Features

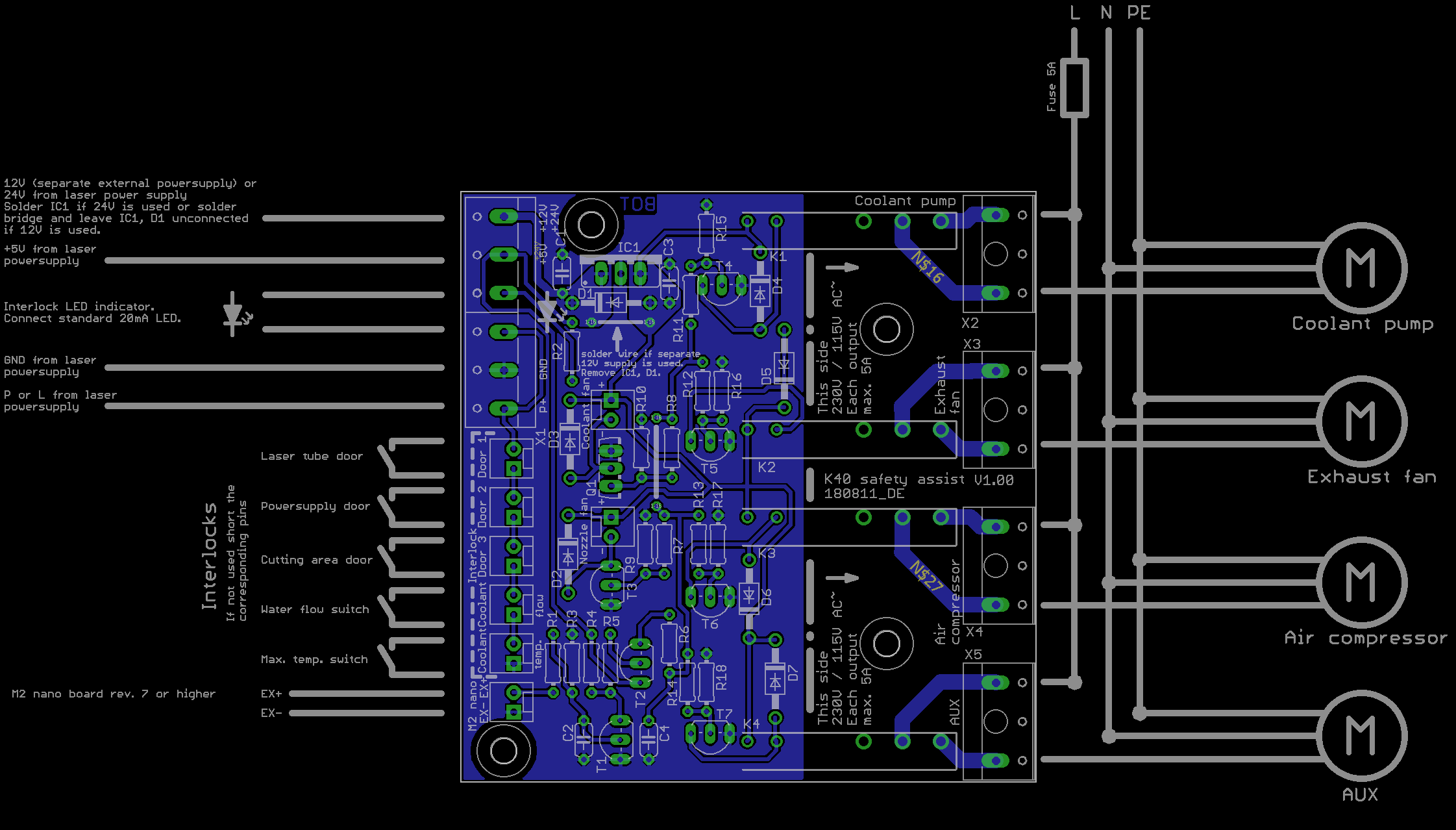

The following features are added using a small PCB:

1. Safety features

- Interlock switches for the three doors

- Over temperature input for the coolant temperature

- Flowmeter input for the coolant

- Status LED (Laser active / inactive)

2. Comfort features

- 4 relay outputs (coolant pump, exhaust fan, air compressor, AUX)

- 12V nozzle blower

- 12V cooling fans (e.g. for closed loop cooling system)

Before starting:

Working on the K40 laser is dangerous. The power supply has output voltages of 25kV touching this during operation is will cause death. Also the mains power can be dangerous for you life. If you don't know what you are doing consult an expert.

BEFORE modifying the Lasercutter REMOVE power cord. Never touch the high voltage output of the power supply even if the power cord was removed.

Wiring of the signals

Safety Assist PCB

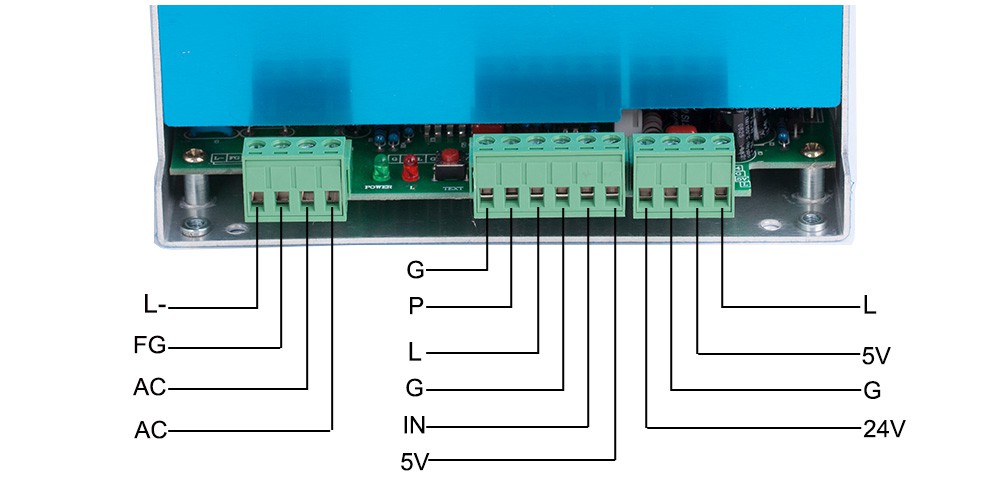

Laser Power Supply

| L- | Laser Tube Cathode |

| FG | Chassis Ground |

| AC | Phase AC 115/230V |

| AC | Neutral AC 115/230V |

| G | Ground |

| P | Water protection (normal operation when LOW, Laser off if OPEN) |

| L | Laser Switch (active LOW) |

| IN | Laser Current Control (PWM / analog 0V-5V) |

| 5V | Output +5V |

| 24V | Output +24V |

How it works

1. Safety features

All interlock inputs are connected as a chain. This means all of them must be closed to switch on the laser. If not, the laser remains off. If some of the features (e.g. flow meter) are not used the connector pins must be shorted.

2. Comfort features

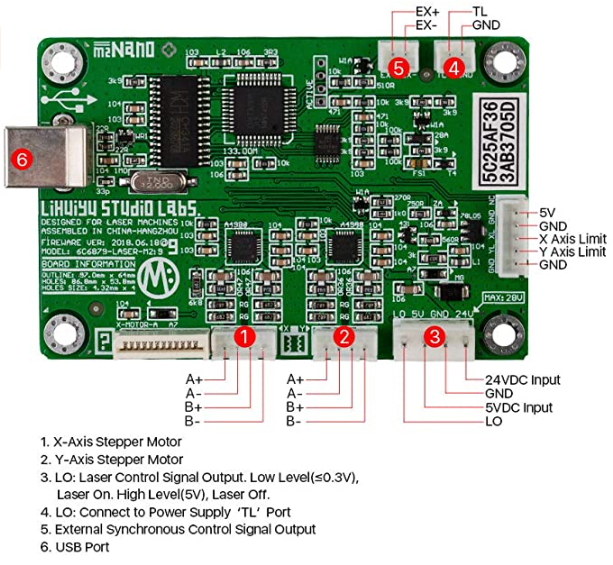

The comfort features all relay on the presence of the M2 nano EX output (connector 5). This is available from board revision 7 or higher. The M2 nano outputs a high level on that pin if the stepper motors are anabled. It also provides an afterrun feature because the pin stays high for some time after cutting has been finished.

Additional material

Things required to complete the project

Here some Aliexpress links to temperature protection switches, flow meter, micro switch.

Flow meter, temperature switch, microswitch

3D printed acessories

License

This project is released under the Attribution-NonCommercial ShareAlike 4.0 (CC BY-NC-SA 4.0)

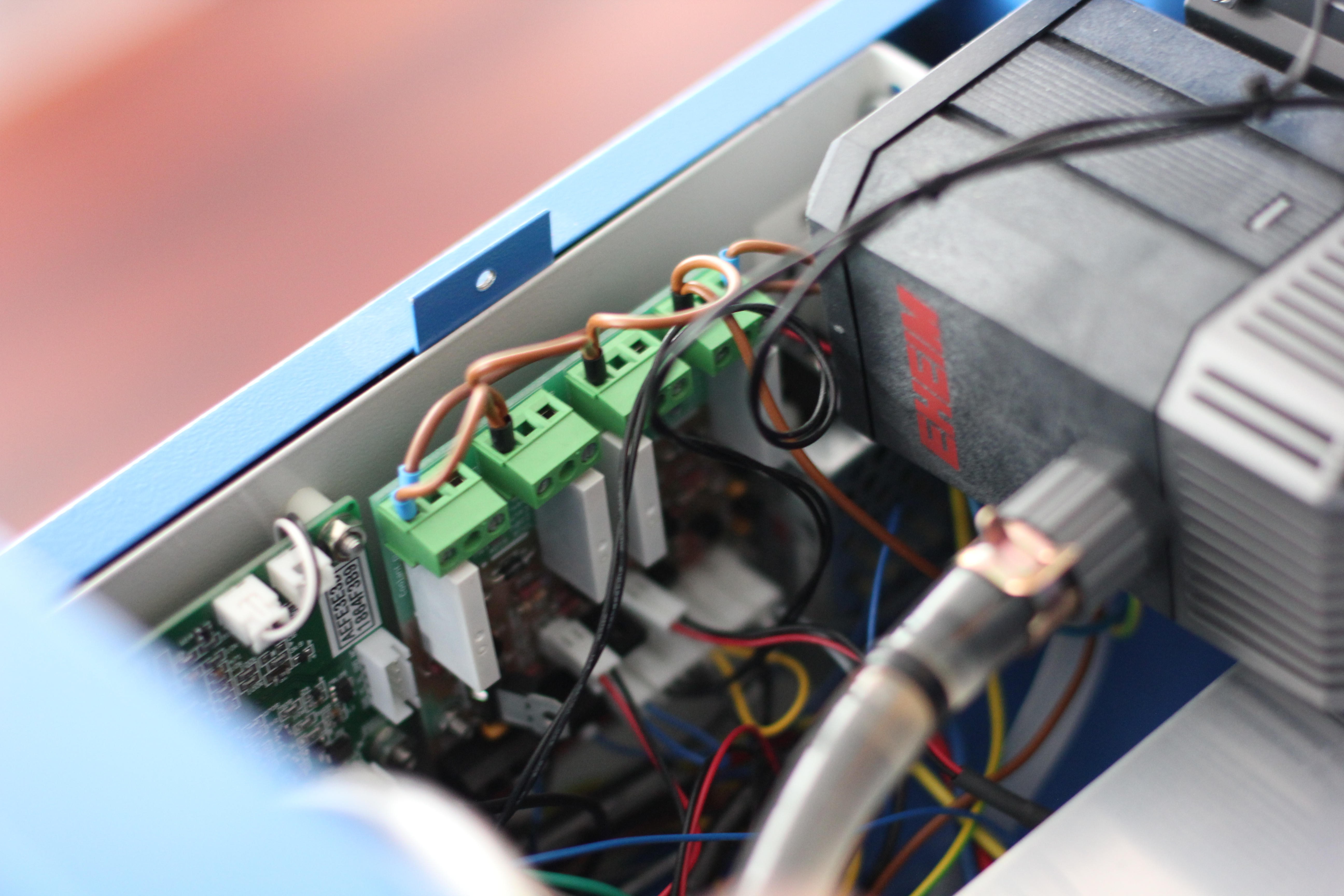

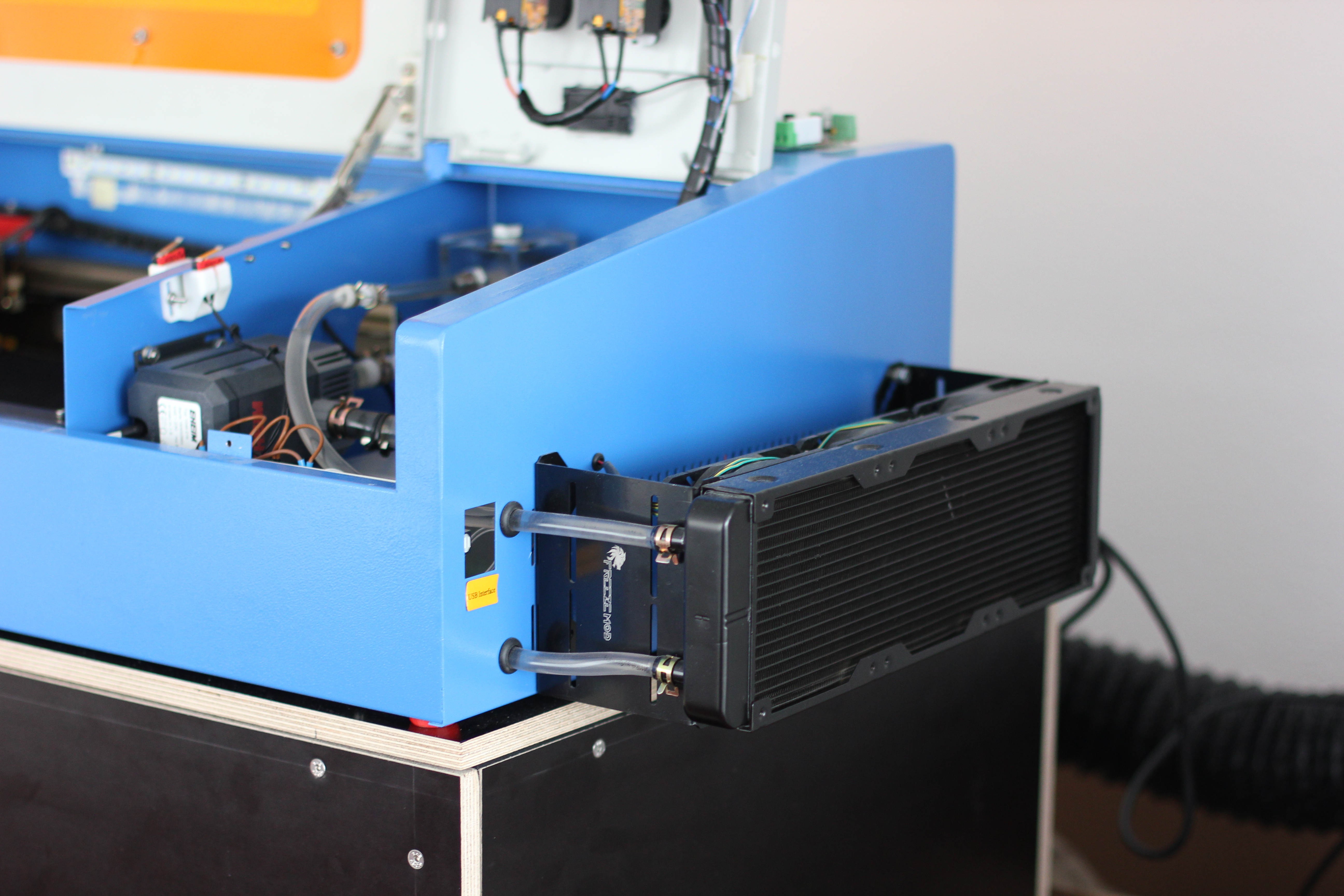

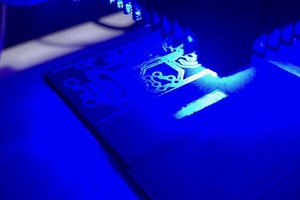

Pictures of my K40

Mounting of the PCB

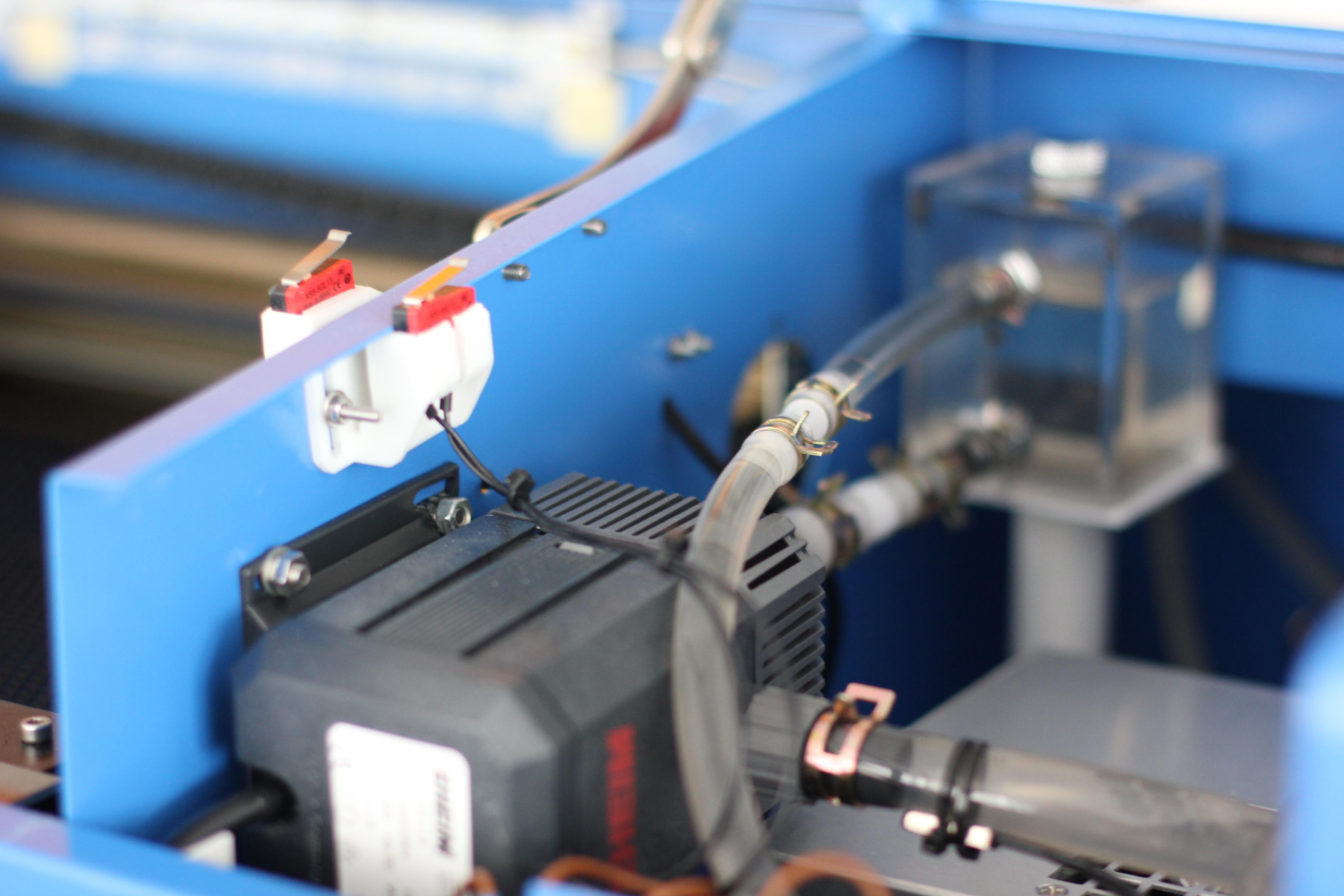

Microswitches as door interlock

Closed loop water cooling

igorfonseca83

igorfonseca83

Ray Burne

Ray Burne

FabLab München

FabLab München

Cool project! I don't have a K40, but I've been eying one for a while. It seems cooling is the hardest part.

I think your project could be improved by replacing the temp. switch with two temp. sensors, located at the inlet and outlet of the tube, to assure the tube is being appropriately cooled.

While overheating is an obvious concern, it's worth noting that using water that is too cold will stress the glass between the CO2 and the coolant.

Using a pair of comparators and trim pots, you could prevent the laser from operating when the inlet is too cold (less than 15°C) or the outlet is too hot (greater than 26.5°C).

I arrived at these figures with back of the envelop calculations using figures on the datasheet for a tube similar to the K40's (SPT C40).

You might also consider adding a diode and a capacitor to the base of the transistors running the coolant pump and exhaust fans so they continue to run for a bit after the laser is switched off.