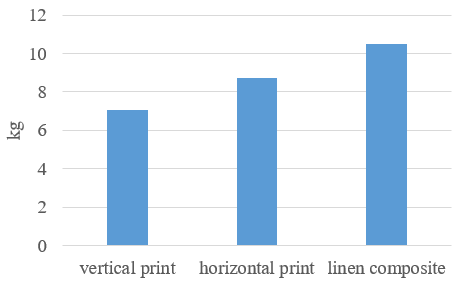

I managed to perform a comparable strength test of the composite material. I decided to test the loading strength of the drone bar assembly. I compared three different bars, one printed from PLA in a vertical direction, one bar printed horizontally and finally a linen composite bar. Bars are 200mm long with a thickness of 0,8mm.

I fixed the bars on one side and loaded them with a scale until they failed.

Fracture/weakness points are shown below. In case of 3D printed parts material failed at the horizontal print lines, where as composite material only buckled and opened at the seams.

Loading weight (normalized to bar weight) is approx. 20% higher for natural fiber composite compared to horizontally printed composite and 50% higher than the vertically printed one.

Overall I am satisfied with the results, especially since the composite bars outperformed the 3D printed parts without a catastrophic failure (points also to a good impact resistance). I am planning to perform a strength test where the seam of the composite material would be excluded from the experiment. It would also make sense to redesign the seam design for future products to take the full advantage of the composite material.

Mitja Breznik

Mitja Breznik

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.