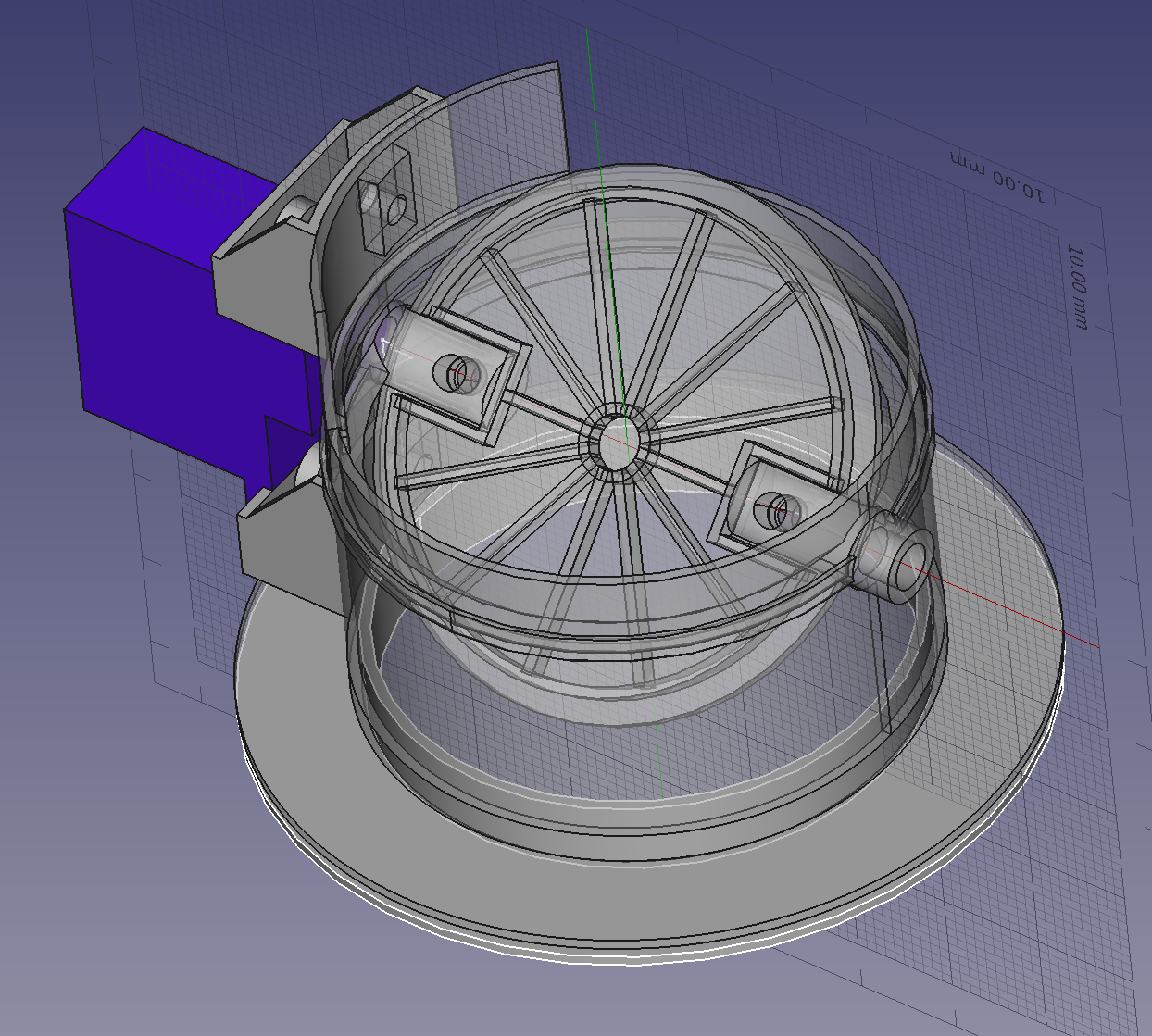

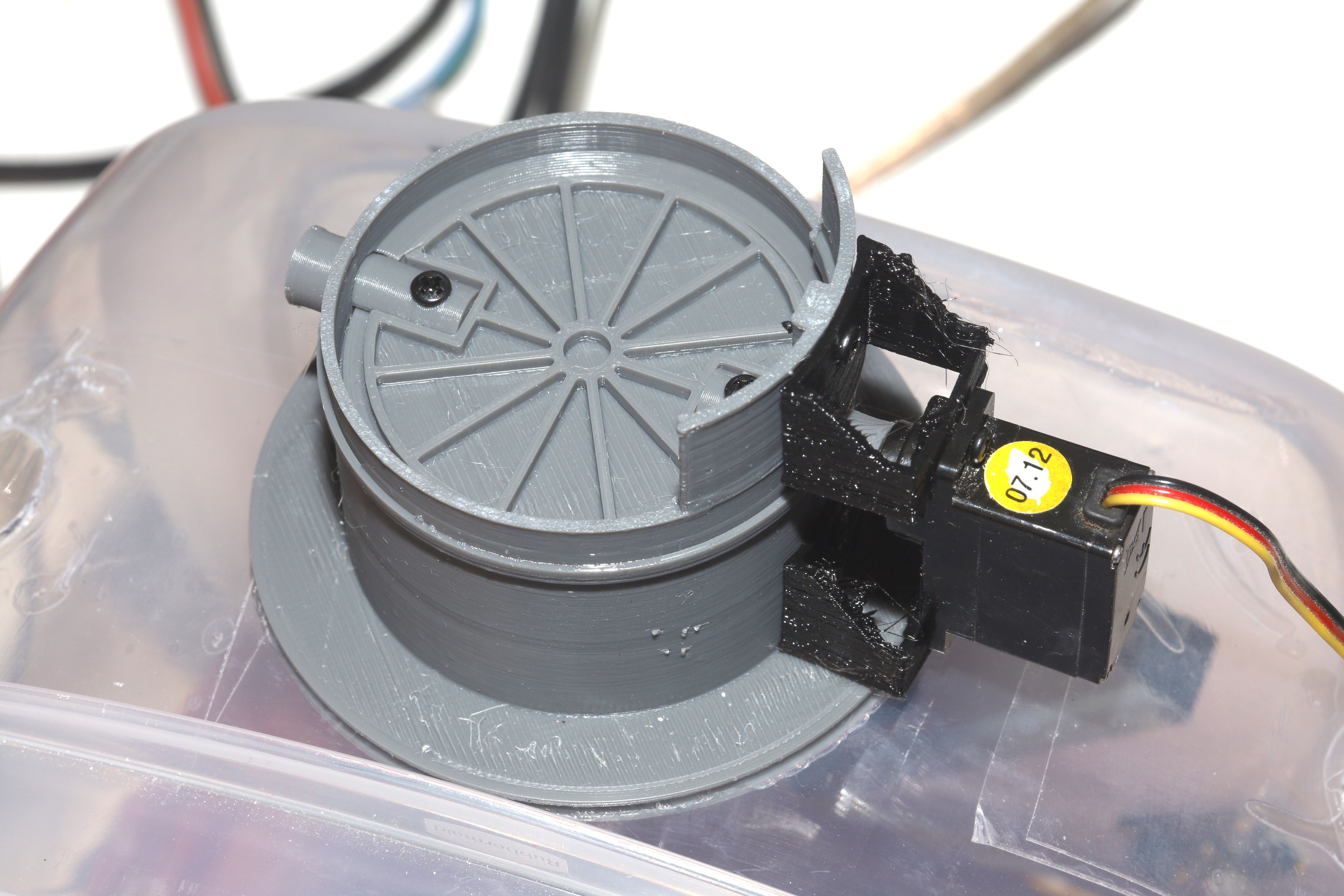

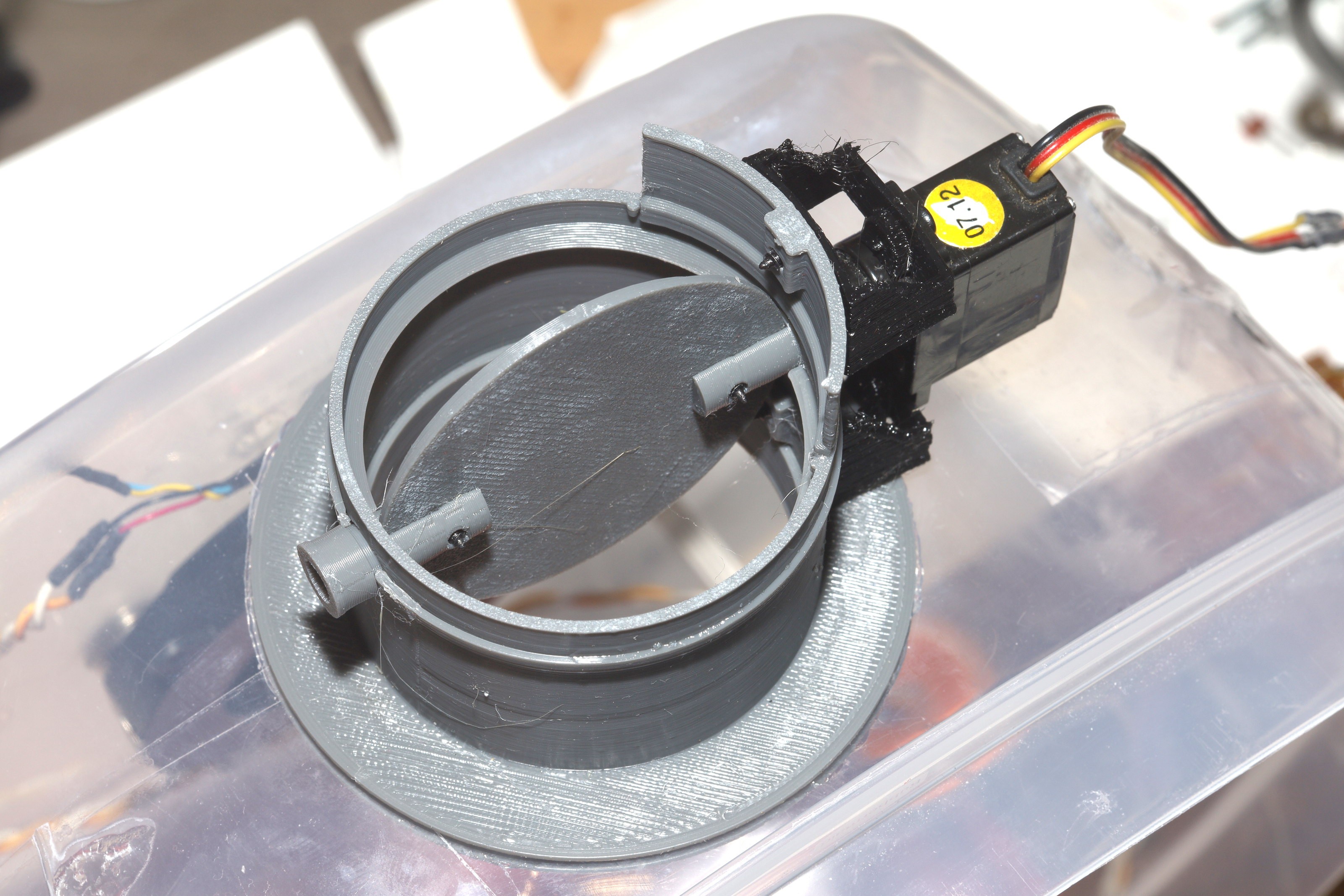

A solid week of banging on CAD models yielded a butterfly valve.

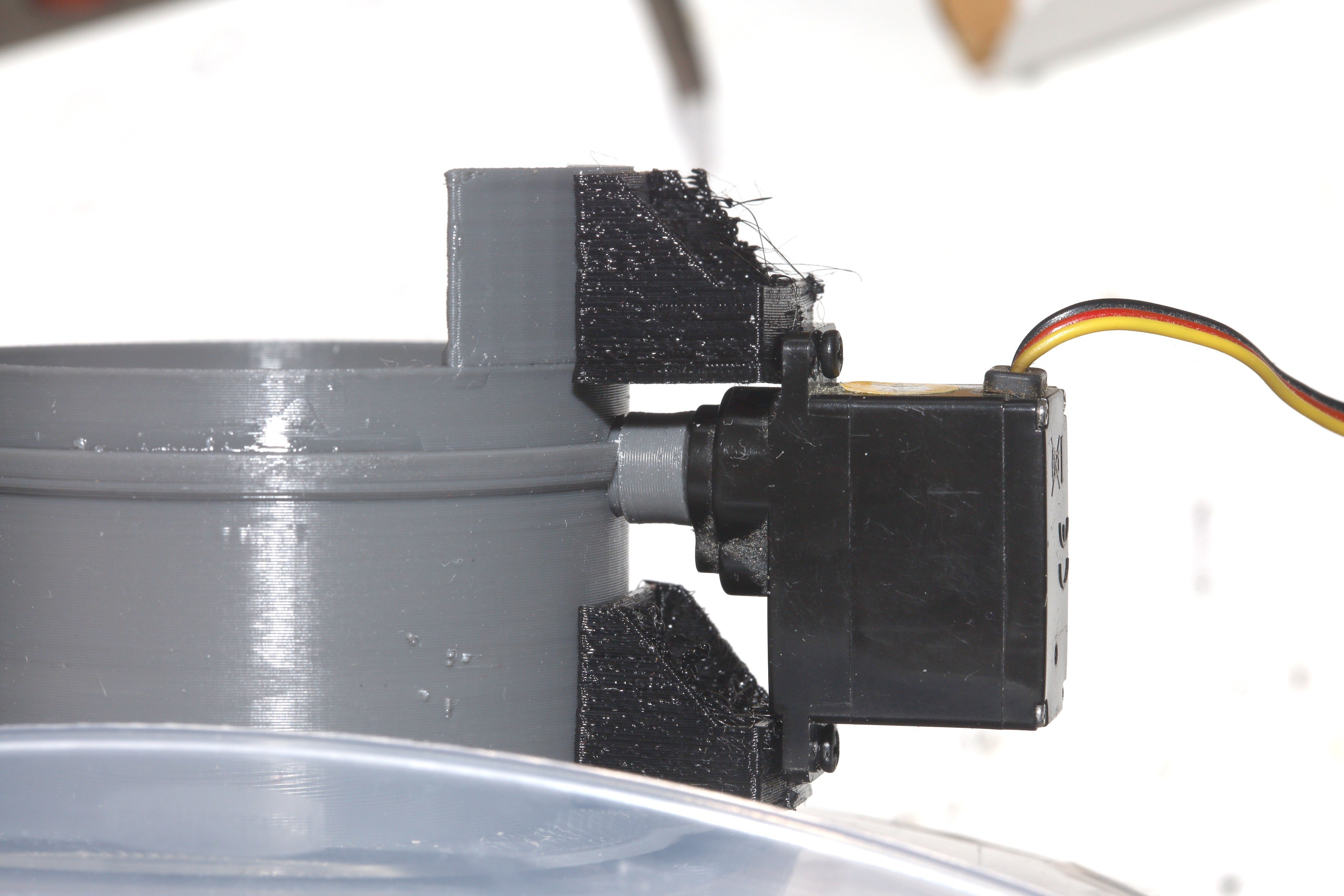

This was the 1st to directly couple a PLA shaft to a servo shaft. To start with, it uses friction. It could resort to CA glue. To achieve a static pressure on the valve, it relies on the servo supports applying a static spring pressure on the torque tube. The servo powers off after 5 seconds to avoid wearing out the motor. There's no sensor for valve position, so it could get stuck in 1 position.

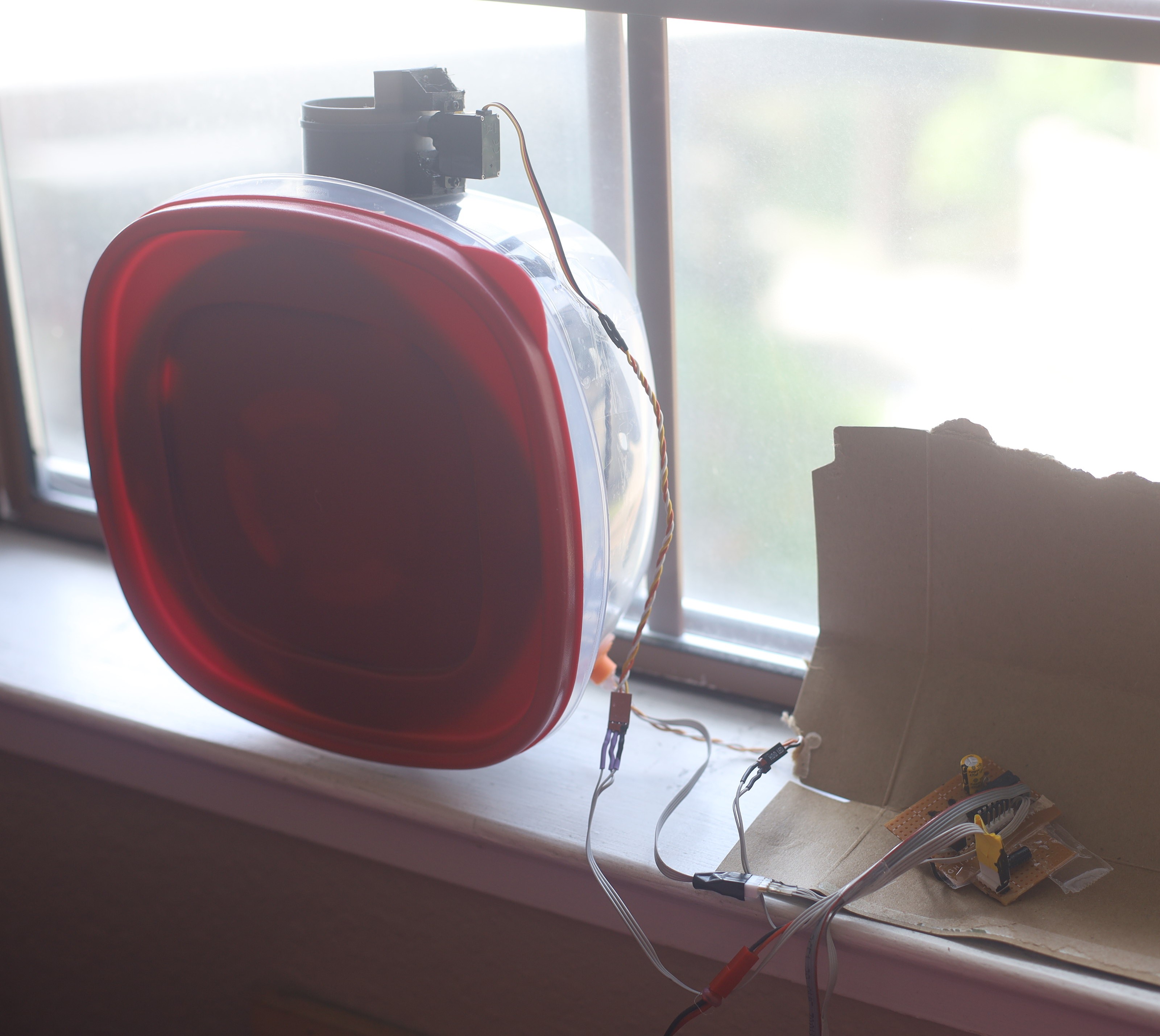

The latest idea was a container with just 1 big valve. The inside air should get hot during the day. When the valve opens, the hot air leaves & the cold air enters. At night when the container is colder than ambient, no air is replaced. The valve is not as air tight as the former tubes.

The board got converted back to 5V, a MOSFET got taken out, a PWM driver got put in.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.