Let's start with the quirk: A bad configuration will not load and a not properly loaded configuration will require the printer to be power cycled.

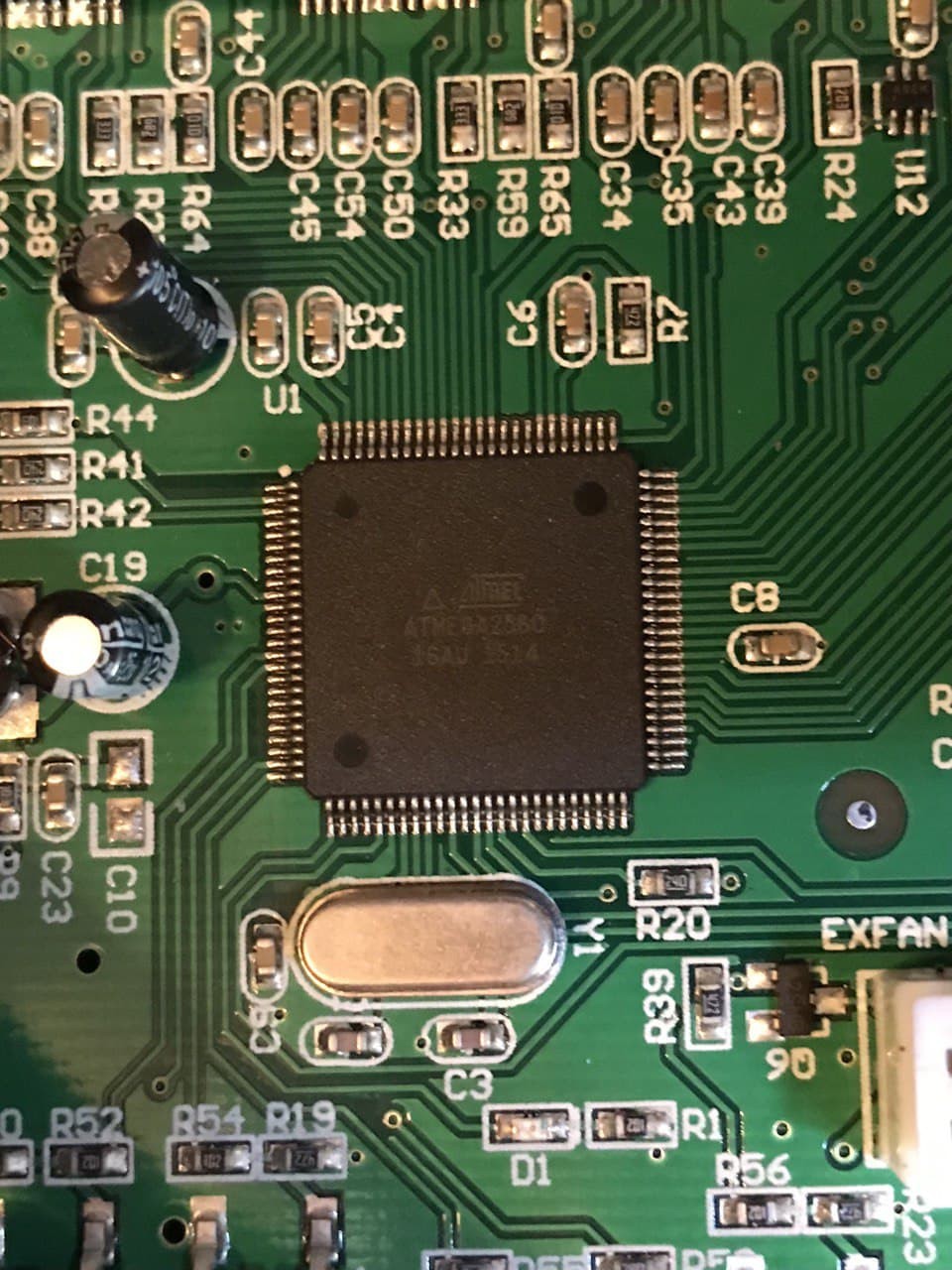

My Malyan M180 is a bit special in that it has a different extruder and was running full blown Marlin 2.0.x before. So lucky for me, I already did all the hard work figuring out what pins are being used and how the temperatures are being measured.

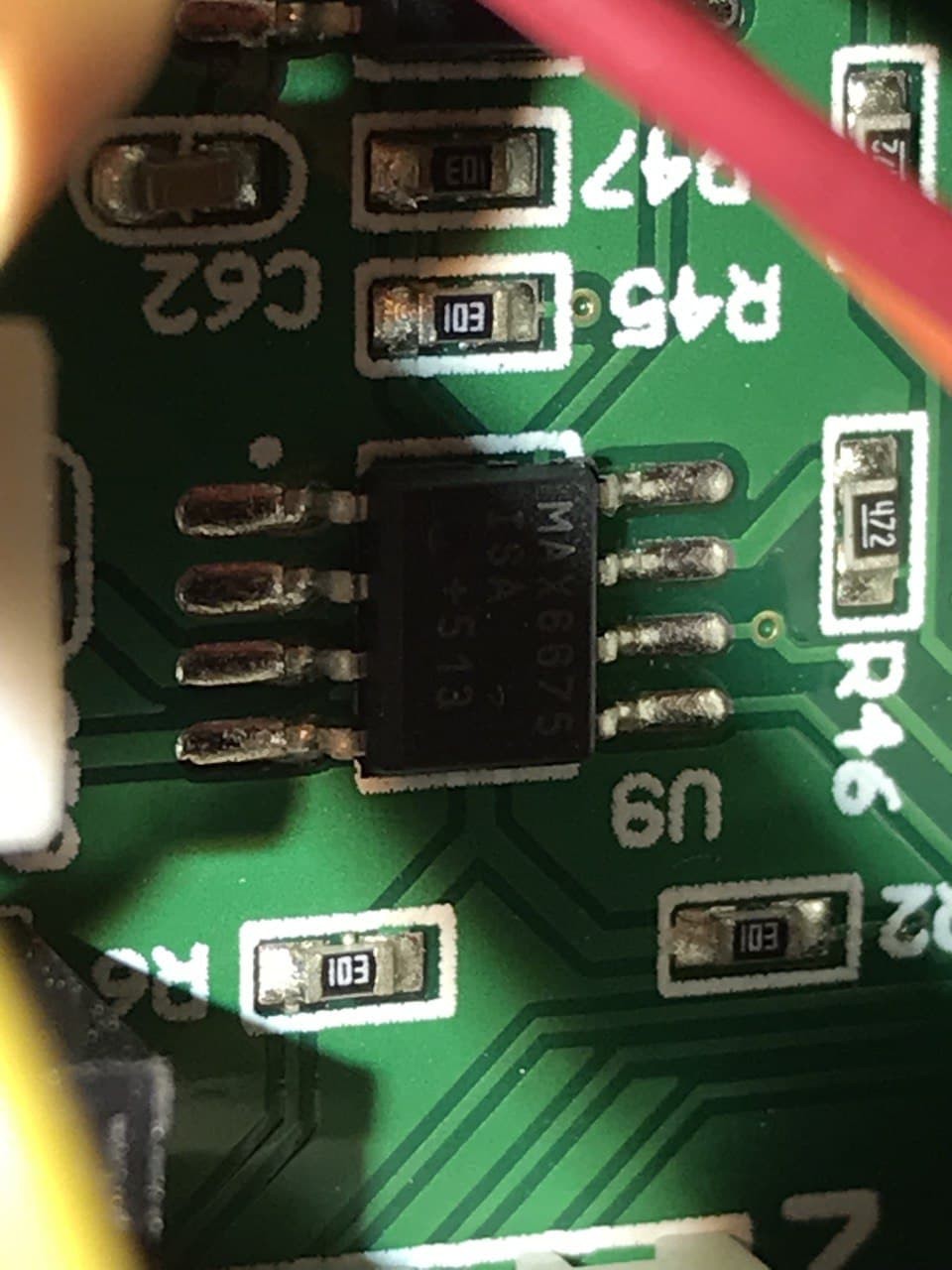

For the temperatures specifically, I have a (not supported) 10k thermistor for the bed temperature and a MAX6675 thermocouple sensor IC (very different idea from a thermistor) for the hotend which is read via SPI.

Two issues: How do I get the 10k thermistor understood by Klipper and how can I make an SPI interface work that only needs three wires in this case: SCK, MISO, CS and not MOSI. However, Klipper requires the definition of a MOSI pin when the SPI port is used. I needed to find an unused pin on the board so I looked at the picture:

To be honest, I took a wild guess and just chose PB2 aka Digital Pin 51, which is Hardware SPI MOSI. I thought, when Malyan goes through the trouble of using software SPI, the hardware SPI is likely unused.

With the extruder temperature done, I looked at how to integrate the 10k thermistor.

Turns out there is a way to add custom thermistors to Klipper with ease. I dug through the Marlin implementation and found how they define this general purpose thermistor (which really only needs to show a reasonable temperature for the bed and doesn't have to be precise at all).

[thermistor M180_10K]

temperature1: 25

resistance1: 10000

beta: 3950With that, the thermistor was also done! Thank you Marlin for the reference!

Here is my entire config file for people who want to see what goes into this. I found it surprising that Klipper doesn't use Arduino pin definitions but since it's designed to run on pretty much everything, maybe it's just the logical next step.

# Configuration for: Malyan M180 with Hemera Hotend Modification

# Configuration pins are taken from Marlin - Malyan M180 pin configuration

# Author: Timo Birnschein (timo.birnschein@microforge.de)

# Version: 0.1

# Date: 2021/12/18

[stepper_x]

step_pin: PF1

dir_pin: PF0

enable_pin: !PF2

microsteps: 16

rotation_distance: 34 # 17 teeth * 2mm belt pitch

endstop_pin: ^PL1

position_endstop: 0

position_max: 250

homing_speed: 20.0

[stepper_y]

step_pin: PF5

dir_pin: PF4

enable_pin: !PF6

microsteps: 16

rotation_distance: 34

endstop_pin: ^PL3

position_endstop: 0

position_max: 160

homing_speed: 20.0

[stepper_z]

step_pin: PK1

dir_pin: !PK0

enable_pin: !PK2

microsteps: 16

rotation_distance: 2

endstop_pin: ^PL7

position_endstop: 0

position_max: 165

homing_speed: 8.0

[extruder]

step_pin: PA3

dir_pin: PA2

enable_pin: !PA4

microsteps: 16

rotation_distance: 7.6

nozzle_diameter: 0.400

filament_diameter: 1.75

heater_pin: PH3

sensor_type: MAX6675

sensor_pin: PE3

spi_software_sclk_pin: PE2

spi_software_miso_pin: PE5

spi_software_mosi_pin: PB2

control: pid

pid_Kp: 22.2

pid_Ki: 1.08

pid_Kd: 114

min_temp: 0

max_temp: 320

[thermistor M180_10K]

temperature1: 25

resistance1: 10000

beta: 3950

[heater_bed]

heater_pin: PL4

sensor_type: M180_10K

sensor_pin: PK7

control: watermark

min_temp: 0

max_temp: 110

[fan]

pin: PH4

max_power: 1.0

shutdown_speed: 0

off_below: 0.20

[mcu]

serial: /dev/serial/by-id/usb-1a86_USB2.0-Serial-if00-port0

[printer]

kinematics: cartesian

max_velocity: 200

max_accel: 3000

max_z_velocity: 10

max_z_accel: 30

Overall, the entire process including setting up a completely new Octoprint installation took about 9 full hours. However, I didn't even expect to get this to work today, so I can say that I am extremely happy with the current state.

Next up, I want to get Input Shaper to work and will order an accelerometer from Amazon for this purpose. The rest is really just a tuning exercise get everything dialed in properly.

My first test print was already a huge success. WAY faster than before and definitely nicer to look at for the speed the part popped out.

Timo Birnschein

Timo Birnschein

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.