After years of horrendous chinese pinball machine buttons, it was time to upgrade to soft touch MHPS2283V buttons. The amount of force required by the pinball buttons eventually causes injuries.

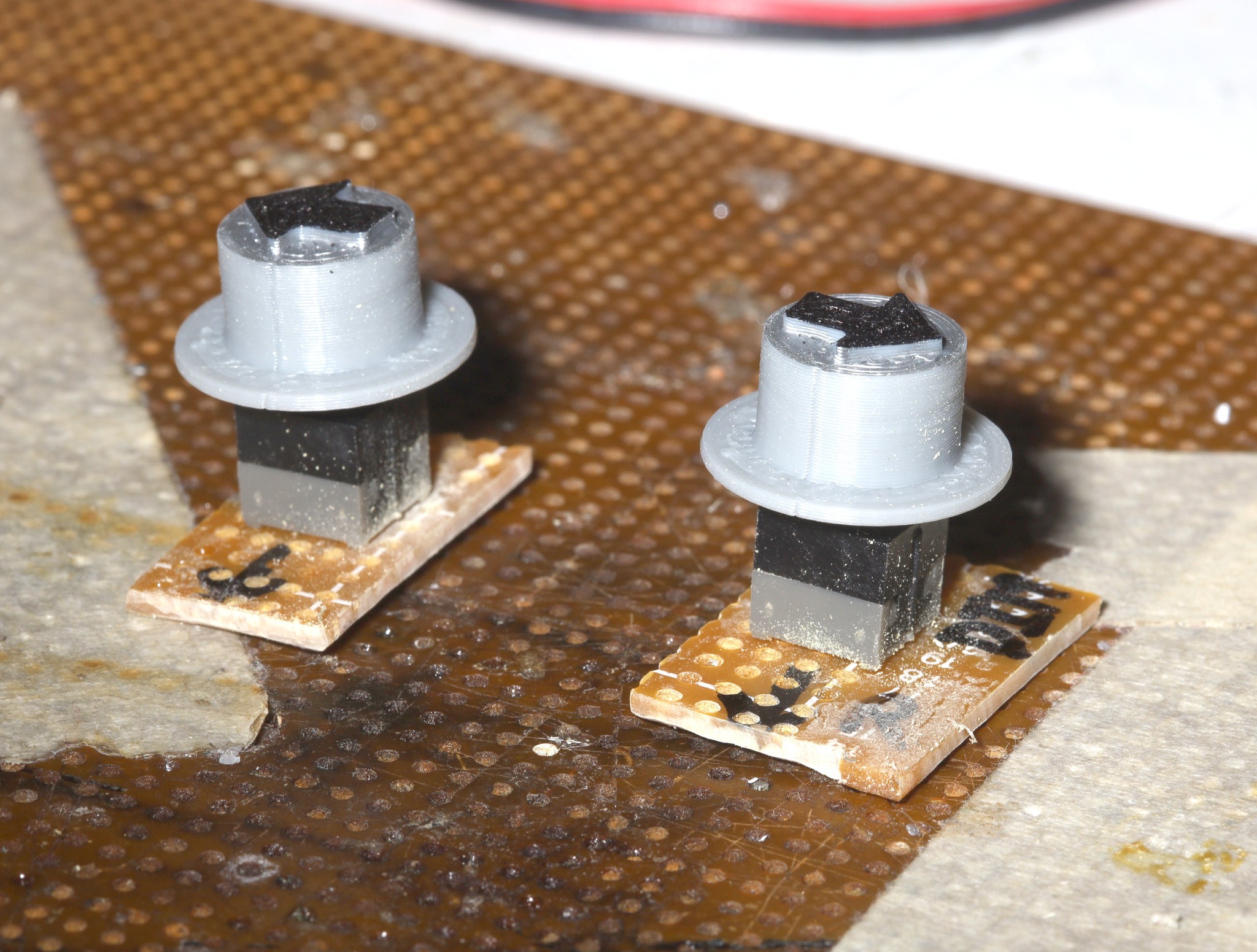

The soft touch buttons require carrier boards which must be painstakingly trimmed to get the positioning right.

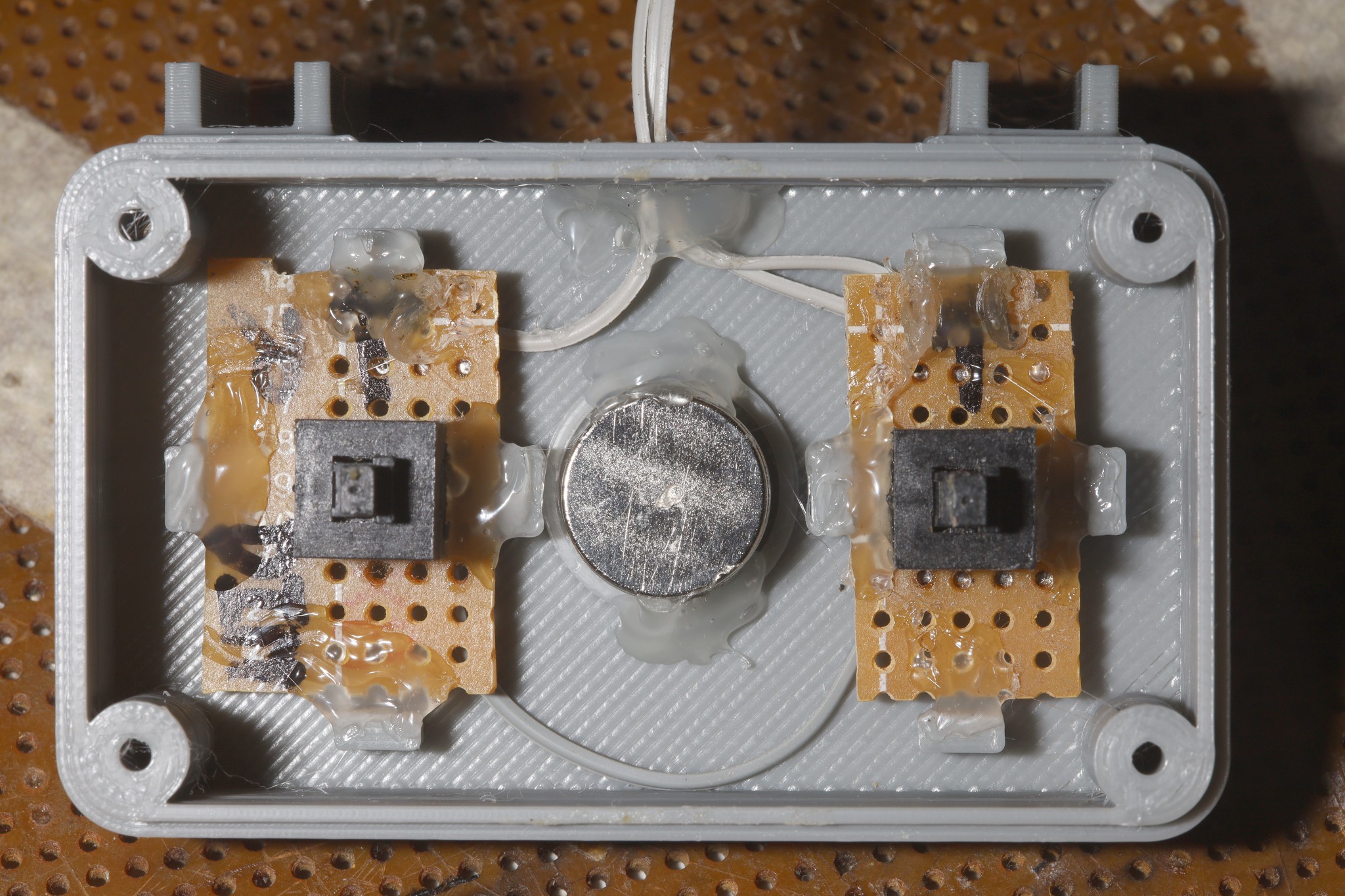

Then they need to be hot snotted in. There's no way to service the wiring after that. The hot snot interfered with the upper standoffs. There should be a smarter way to mount MHPS2283V's besides carrier boards. A carrier board was necessary for 8 but PLA might be good enough for 2.

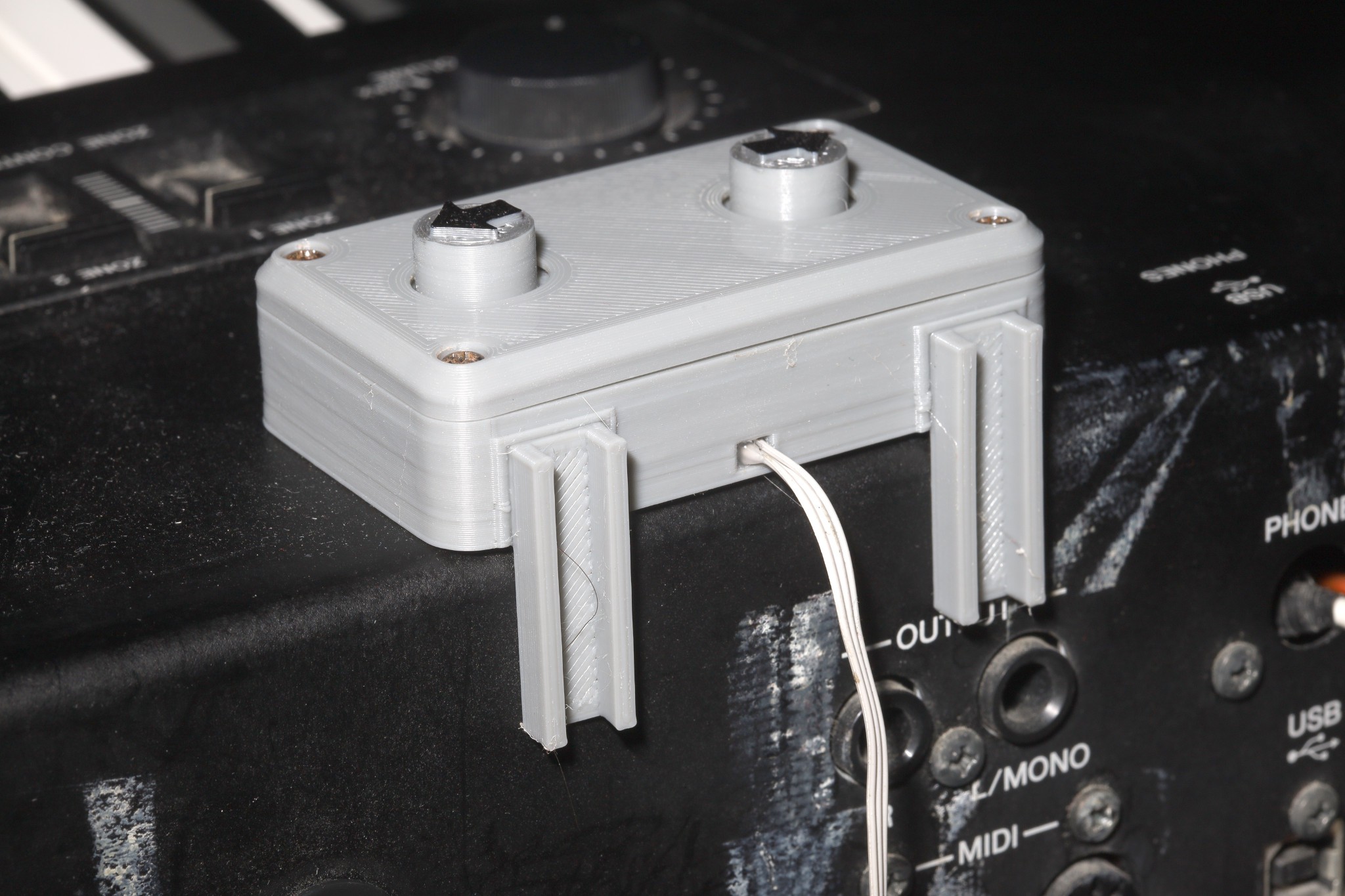

The upper standoffs made it bulge on purpose.

Alignment was still slightly off but they managed to not jam.

There were problems. There were too many layers below the magnets. The bottom was too slippery. The magnets should be as close to the edge as possible. Maybe the magnets should go on the back.

The only thing which might improve servicability is making it bigger, but there's limited space in the apartment.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.