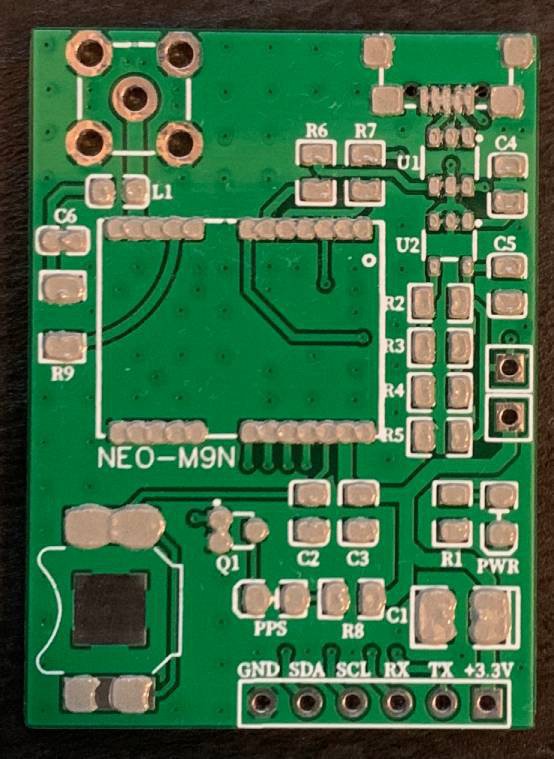

The second reflow attempt is a success. One of the key points to take into consideration when applying the solder paste is to make sure that the stencil adheres perfectly to the surface of the pcb. Apply the right amount of paste to cover all the pads by spreading it with a sufficient pressure by holding the squeegee with an angle of about 60 degrees to the stencil. Too much pressure can cause "bleeding" of the solder paste between the stencil and the PCB.

Some of the pads, especially the ones of the GPS module, are shorted or "bridged" by the solder paste but it is fine. Once the hot plate starts to heat the board reaching the reflow temperature, the paste will be "attracted" by the pads and the solder mask ensures the separations.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.