OK, I have encountered some problems with the mechanics.

The first was the floppy arm lol. One arm was used as a guide when drilling the 8mm holes for the motor shafts so it was a bit of a loose fit.

I kept tightening it but eventually the Stainless Steel M3 screw just snapped so I found some bolts at the hardware store and upgraded them to M5.

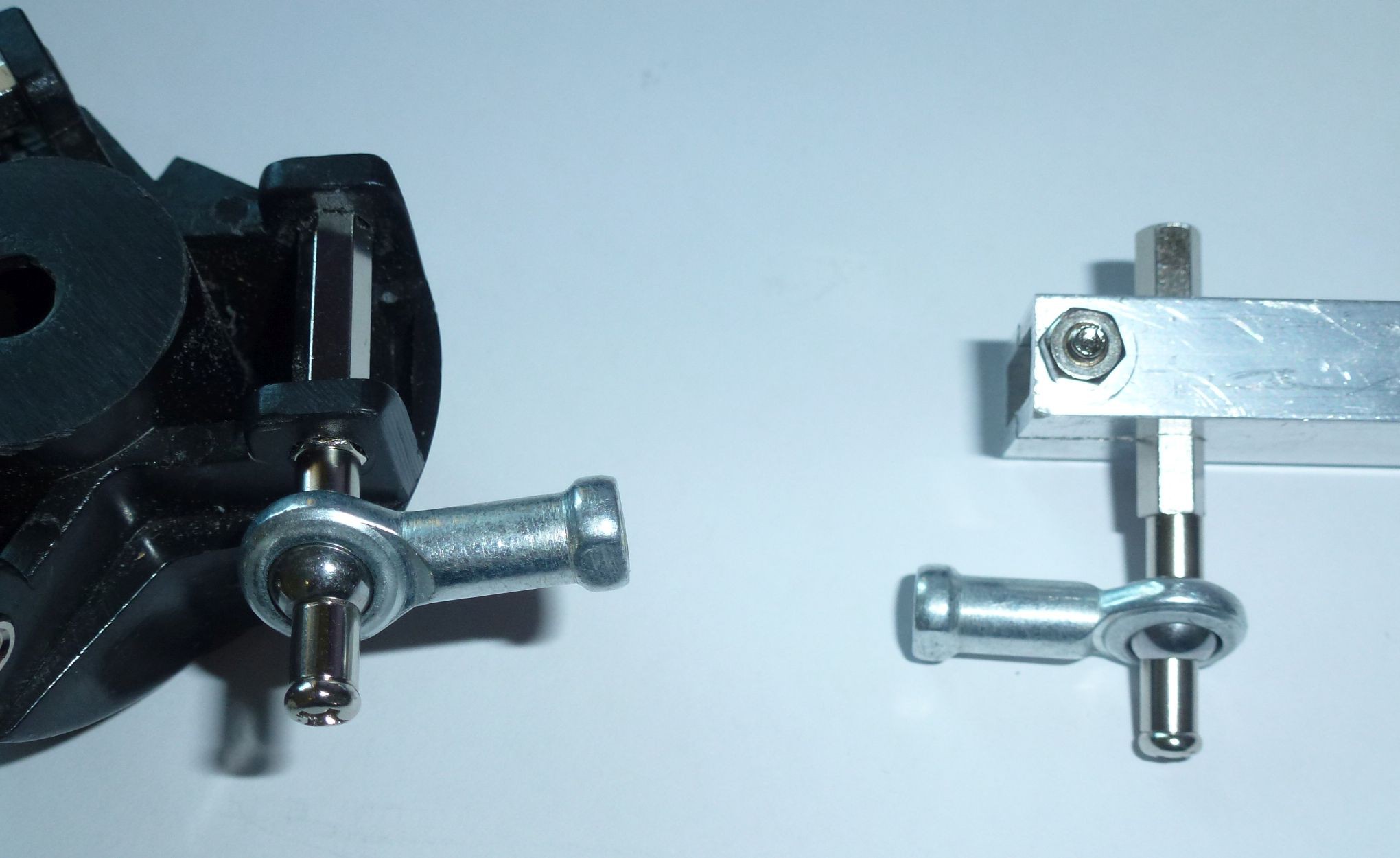

The next problem was binding of the bearings to the hex shaft so I added some spacers. These spacers are still a little to large so I have ordered some thin tube to make spaces with a smaller outer diameter.

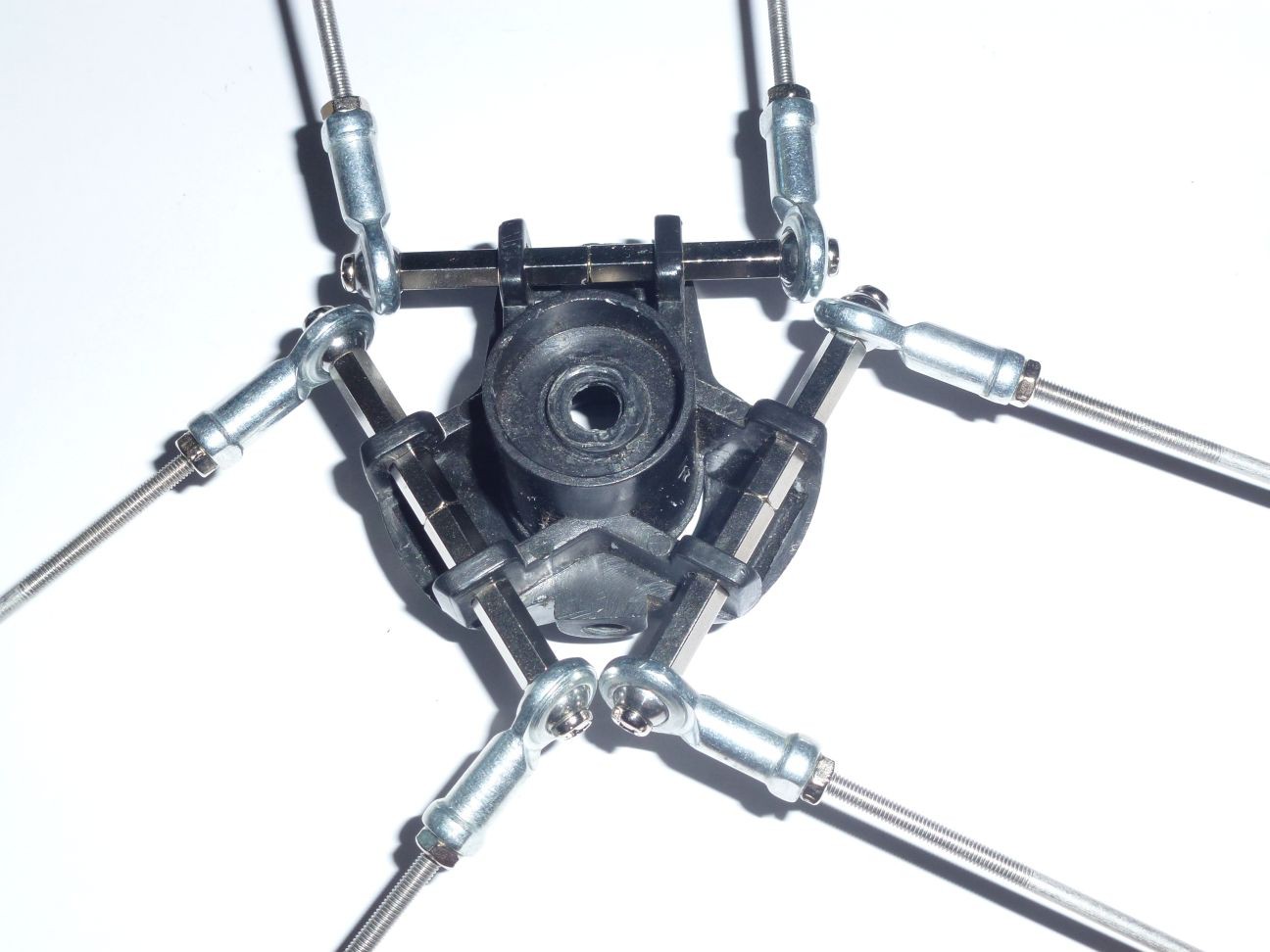

The original setup was line this -

Now I have removed one of the hex shafts to make way for the spacers. I also files the middle section of the hub flat to make it easier to mount a motor.

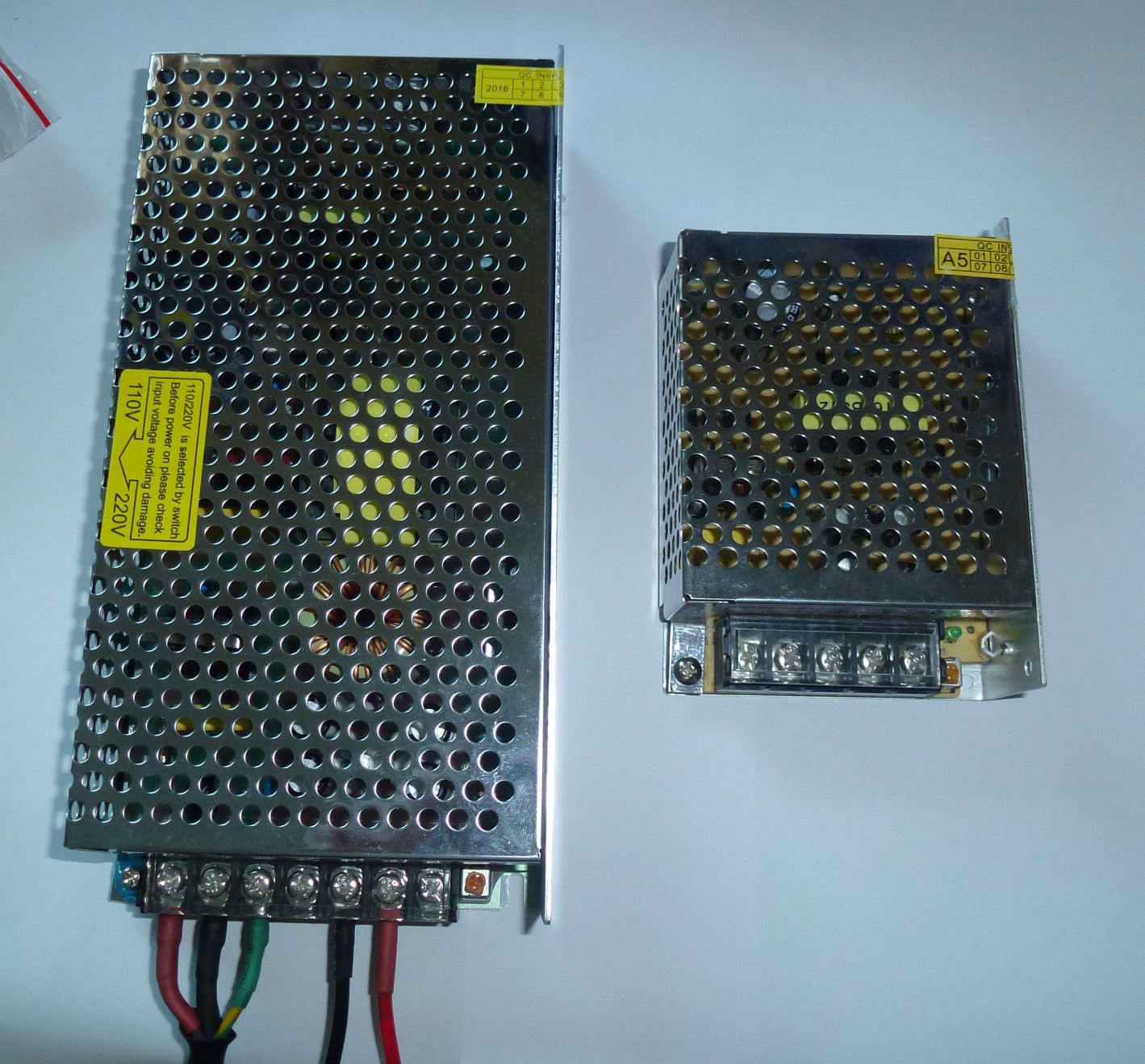

Also the original power supply was intended for the smaller stepper motors that I was first using and it only had the capacity to drive one of the new steppers so it had to be upgraded to -

Hacker404

Hacker404

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.