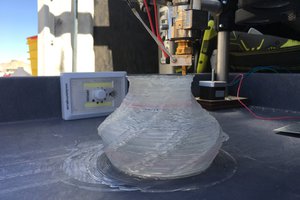

The 3D printer is made using the following components

- An frame using aluminum extrusion, timing belts and stepper motors. Loosely based on http://openbuilds.org/

- A SlushEngine controller (no plug intended, its just the most convenient controller)

- Linclon MIG welder (140c)

- Some metal plates to weld on to

roboteurs

roboteurs

TTN

TTN

Gorky

Gorky

Charlie Godfrey

Charlie Godfrey

Sam Smith

Sam Smith

A good way to increase efficiency of the welder used for printing would be to contain the machine in a housing that keeps it pressurized with Nitrogen to help strengthen the parts that are printed while increasing consistency in the arch. Also you could do a 1 stage CNC cut to build the base of the part that could be cleaned up after printing. I managed to grab a transformer out of an old flux welder. I think I'll start experimenting with it.