The problem with hardware is that bugs are much more of a pain in the arse. Unlike software you can't hide your hacks behind library boundaries

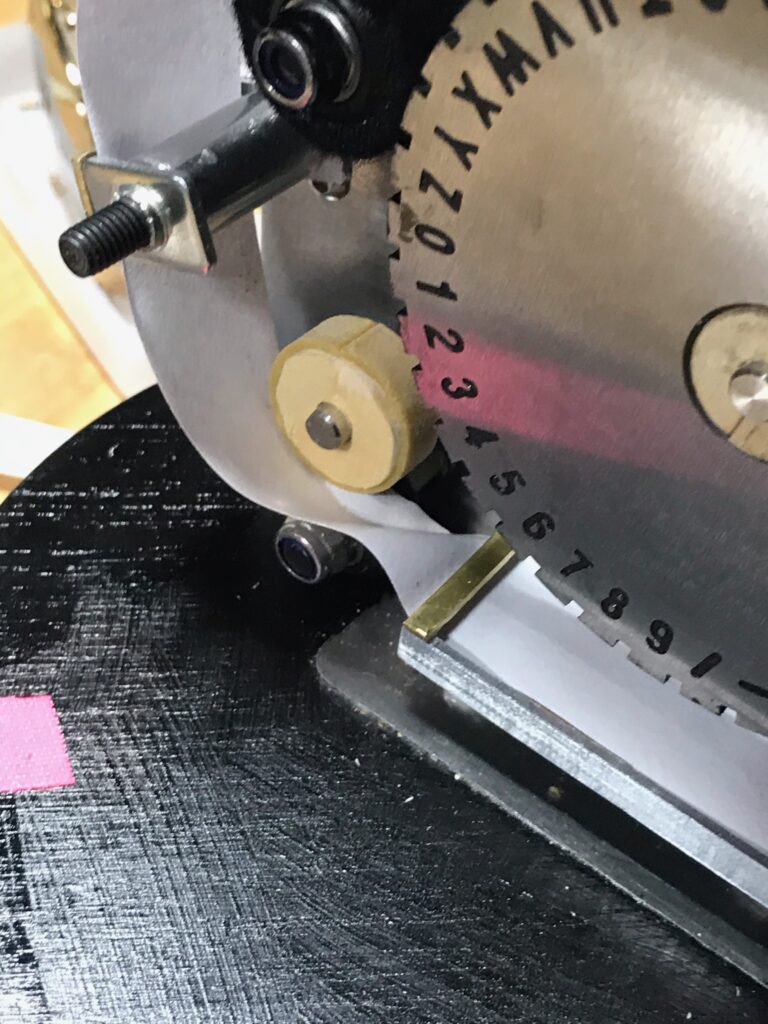

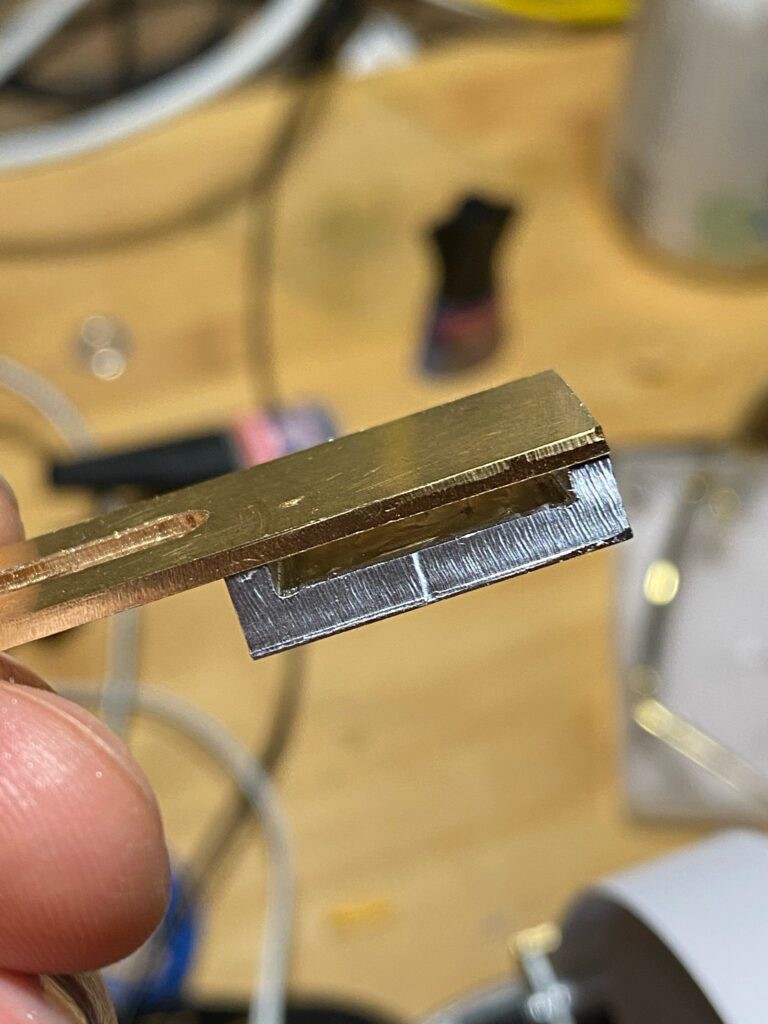

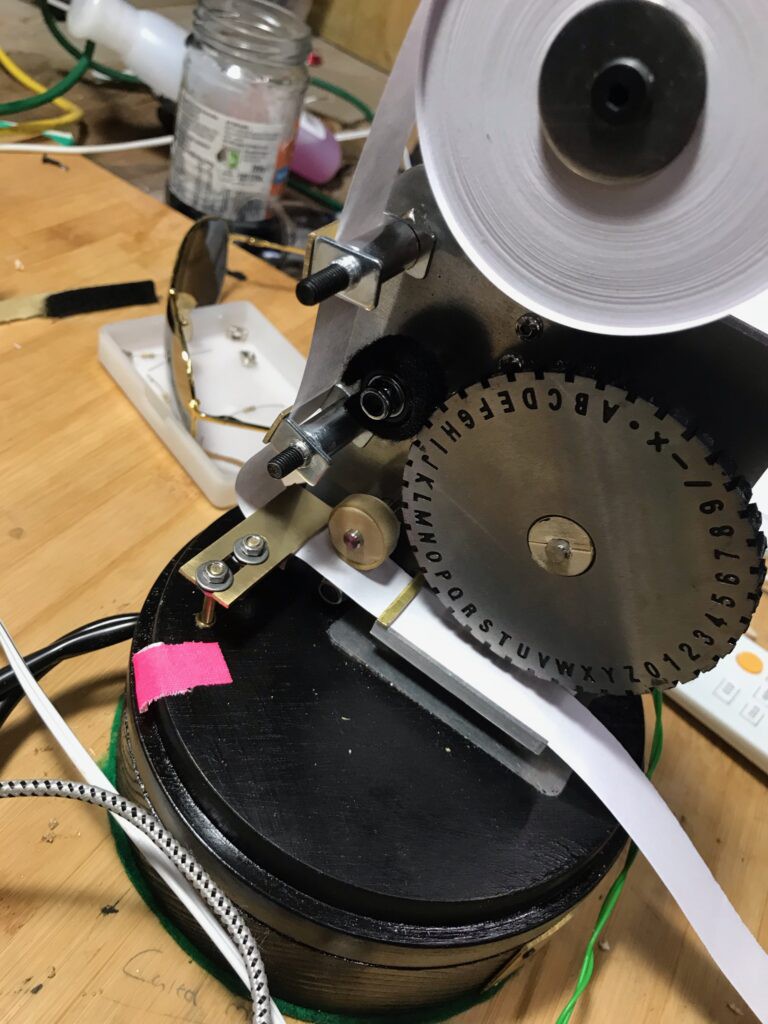

Because the paper can move left and right relative to the presser plate, it gets pinched. Which makes everything go wrong. This took a lot of fiddling to correct, but in the end the solution is quite simple:

The conformer makes sure that the paper can't move left or right, and surprisingly it works really well. It has lots of room for adjustment, which is a bit ugly, but means it actually works.

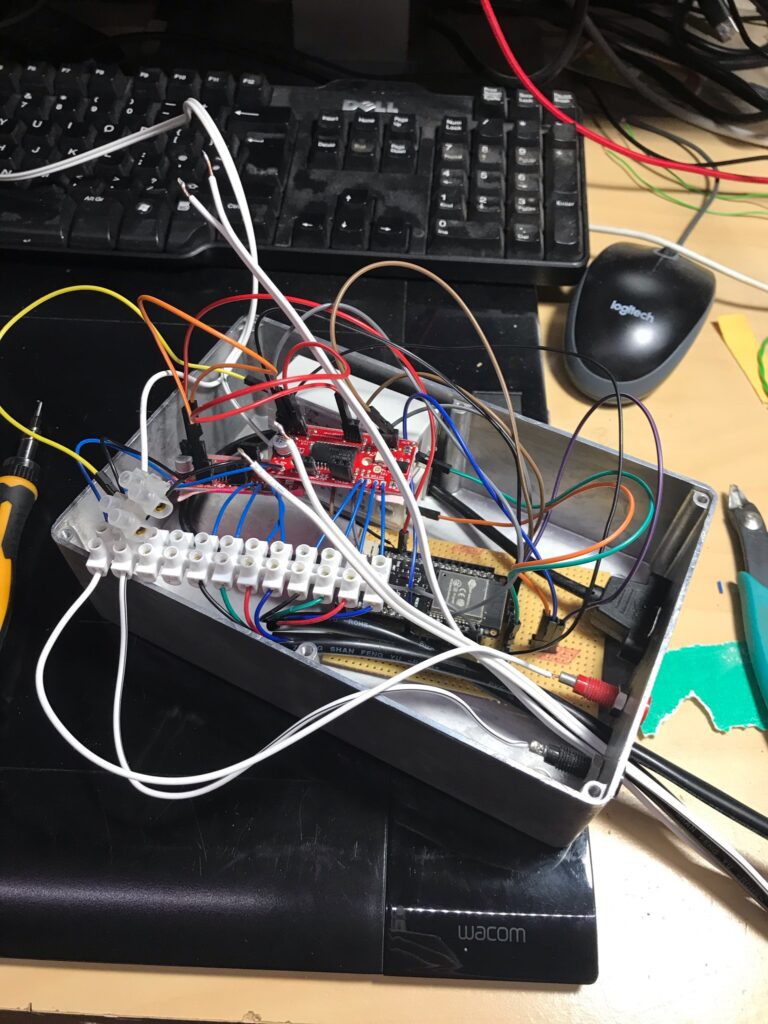

The other mess was the electronics. There is nothing ground breaking here, just two stepper controllers, a solid state relay and an ESP8266(wildly over powered). As we are dealing with 24v and lots of noise from the solenoids, I used a beefy SSR, so I didn't run the chance of accidentally shoving -32v through a USB line.

Its messy though

but with a bit of wobbling, it was tamed. Plus with this lid on, you can see it. Perfect is the enemy of good and all that.

secretbatcave

secretbatcave

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.