Group project for students at UiT Norway's Arctic University, spring 2021.

The project's main goal has been to provide an extensible, adaptable "floating platform" which our university may use for educational and scientific purposes.

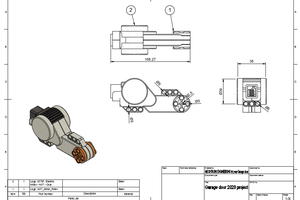

Mechanical Engineering students responsible for vessel hull: Jacob Ludvigsen, Jørgen Ødegård, Lasse Bertheussen, Thomas Karlsen.

The complete source (for the hull) is licenced under CERN-OHL-W, but individual components (such as servos and metal extruded profiles) may not be as such.

Feel free to copy and redistribute, and modify freely our complete source in accordance with the licence.

Parts of the project which JL, JØ, LB & TK aren't responsible for may be subject to different licence.

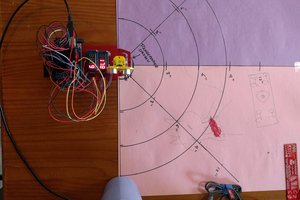

Automation Engineering students responsible for electronic outfitting and automation: Robin Liebert, Yuriy Yurchenko, Jakob Nystuen Sørfjordnes.

Sander Daniel Paulusma helped out also.

Robin Liebert and Yuriy Yurchenko wrote their excellent Bachelor's thesis in Automation Engineering on this project. You can read it here: https://drive.google.com/file/d/1hZ6Jy_0BQfNE0N7jRk4D1pavtWJ1ZYDZ/view?usp=sharing

Their github repository: https://github.com/Nztys/UiT_AutoDorone_2021

There was an article about the project in the university newsletter as well (archived for longevity): https://web.archive.org/web/20210612234926/https://uit.no/nyheter/artikkel/kortnytt?p_document_id=732586

Edward Li

Edward Li

Daniel

Daniel

Ricardo Ferro

Ricardo Ferro

Several years ago I worked up a 'yacht' based off the Ramform. It's designed to be moored in the Gulf of Mexico and use the Gulf Stream to maintain orientation by turning like a weather-vane with changes in the current. The wider stern aids maintaining stability.

No idea how to go from 2d to 3d, much less turn it to 3d printable. Would y'all care for the challenge...?