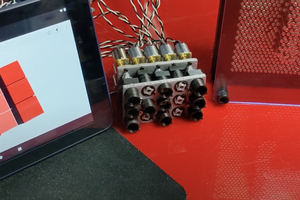

This design uses two cams; one for the segments A, B, G and F (the upper cam), and a second for the segments C, D and E (the lower cam).

The two cams are synchronized by three gears, the center gear being driven by a single inexpensive stepper motor.

The cams are designed to move seven "slides" in a specific sequence in order to produce the displayed digits of 0 through 9. Each cam has one slot for each slide under its control, and a pin on each slide rides in the slot of the cam controlling it. As the cam rotates, the slots induce a linear motion for each slide from 0mm to 3.5mm.

Each of the slides drives a single segment. A pin on the slide fits into a slot on the segment. Slide movement from 0 to 3.5mm induces a rotational movement of the segment of 0 to 90 degrees.

Greg Zumwalt

Greg Zumwalt

hugs

hugs

Wow, very cool design with the multiple cam profiles driving it all. And thanks for posting that CAD video, helped me understand how the guts of this work.