Using EagleCAD to generate the Inverted PS file and using PS2PDF online converter to get PDF to print on transparency. We want it transparent in the areas we want copper.

Samsung M2830DW Laser Printer for printing on transparencies. In the print settings, I use 100% contrast and brightness. I also print twice and tape the two copies together in order to ensure light is fully blocked if one doesn't print 100% black in the proper areas.

Apollo Laser Printer Transparency Film (VCG7060E)

Vantiyaus Photosensitive (30cmx500cm/1ftx16.5ft) PCB Photosensitive Dry Film for Circuit Production Photoresist

AMARS Black LED Lights Strip for Decoration, DC12V 24W 5050 - Using 54 LEDs at 12V

5 1/2" Height of UV LEDs from table

Using a clipboard, glass, and 4 paper clamps to secure transparency to photosensitive film coated board

Scotch TL902 Laminator for laminating the photoresistive film to both sides of the board, set on 5mm and running through 8 times, flipping sides every time

8 minutes of UV exposure each side

Using 1/2 teaspoon of Soda Ash (sodium carbonate) along with cup and a half of warm water to develop the photoresist. Gentle agitation of both sides with a modified toothbrush. Unexposed film starts coming off at the 4 minute mark and with some scrubing the process is complete at 7 minutes. Scratching in the bare copper areas to see if film remains where it shouldn't does help. I expose again for a few minutes if the traces aren't nice and dark.

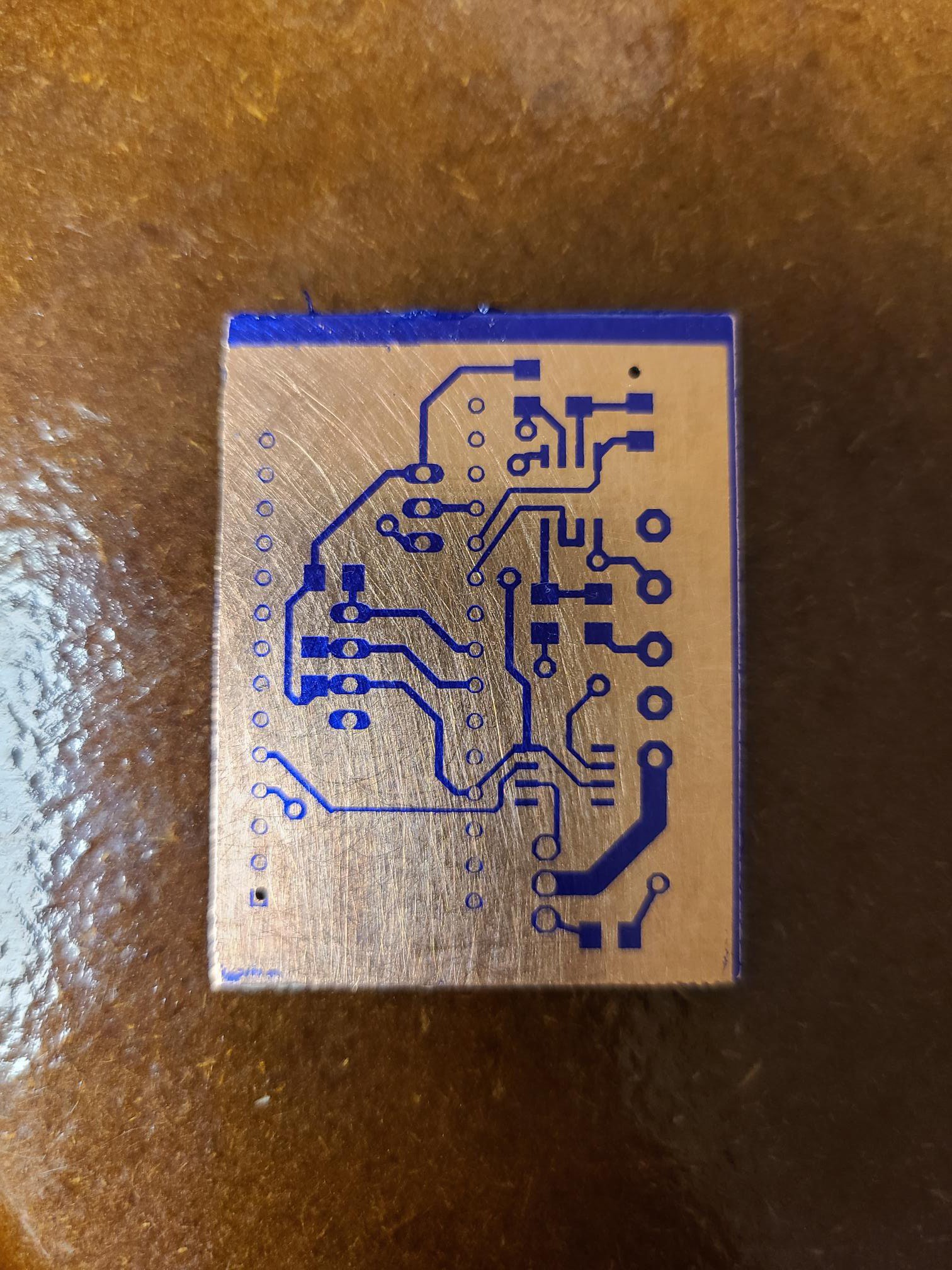

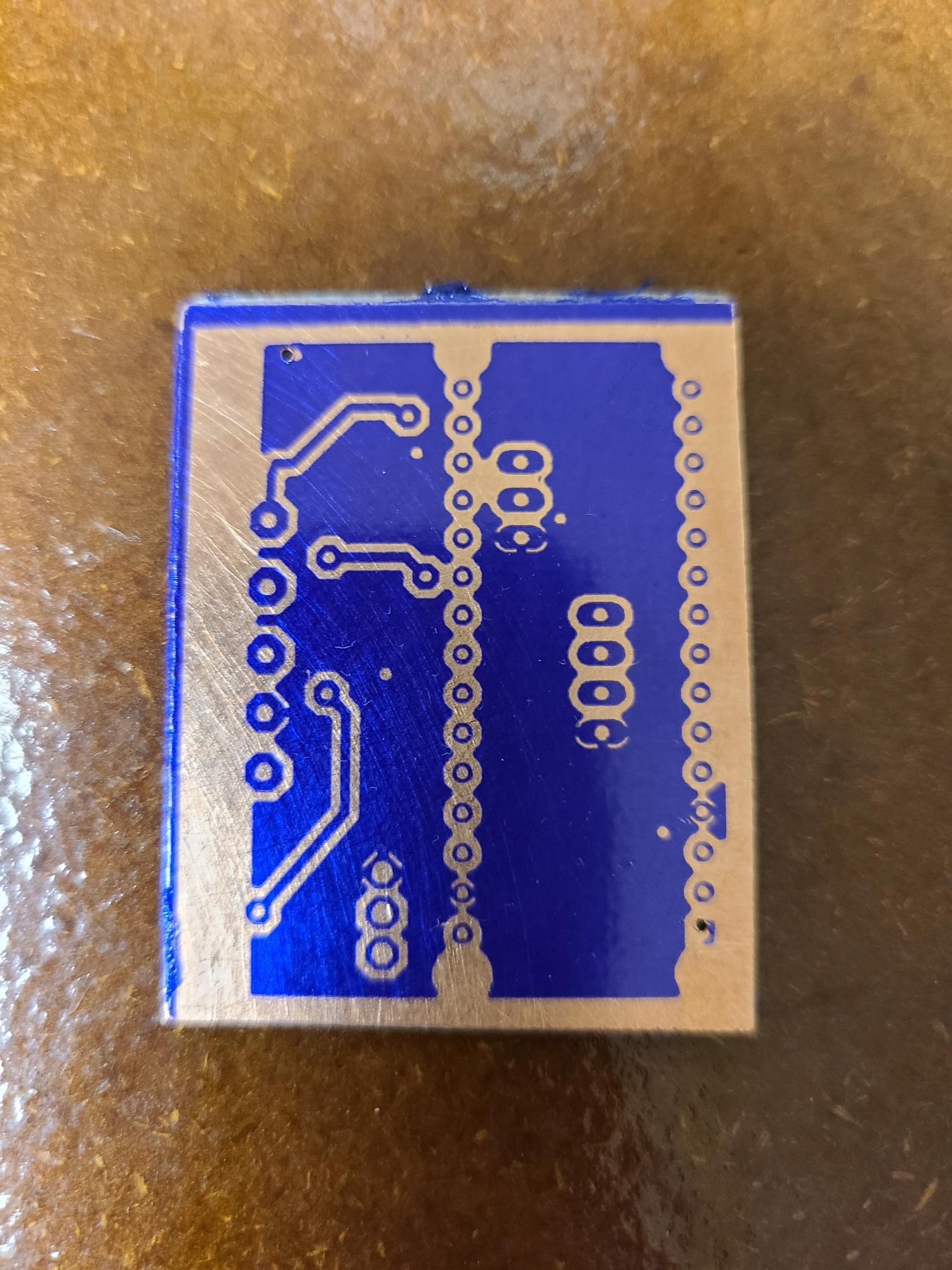

Results can be seen below, before Ferric Chloride etching. I am happy with the results, all traces are there and should etch well. For reference, the smallest traces are .016" (.4mm). As a side note, I usually use .024" (.6mm) isolation on polygons to stay out of trouble. With these results I could probably drop that to .016" (.4mm) Next log will post results from etching.

KSUdoubleE

KSUdoubleE

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.