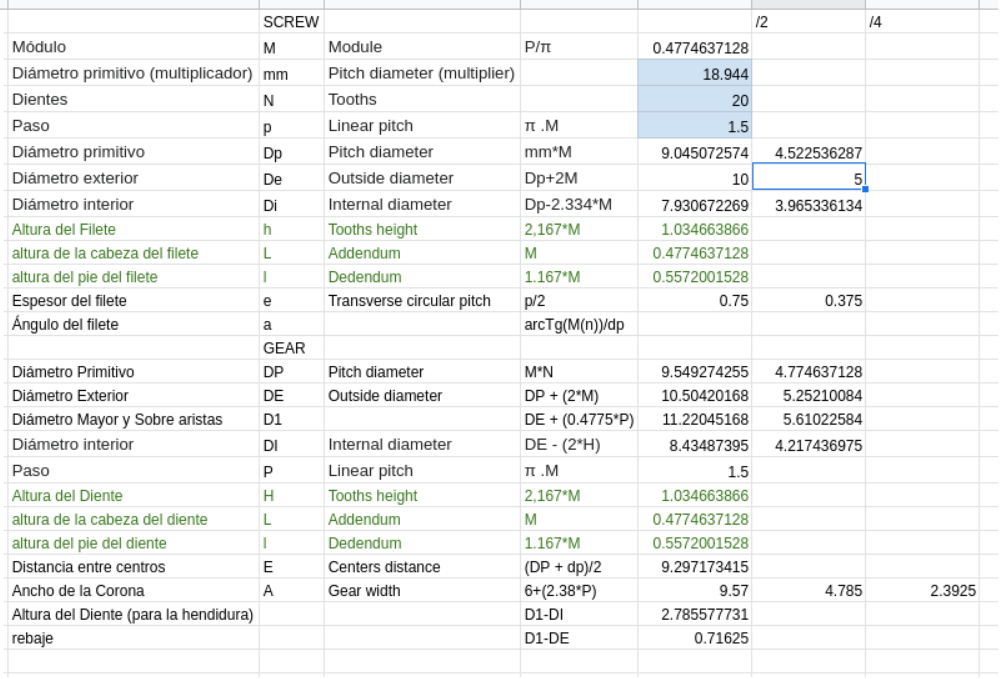

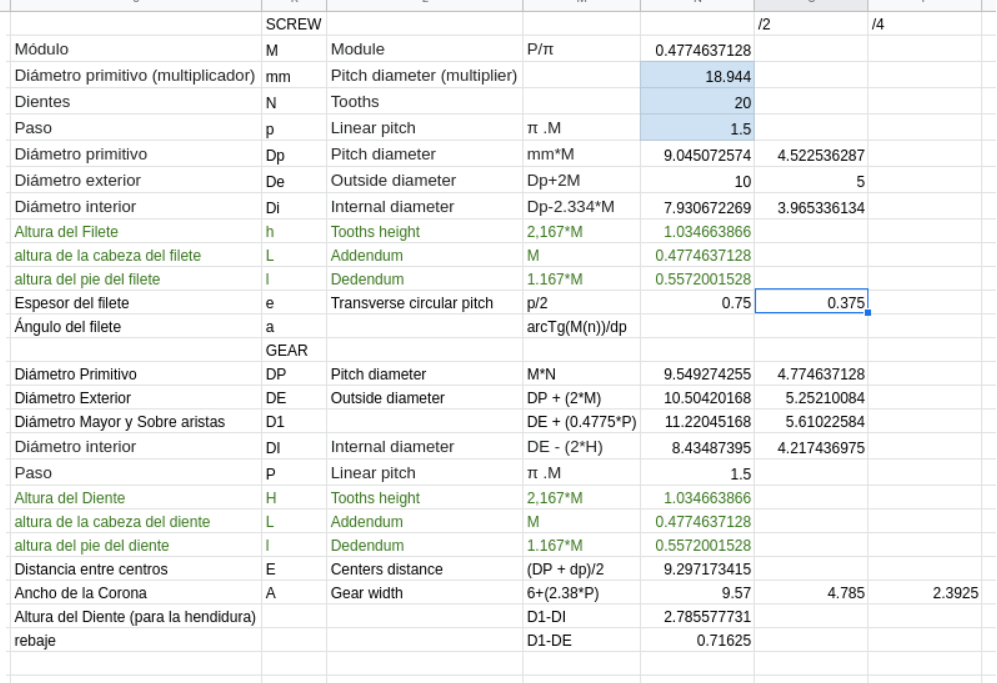

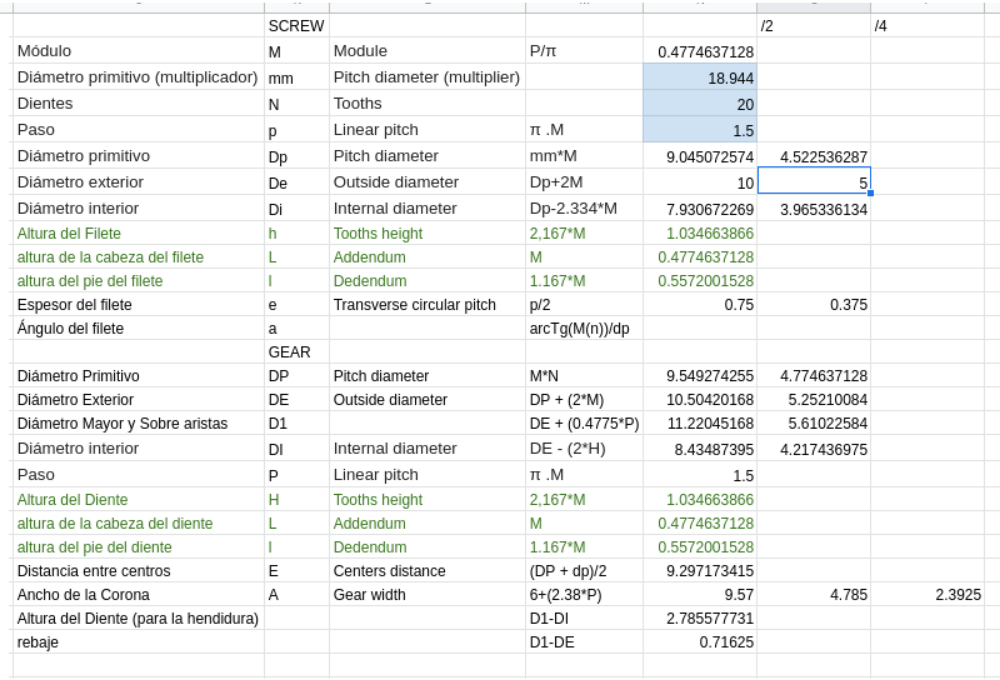

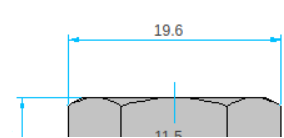

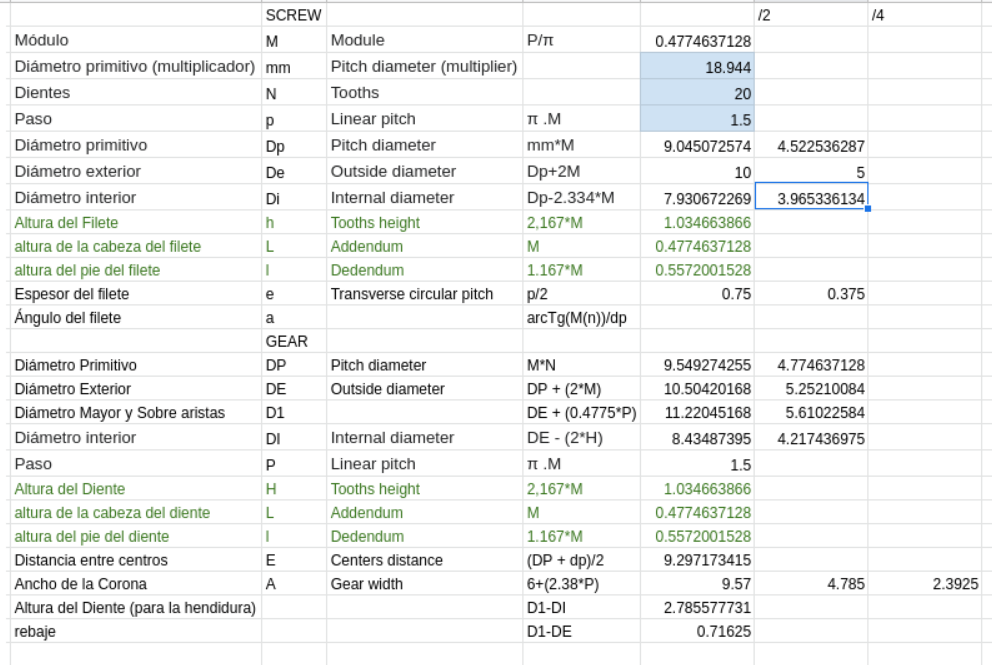

http://www.valvias.com/prontuario-rosca-metrica-din-13.php?m=11

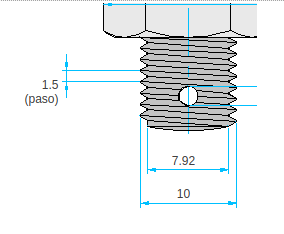

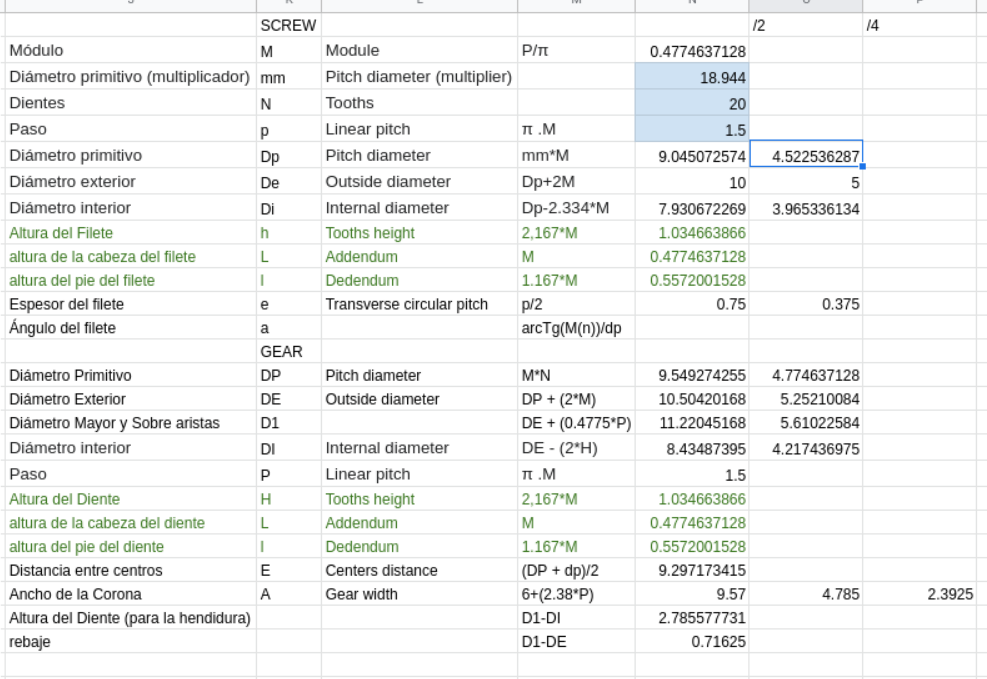

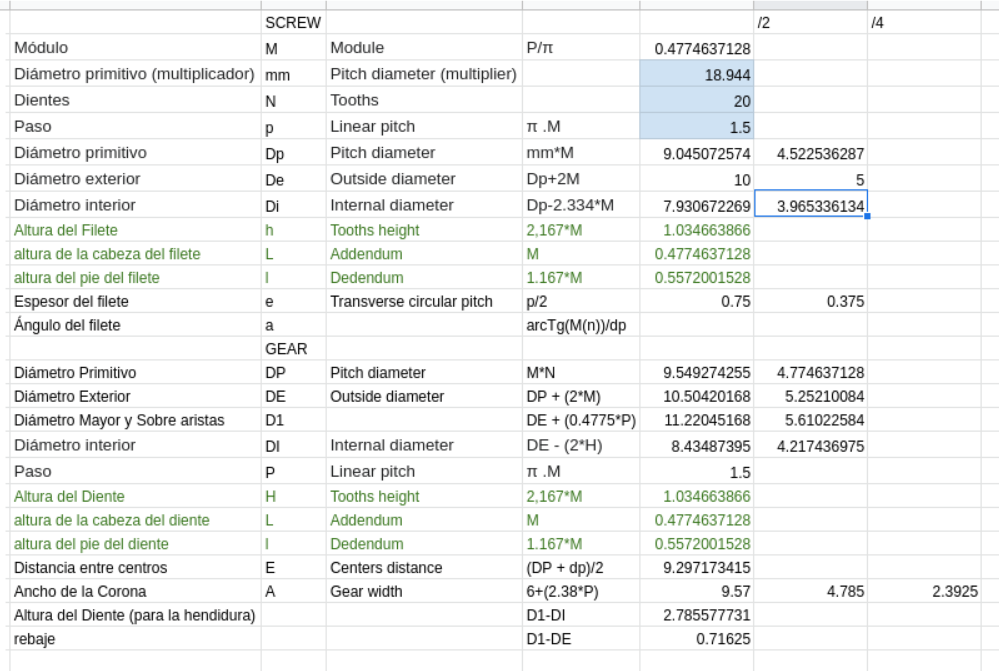

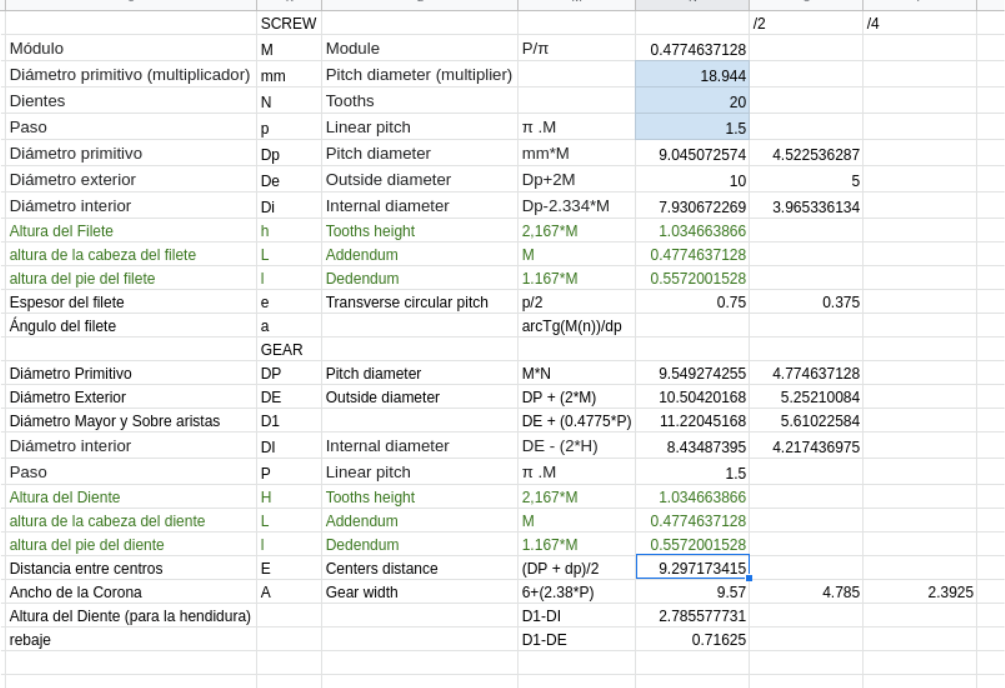

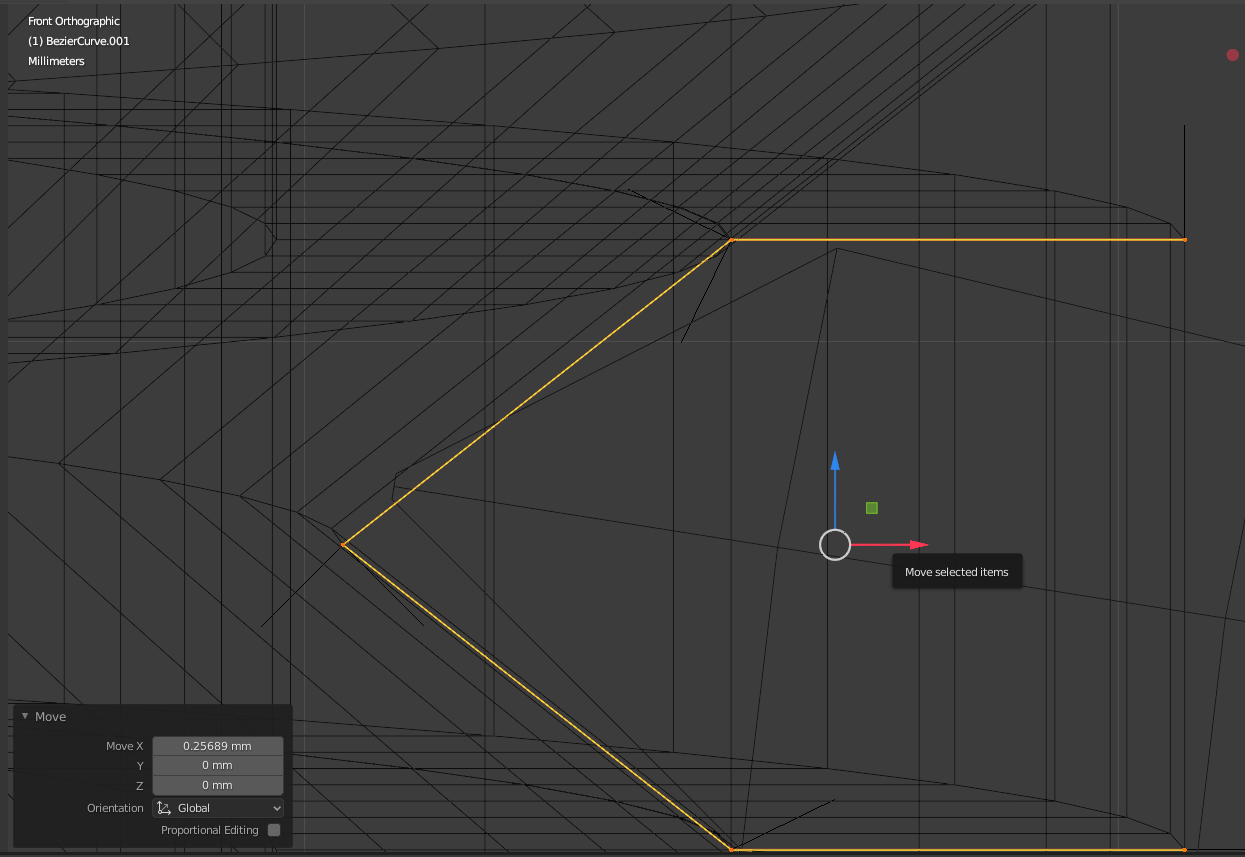

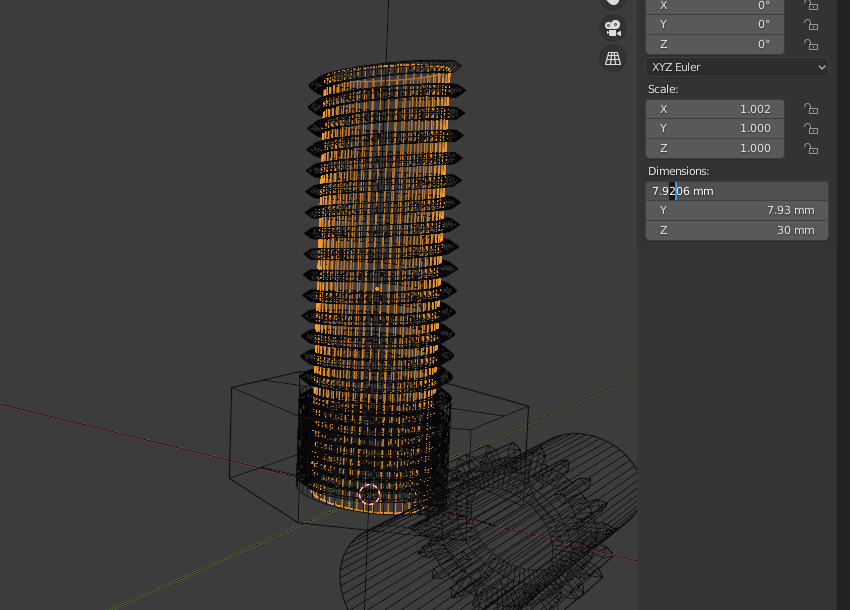

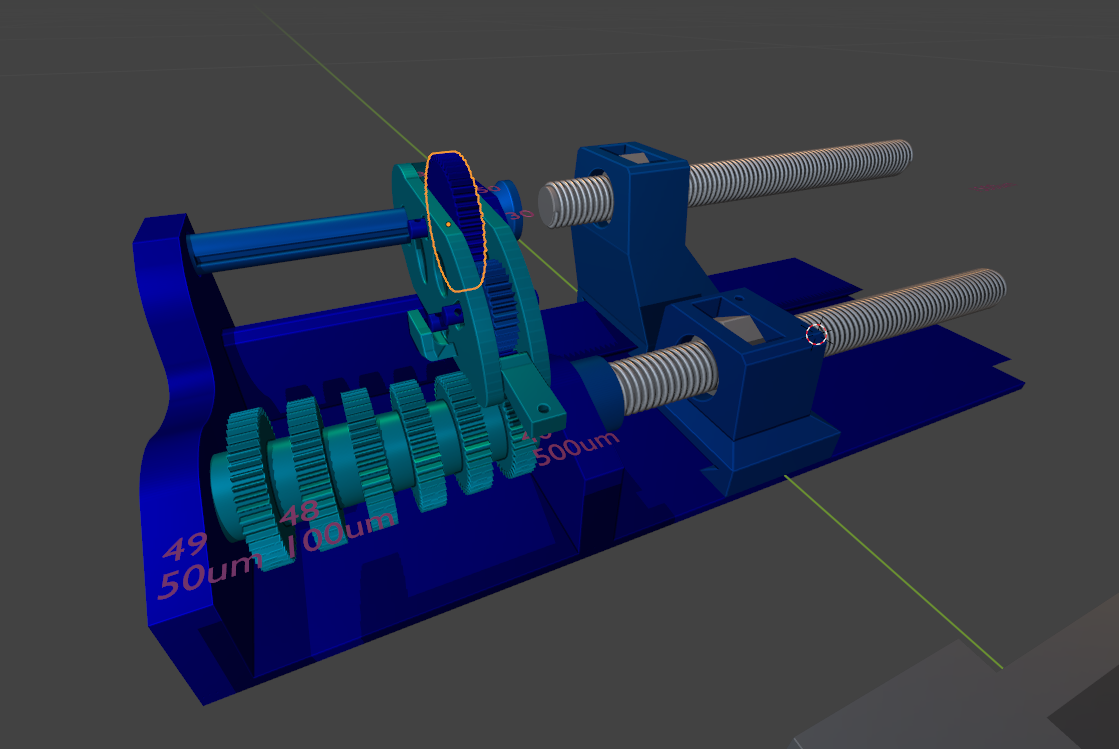

Linear pitch: 1.5mm

Tooths: 20

Adapt Pitch diameter multiplier to get Outside diameter (10mm)

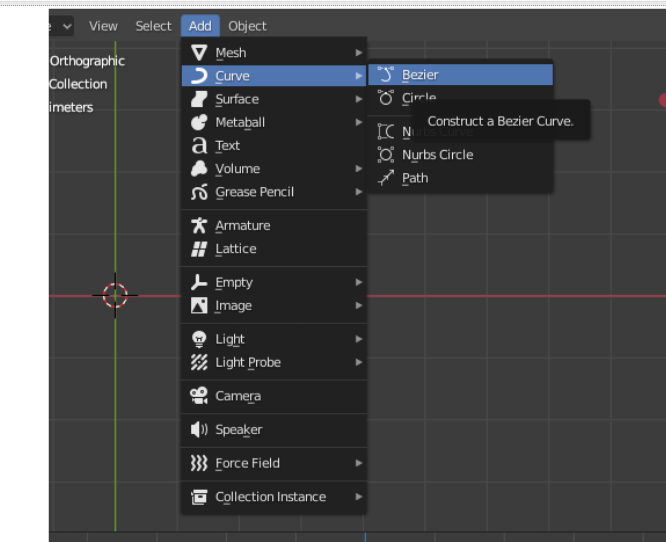

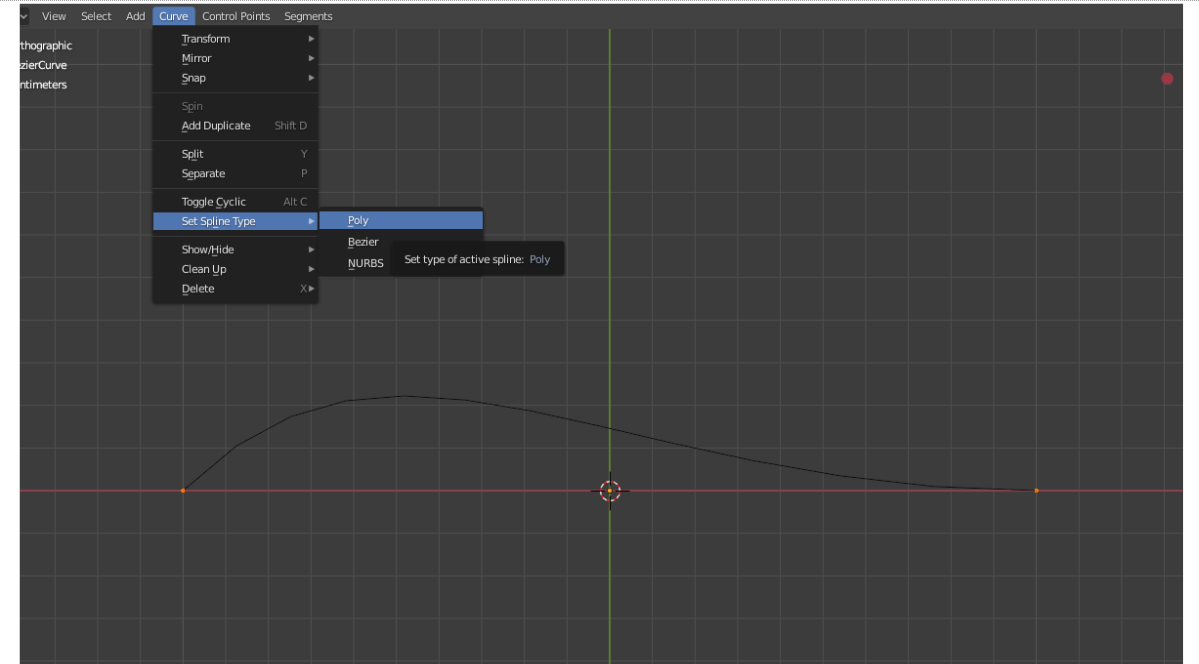

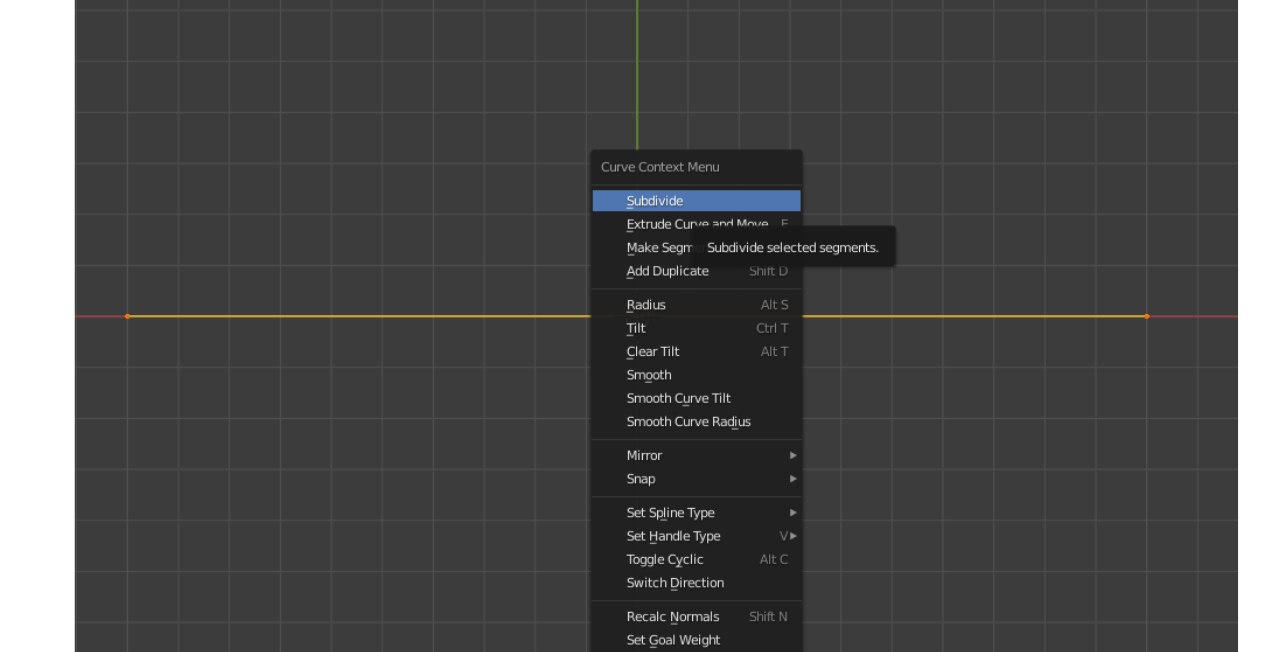

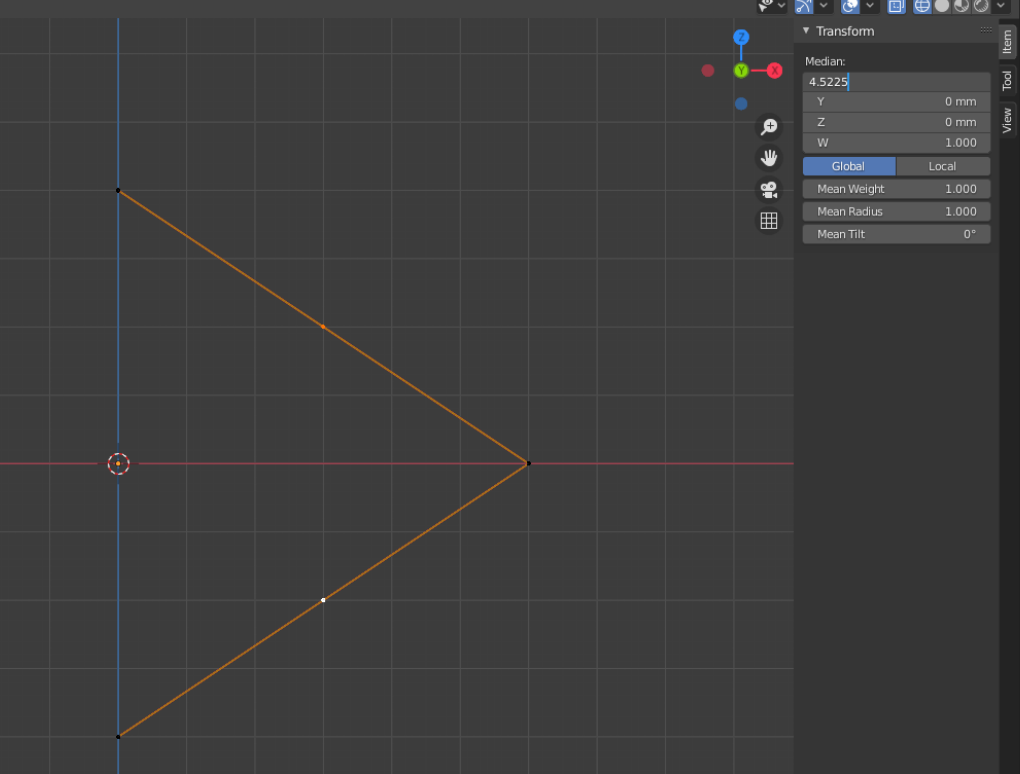

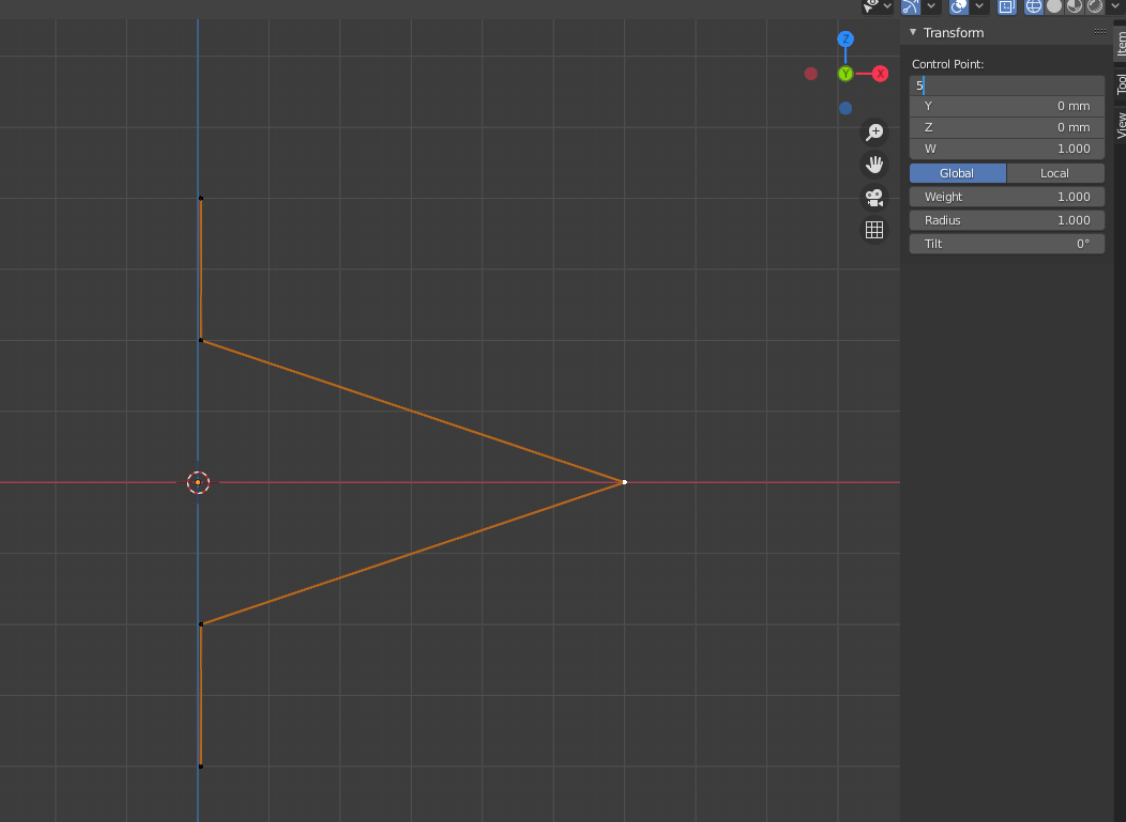

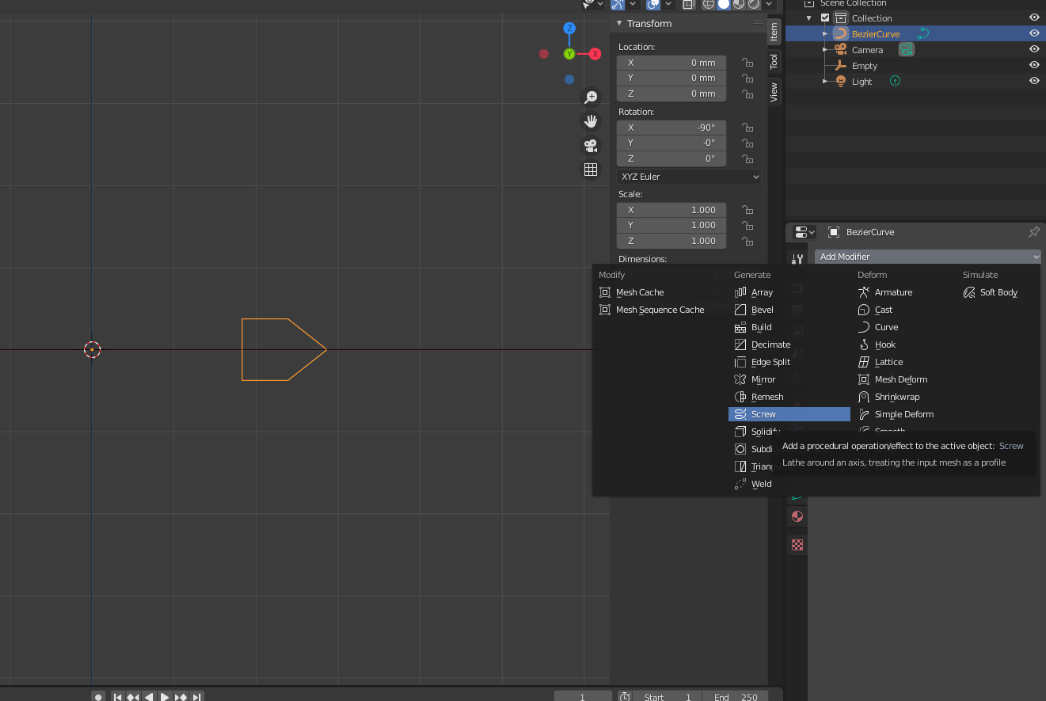

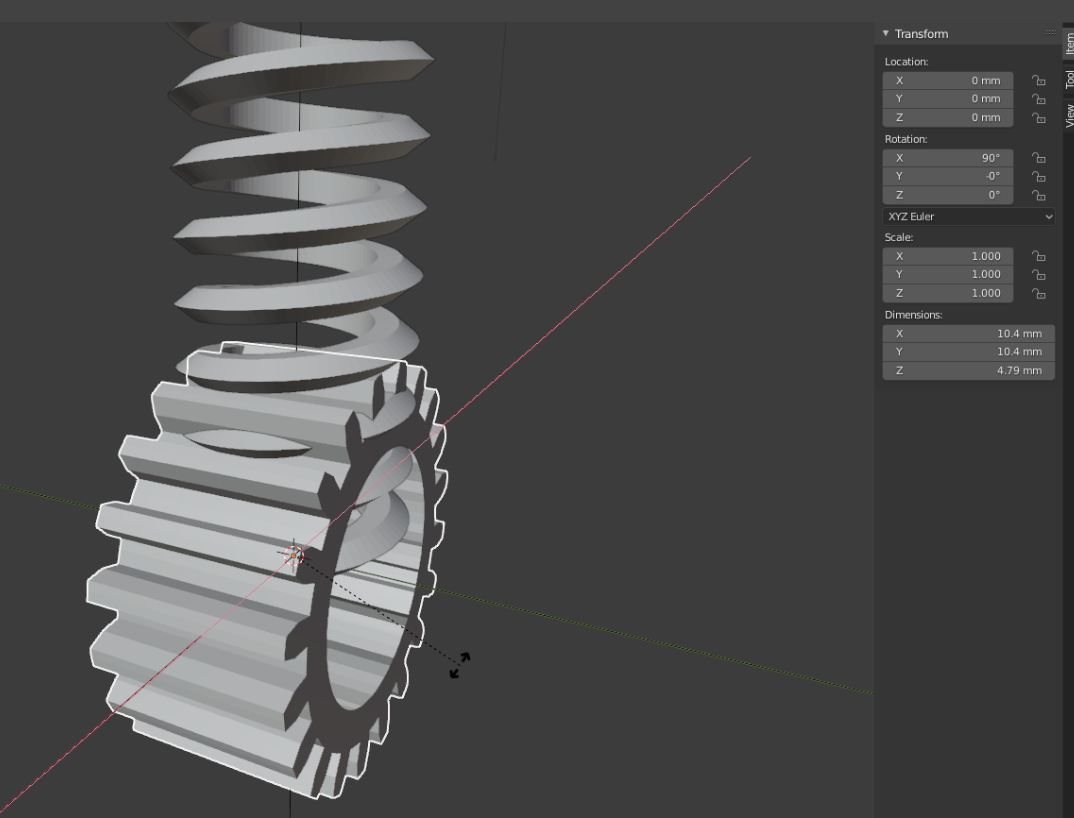

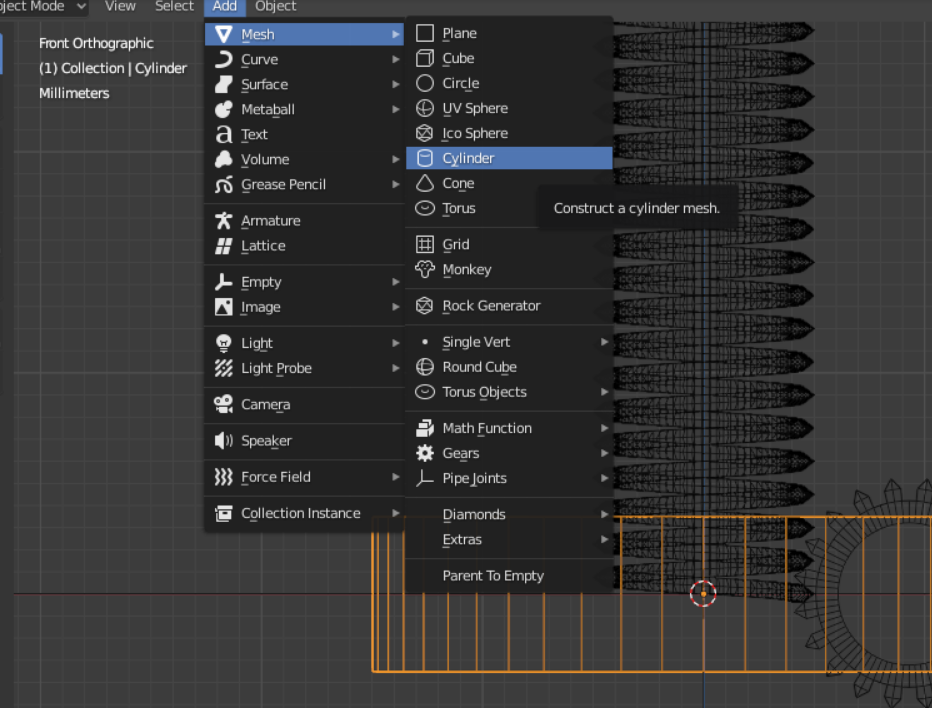

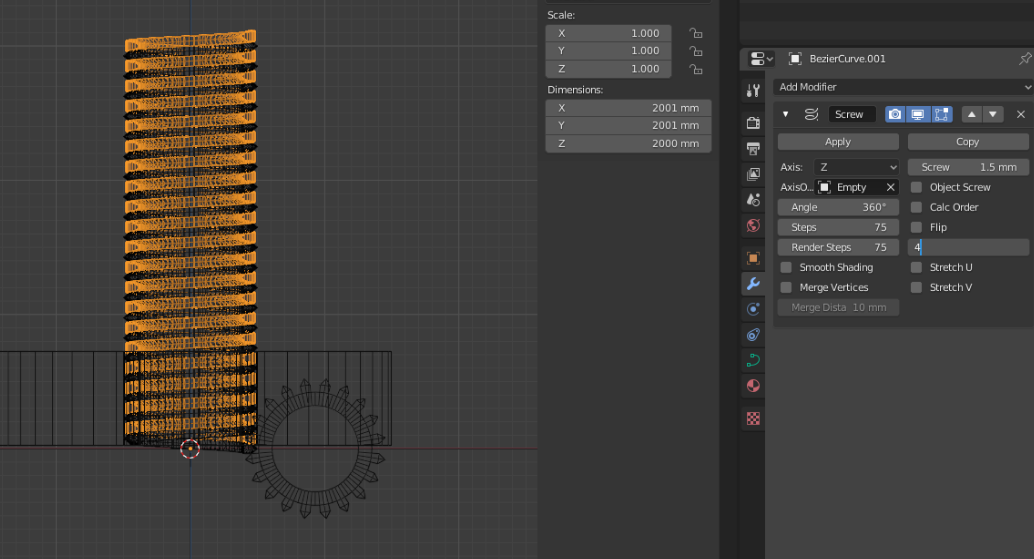

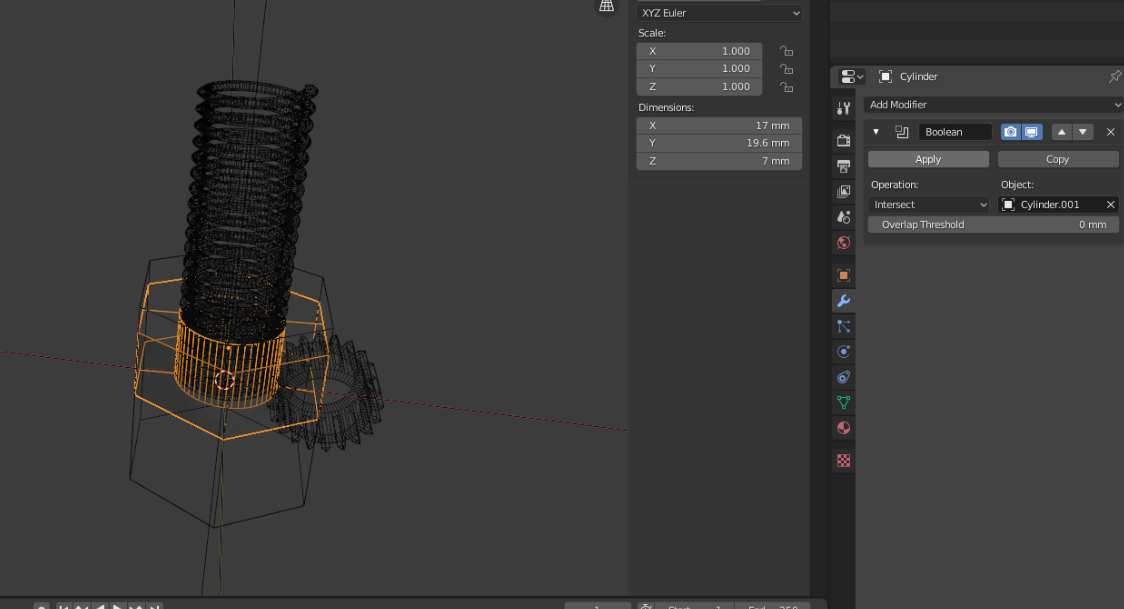

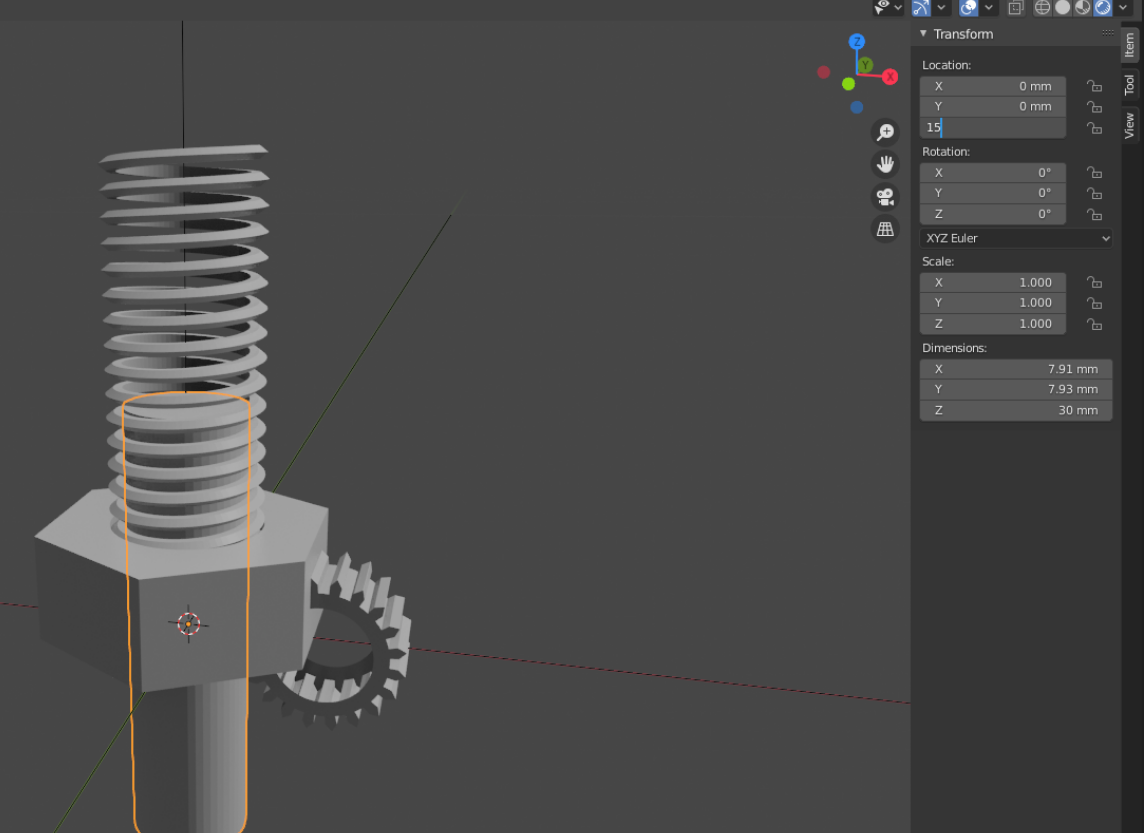

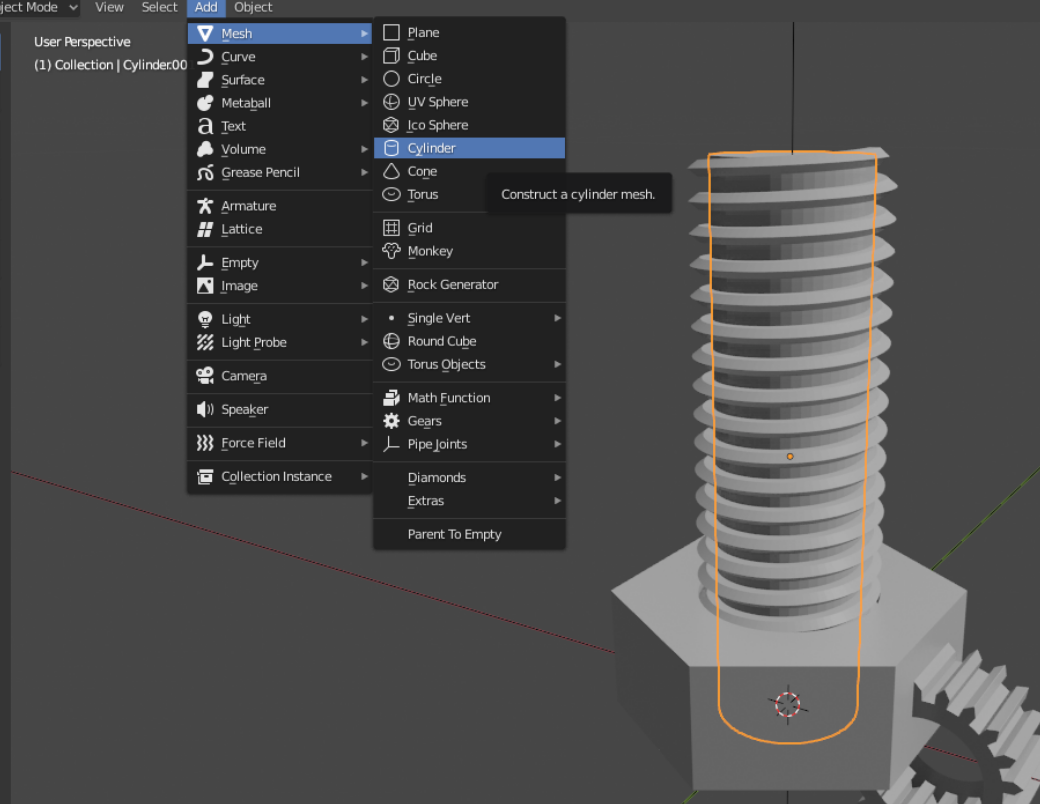

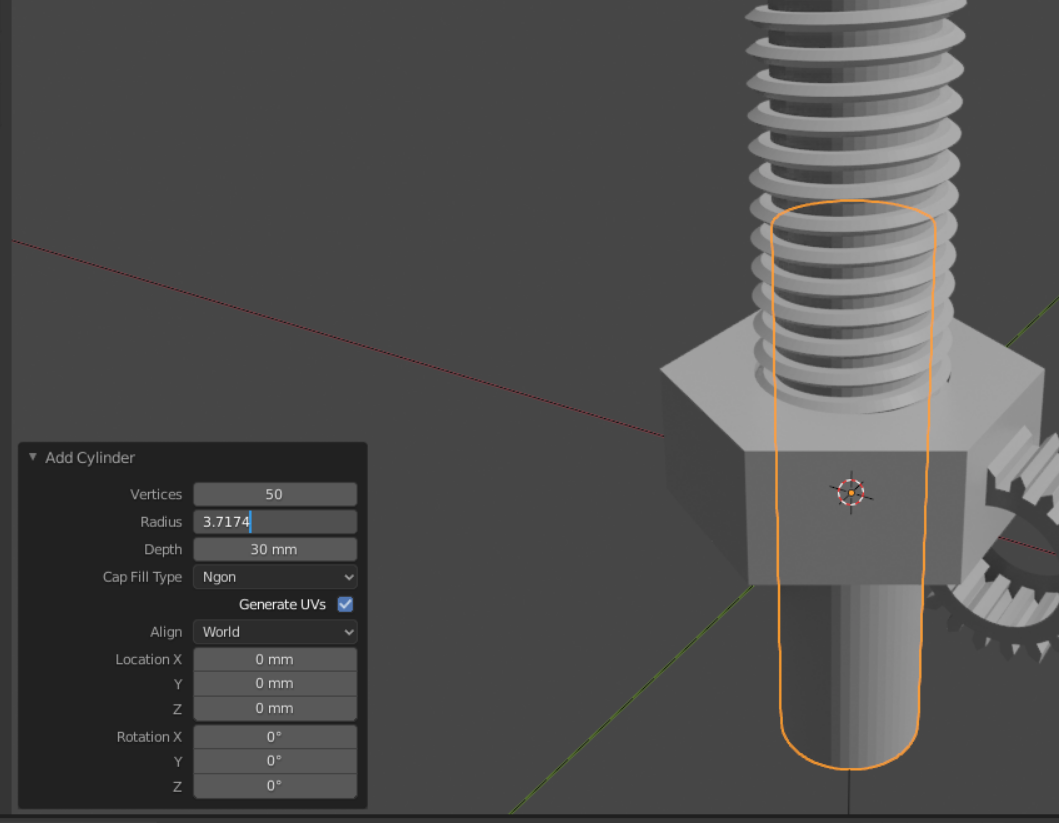

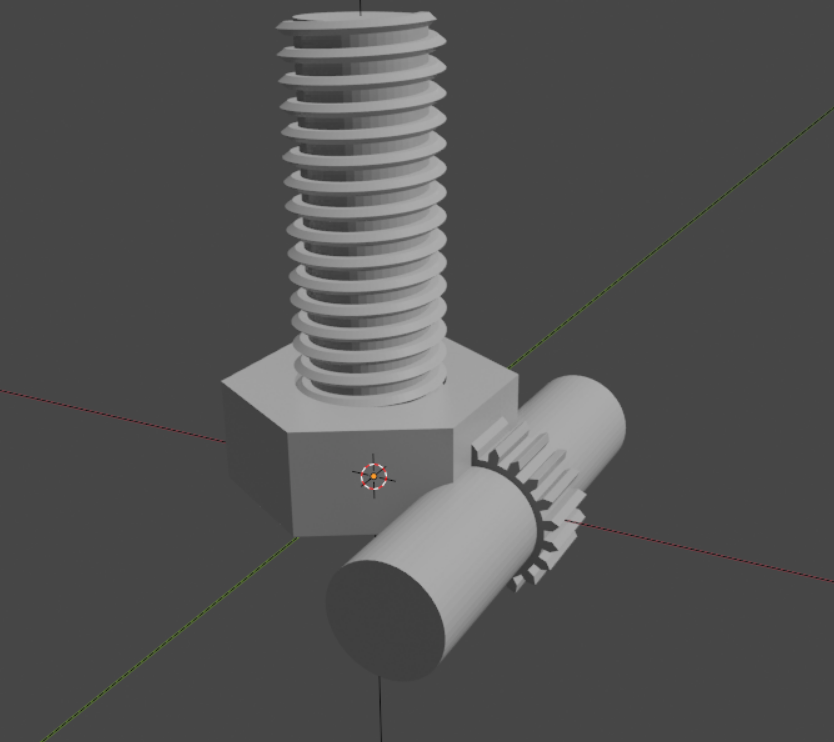

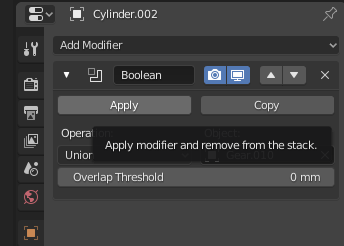

Creating the screw

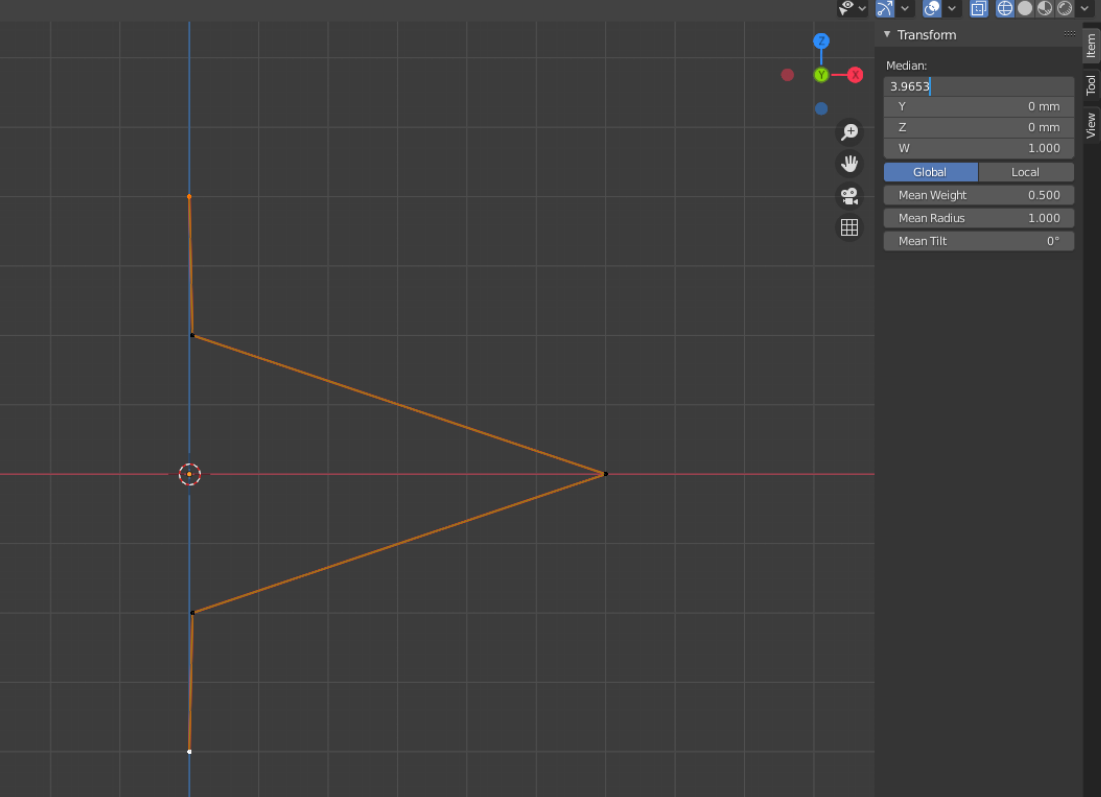

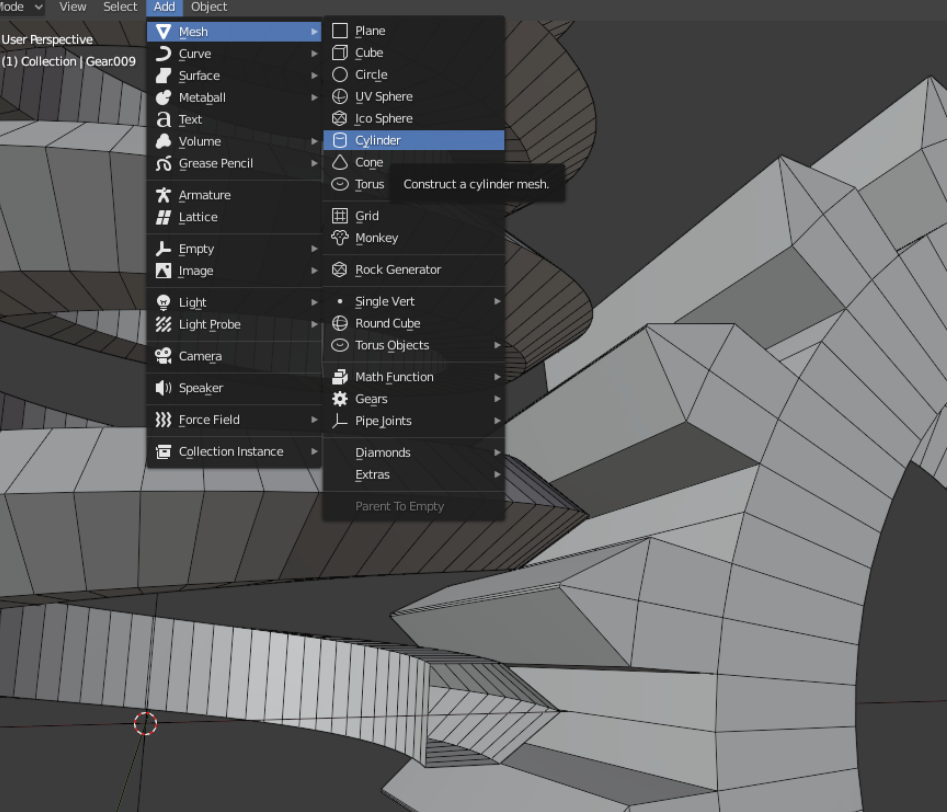

Creating the gear

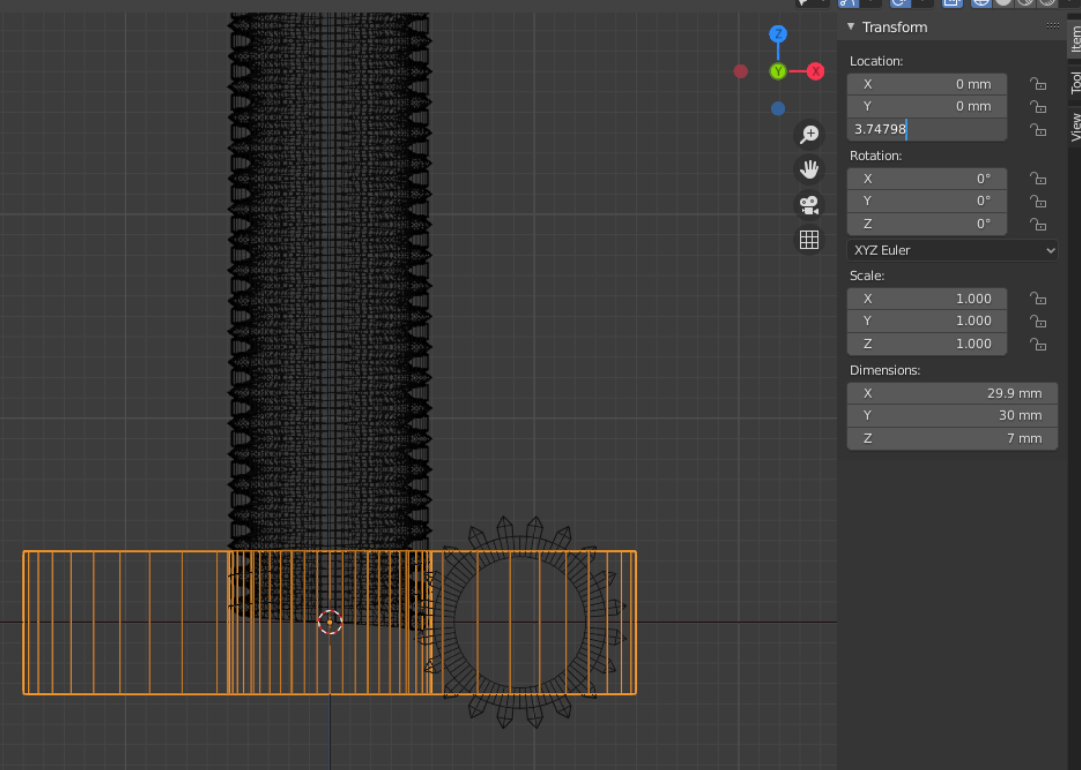

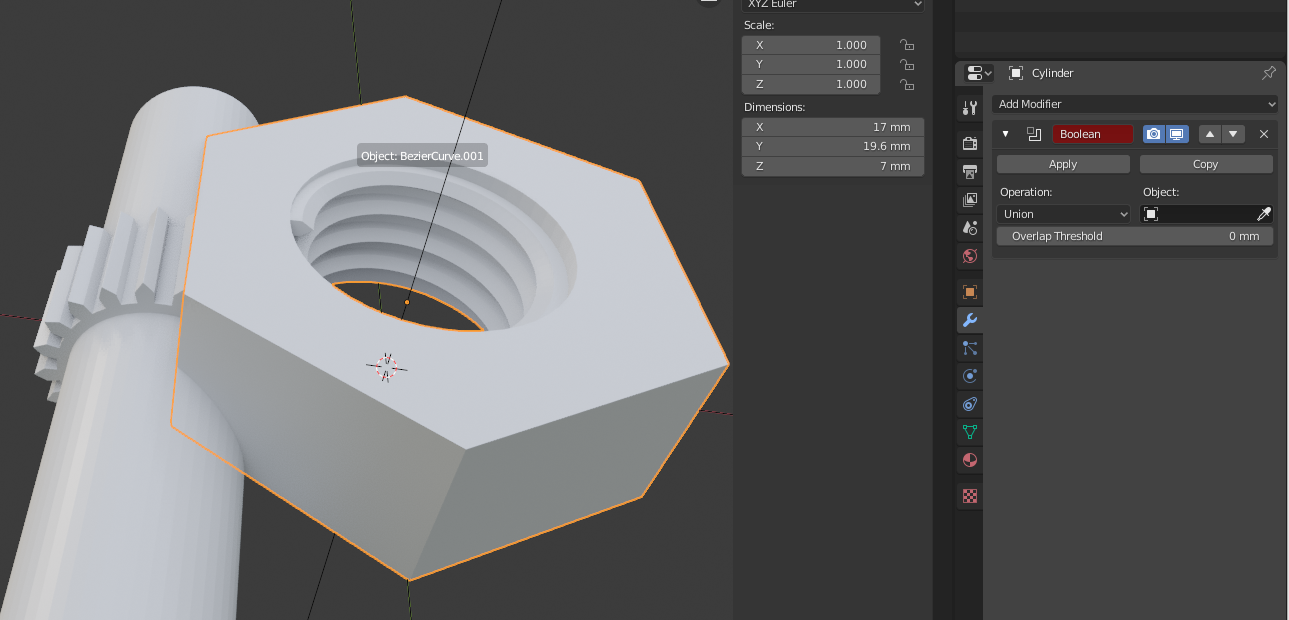

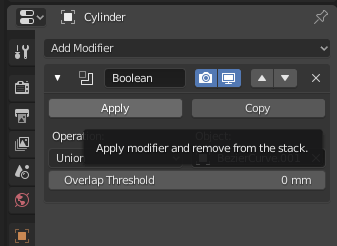

Creating one screw nut

-

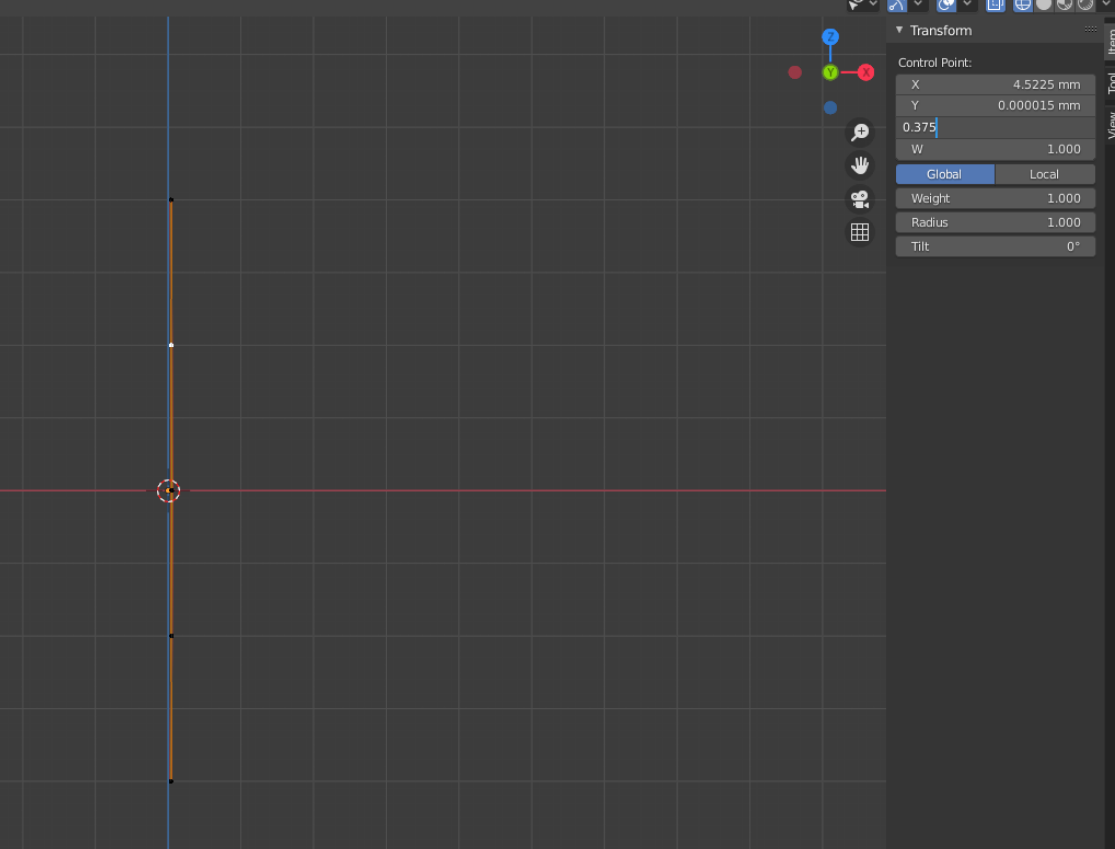

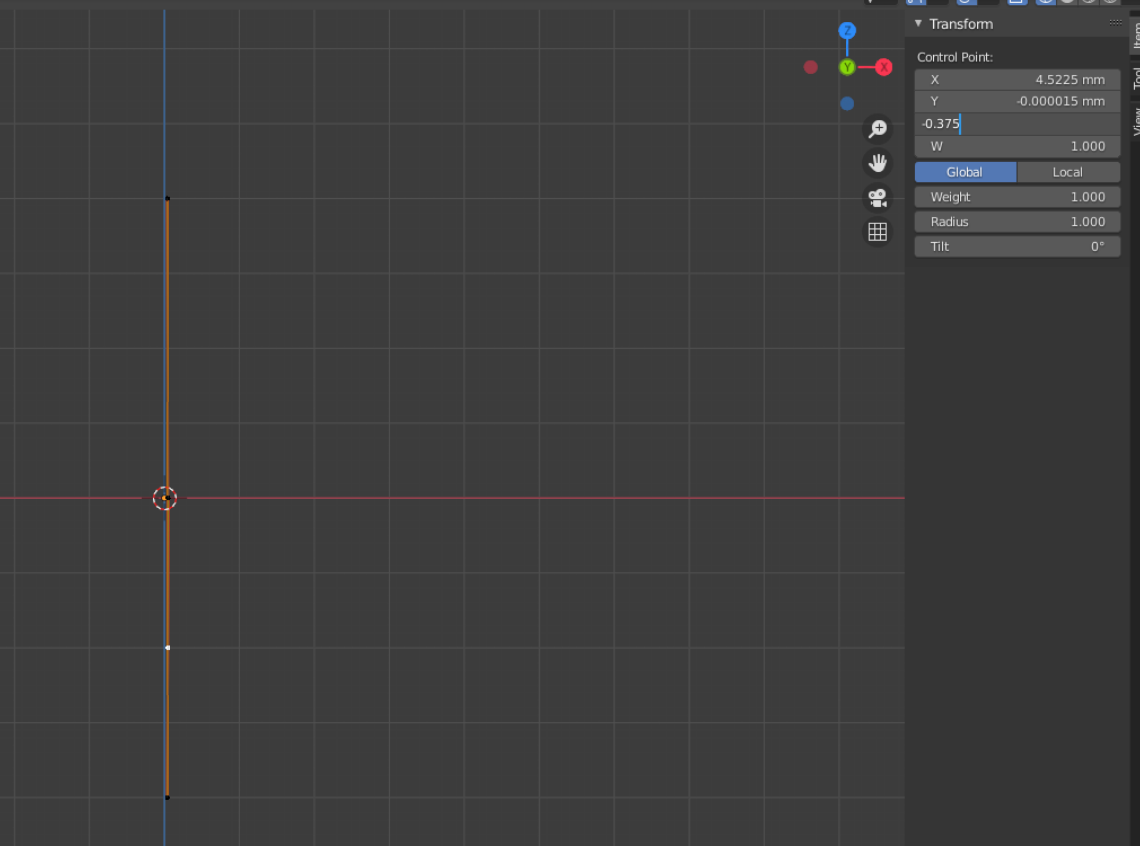

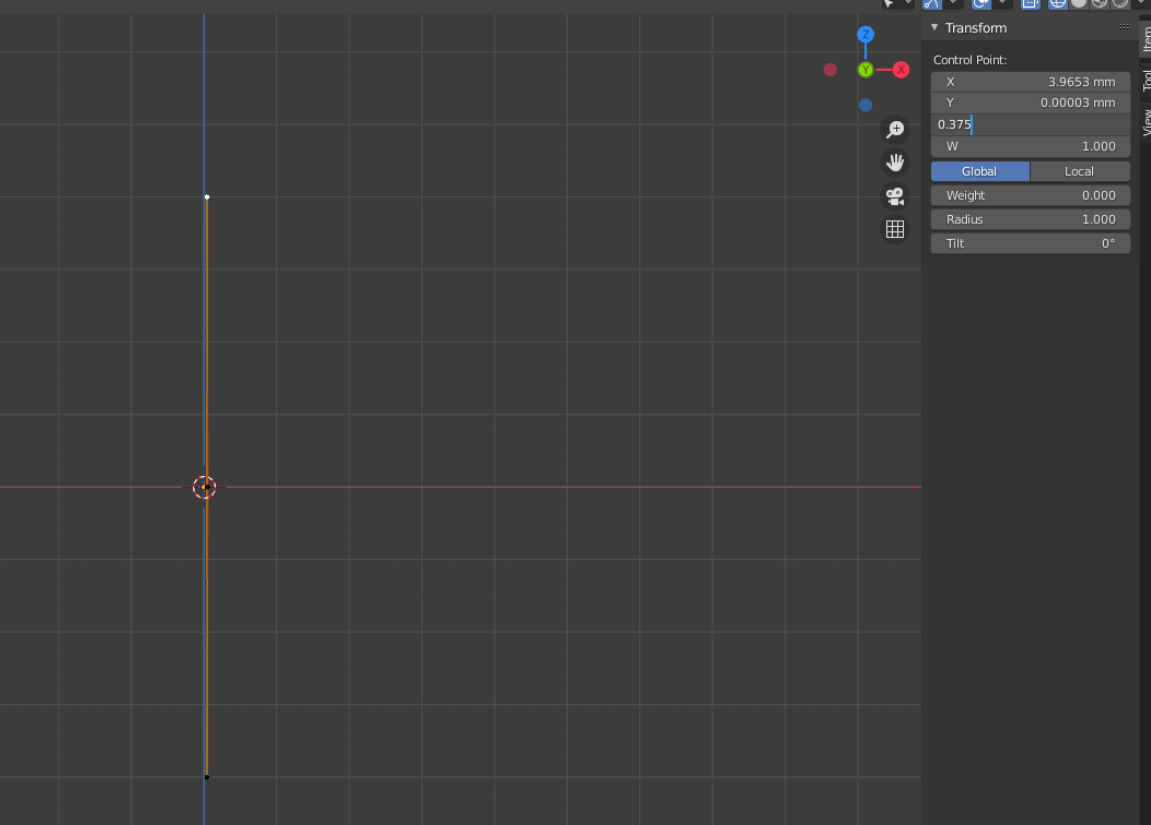

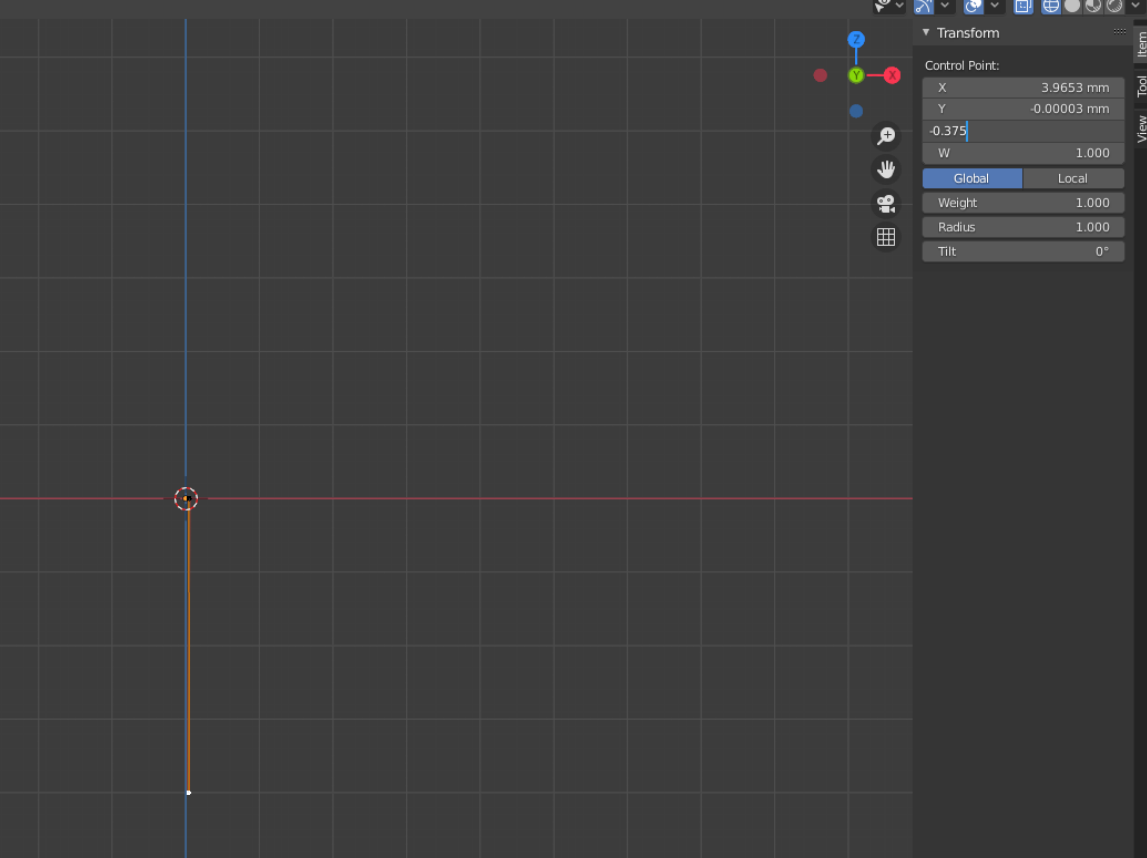

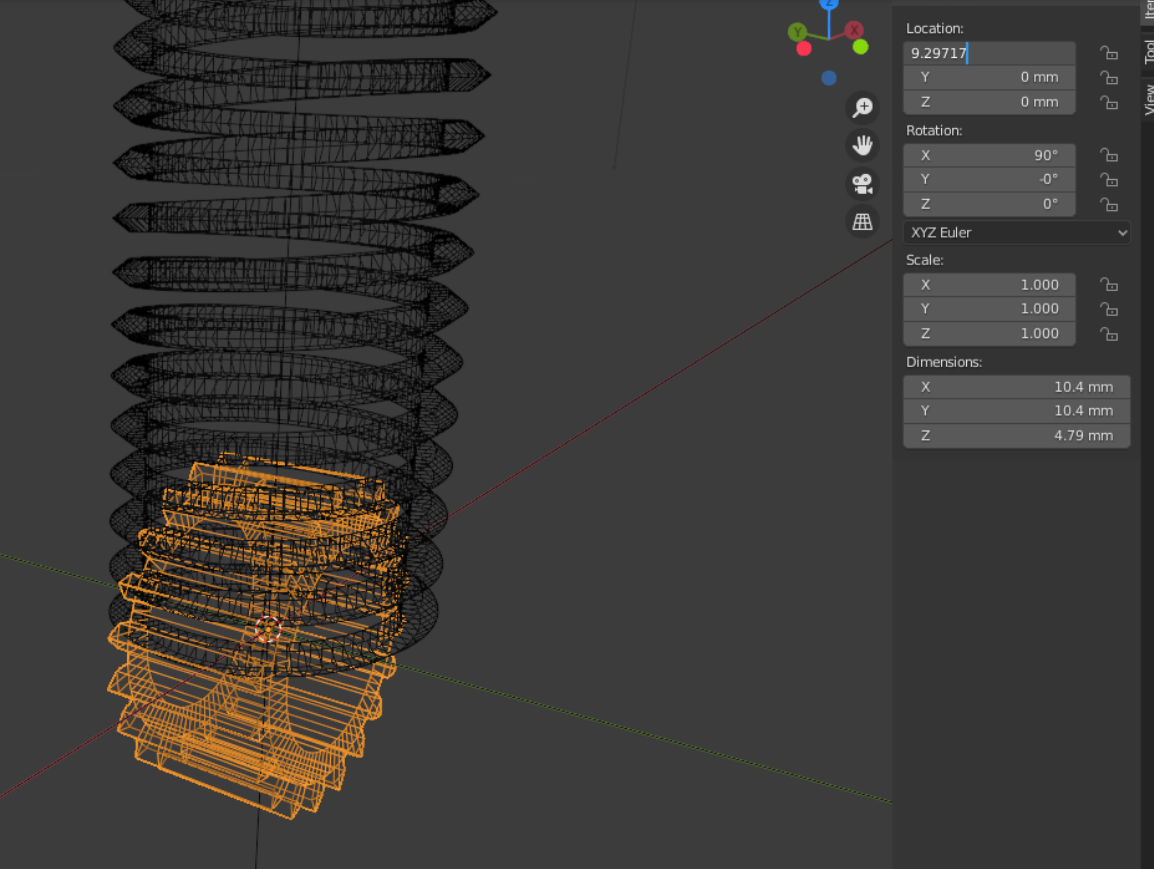

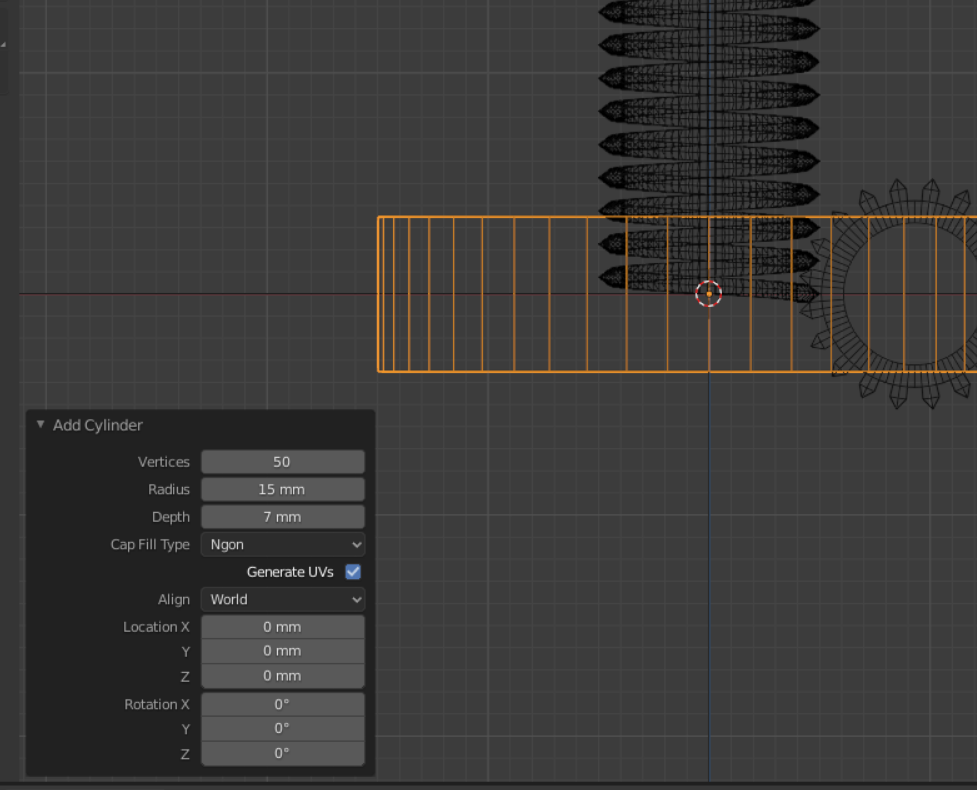

Creating the screw axis

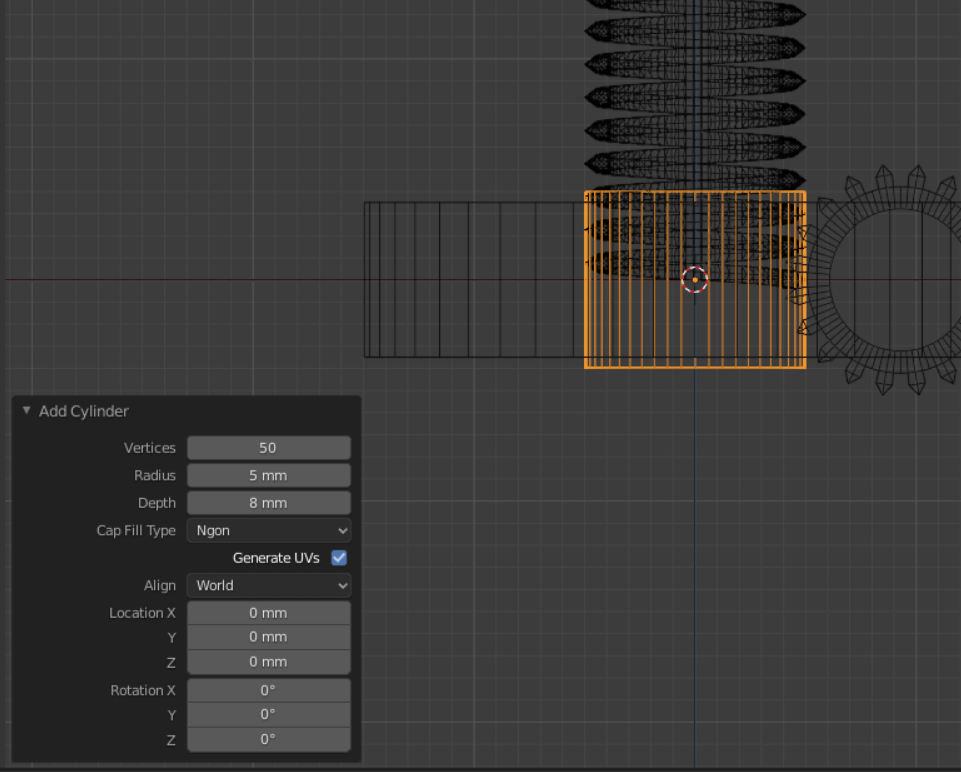

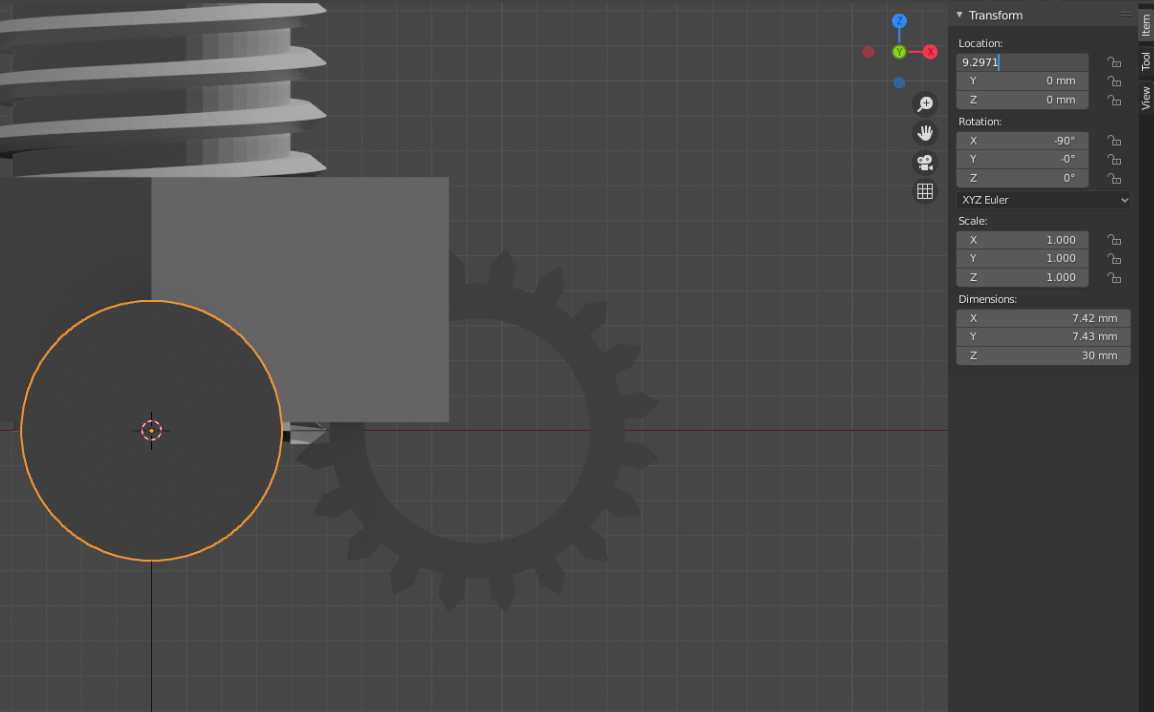

Creating the gear axis

Sources:

https://www.metalmecanica-facil.mahtg.com/tsinfycor/calculador-tornillo-sinfin-y-corona.html

http://www.valvias.com/prontuario-rosca-metrica-din-13.php?m=11

https://docs.google.com/spreadsheets/d/1aFcktbNmx7cTsuAU0JgZB2Xayx76sSm1ici_PpTlju8/edit?usp=sharing

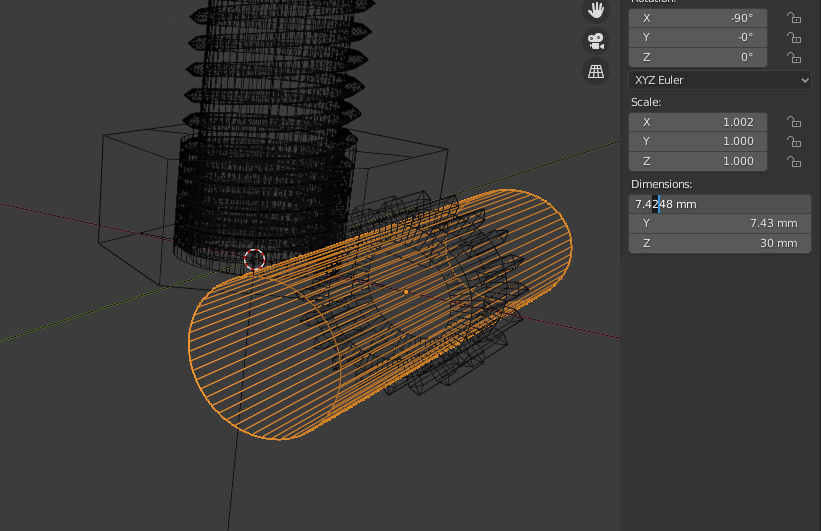

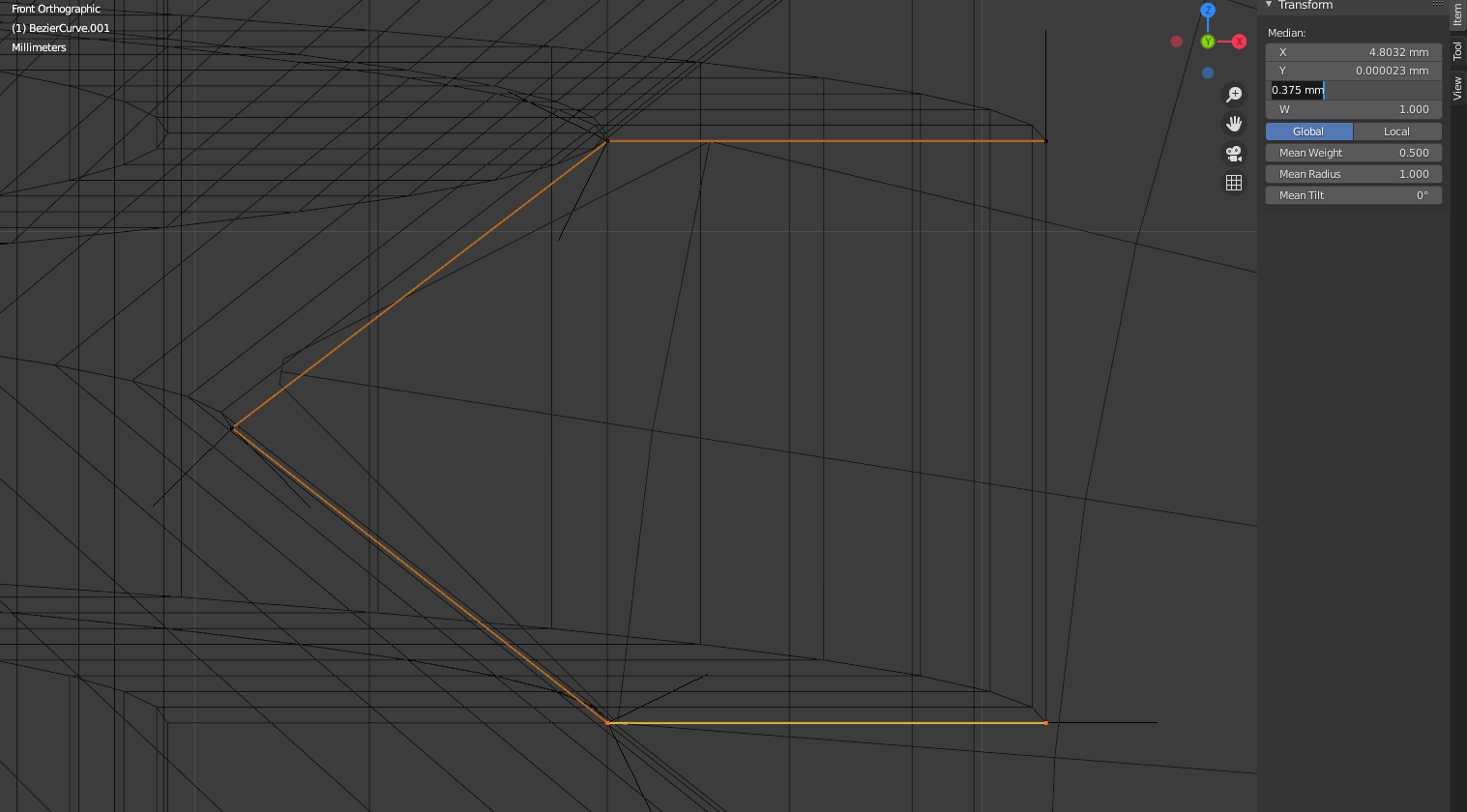

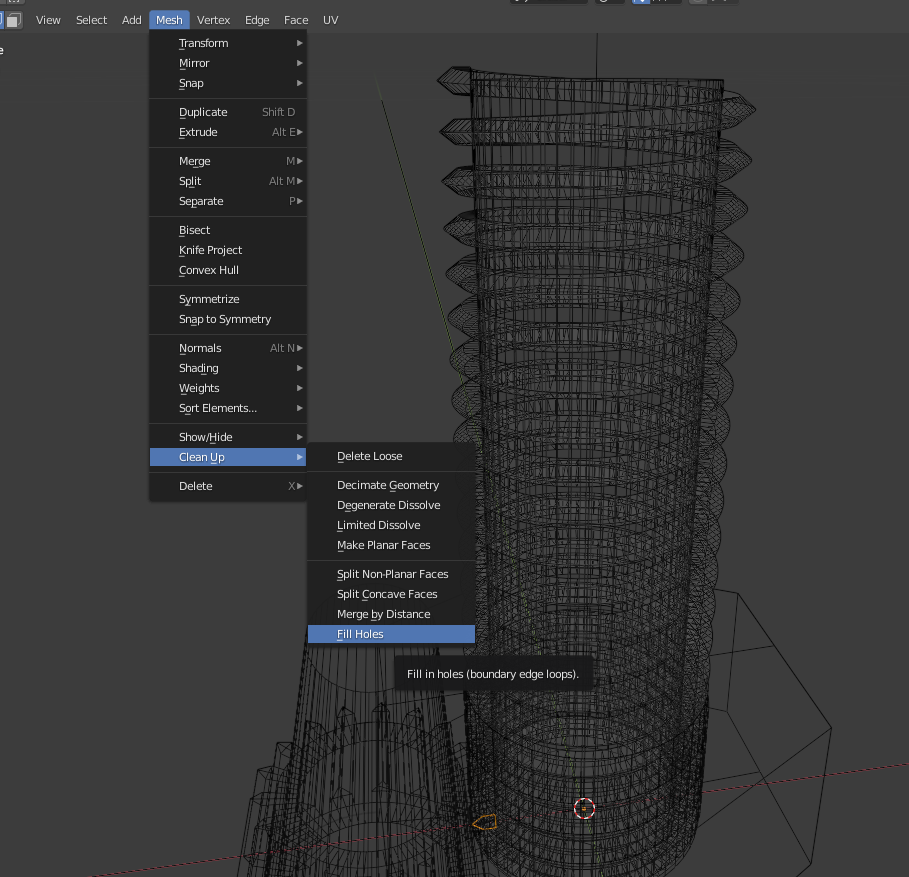

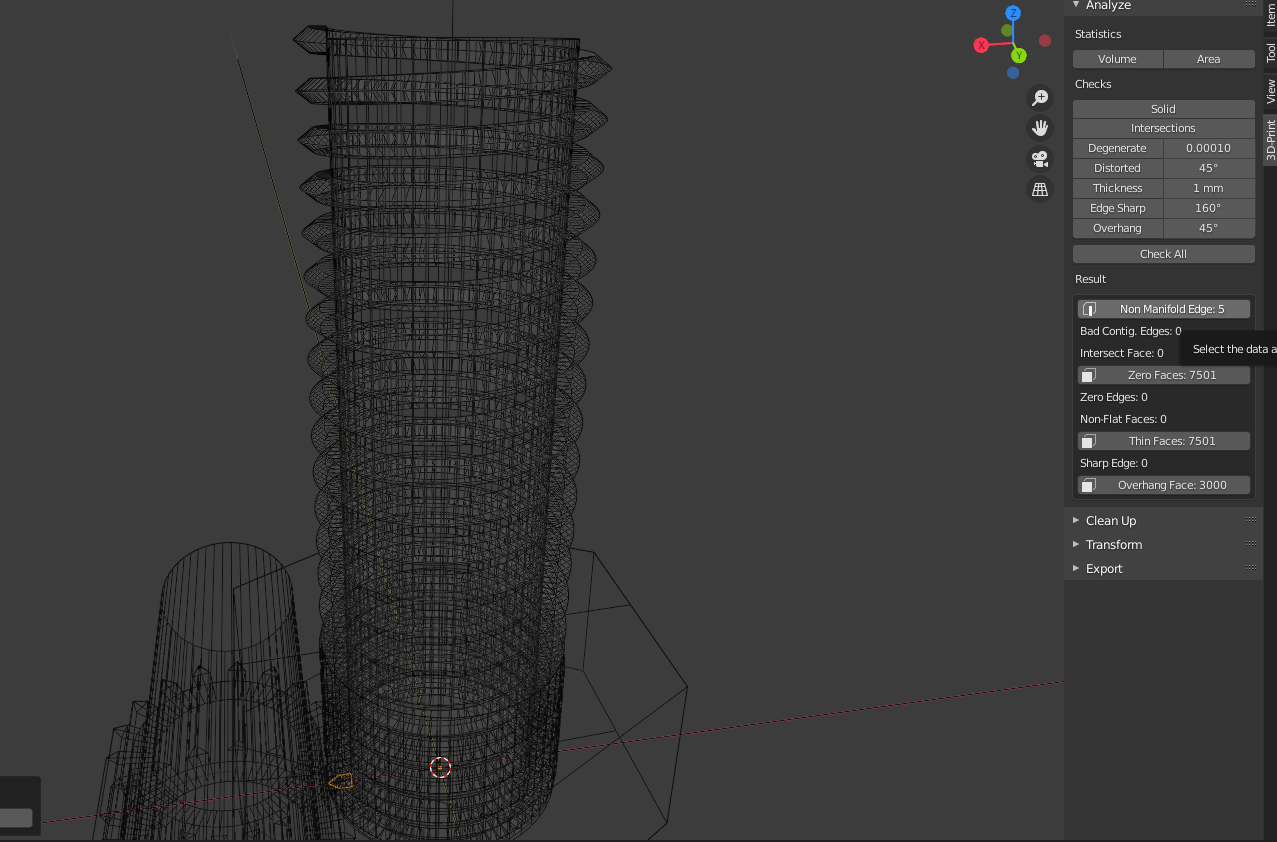

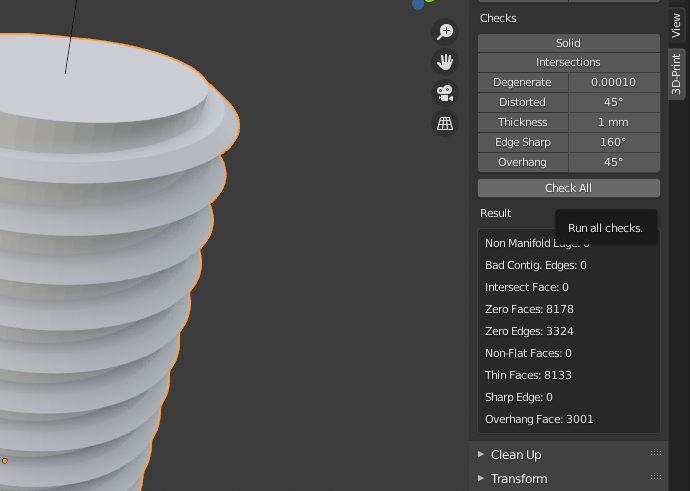

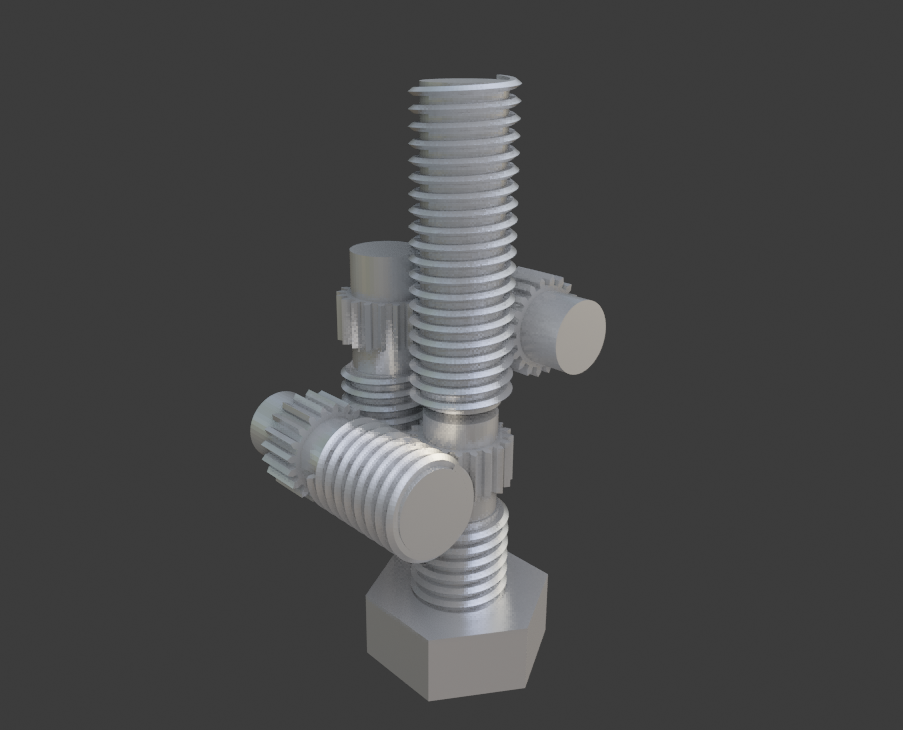

CONF adjusting tolerances:

Reduce 10um gear axis diameter

Reduce 10um screw axis diameter

Down 10um nut tooth top (1.125mm to 1.115mm)

Up 10um nut tooth top (0.375mm to 0.385mm)

Note: Make the same for the nut tooths

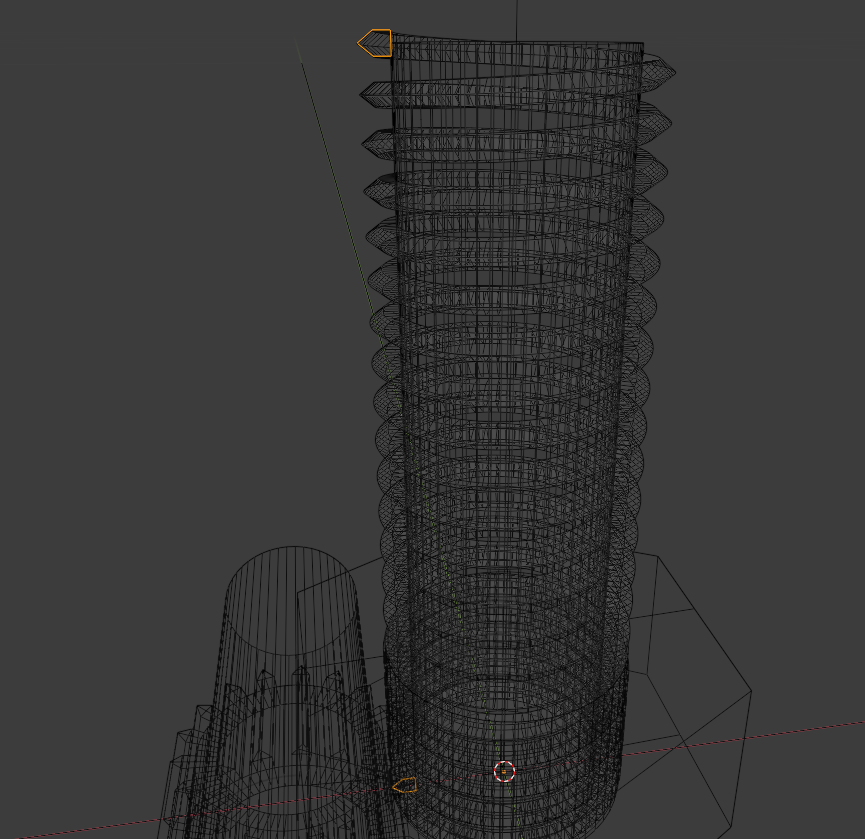

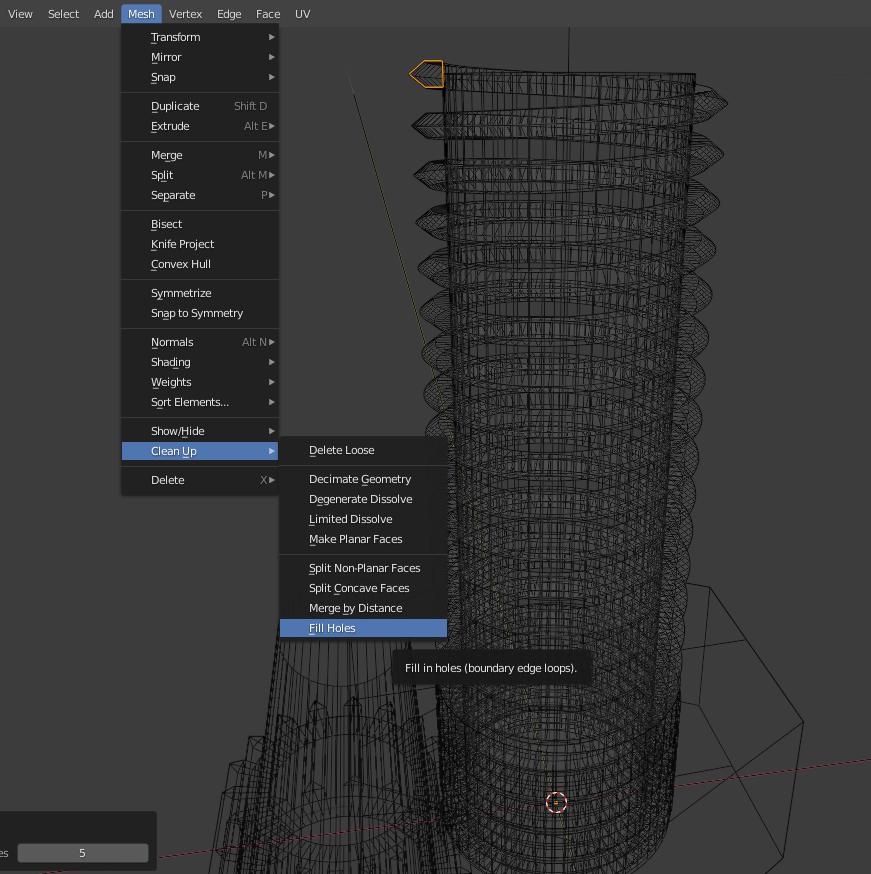

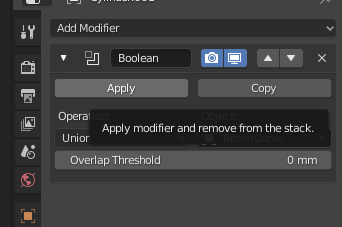

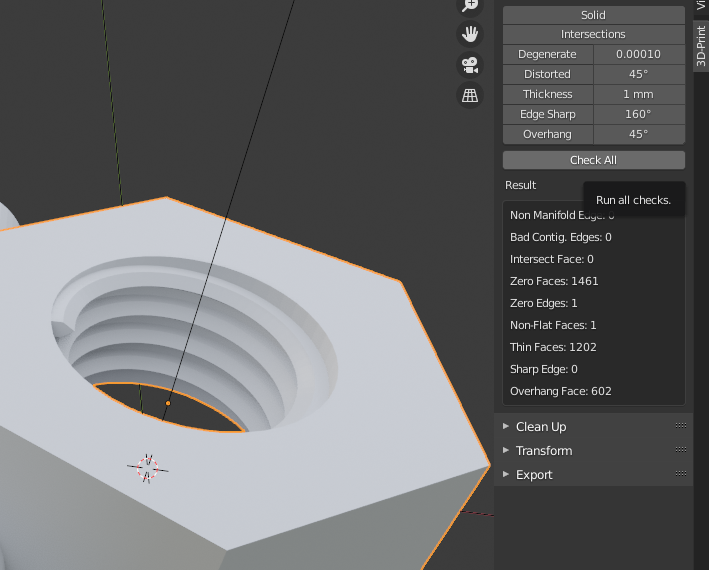

Now join the axis tooths

and nut tooths

and gear axis

-

-

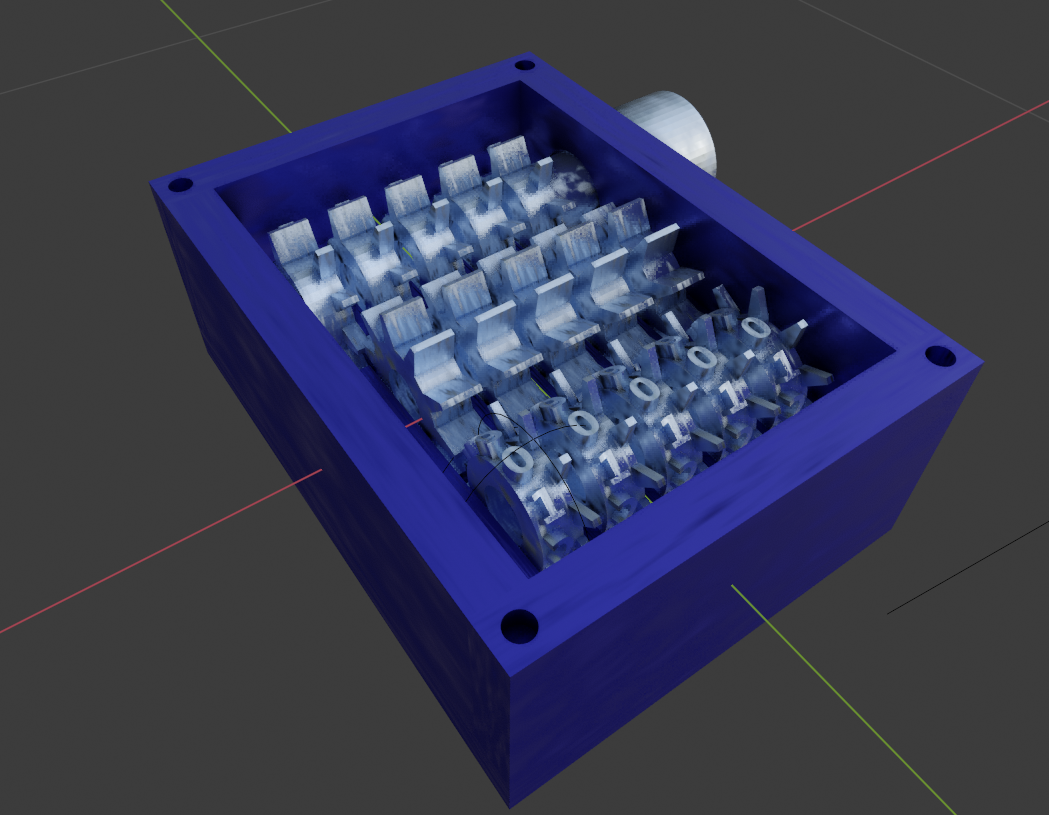

20 tooths = 1:20 (around 75um per 1.5mm step)

reductor multiplier :)

1.5mm/20 = 75um

75um/20 = 3.75um

3.75um/20 = 187.5nm

187.5nm/20 = 9.375nm

If I place more of these I could do a kind of clutch disconnecting 2 and 3 and connecting 1 and 4 when apply some movement of joystick. I will need to handle micro-things in 2D/3D for future projects.

3drobert

3drobert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.