Quick recap

The global chip shortage snatched away the "ultra high sensitivity" hall switch I was planning on using for the Tardygrade controller pcb. So now I need to make do with a non-ultra alternative.

What the consequences are

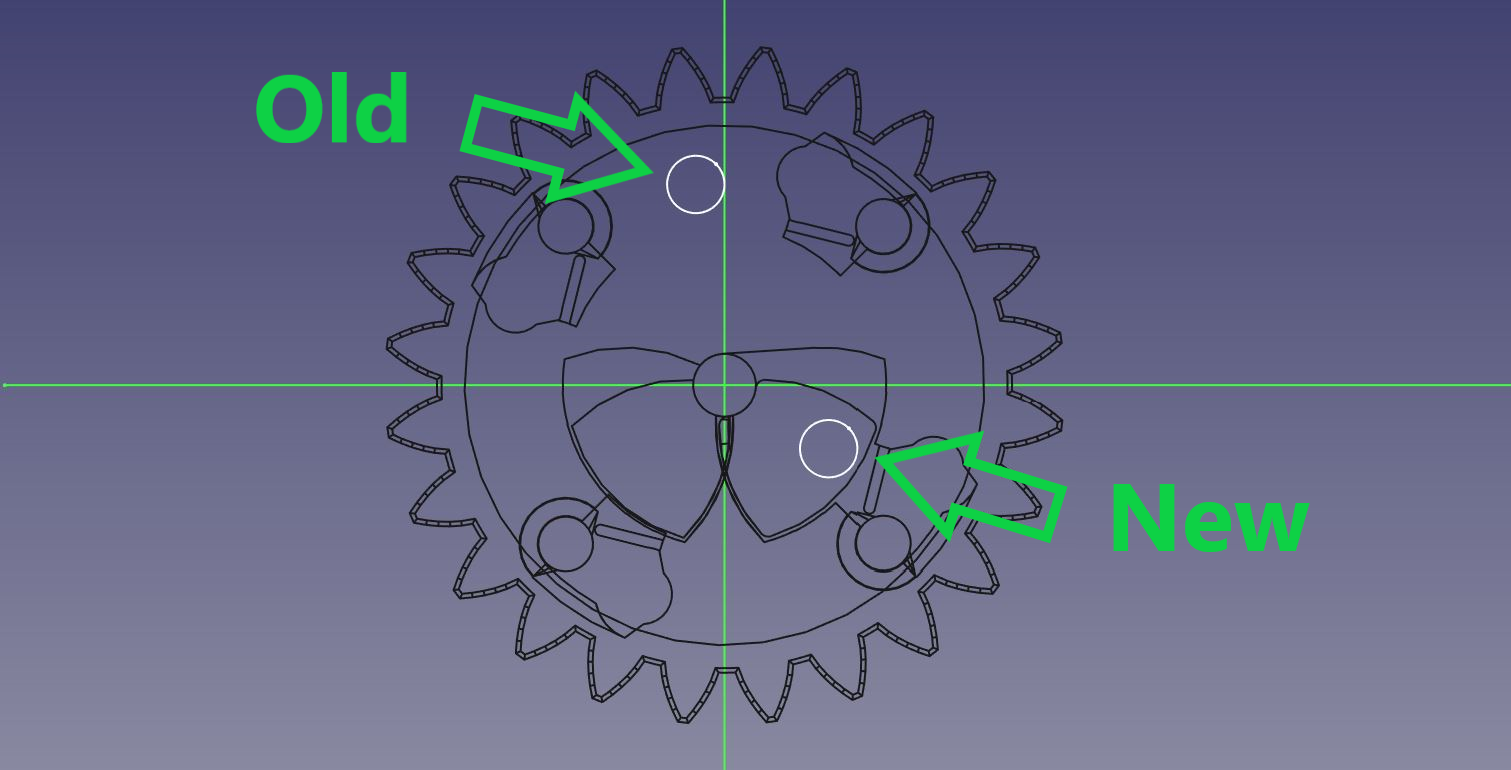

Due to the lower sensitivity of the new IC I needed to move the magnet in the main gear closer to the controller pcb in order for it to be detected. The old design had the magnet embedded inside the body of the gear, which allowed me to place it at any angle with respect to the cams. This allowed me to layout the pcb as I pleased, since the magnet position could be adjusted to fit the layout of the hall switches.

The only way to get the magnet closer to the pcb is to slot it into the upper cam. But that also means I'm committing to a specific radial placement of the magnet, which leaves me with only one way of placing the hall switches.

What to do about it

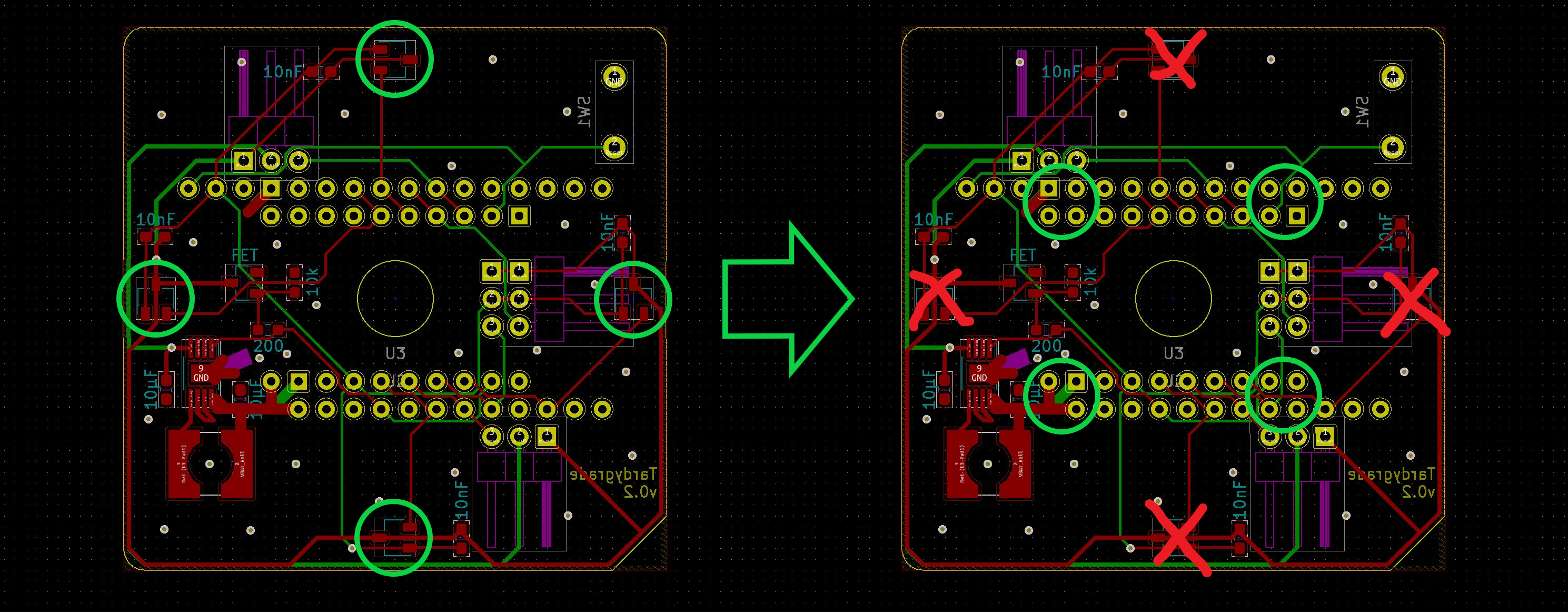

For the next pcb prototype I'll turn the pin headers for the ESP32 board to a 45° slant in order to make room for the hall switches. But before ordering new boards I wanted to test the whole concept in practice by retrofitting one of my current prototype boards.

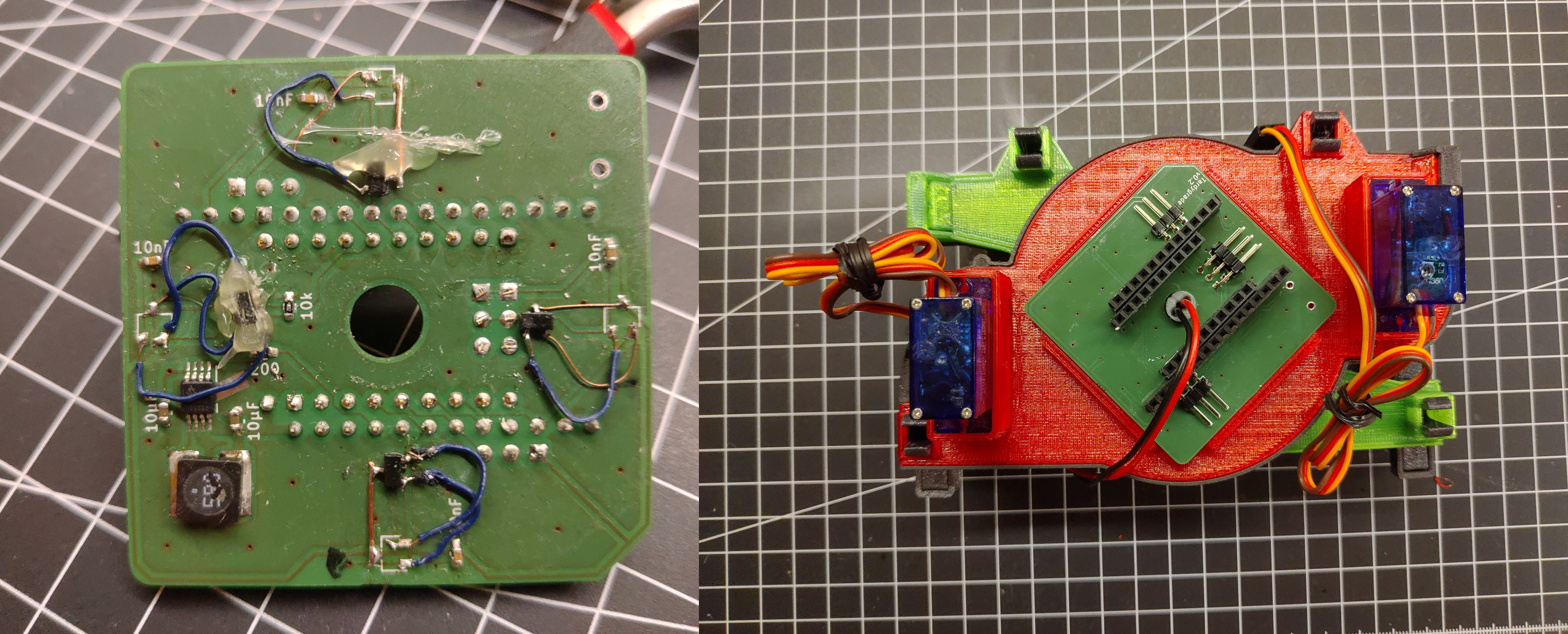

With the use of hot glue and some tricky soldering I transplanted the hall switches to coincide with the new magnet path. I then mounted the pcb at a diagonal to simulate the new hall switch placement.

The result

I'm happy to report that this setup worked out well in testing. The magnet was being detected consistently, which was the main thing I was worried about. Accuracy seems to be as good as before or perhaps even a bit better. Maybe that has to do with the "edge" of the magnet field being less diffuse at a shorter distance, but that's just my speculation.

In conclusion

Crisis is averted. Project still alive and kicking.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.