The build of the printer is almost finished, only the print plate is missing.

Some problems occurred during the build:

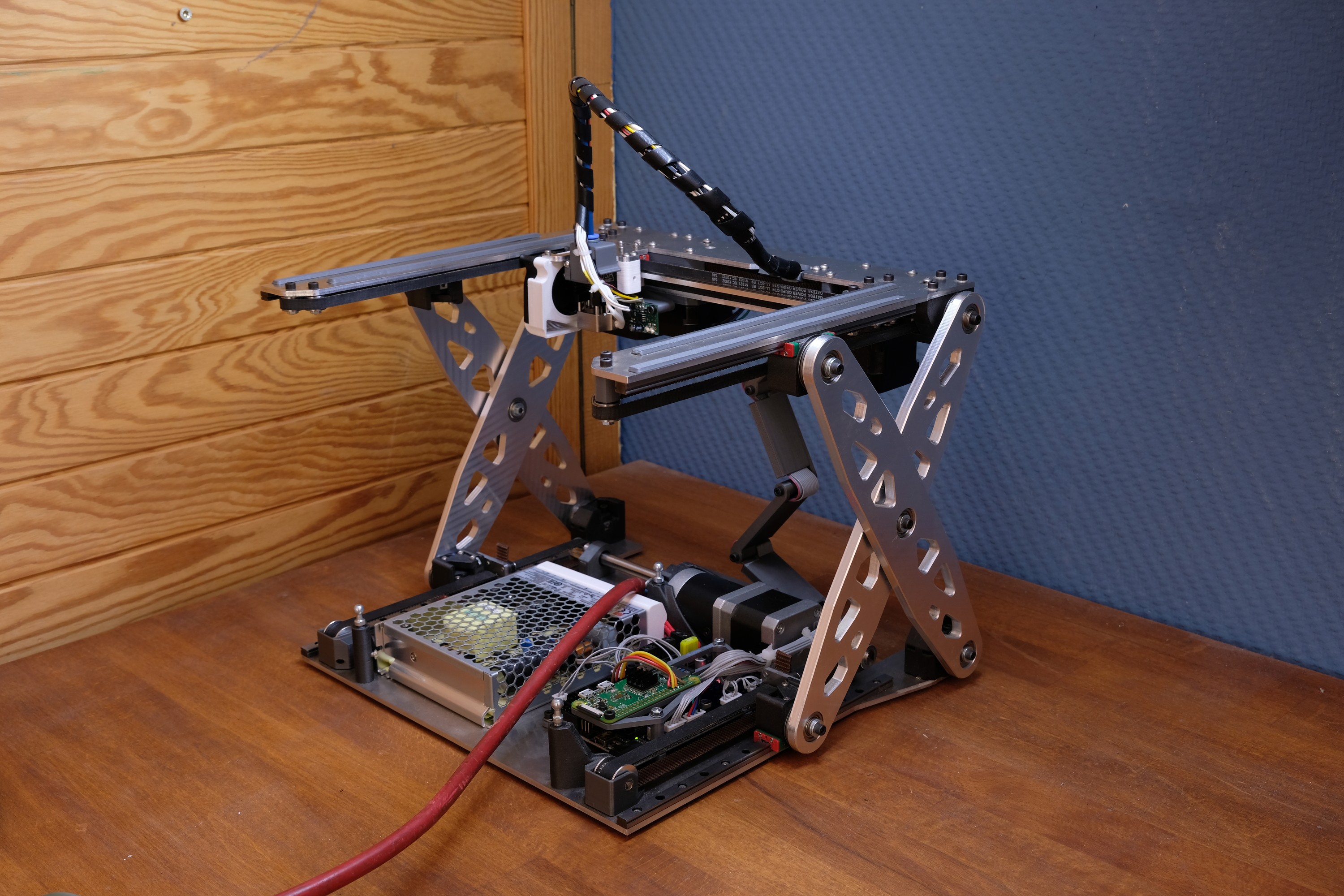

The ball bearings for the joints of the scissor-lift were chosen much too fragile, so they had to be replaced. As a result the entire arms of the scissor-lift had to be remodelled and instead of being made out of two 3mm Aluminium plates, they were now milled from 6mm aluminium.

Learnings / mistakes

cheap mgn7 rails are pretty loose, they have a lot of play when applying torque to them. Half of the scissor-lift joints are mounted on these mgn7-carriages, so the whole scissor-lift looses stiffness due to that, which is very unfortunate.

Maybe the mgw7-Rails (wide version) have less play because the are two times wider.

To make the printer as thin as possible I made two cut-outs for the X/Y motors in the base-plate, so the printer could fold together even smaller. However, this weakens the attachment points of two joints, therefore reduces stiffness of the scissor-lift.

Due to a dimensioning mistake in the design, the printer can't collapse as thin as I planned it. The collapsed height of the printer is now 3-4mm taller.

things that worked well

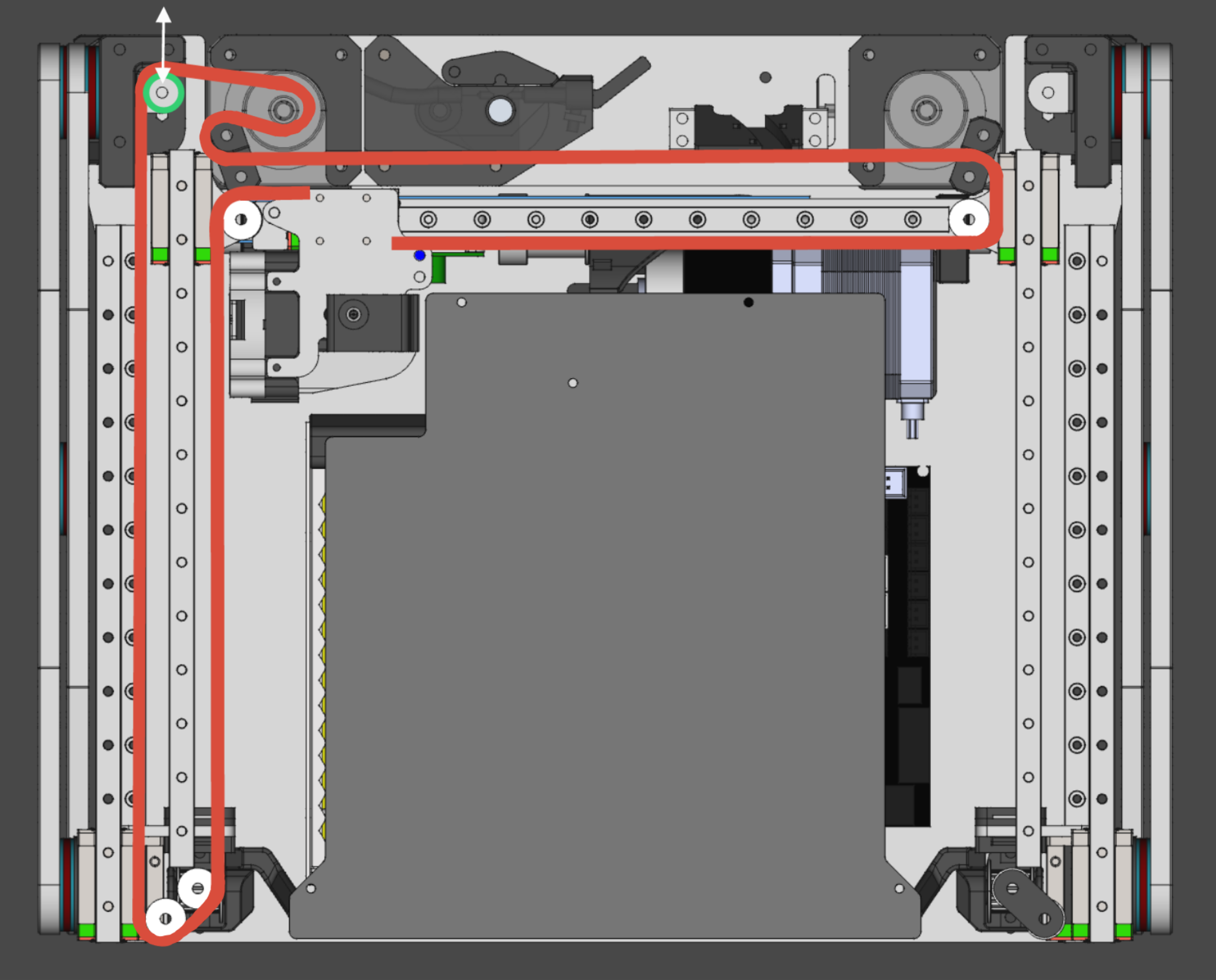

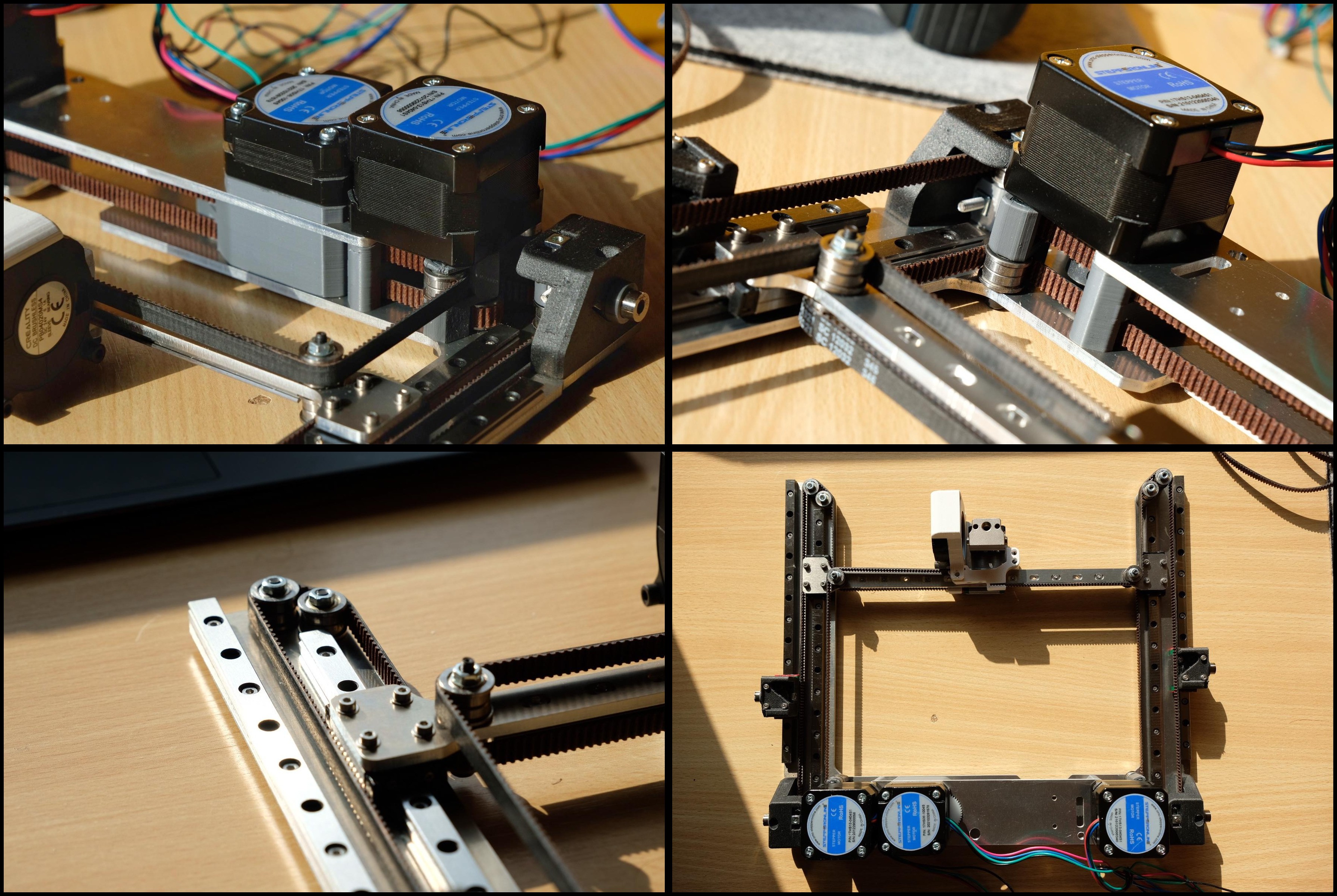

- The pathways of the CoreXY belts are running through the mountings of the X/Y motors and the extruder.

- The tensioning mechanism for the CoreXY belts consists of the rear idler pulley, which can be pulled further backwards by a screw. Which works very well.

Stiffness

When the printer is fully unfolded (print height approx. 115mm) and a force acts orthogonally to the scissor-lift, it is not very stiff. I think printing that high will only be possible with low printing speeds. I am curious how the printer will print in general and if it is stiff enough for reasonable print speeds.

Printhead

the printhead uses a Mosquitto hotend which sliceengineering kindly provided. In the picture you can the the folding mechanism of the bowden tube, when the printer gets stored away.

All in all, I am not very happy with how the printer turned out, because it is not stiff enough. It is difficult to minimize something with moving parts without loosing stiffness.

I really like the concept of a 3d printer with a scissor-lift and already thought about how I can use steel wire to stiffen the scissor-lift and printer. I have to give this idea a try in the next redesign

Malte Schrader

Malte Schrader

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Very nice to see that this project got an update!

Are you sure? yes | no