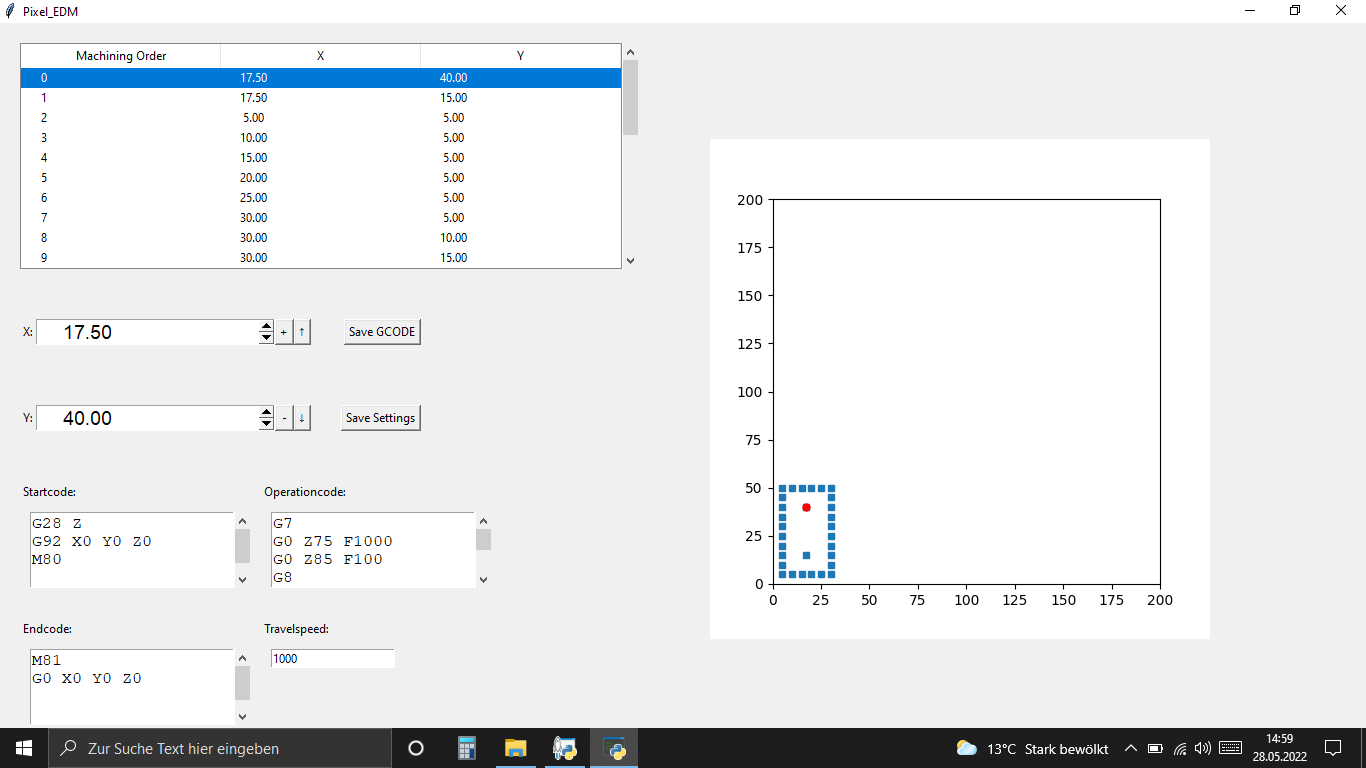

Over the last few days I wrote some code for makeing it easier to place multiple drilling locations next to each other (easier than writing the whole gcode per hand).

And with the GCODE created by the tool I did another test:

This time I cut out a small bracket. The cut took around an hour with no need for observation or intervention while machining. I think workpieces like this can be cut to do actually useful things with the machine. So the good things are that the machine is now working reliable and also quite precise. The problems remaining are that the machining takes quite long and the DI filter and electrode need to be replaced after some time. The machining time can be reduced by using a more powerfull PSU, but the need for replacement of the DI filter + electrode will remain.

So for now I think this is the best result that I can get with my EDM machine.

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.