Motor wheel base: 650mm diagonally

Motor mounts suitable for motors: 2205, 2212, 2206, 5010

Fiber composite weight: 187g

3D printed components weight: 142g

Assembled frame: 350g (with M2.5x8mm stainless hardware)

A second attempt :) at making a bio-degradable composite material that could be used to replace existing epoxy based solutions.

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

Motor wheel base: 650mm diagonally

Motor mounts suitable for motors: 2205, 2212, 2206, 5010

Fiber composite weight: 187g

3D printed components weight: 142g

Assembled frame: 350g (with M2.5x8mm stainless hardware)

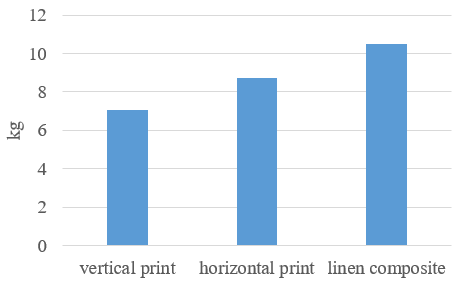

I managed to perform a comparable strength test of the composite material. I decided to test the loading strength of the drone bar assembly. I compared three different bars, one printed from PLA in a vertical direction, one bar printed horizontally and finally a linen composite bar. Bars are 200mm long with a thickness of 0,8mm.

I fixed the bars on one side and loaded them with a scale until they failed.

Fracture/weakness points are shown below. In case of 3D printed parts material failed at the horizontal print lines, where as composite material only buckled and opened at the seams.

Last time I tried making a composite sheet from PLA and natural fibers I used cut pieces of filament and jute cloth. I put both in the oven and waited for the results :) (https://hackaday.io/project/171199-bio-degradable-pla-jute-composite-drone/log/176534-production-of-composite-material).

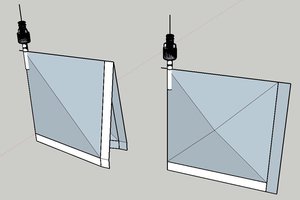

I have since found a better way of producing the composite material by 3D printing thin sheets of transparent PLA and sandwiching the linen cloth inside the PLA sheets. After laminating the stack with a hot iron the results are much better than last time:

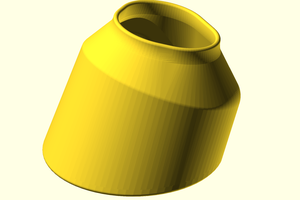

In order to best utilize this sub 1mm thick material I used molds to make bars for drone arms and reinforce the central base plate:

I decided to make the connecting pieces with 3D printed PLA parts and use the M2,5 stainless bolts to connect all the pieces.

After a few redesigns of the connecting parts I managed to finalize the frame design. Majority of the time went into getting the angles right for the legs and reinforcing the connections with chamfers.

I also managed to perform some flight tests with the parts I had from the previous drone build.

I am planning to perform additional flight tests and find new way to use natural fiber composites.

In the meantime if anyone is interested you can get 3D printed parts files on Thingiverse (link on the project page) and composite parts on Tindie (link on the project page).

Create an account to leave a comment. Already have an account? Log In.

Yes, I am familiar with the described problem. I try to keep the low humidity when storing PLA and fibers as well as drying the cloth before lamination as proposed. I have not looked into chemically treating the fibers yet.

I will try to perform some comparable strength tests in the following weeks. Pure PLA vs new flax composite...

Hi Mitja,

I've seen your strength (comparison) test and found it most interesting as you did. It then showed a poor improvement in strength based on several issues, that you tried to solve thereafter.

How about conducting a similar test to compare with the previous material to show the results of your new findings?

As you are using the new material in your new drone as structural component, I am not so much interested in the impact resistance but in the (reinforcing) strength of that composite...

Hi Pascal,

thank you for your interest.

I performed a (non-standardized) strength test in the previous project log (https://hackaday.io/project/171199-bio-degradable-pla-jute-composite-drone) that showed that strength was marginally improved compared to PLA. I have to repeat the tests with the new composite which has a much higer fiber/PLA ratio as well as better fiber to PLA adhesion. If you have a proposal or a way to test the strength of such thin sheets please contact me.

From the experience, the impact resistance should be significantly improved by adding the fibers (similar to other fiber based composites). I have not made a standardized test for it either, but I think strength(/weight) and impact resistance would be interesting to test.

Thickness of the material is approx 0,8mm and currently sheets of max. 200x200mm can be made. I could make larger sheets by getting a 3D printer with larger xy build area and laminator (oven, iron, etc).

Hey Mitja,

your experimental approach is really amazing. Looking for solution of bringing sustainable ideas for drone builders in Africa, I think your findings lead in a good way. Have you done any more strength/comparison tests on the improved material?

The intention of this question is to get a feeling of what maximum weight would be achievable for your drone ?

What's the size and thickness of sheets that can easily be fabricated in such a "simple" manner?

Best, Pascal

Hi Pascal,

thank you for your interest.

I performed a (non-standardized) strength test in the previous project log (https://hackaday.io/project/171199-bio-degradable-pla-jute-composite-drone) that showed that strength was marginally improved compared to PLA. I have to repeat the tests with the new composite which has a much higer fiber/PLA ratio as well as better fiber to PLA adhesion. If you have a proposal or a way to test the strength of such thin sheets please contact me.

From the experience, the impact resistance should be significantly improved by adding the fibers (similar to other fiber based composites). I have not made a standardized test for it either, but I think strength(/weight) and impact resistance would be interesting to test.

Thickness of the material is approx 0,8mm and currently sheets of max. 200x200mm can be made. I could make larger sheets by getting a 3D printer with larger xy build area and laminator (oven, iron, etc).

Become a member to follow this project and never miss any updates

By using our website and services, you expressly agree to the placement of our performance, functionality, and advertising cookies. Learn More

PointyOintment

PointyOintment

TRAN.VINH.QUANG

TRAN.VINH.QUANG

Andrea Piccinno

Andrea Piccinno

btw, have you seen this:

"

But natural substances have their drawbacks that the researchers had to come to terms with in the project. In the case of jute fibers, it was the high affinity to water and the polar fiber surface. Both of these factors hinder the optimal binding of the fiber to the duromer matrix. The difficulty: As a natural raw material, the jute fiber draws water from the air even after harvesting. The researchers have solved this problem by drying in an oven at 80 degrees Celsius. " However, the fibers had to be processed immediately, because as soon as they are exposed to the ambient air again, they draw water once more. So the time window was very short," reports Hüttl.

The polarity of the surface results from organic residues found on the natural raw material. Hüttl reports that a method developed by the Indian partners came to the rescue here. "The organic residues were removed with hydrogen peroxide, i.e. by chemical bleaching. Afterwards, the adhesion was measurably better."