The hardest part in an operation like this is the enclosure.

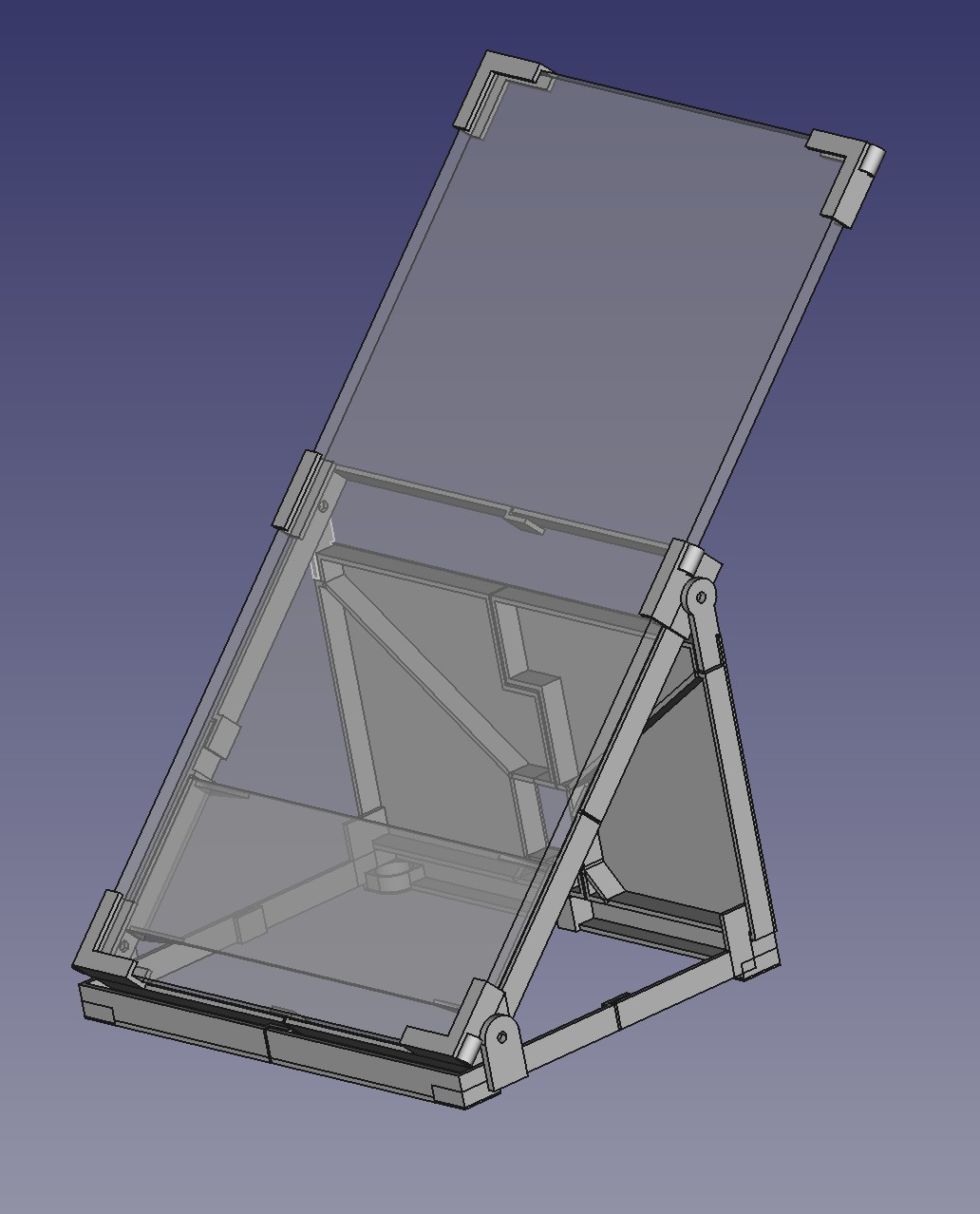

Each panel would have its own stand. The stand would attach by magnets & fold up. It was too big to fit on the print bed, thus began the brutal experience of modeling & gluing 10 pieces. The dimensional accuracy of a model split into many pieces is horrible.

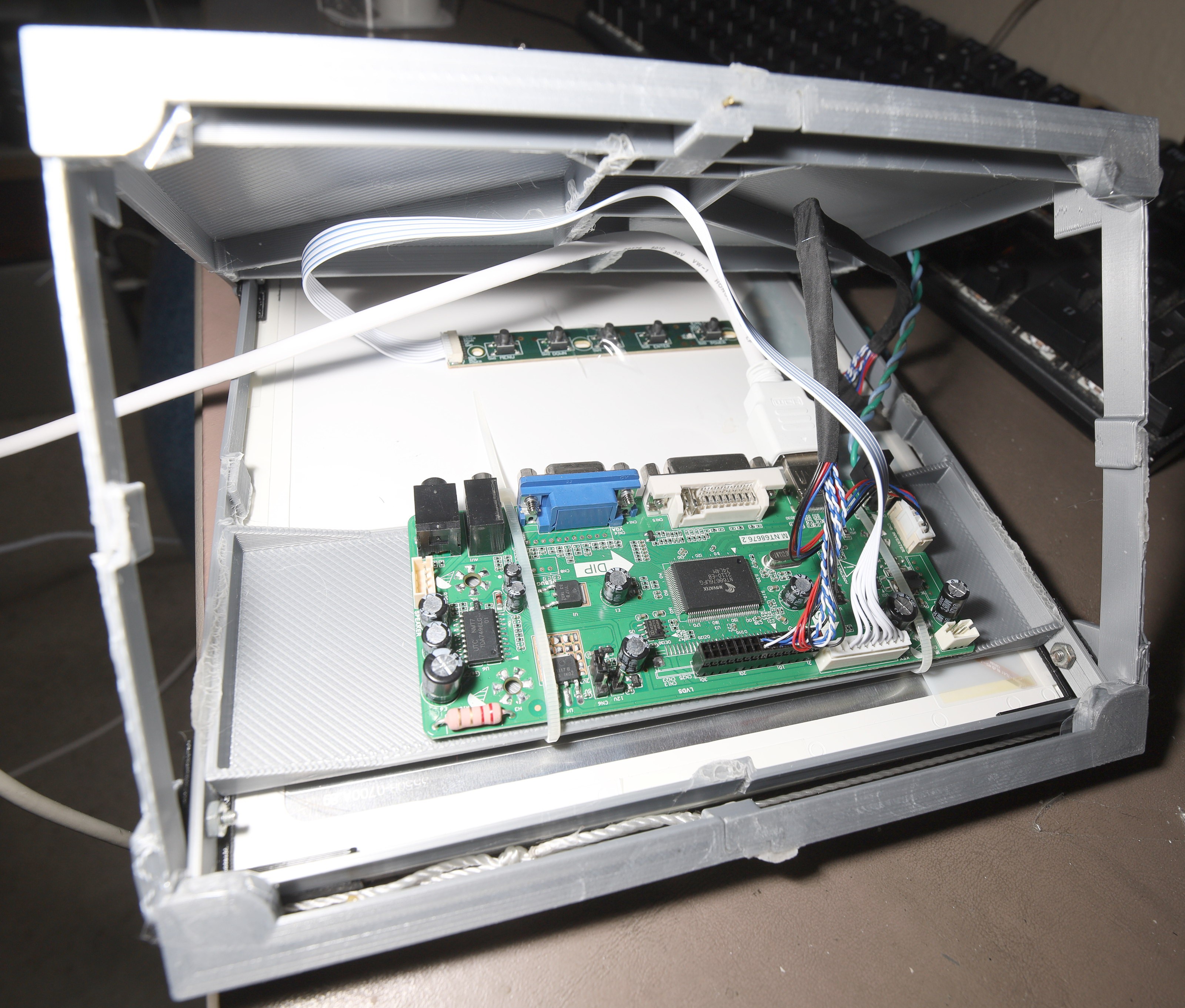

Tolerances were bad enough to keep it from folding up. The wires took up a lot of space.

The LVD cable needed the living daylights bent out of it to fit in there.

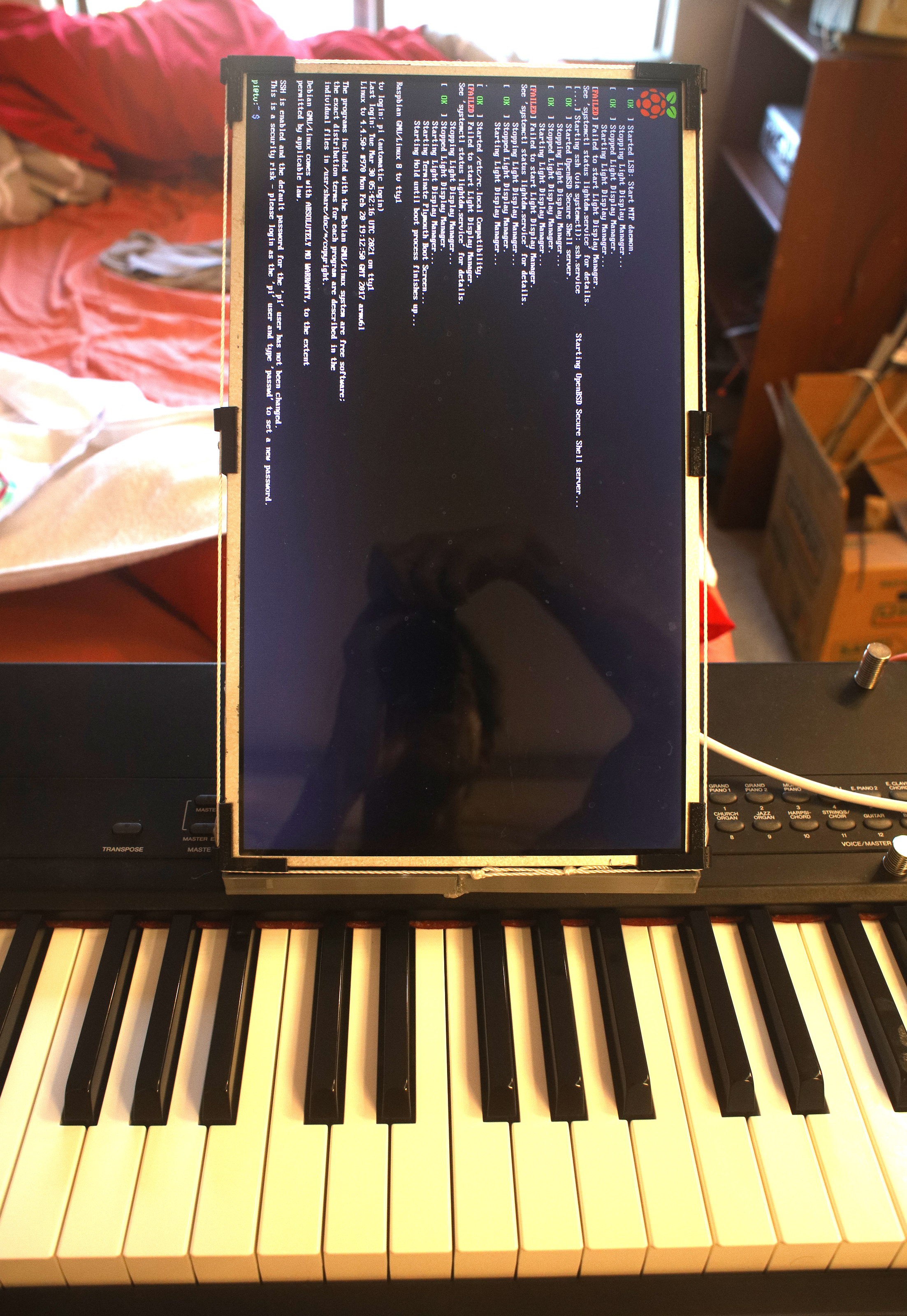

The magnets held it on. It needed a hair more clearance over the buttons.

Viewing angle was as bad as expected. It may end up being a single page if 2 pages are too far apart.

Rear panel either came out too narrow or the LCD panel came out too wide. Rear panel doesn't need a solid sheet. LCD panel needs gaps to route cables next to the panel.

Might have to leave it unfolded & make a bigger cover.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.