With this new size and enclosure, this laser has really a lot of potential. Here's a few things I made:

Two wall lights for the kids. I don't have a picture of the raw cuts but this is 4mm plywood poplar glued together. The back has some spacers to install a LED strip. I cut the plywood in two passes at 270mm/min@100 %

The dimensions of both lights are 400mmx400mm so I had to slice the base in two pieces so that it looks like one piece in the finish product.

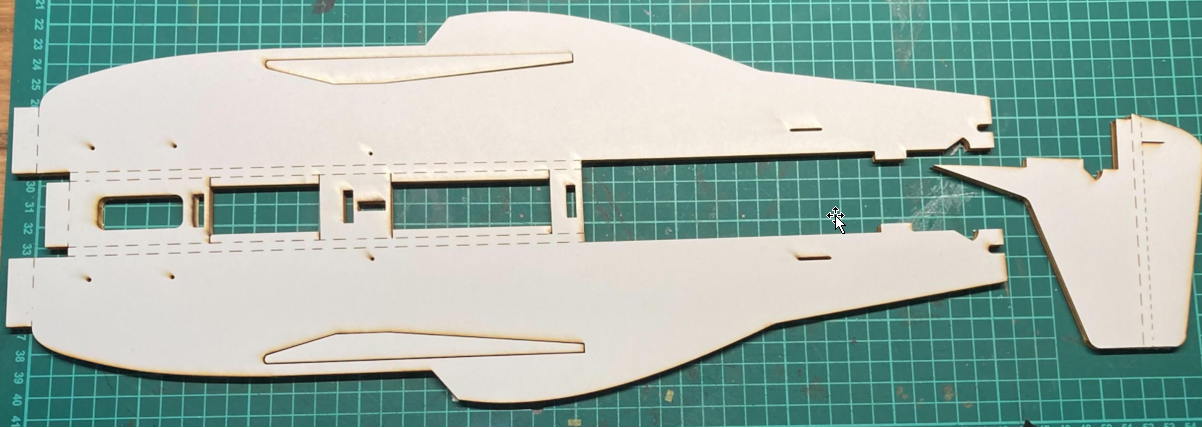

And here's another project in progress: a RC mustang P51 made of 5mm foamboard from Flitetest

The cuts are made at 350mm/min@70% in two passes and the score at 500mm/min@50% in one pass. The foamboard is a bit more sensitive to heat and therefore the power has to be decreased. I tried at lower speed at 100% and the top looked good but the bottom was charred in some spot.

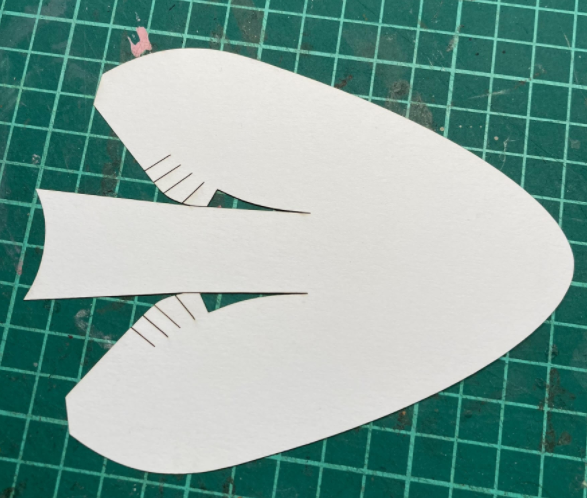

Here's the cockpit, cut in thick white paper (0.4mm) at 400mm/min@45% one pass. No burn mark and very precise cut.

I also made other tests with other types of plywood and the thicker I could process was beech plywood with poplar core at 8mm. I tried 10mm birch plywood but I couldn't go through it after 16 passes so I'm not going to insist.

vincentmakes

vincentmakes

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.