We have been investigating getting the LED panels injection moulded (soft tooling as this is much quicker). This allows us to make a much more precise part that fits the case better and will make the kit very easy to assemble.

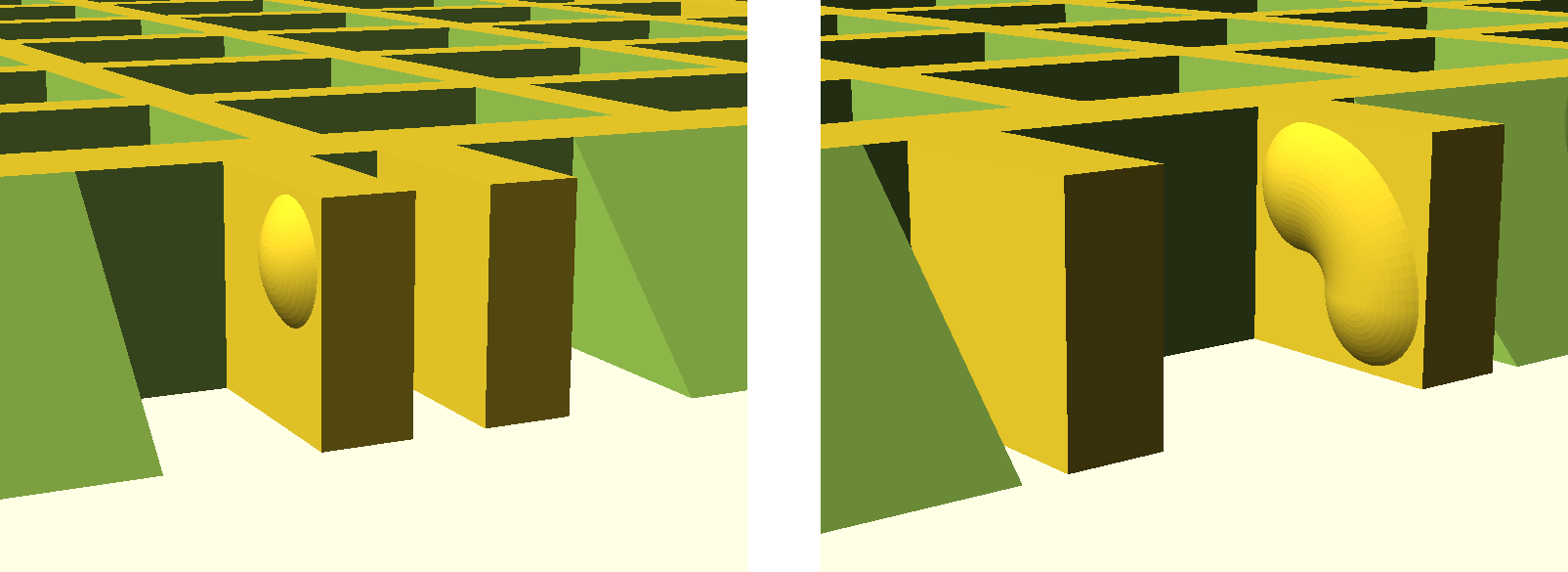

Some of this week was spent trying out various designs, to allow the panels to snap together. The ultimate rigidity of the cube will likely always rely on a few screws, but these snap fittings should make assembly (by the user) much easier. Above is pictured an idea for a right-angle fixture between adjoining panels. The idea is that the curvature is gentle enough for an injection moulding bumpoff, but still deep enough to hold the panels firmly during assembly.

Matt

Matt

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.