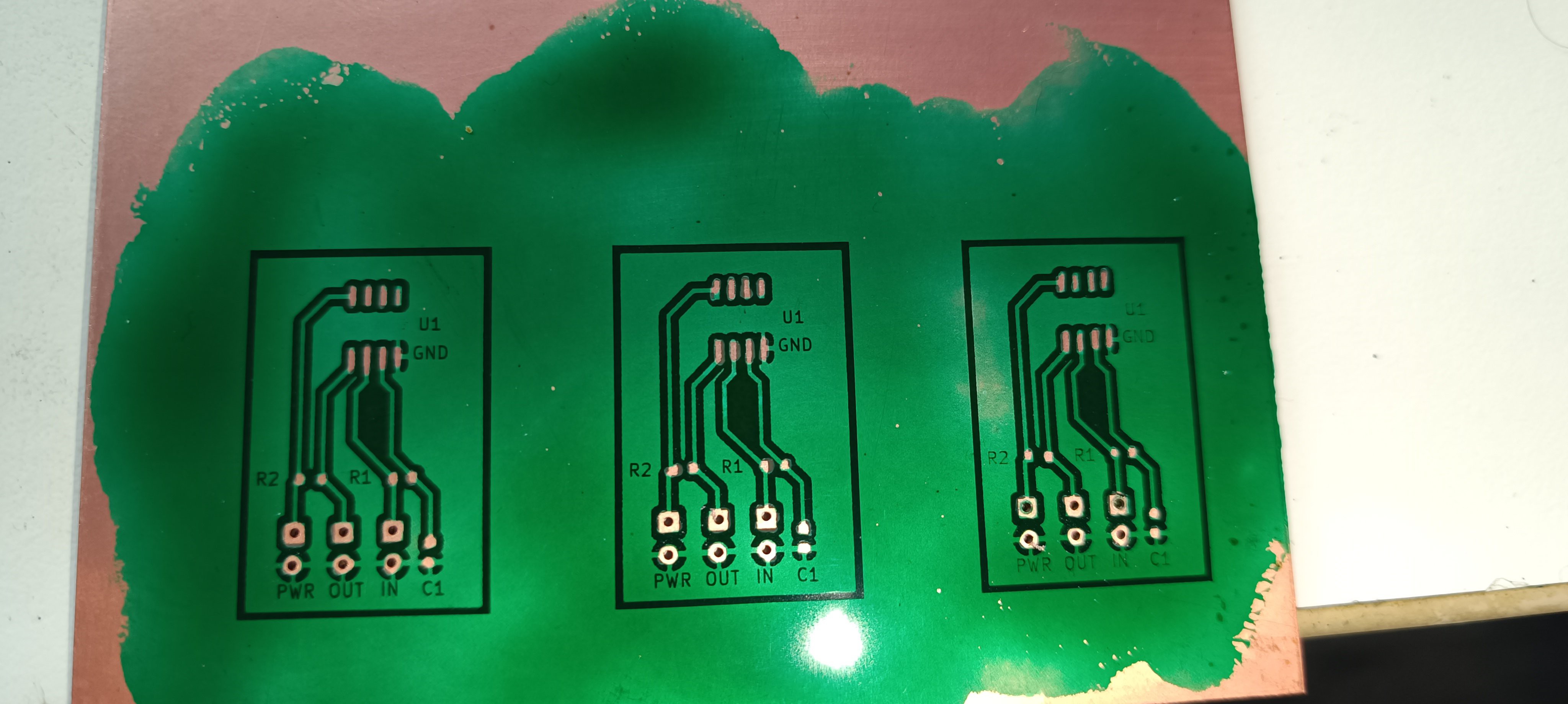

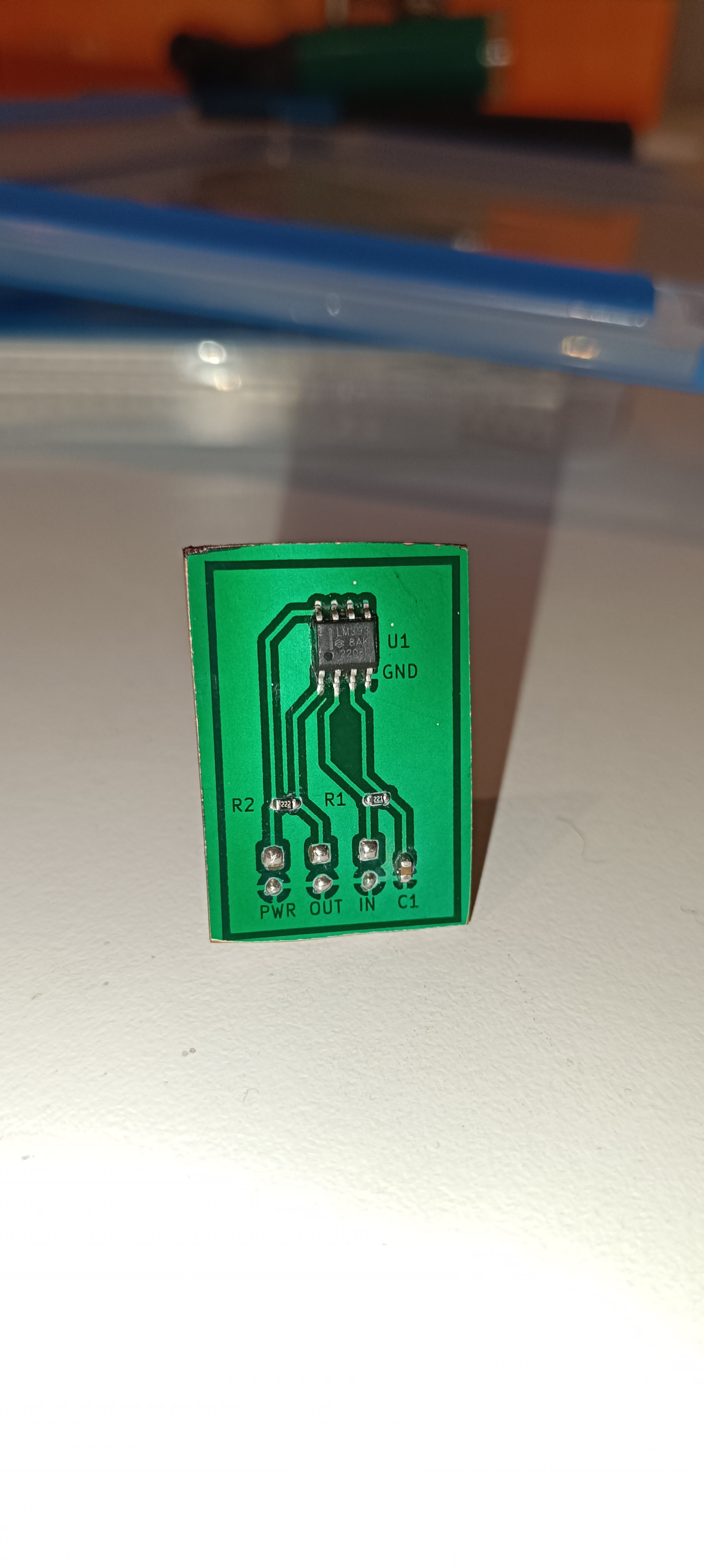

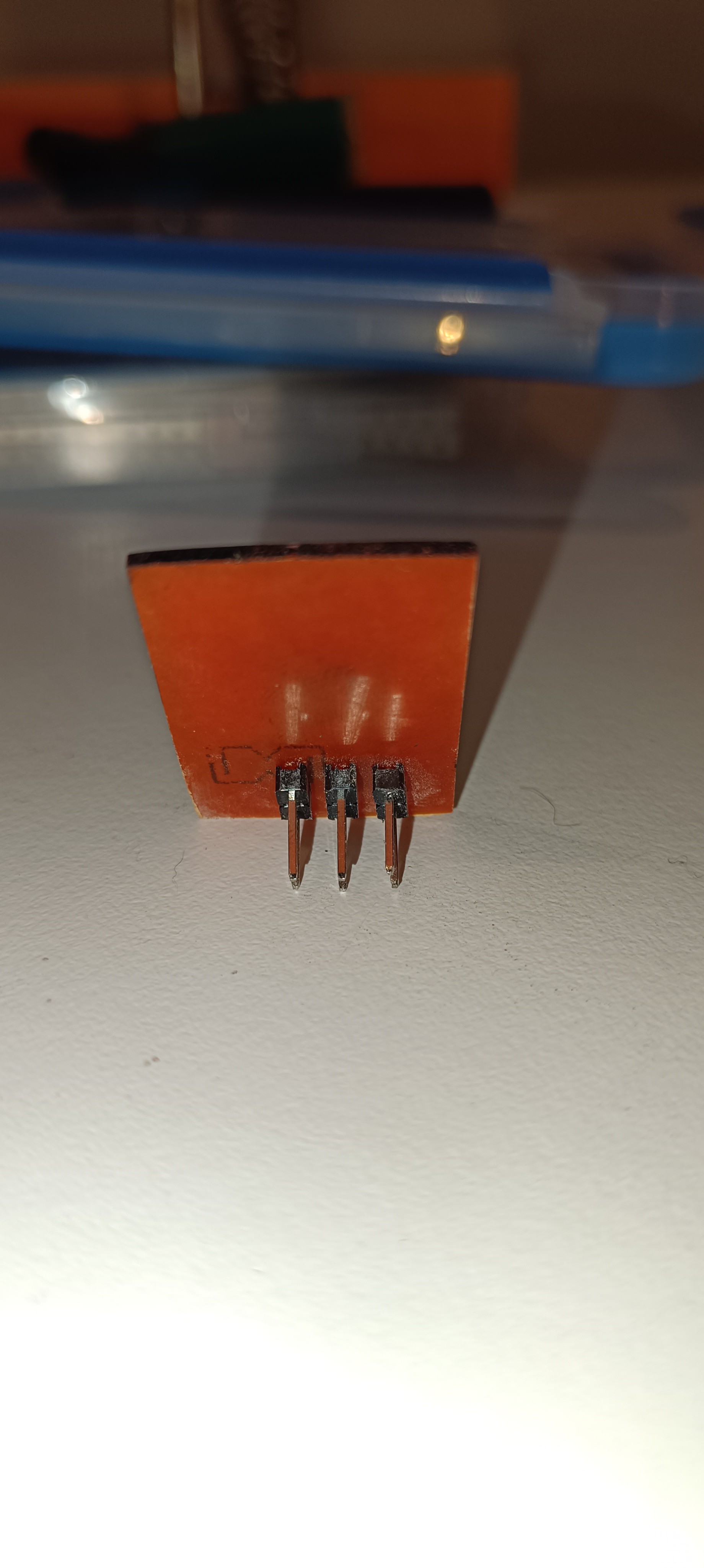

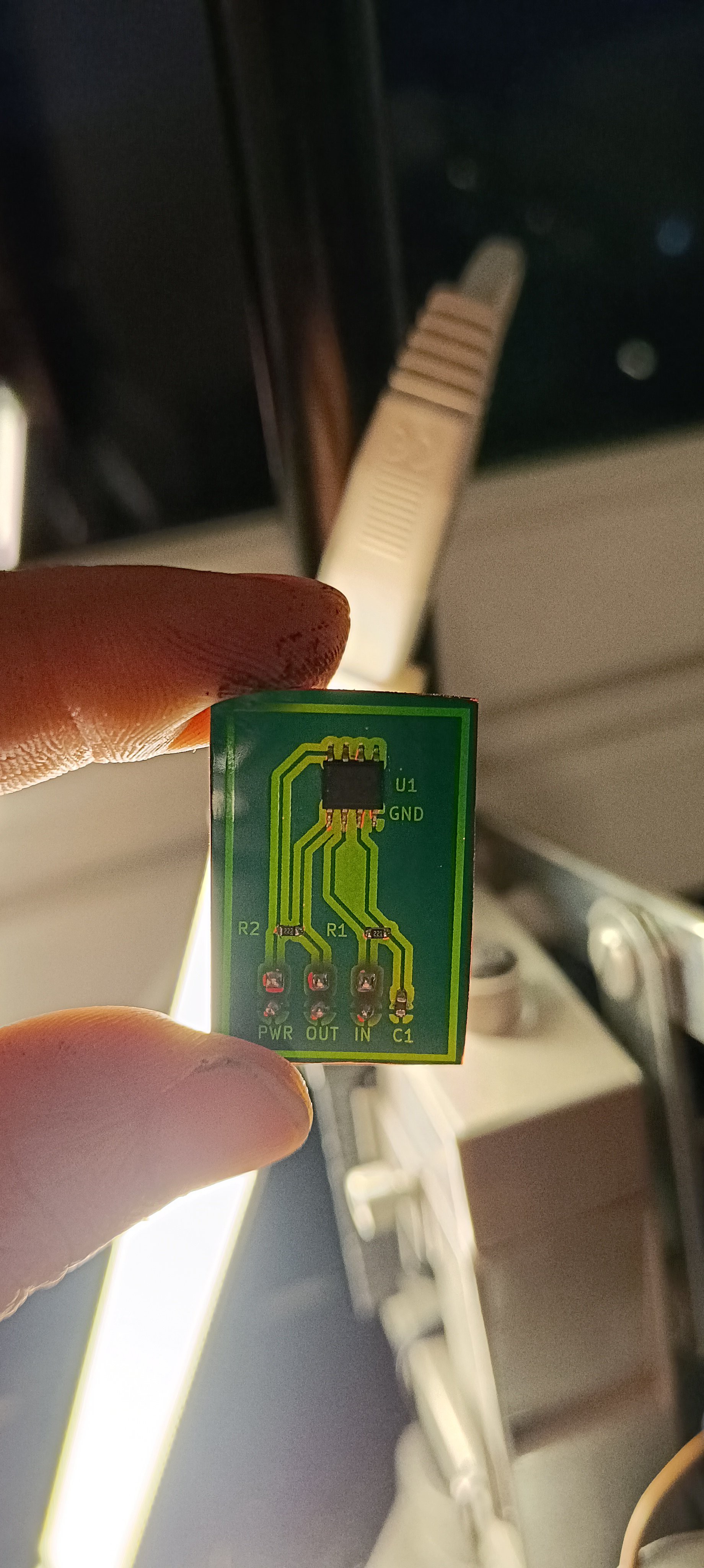

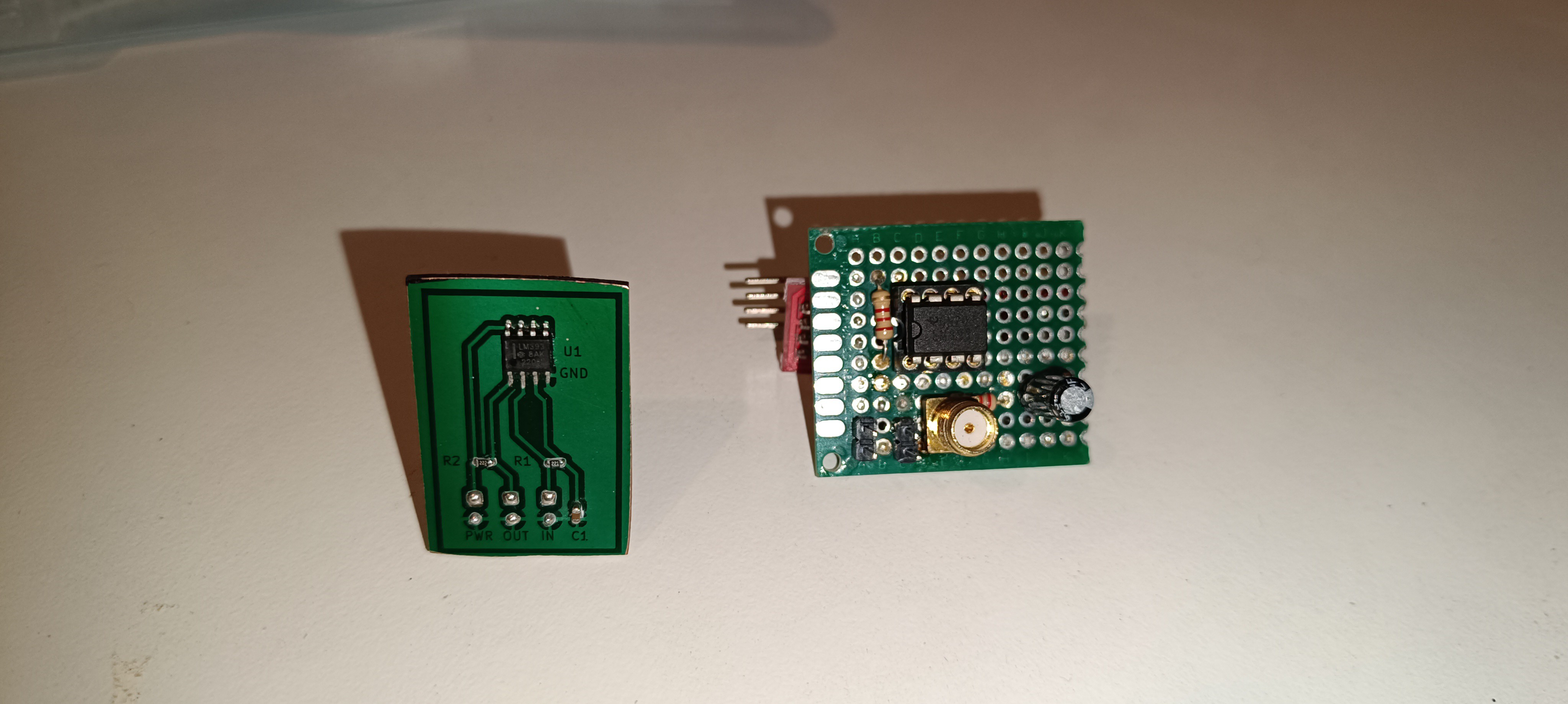

PCB Manufacturing Footage:

I think having figured out a way of PCB manufacturing that works well for me will help move the project forward and will also be very useful for future projects.

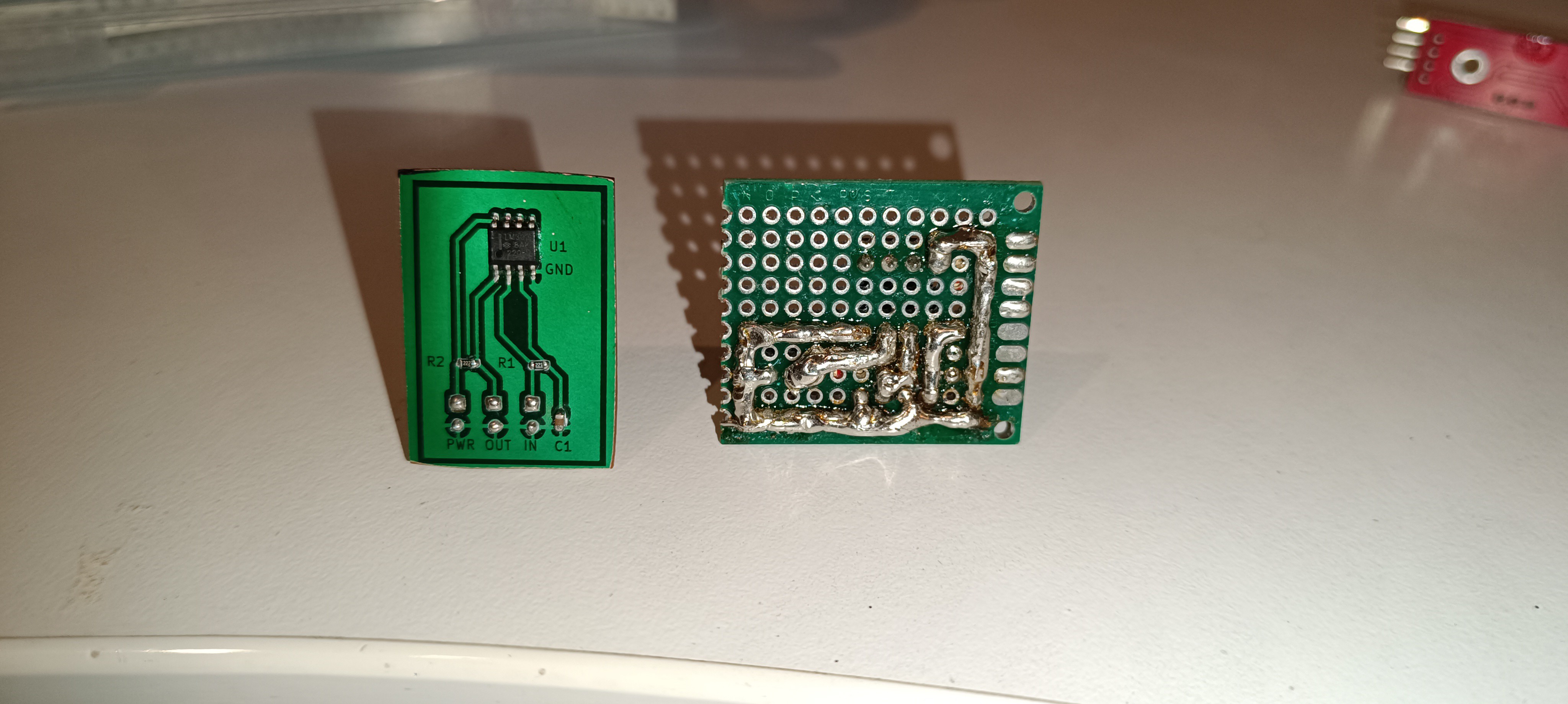

Until now, I always had to build circuits on perfboards and connect the components with solder wire. This was a lot of work and also looked ugly compared to the new design.

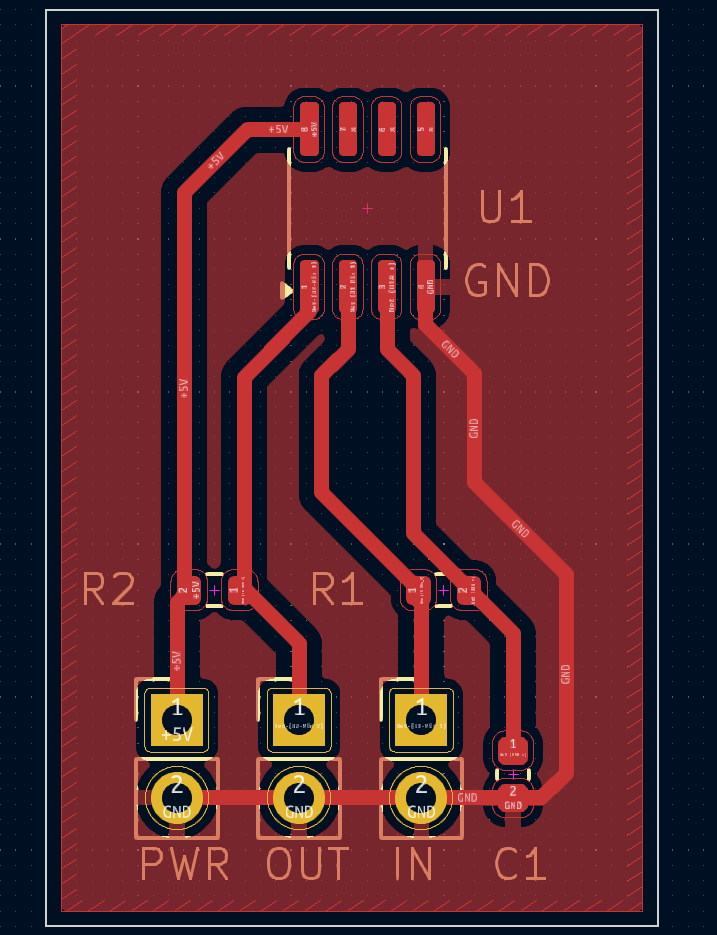

It's also an advantage that the circuit and PCB layout can be designed on PC for lasering it 1:1 onto the copper PCB.

This makes the process similar to 3D printing, which will make it easy to share the design with others and will ensure that each copy of it will be identical.

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.