Ok. Since I couldn't just squirt the superglue through the mesh, and I couldn't put down a layer of glue, then press the mesh on top of it, what if I had a ring that I could use to make a mesh sandwich.

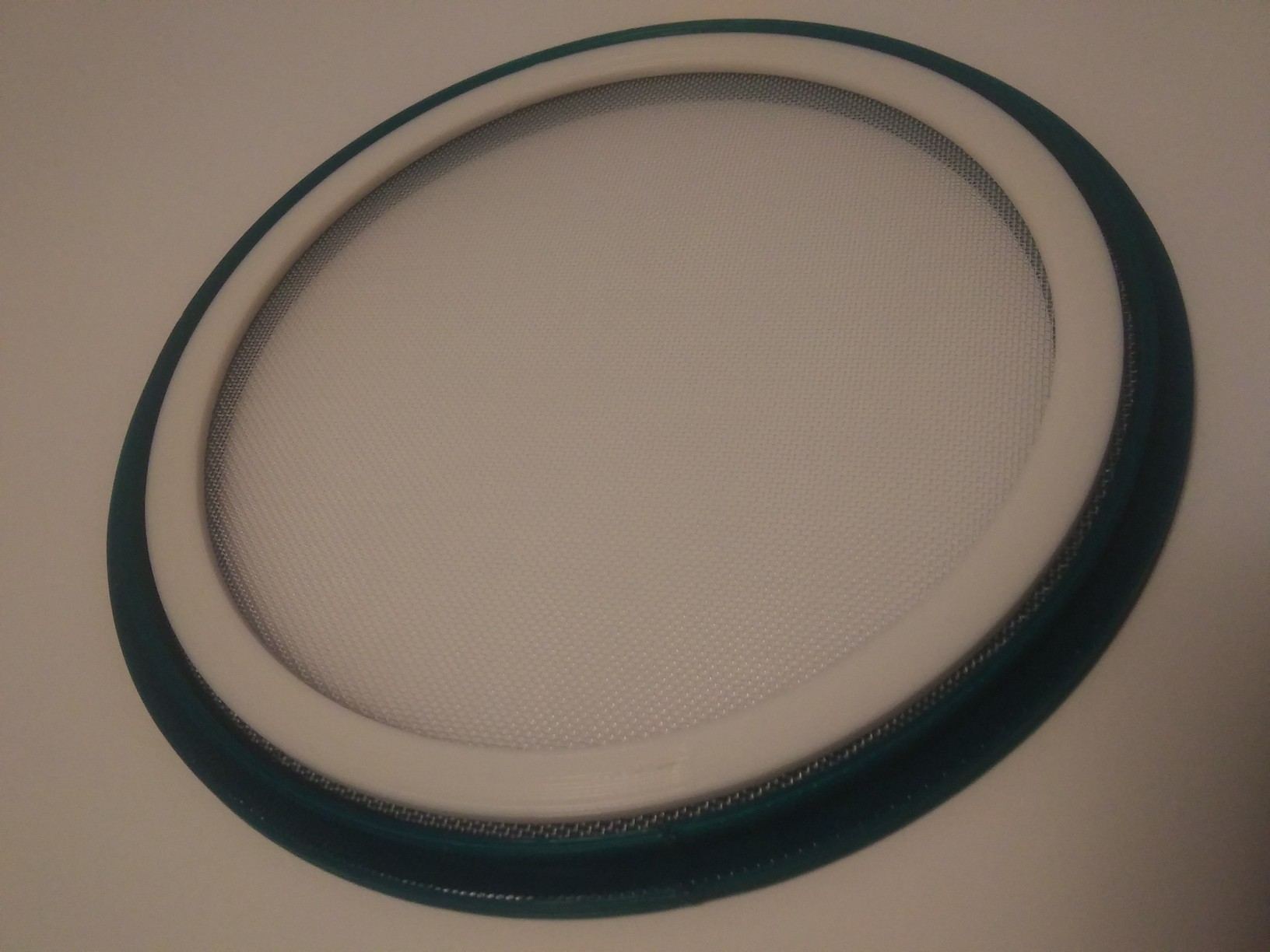

So I printed a ring sized to fit inside the part and proceeded to make the mesh sandwich.

First I put a nice fat layer of superglue on the lip of the part. Then I gently laid the mesh on top that, then pressed the ring down onto the mesh.

Less sticky this time, and the glue pressed though the mesh so that it was in contact with the lip and the bottom of the ring.

However...

It didn't set. I left it overnight and it still wasn't set, probably due to the dryness of the PLA. So using accelerator, I set the glue and happily proceeded to make another one.

The next one set fine but when tested showed that this wasn't vary viable, as it had low strength and the unevenness of the print allowed fine particles through.

There must be another way.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.