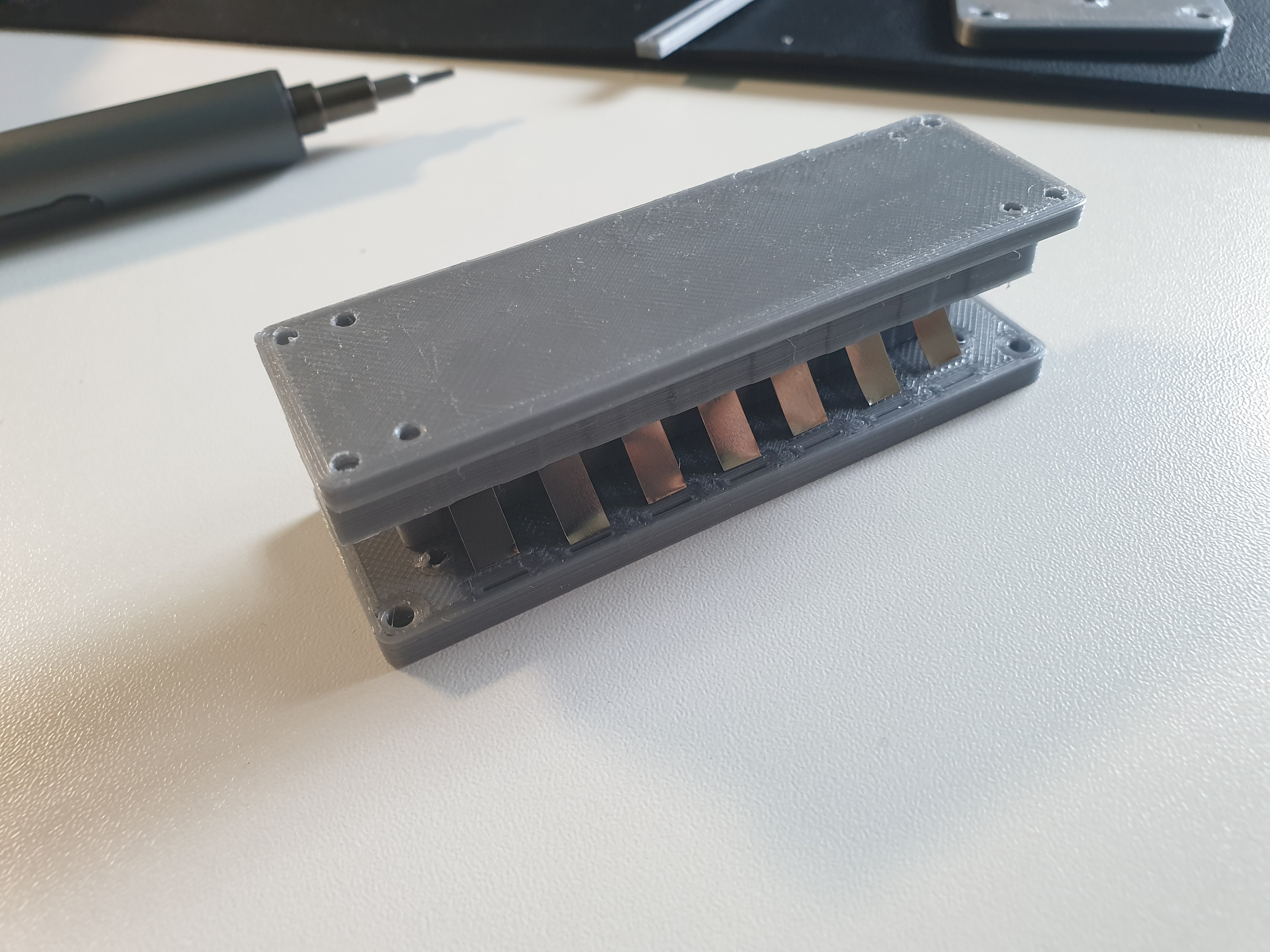

As I explained in the last log, when assembling the bottom stack I realized the cable management was poor between the top and bottom panels. The serviceability and ability to make changes would be limited by such design. At first, I started looking throughout my stuff for any modular connector that could be incorporated to the panels. The main signals to go through these would be the sensor inputs to the Arduino. After going through many ideas, I settled on making my own connectors. Why not some experimentation too? That's part of what this is about!

Maybe this log deserves to be a whole separate project, but the motivation for making these connectors was the RGCS.

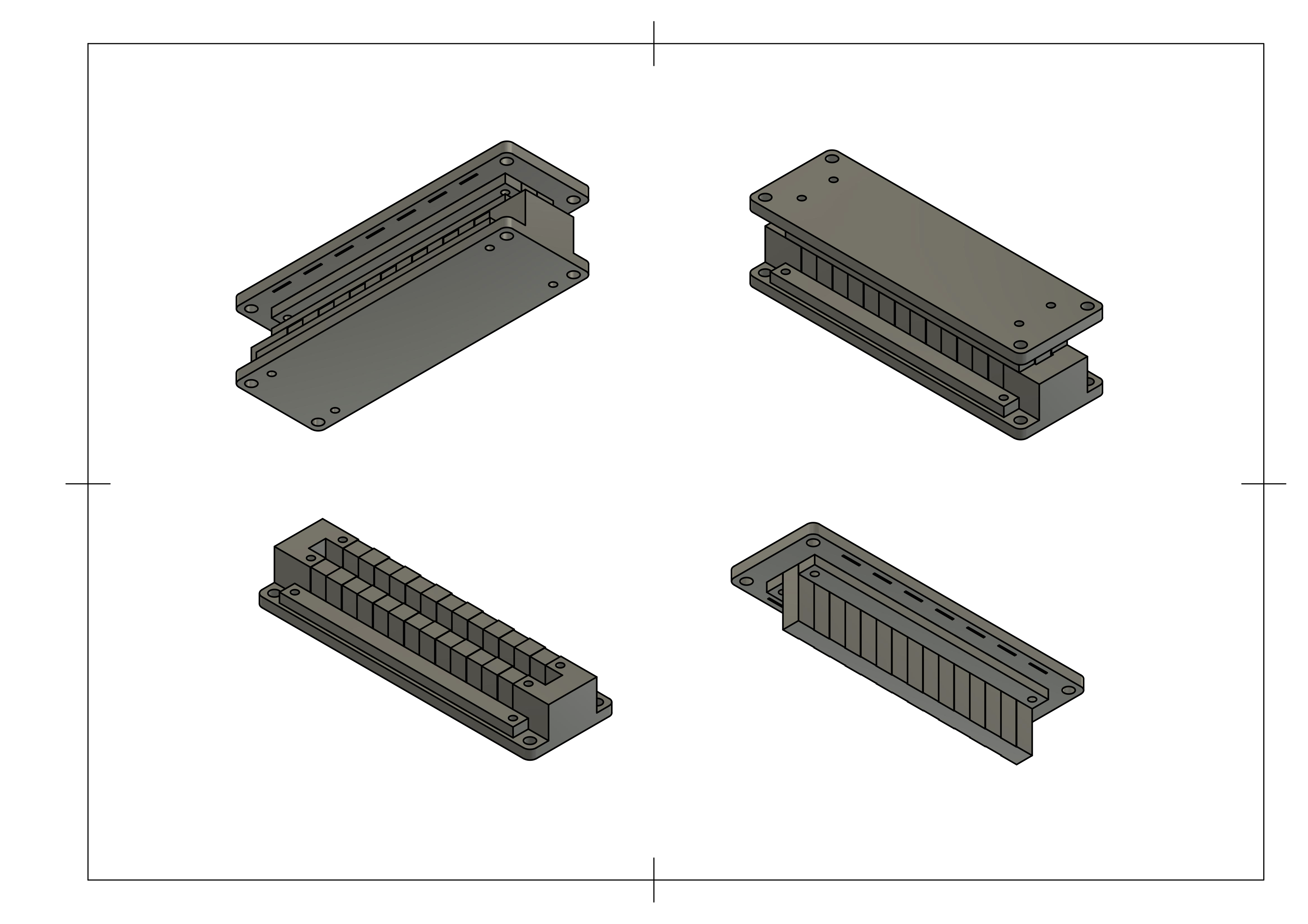

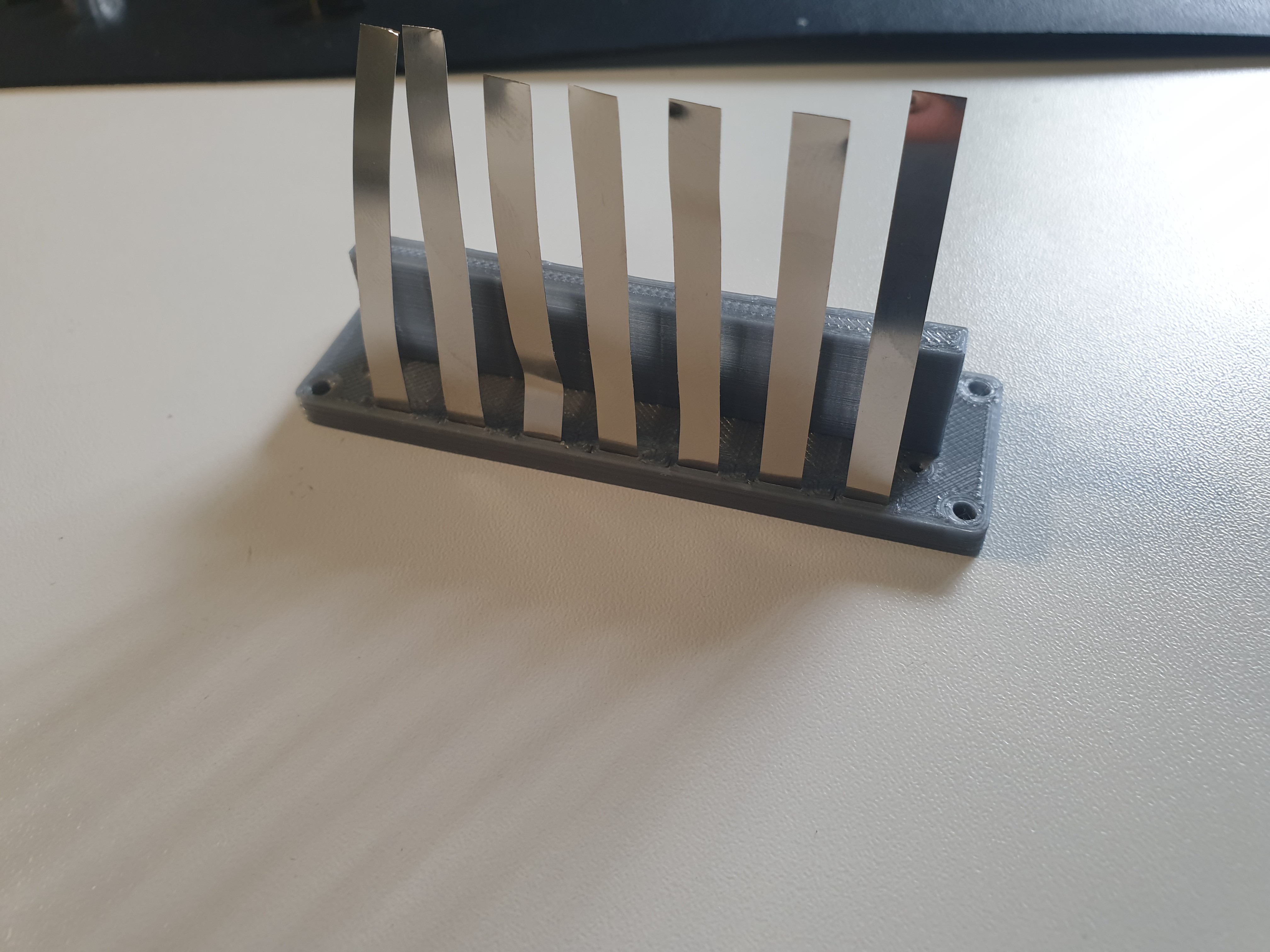

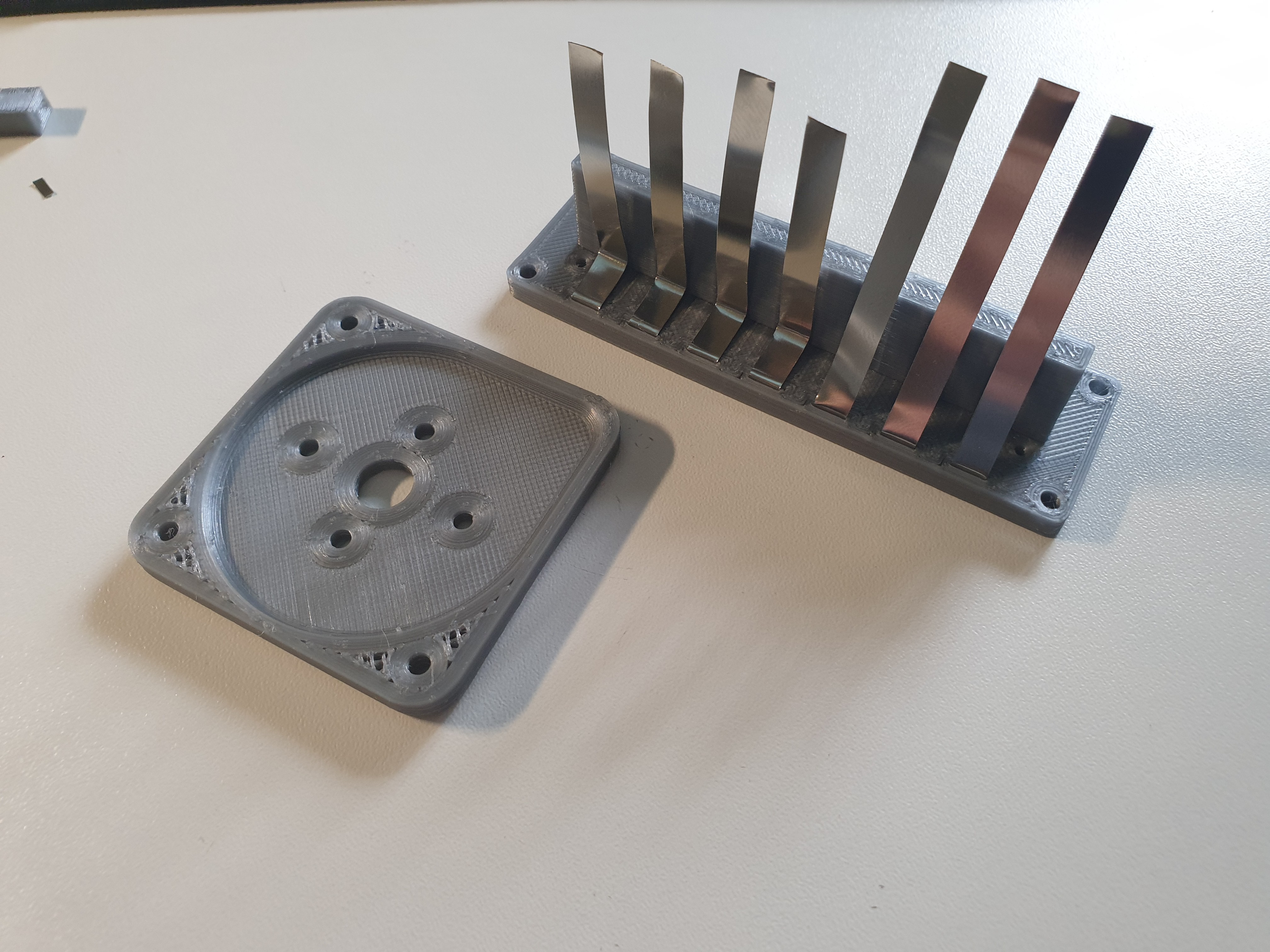

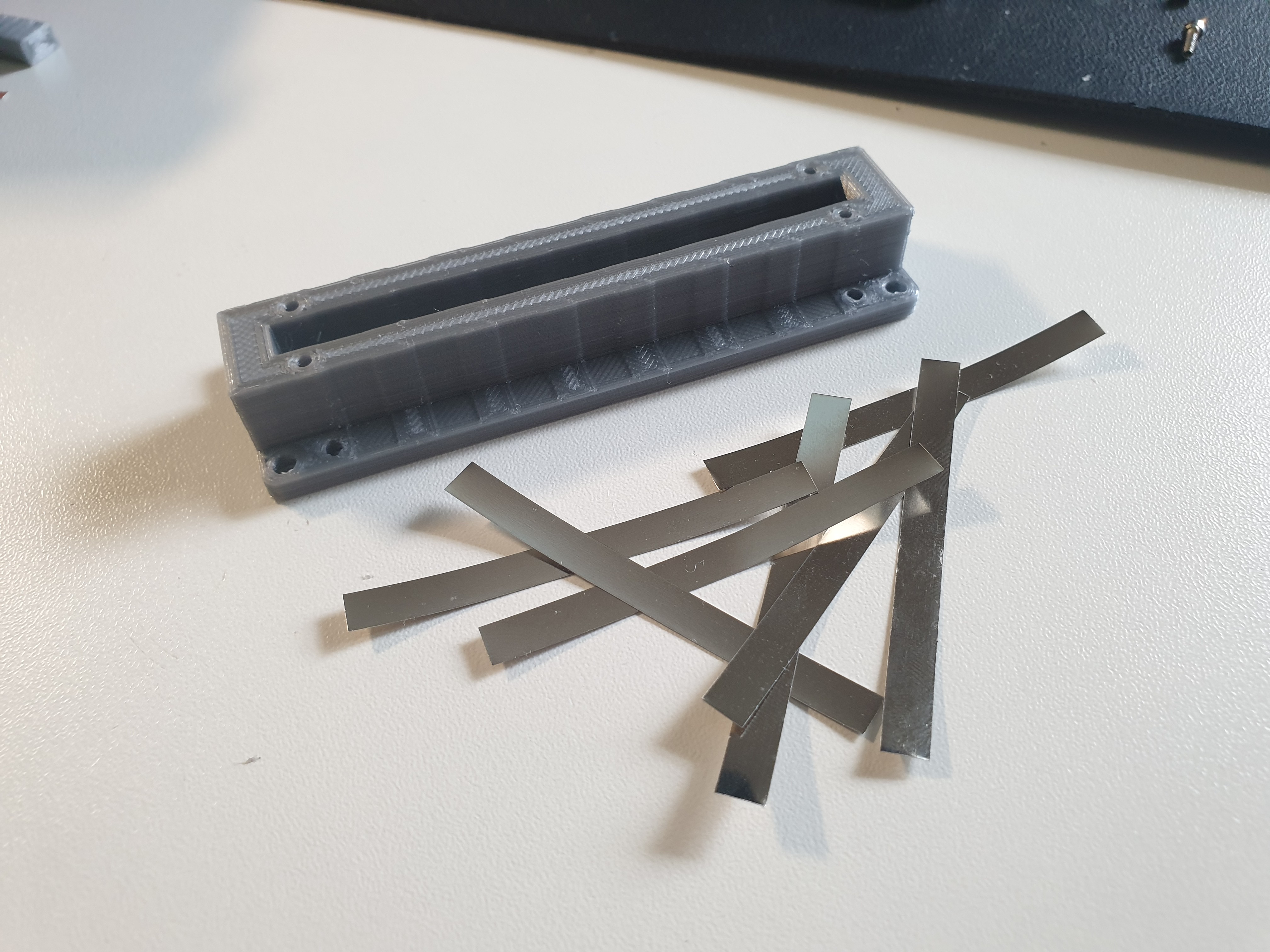

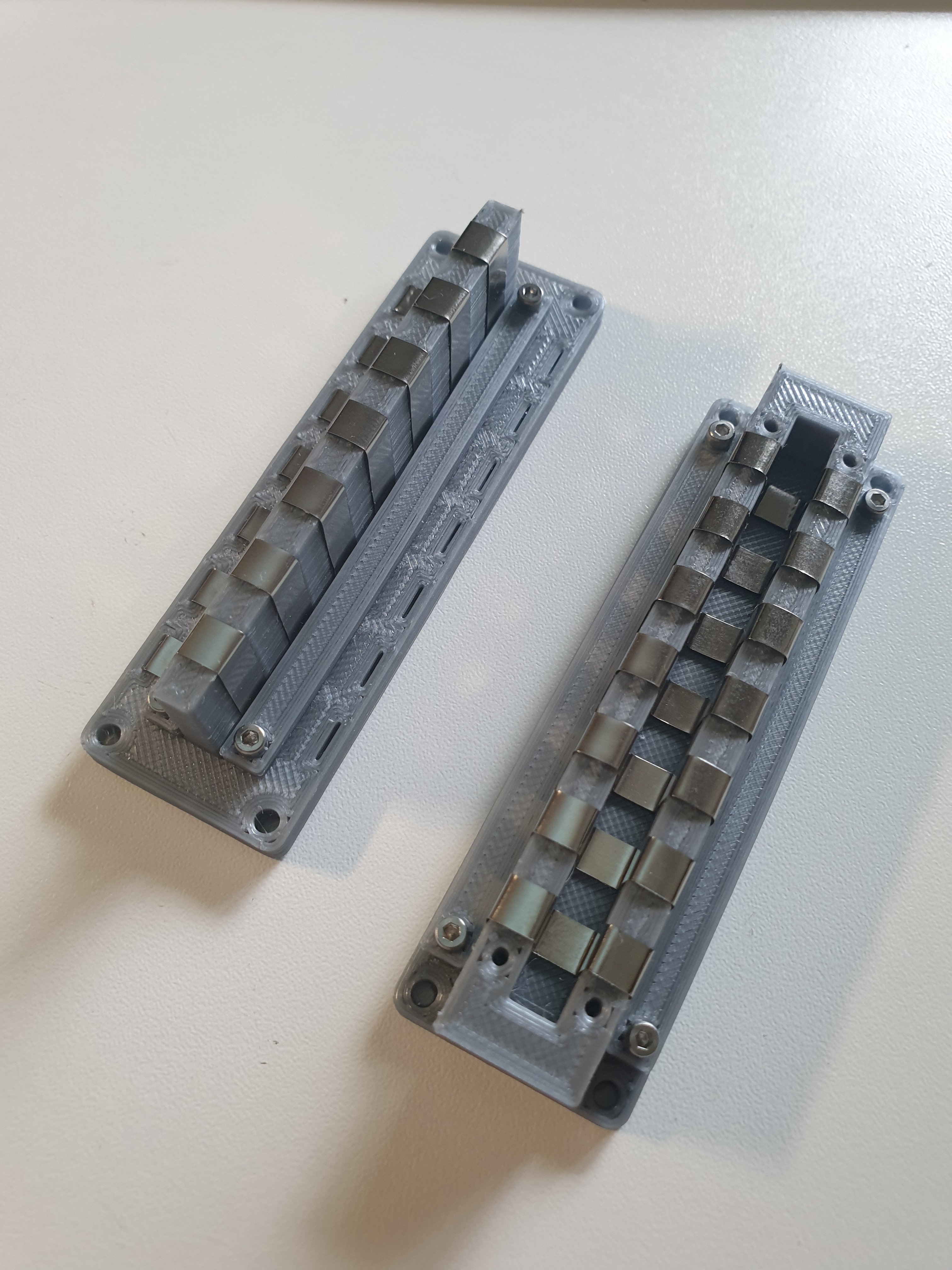

I had some 0.2 mm nickel strip for building lithium ion packs, that seemed to make a good contact surface. The tricky part was how would I get to hold the strips in place. So I made a quick design and printed a test.

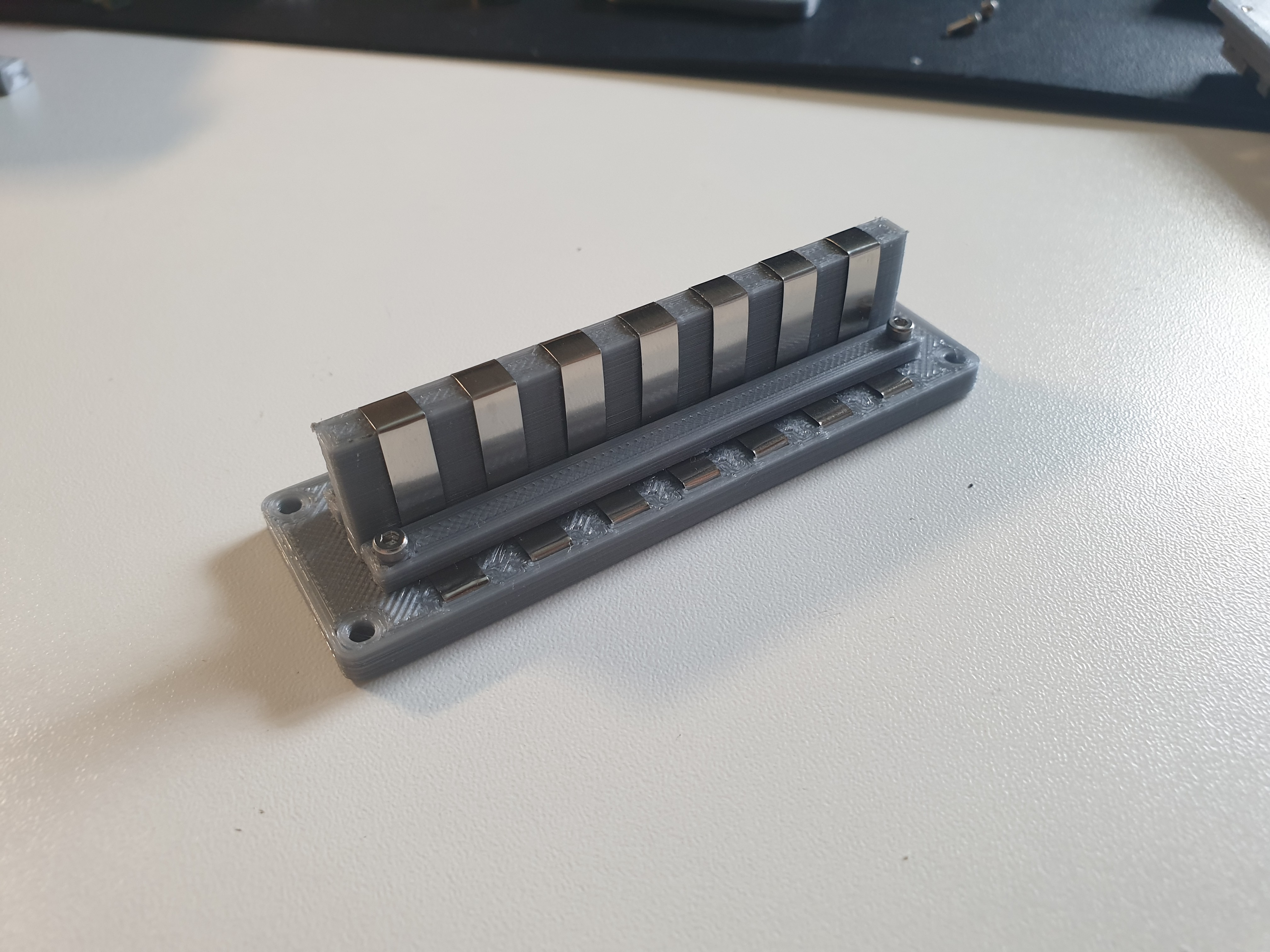

This looked promising!

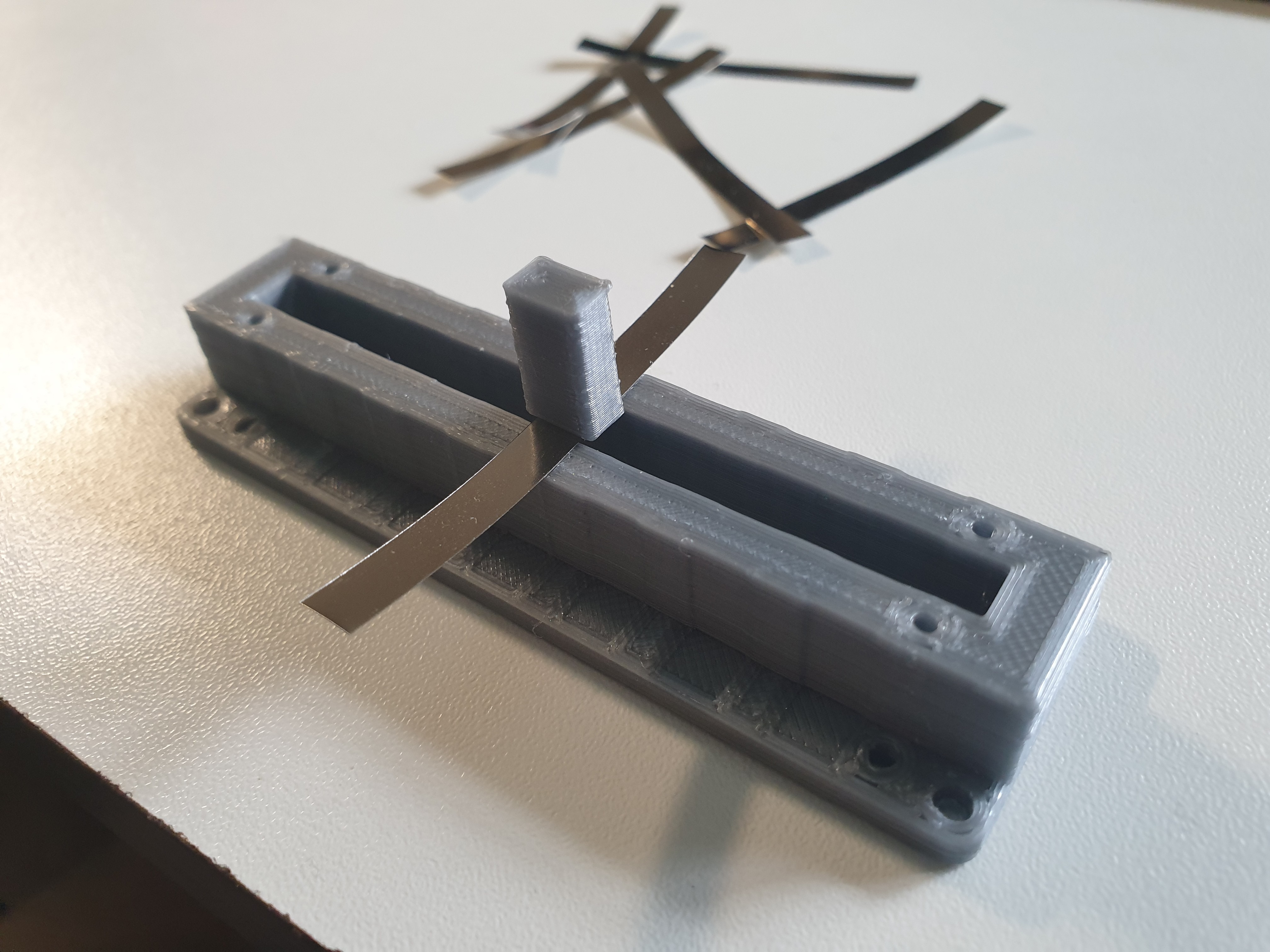

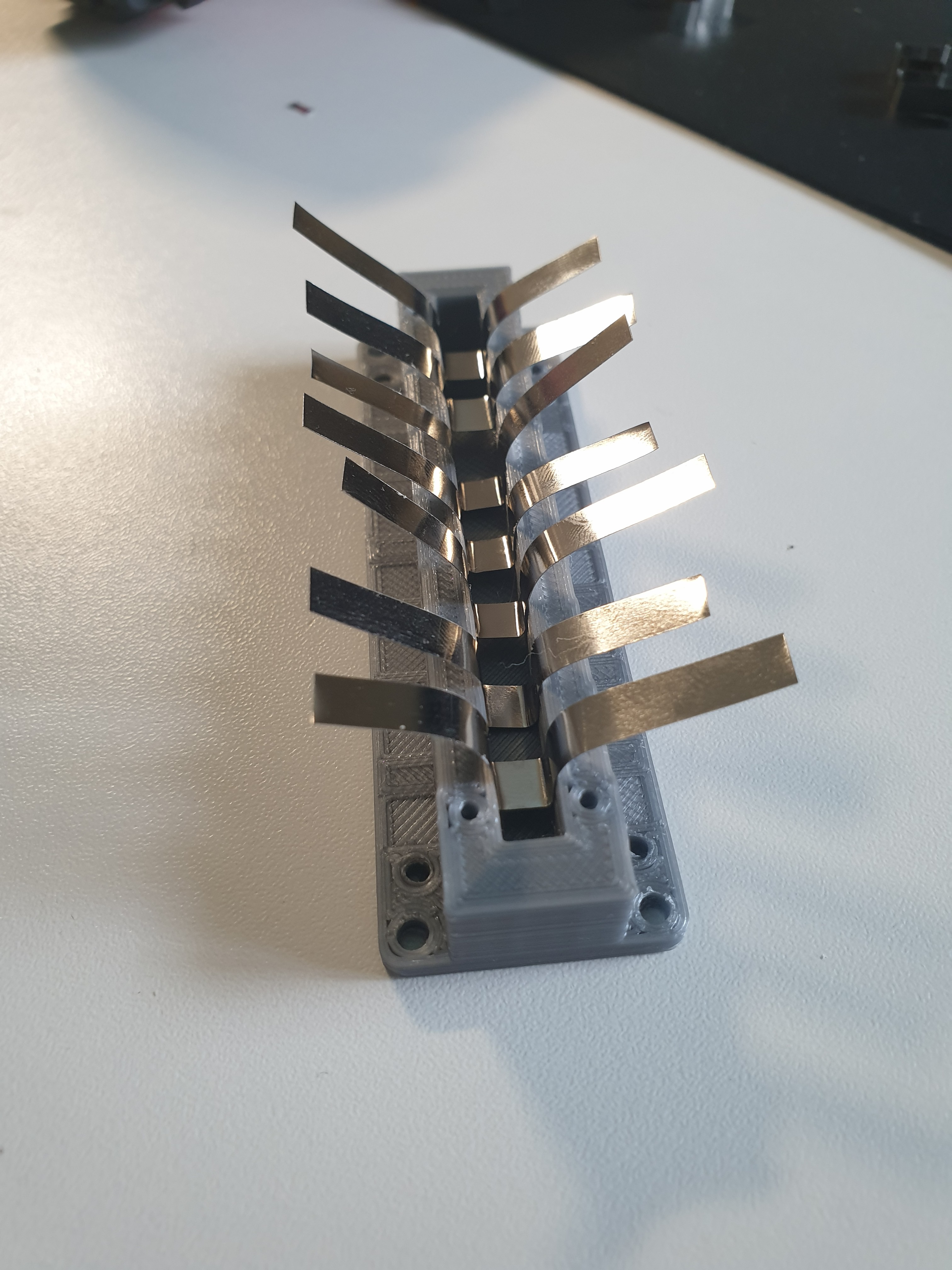

I still had to figure out how the strips would be held in place. Due to the size of the strips (and I didn't want to cut them longitudinally) and the limited ability to hold them down firmly, the connectors had a nice gap in between contacts.

Each connector part (m/f) consists of 3 pieces. A main piece where the contacts are placed, and two plastic strips that are screwed down on top of the nickel to hold it in place. You might get a better idea when seeing assembly pictures.

Maximiliano Palay

Maximiliano Palay

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.