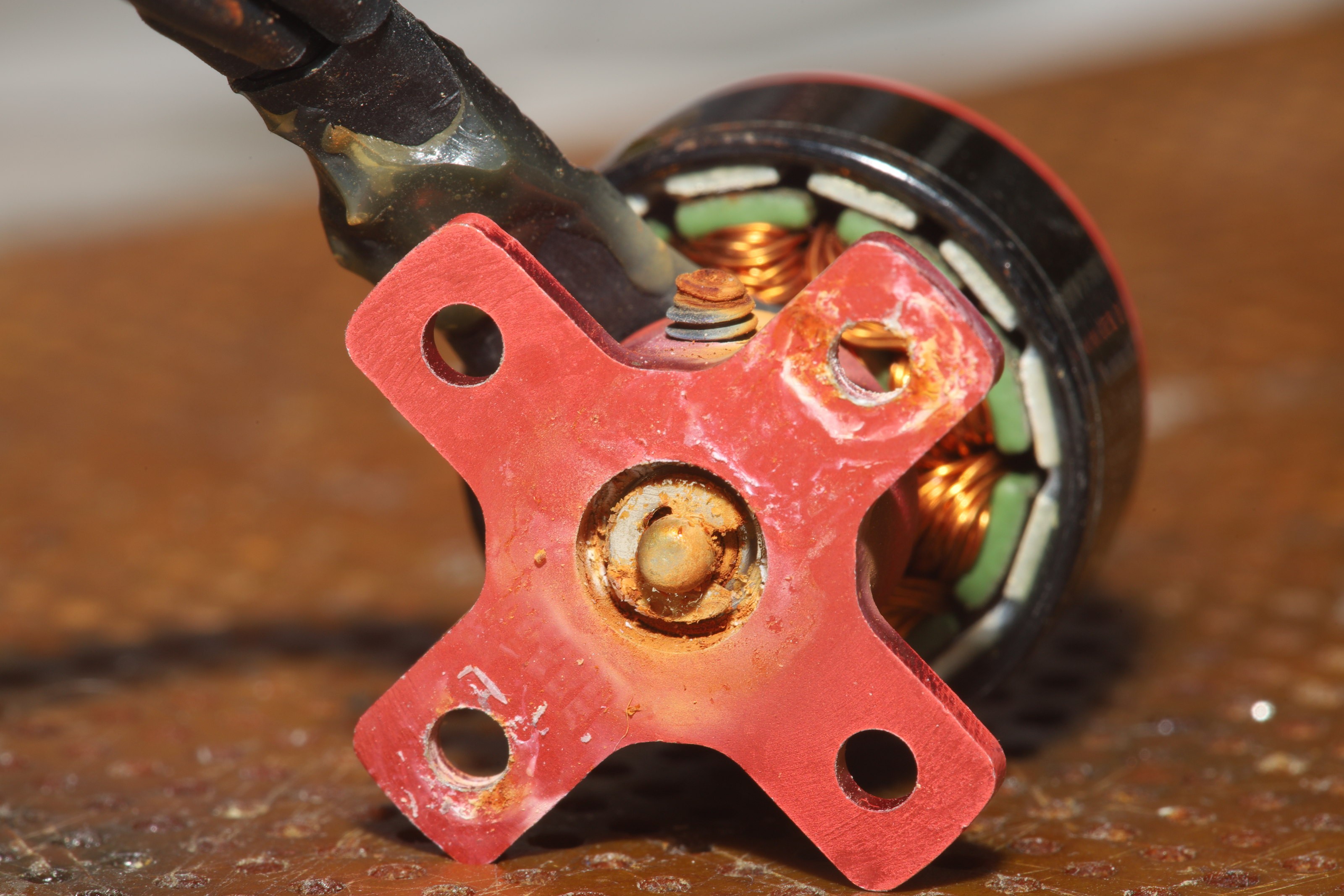

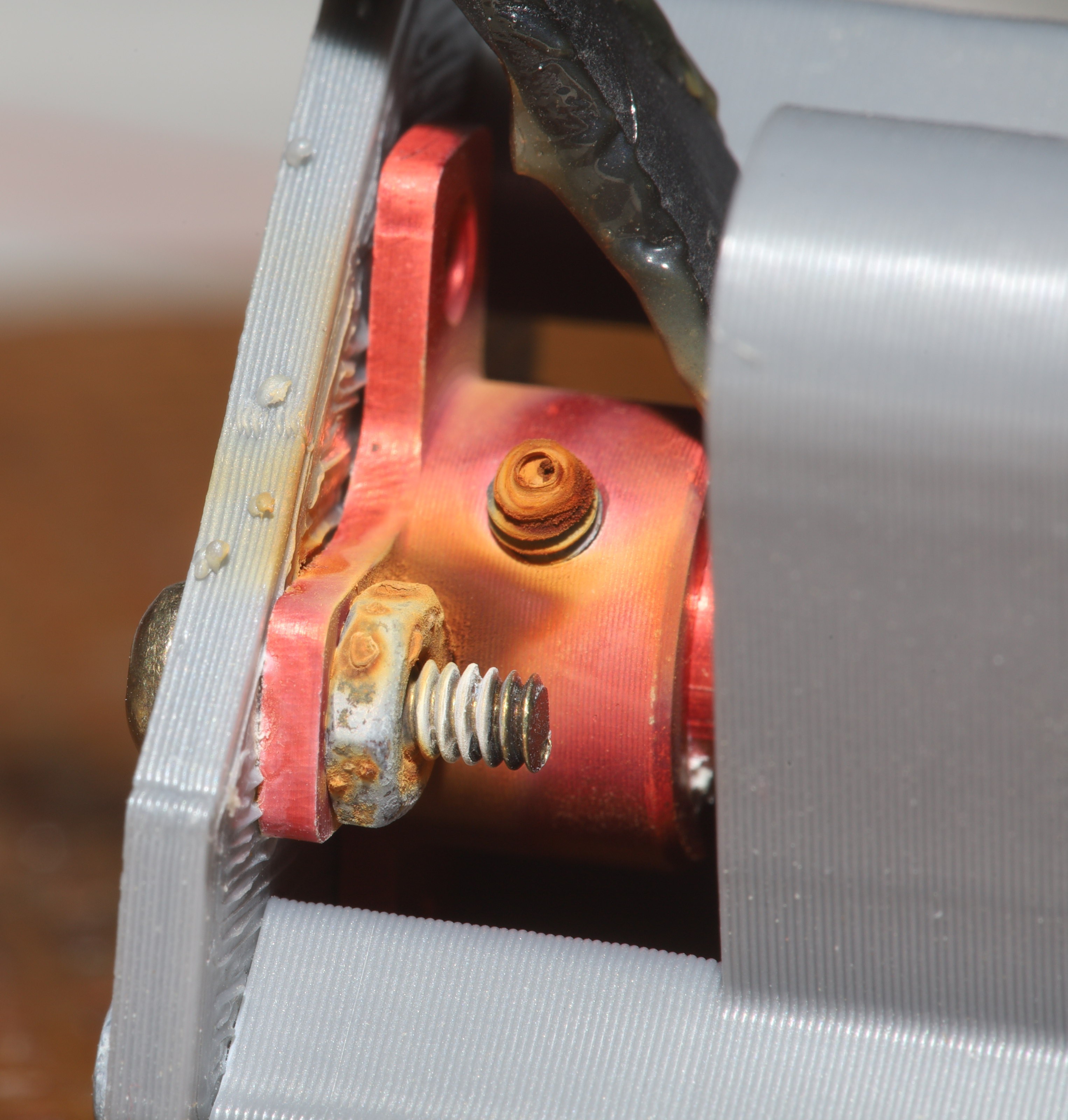

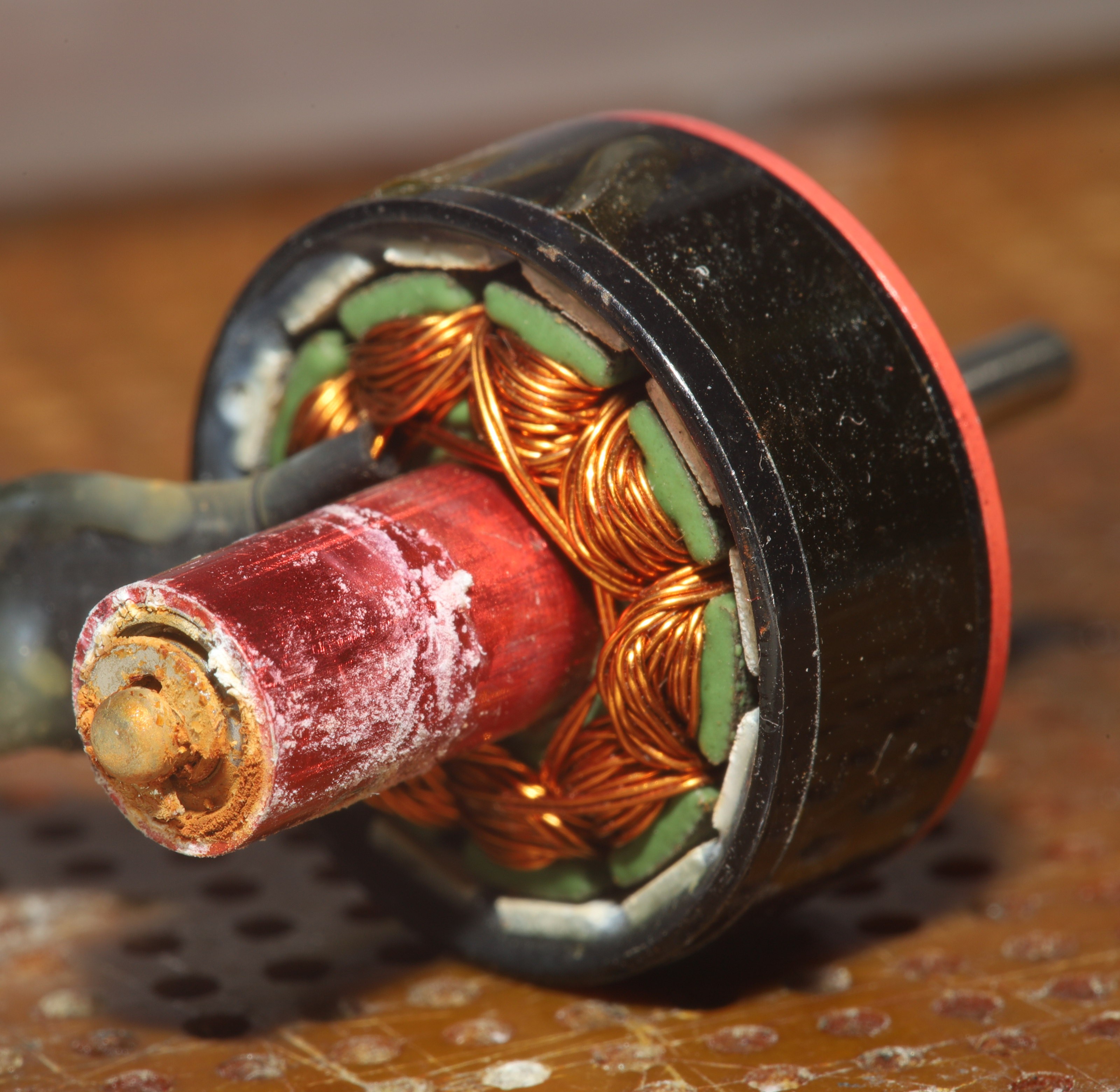

The gatorade bottle & level sensor worked well, after the initial problems with corrosion & siphoning. Sadly, 1 month submerged turned the motor into a rusted mess. The motor bearings & set screws rusted. All the steel farsteners rusted.

It was exactly as feared. There was a momentary push for another novel pump design. Anything spinning would require expensive stainless steel bearings. Reciprocating pumps were already tried.

The dream of a 3D printed pump was busted, but only at a certain price. If the steel motor parts were all replaced with stainless steel & the electromagnets had 3D printed cores, it might work. The lion kingdom would need machine tools to fabricate a custom motor. It would cost more than a commercial pump & be less efficient.

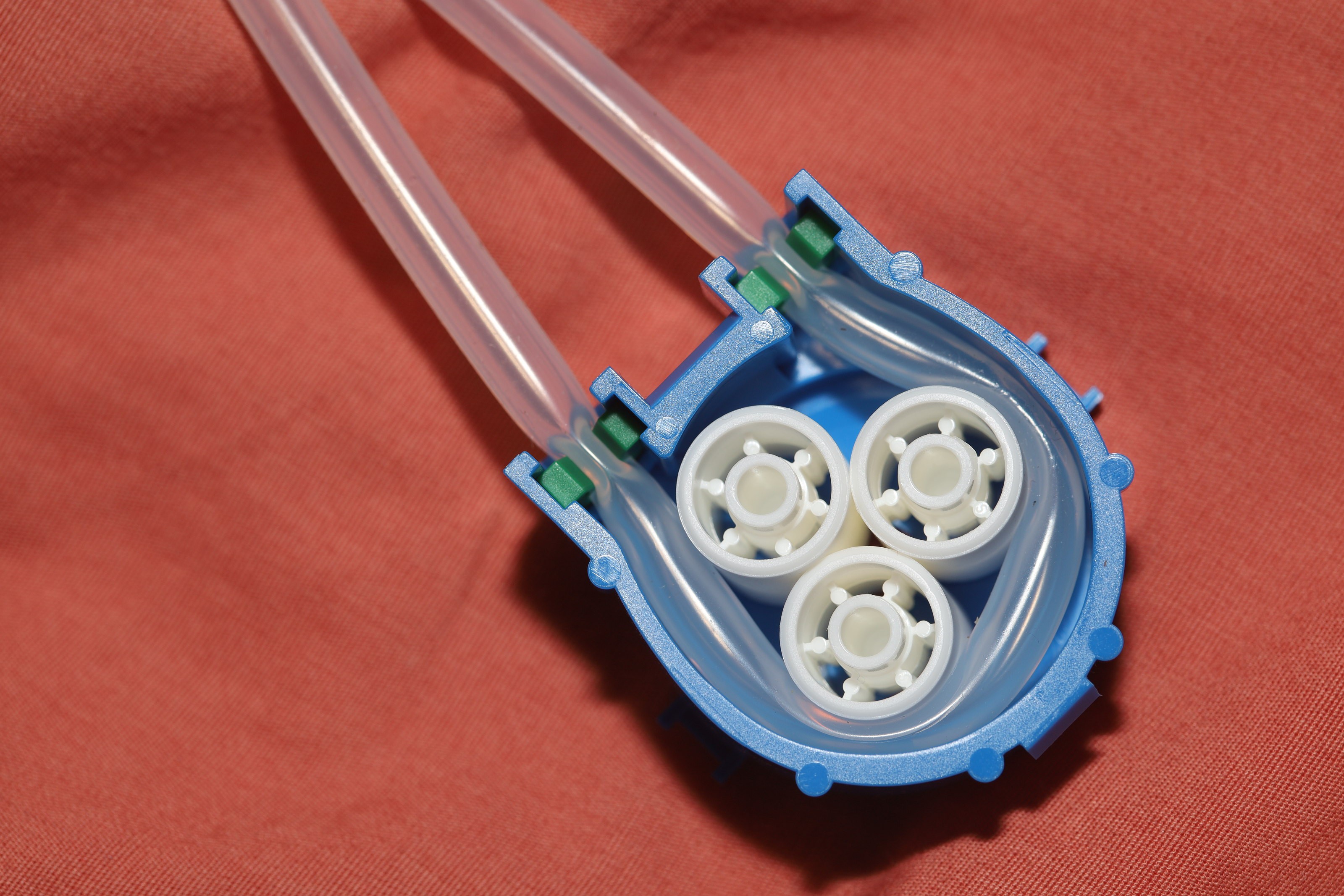

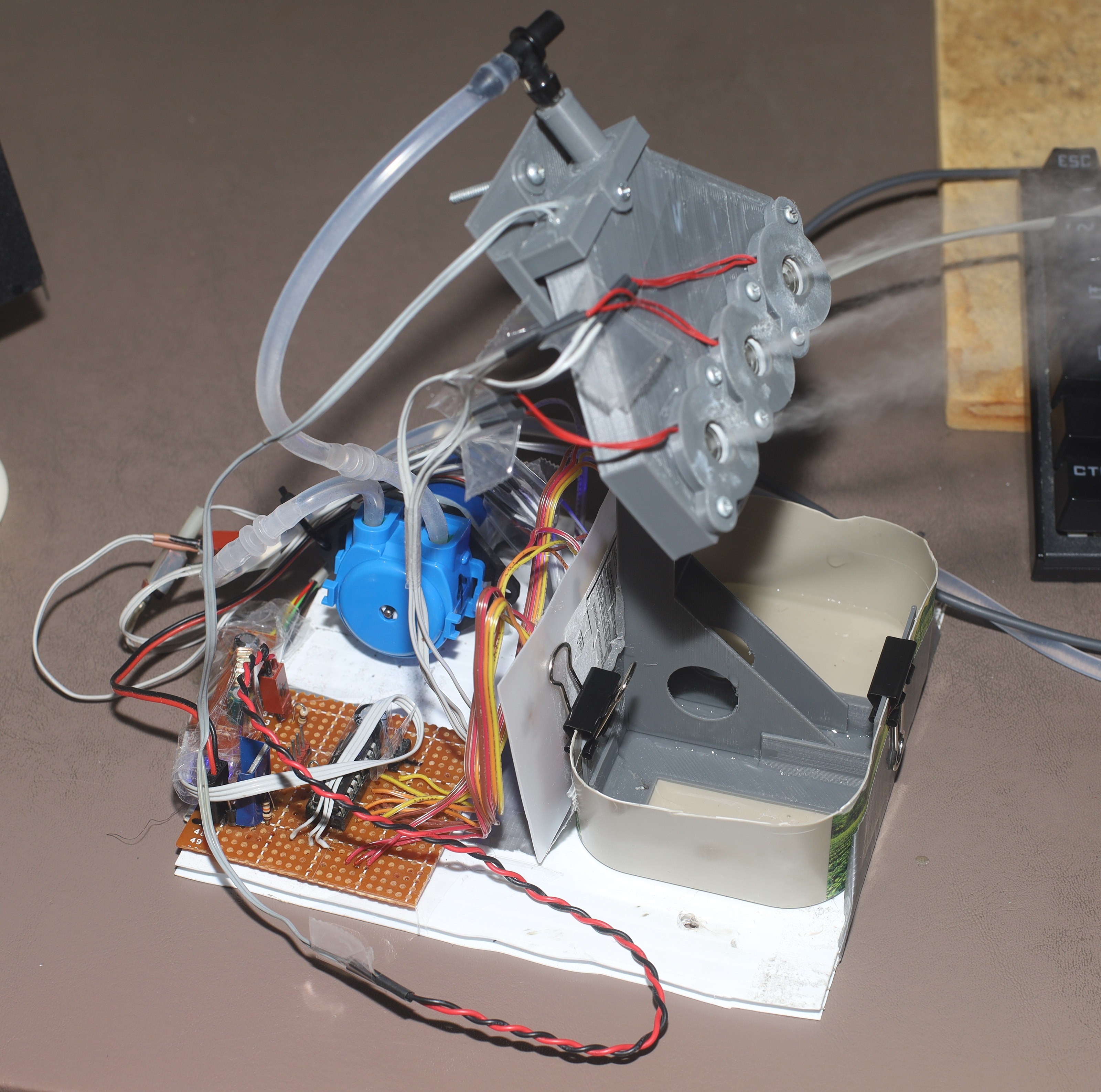

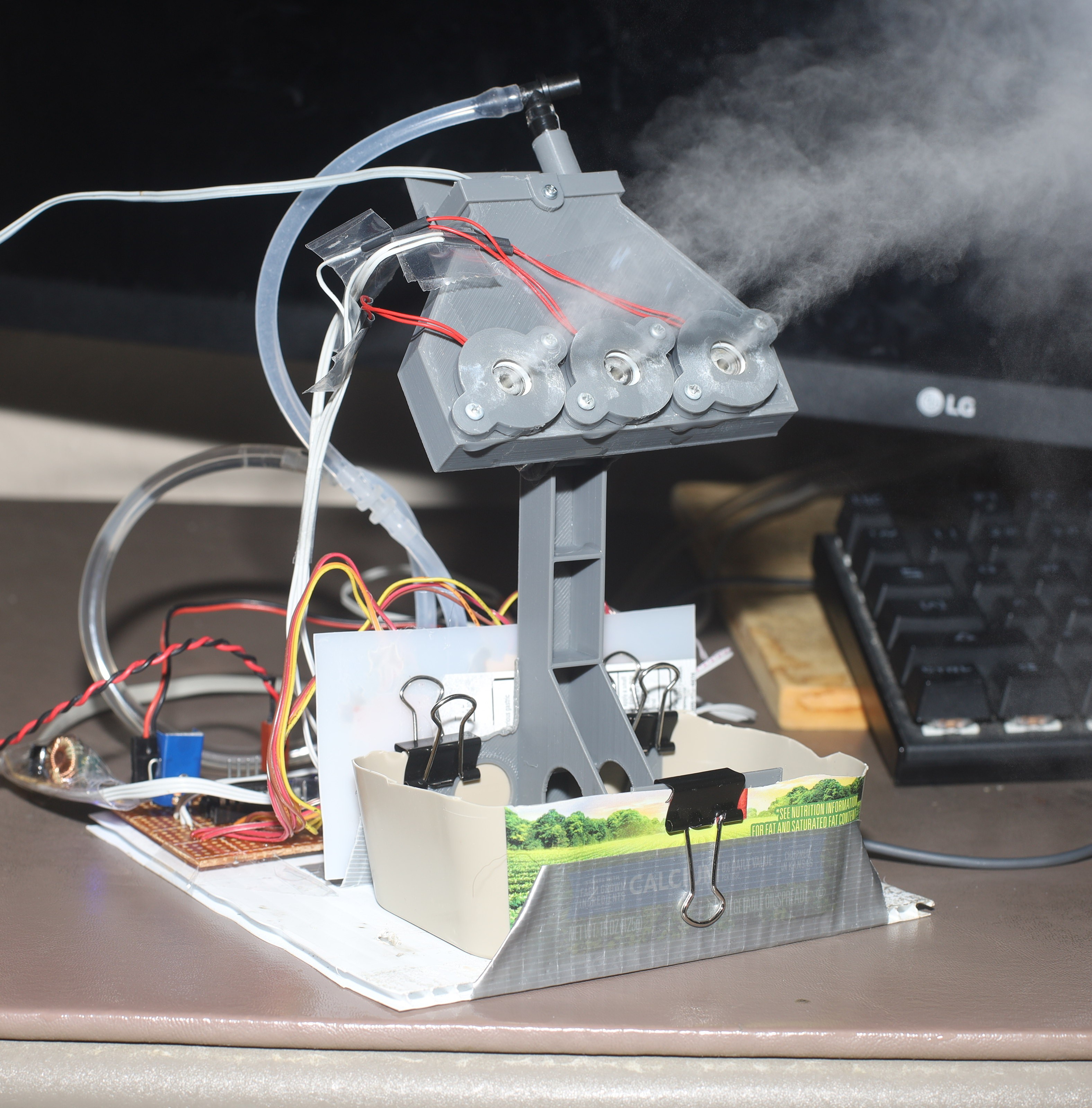

The lion kingdom was out of time, so just ordered a peristaltic pump. It would be self priming, immune to siphoning, & dry. It could be in the same enclosure as the electronicals. The water bottle could be any height. Eventually, the silicone tube would wear out & empty the entire bottle on the desk, but it was good enough for at least a summer.

https://www.amazon.com/dp/B07GWJ78FN

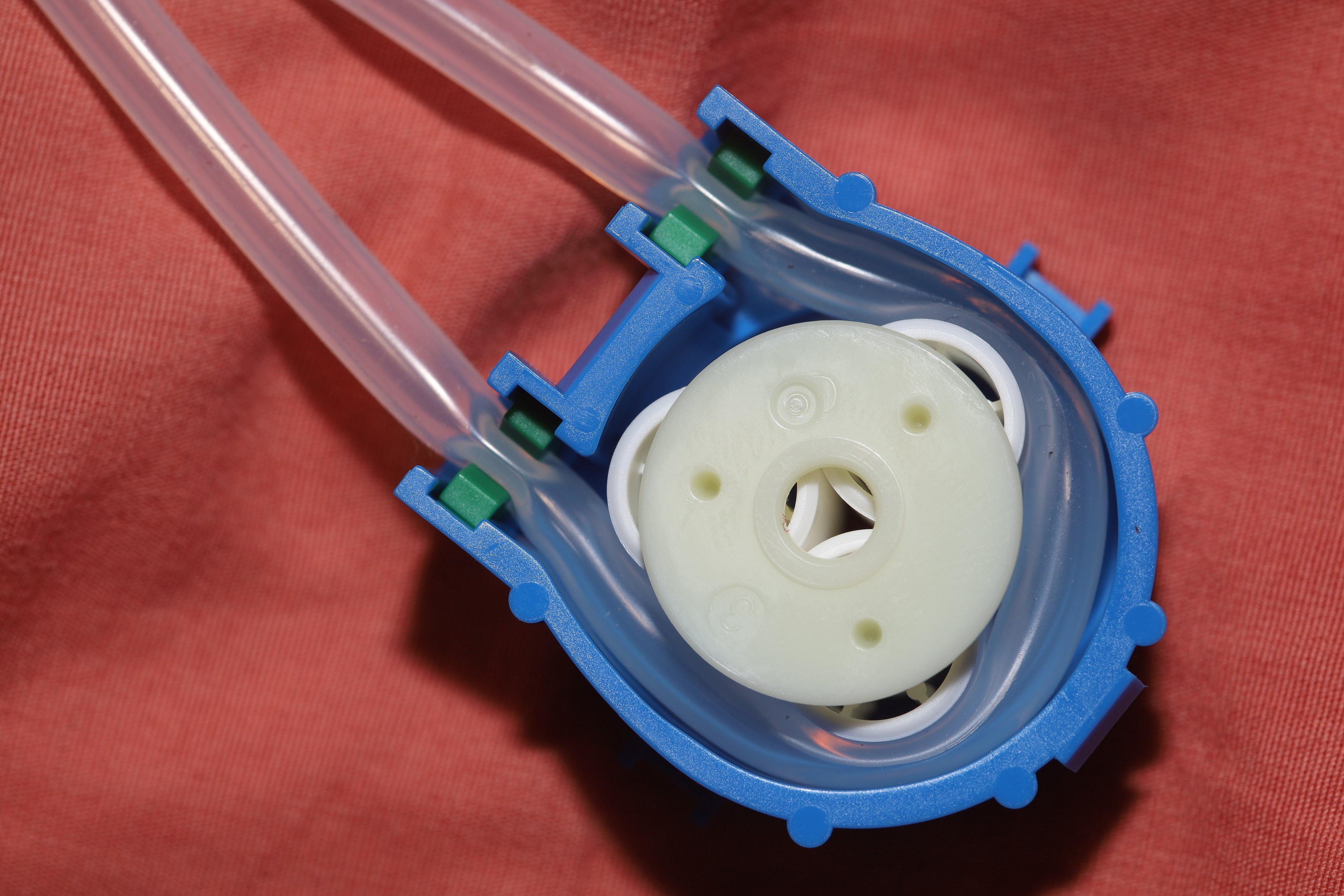

The heart of the peristaltic pump is a planetary gear where the sun gear is the motor shaft, the planet gears are rollers, & the ring gear is the tube. There is a high gear reduction between the motor shaft & tube.

The rollers are precisely sized to press the tube closed & press the motor shaft.

The rollers are precisely sized to press the tube closed & press the motor shaft.

There is a retaining ring to keep the rollers pressed on the motor shaft in the 1 part where there is no tube. Some more clamps keep the tube from getting pushed out.

Water drips out at the full 12V, 200mA. It's nowhere close to a much smaller 3D printed impeller pump.

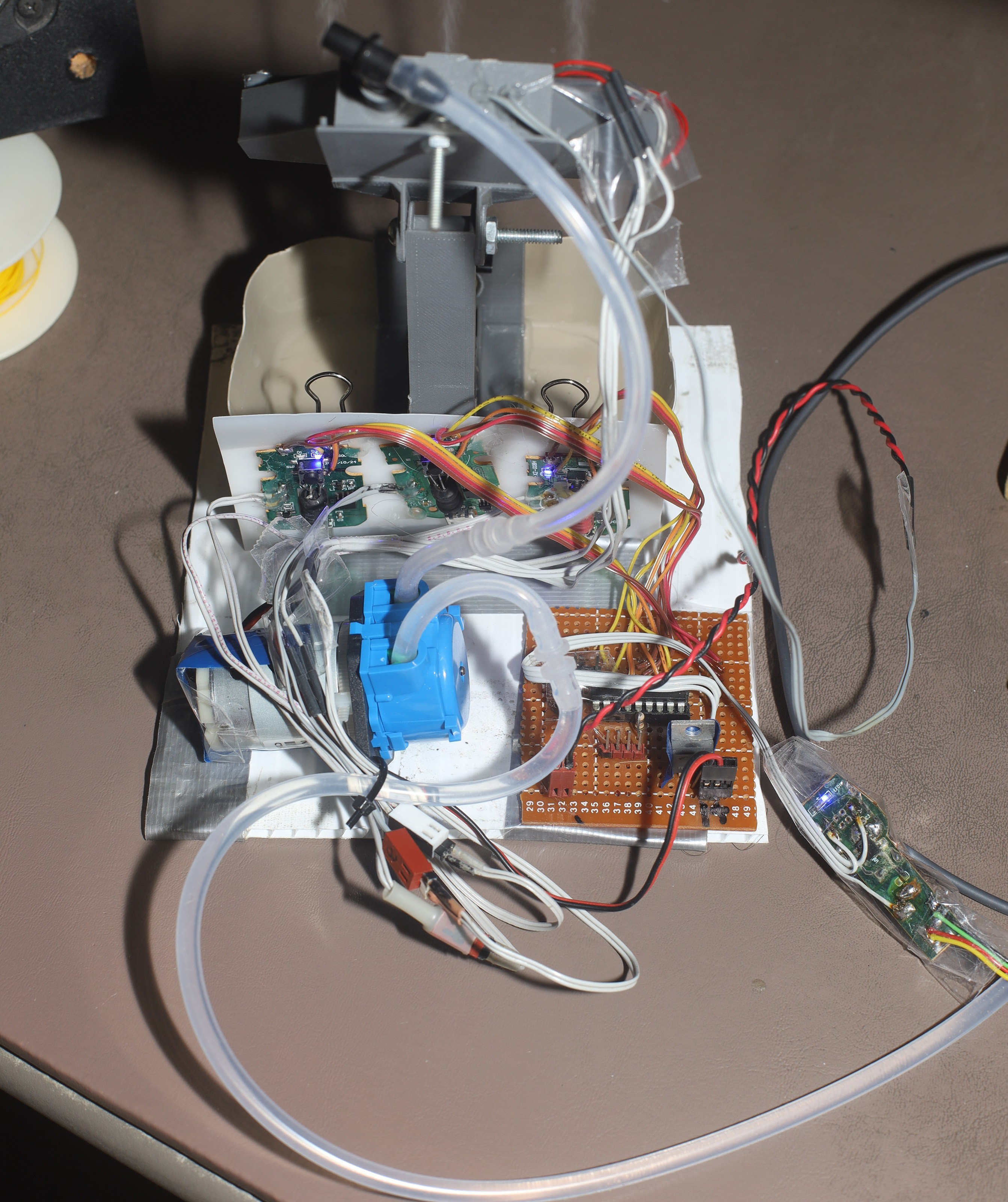

The air conditioner finally got its final board, made of a PIC18F1320. It had to use the ADC to read the LED voltages since they don't go to 0. The peristaltic pump uses a MOSFET instead of a 3 phase motor driver. The 5V regulator got replaced by a much more efficient buck converter.

The water level sensor didn't work anymore from deposits & had to be cleaned. 1 transducer board burned out because the transducer wasn't connected. They can't be turned on without the transducers.

The 5mm hose for the pump is incompatible with the locally sourced 1/4" fittings for drip irrigation hose. The AC needs a new elbow fitting & inlet for 5mm hose.

The transducer tank is really loose on the stand. It should be glued to its drainage plate instead of bolted as it currently is. The original idea was to make it slide up & down the drainage plate, but it proved easier to print a new stand to adjust height.

It burns .5A when pumping & .3A when just spraying.

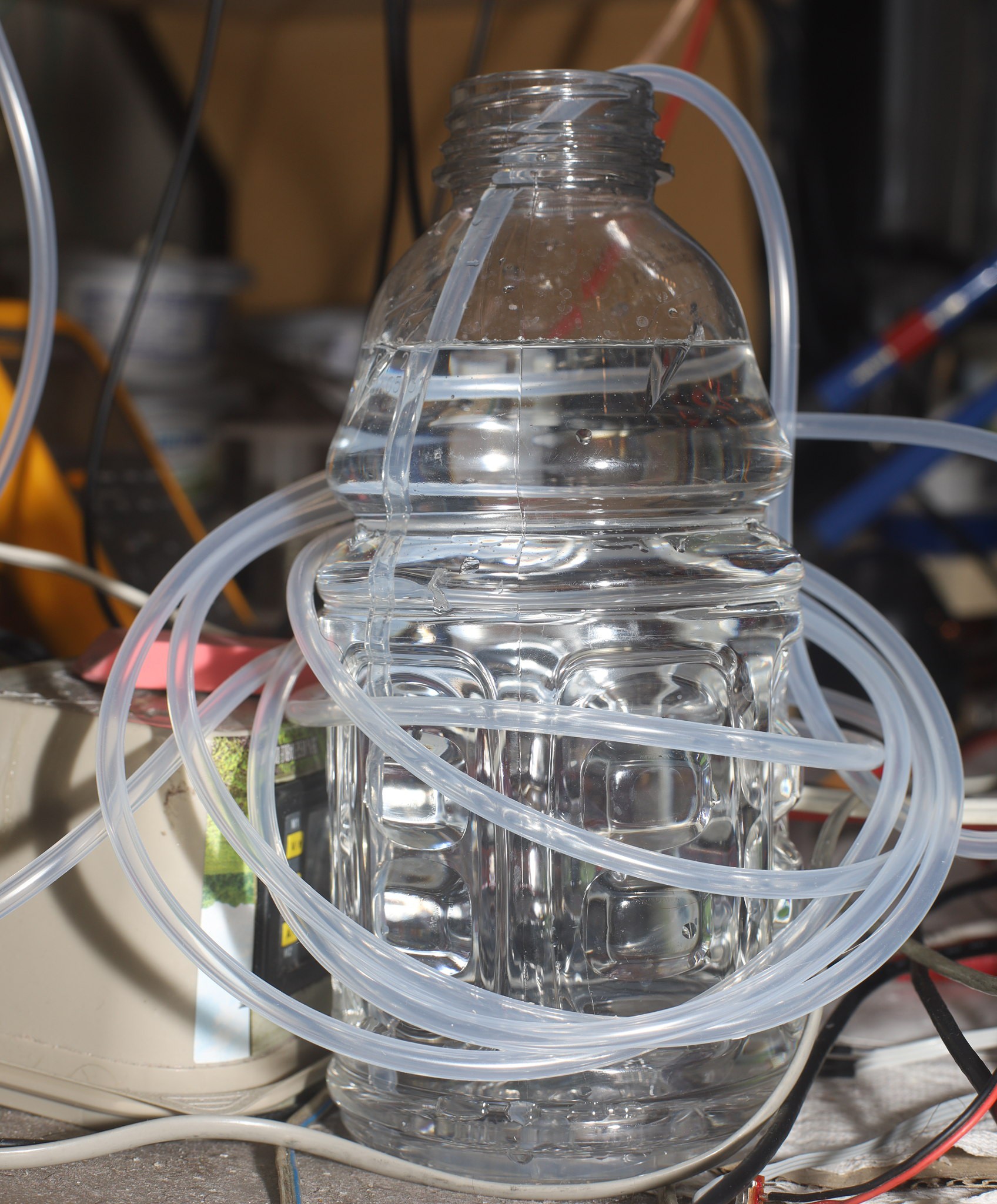

The gatorade bottle now just has a hose.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.