OK, let's kick it off. Welcome to the Hack Chat, I'm Dan, Dusan and I will be moderating today as we welcome Amy Qian to the chat. We're going to talk all about compliant mechanisms and flexures, and I assume a little about bendy straws too ;-)

OK, let's kick it off. Welcome to the Hack Chat, I'm Dan, Dusan and I will be moderating today as we welcome Amy Qian to the chat. We're going to talk all about compliant mechanisms and flexures, and I assume a little about bendy straws too ;-)

woo!

woo!

Amy, what is it about these mechanism that you find interesting?

Amy, what is it about these mechanism that you find interesting?

Aside from being very satisfying when they work, I think they are pretty easy to make, sometimes more so that "traditional" mechanisms

Aside from being very satisfying when they work, I think they are pretty easy to make, sometimes more so that "traditional" mechanisms

they aren't appropriate for all cases when you want a mechanism. But there are lots of cases where they shine.

they aren't appropriate for all cases when you want a mechanism. But there are lots of cases where they shine.

![]() Hi @Amy Qian ,

Hi @Amy Qian ,

![]() How do you start to ideate for mechanisms ?

How do you start to ideate for mechanisms ?

HellO!

HellO!

I guess I got ahead of myself there. I should have started off with the "tell us a little about yourself" thing

I guess I got ahead of myself there. I should have started off with the "tell us a little about yourself" thing

oh hmm, there's usually some day dreaming and doodling involved.

oh hmm, there's usually some day dreaming and doodling involved.

haha, sure thing

haha, sure thing

![]() Hi everybody

Hi everybody

I am a mechanical engineer by training and mostly by profession, too. I like to tinker a lot (like lots of folks here). Mostly mechanical, although slowly crossing into more electrical things. A lot of my projects are shop improvements, shop tools, furniture, random things around the house, stuff for my car which is a small camper van.

I am a mechanical engineer by training and mostly by profession, too. I like to tinker a lot (like lots of folks here). Mostly mechanical, although slowly crossing into more electrical things. A lot of my projects are shop improvements, shop tools, furniture, random things around the house, stuff for my car which is a small camper van.

![]() When I design compliant mechanisms, I'm usually trapped betrween "Ok, do it right, calculate everything and make a proper simulation" and "Just draw something, print it, and it might work without thinking to much about it".

When I design compliant mechanisms, I'm usually trapped betrween "Ok, do it right, calculate everything and make a proper simulation" and "Just draw something, print it, and it might work without thinking to much about it".

So what is your way? Do you make proper engineering in this cases, or more try and error?

related: How do you prototype?

related: How do you prototype?

Was there anything in your ME training that covered compliant mechanisms? IOW, was there a "Compliant Mechanisms 201" course?

Was there anything in your ME training that covered compliant mechanisms? IOW, was there a "Compliant Mechanisms 201" course?

I'm definitely Team Trial and Error. I'm almost never designing mechanisms that operate on the edge of material properties, so it's pretty low risk. Also, most of my flexures are laser cut, so that is pretty quick to iterate

I'm definitely Team Trial and Error. I'm almost never designing mechanisms that operate on the edge of material properties, so it's pretty low risk. Also, most of my flexures are laser cut, so that is pretty quick to iterate

My all-time favorite compliant mechanism https://openflexure.org/ that achieves sub-micron scale XYZ stages.

My all-time favorite compliant mechanism https://openflexure.org/ that achieves sub-micron scale XYZ stages.

https://openflexure.gitlab.io/microscope-handbook/learn-about-the-project/publications.html might give insight in to more scientific process.

do you use polypropelene?

do you use polypropelene?

The heart of compliant mechanisms is beam bending! Which is a heavily covered topic in most mechanical engineering programs (think stress-strain curves)

The heart of compliant mechanisms is beam bending! Which is a heavily covered topic in most mechanical engineering programs (think stress-strain curves)

As for how to turn bending beams into mechanisms, there's lots of great examples out there to build off of. But also, sky's the limit, let your creative juices flow.

As for how to turn bending beams into mechanisms, there's lots of great examples out there to build off of. But also, sky's the limit, let your creative juices flow.

@Amy Qian thanks for sharing and your youtube channel, liked some vids and subbed! do you have any suggestions of resources that break down the different effects/areas necessary to design flexure mechanisms? for example, if I had an ideas like yours, "I want a 7-option infinite rotation device [wheel], only moves one way [ratchet and pawl], two binary switches, and the switches to reset upon a single rotation of the device", how would i determine the different components and design, let alone thicknesses based on material type, and durability/determining minimum number of times each piece can be flexed?

@Amy Qian thanks for sharing and your youtube channel, liked some vids and subbed! do you have any suggestions of resources that break down the different effects/areas necessary to design flexure mechanisms? for example, if I had an ideas like yours, "I want a 7-option infinite rotation device [wheel], only moves one way [ratchet and pawl], two binary switches, and the switches to reset upon a single rotation of the device", how would i determine the different components and design, let alone thicknesses based on material type, and durability/determining minimum number of times each piece can be flexed?

I mostly prototype in Delrin or Acetal (both really similar, I think Delrin is a specific type of Acetal) plastic. It laser cuts really well and is not brittle like acrylic. Polypropelene is really melty on the laser cutter, hard to get good edges.

I mostly prototype in Delrin or Acetal (both really similar, I think Delrin is a specific type of Acetal) plastic. It laser cuts really well and is not brittle like acrylic. Polypropelene is really melty on the laser cutter, hard to get good edges.

Also 3D printing in ABS is great too. I've really only used ABS and PLA. PLA gets too brittle over time, but fine for iterating on designs.

Also 3D printing in ABS is great too. I've really only used ABS and PLA. PLA gets too brittle over time, but fine for iterating on designs.

Did you have any luck with mechanisms laser cut from ply wood?

Did you have any luck with mechanisms laser cut from ply wood?

not really, but that's not to say that wood can't be used for flexures. You just have to respect the grain direction of the wood. Maybe that's an added design constraint, or maybe in some cases a feature, depends on your application. A wooden bow (and arrow) is an example where wood is being used for its compliant properties.

not really, but that's not to say that wood can't be used for flexures. You just have to respect the grain direction of the wood. Maybe that's an added design constraint, or maybe in some cases a feature, depends on your application. A wooden bow (and arrow) is an example where wood is being used for its compliant properties.

Plywood is usually made from layers of wood where the grain of alternating layers is perpendicular. This has lots of great benefits. But when it comes to making a compliant member, it likely means at least half your wood fibers are not oriented in an optimal direction.

Plywood is usually made from layers of wood where the grain of alternating layers is perpendicular. This has lots of great benefits. But when it comes to making a compliant member, it likely means at least half your wood fibers are not oriented in an optimal direction.

![]() Do you know this book: https://onlinelibrary.wiley.com/doi/book/10.1002/9781118516485

Do you know this book: https://onlinelibrary.wiley.com/doi/book/10.1002/9781118516485

I use it quite a lot. Do you have other literature on this topic you find usefull?

The issue I had with ply wood was creep where permanently loaded parts would give over time and loose their force and/or form. Did you run into similar issues with plastics?

The issue I had with ply wood was creep where permanently loaded parts would give over time and loose their force and/or form. Did you run into similar issues with plastics?

@samy kamkar hi! Here is MIT's OCW on the course that goes into beam bending, stress/strain, fatigue, etc. https://dspace.mit.edu/handle/1721.1/39140 But I realize that courses like this may also contain lots of other info that aren't directly helpful to your design challenge. It is actually on my list to make some kind of fundamentals-of-flexure-design video!

@samy kamkar hi! Here is MIT's OCW on the course that goes into beam bending, stress/strain, fatigue, etc. https://dspace.mit.edu/handle/1721.1/39140 But I realize that courses like this may also contain lots of other info that aren't directly helpful to your design challenge. It is actually on my list to make some kind of fundamentals-of-flexure-design video!

Do you think it'd be feasible to make a compliant mechanism from a PCB (FR4)? They're so cheap to get manufactured these days that it seems like it could be an amazing option for those of us without access to a laser cutter (if it works). I recently came across http://www.cy384.com/blog/flex-pcbs.html which has some awesome examples of non-repeated FR4 bending out of the plane, but haven't seen anything on repeated bending or bending in the plane (maybe because it doesn't work well?)

Do you think it'd be feasible to make a compliant mechanism from a PCB (FR4)? They're so cheap to get manufactured these days that it seems like it could be an amazing option for those of us without access to a laser cutter (if it works). I recently came across http://www.cy384.com/blog/flex-pcbs.html which has some awesome examples of non-repeated FR4 bending out of the plane, but haven't seen anything on repeated bending or bending in the plane (maybe because it doesn't work well?)

Hello Amy! thanks for being here! How do you determine how many times a mechanism can bend / longevity and how brittle over time it will become? Also have you ever tried anything in SLA printing? It's tough with standard resin that doesn't flex much but even then it works surprisingly well!

Hello Amy! thanks for being here! How do you determine how many times a mechanism can bend / longevity and how brittle over time it will become? Also have you ever tried anything in SLA printing? It's tough with standard resin that doesn't flex much but even then it works surprisingly well!

Have you tried making mechanisms that deform in two directions (for example to make an alternating push-push function?) Have enjoyed your videos, thanks for providing them!

Have you tried making mechanisms that deform in two directions (for example to make an alternating push-push function?) Have enjoyed your videos, thanks for providing them!

@Evilamblonyx yes! I have that book! it is great. Prof Larry Howell (one of the authors) heads a university research group I think. Their website is also full of tons of useful resources and fun videos

@Evilamblonyx yes! I have that book! it is great. Prof Larry Howell (one of the authors) heads a university research group I think. Their website is also full of tons of useful resources and fun videos

![]() Hi Amy, do you have any tips for scaling up or down the size of compliant mechanisms? Do you always prototype at the same scale as your intended designs or start with another size that makes it easier to iterate?

Hi Amy, do you have any tips for scaling up or down the size of compliant mechanisms? Do you always prototype at the same scale as your intended designs or start with another size that makes it easier to iterate?

thanks!

thanks!

@Scott Bezek I am SUPER excited to explore flexures in PCBs. I actually just kicked off my first PCB ever last week, ridiculously simple, but we all gotta start somewhere. I would imagine that FR4 should be for lots of cycles, and that in-plane cycling is possible if you cut a narrow enough feature for bending. But I imagine the copper traces don't love being stretched and compressed a lot? Again, it's all about how much you want to stretch/compress stuff balanced with how many times you want to cycle.

@Scott Bezek I am SUPER excited to explore flexures in PCBs. I actually just kicked off my first PCB ever last week, ridiculously simple, but we all gotta start somewhere. I would imagine that FR4 should be for lots of cycles, and that in-plane cycling is possible if you cut a narrow enough feature for bending. But I imagine the copper traces don't love being stretched and compressed a lot? Again, it's all about how much you want to stretch/compress stuff balanced with how many times you want to cycle.

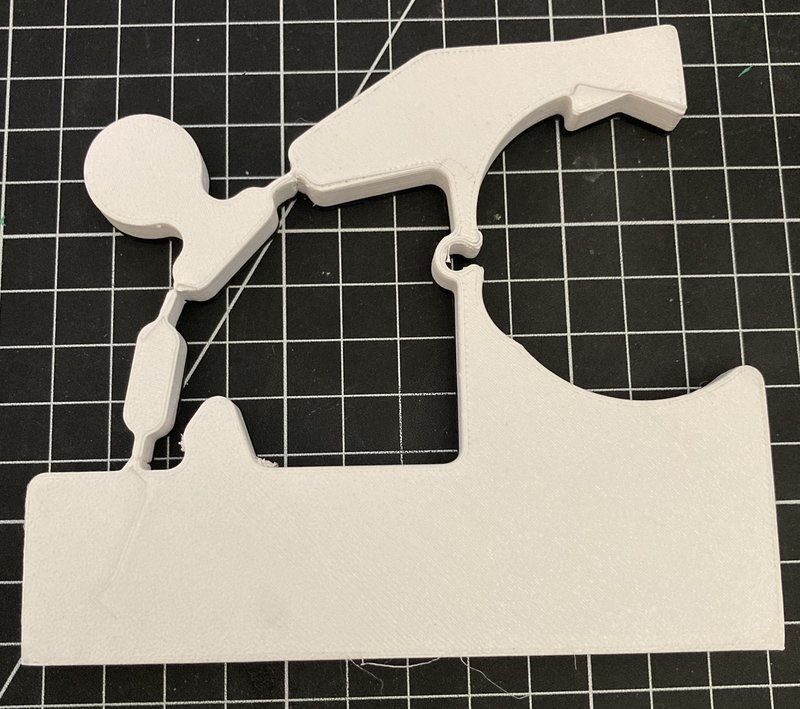

I would love critique of this bistable compliant clamp

I would love critique of this bistable compliant clamp

![]() Silicon is pretty interesting for its bending properties. Extreme fatigue life. Very common in MEMS devices.

Silicon is pretty interesting for its bending properties. Extreme fatigue life. Very common in MEMS devices.

Saw a couple questions about the longevity of a flexure - "fatigue limit" is a good search term for that. https://en.wikipedia.org/wiki/Fatigue_limit This is often mostly applied to metals though, because plastics make terrible springs for a few reasons. Even on the first graph of this link you can see that steel has an endurance limit where below a certain stress level, infinite cycles are possible. That's why you see lots of springs made from steel and none (good ones at least) from aluminum

Saw a couple questions about the longevity of a flexure - "fatigue limit" is a good search term for that. https://en.wikipedia.org/wiki/Fatigue_limit This is often mostly applied to metals though, because plastics make terrible springs for a few reasons. Even on the first graph of this link you can see that steel has an endurance limit where below a certain stress level, infinite cycles are possible. That's why you see lots of springs made from steel and none (good ones at least) from aluminum

Tell that to the plastic slinky manufacturers

Tell that to the plastic slinky manufacturers

@Ethan Waldo the new plastic ones are so durable though! My kids haven't snapped one yet

@Ethan Waldo the new plastic ones are so durable though! My kids haven't snapped one yet

![]() Thought. Hybrid manufacturing. 3d-print rigid parts, with "pockets". Cast silicone rubber into the pockets. Cut off the pockets' lining.

Thought. Hybrid manufacturing. 3d-print rigid parts, with "pockets". Cast silicone rubber into the pockets. Cut off the pockets' lining.

I apologize for the audio on this video, but here's the talk I gave at Hackaday Supercon in 2019 about flexures. Couple fun links in the description

I apologize for the audio on this video, but here's the talk I gave at Hackaday Supercon in 2019 about flexures. Couple fun links in the description

@Chris Thompson Need a link because the plastic ones I've seen work terribly and my kids bent the metal ones out of commission soon after getting them.

@Chris Thompson Need a link because the plastic ones I've seen work terribly and my kids bent the metal ones out of commission soon after getting them.

@Peter Wright I usually iterate in my intended scale because when you bend a beam, the peak stress in the material, force to deflect, and beam thickness are all coupled. But I will sometimes just focus on a chunk of the mechanism

@Peter Wright I usually iterate in my intended scale because when you bend a beam, the peak stress in the material, force to deflect, and beam thickness are all coupled. But I will sometimes just focus on a chunk of the mechanism

@Ethan Waldo I fell like we got a jumbo one 8" dia. down the shore. NJ

@Ethan Waldo I fell like we got a jumbo one 8" dia. down the shore. NJ

That really narrows it down :P

That really narrows it down :P

not sure what critique I can really offer for that bistable mechanism @Chris Thompson. I want to click it though. click click click

not sure what critique I can really offer for that bistable mechanism @Chris Thompson. I want to click it though. click click click

![]() Thanks Amy!

Thanks Amy!

@Amy Qian Thanks. It's fun to snap it closed around the right diameter. this was made for 50mm. I was thinking of replacing toggle clamps in welding jigs.

@Amy Qian Thanks. It's fun to snap it closed around the right diameter. this was made for 50mm. I was thinking of replacing toggle clamps in welding jigs.

Nice idea. You can never have enough clamps and being able to 3d print them is boss.

Nice idea. You can never have enough clamps and being able to 3d print them is boss.

![]() @Chris Thompson you want to clamp something like a tube with the round part on the right, correct?

@Chris Thompson you want to clamp something like a tube with the round part on the right, correct?

Is your mechanism somehow not working as intendet? If I should guess, I would think that it has not as much holding force as you would like it to have, or is something else wrong?

ooh very cool. Post a video somewhere, will watch. I think mechanisms like that are a great example of how compliant mechanisms can be a better solution that traditional mechanisms (rotating pins, etc). In this case you need a limited travel and you can get it out of just one piece!

ooh very cool. Post a video somewhere, will watch. I think mechanisms like that are a great example of how compliant mechanisms can be a better solution that traditional mechanisms (rotating pins, etc). In this case you need a limited travel and you can get it out of just one piece!

![]() @Chris Thompson cool mechanism. The bending elements on the left might be a little too thick? Looks like they cracked a bit at the base

@Chris Thompson cool mechanism. The bending elements on the left might be a little too thick? Looks like they cracked a bit at the base

oh ya, good catch @Peter Wright just realized I could make the image bigger.

oh ya, good catch @Peter Wright just realized I could make the image bigger.

For mechanisms like this, it might be fun to try printing the non-bendy parts and then using a length of spring steel wire to form all the bendy bits. then you are less constrained by what will 3D print well

For mechanisms like this, it might be fun to try printing the non-bendy parts and then using a length of spring steel wire to form all the bendy bits. then you are less constrained by what will 3D print well

Thanks, the material is PETG and has shown it's limited "fatigue limit" Here it is snapped around a 500 bottle.

Thanks, the material is PETG and has shown it's limited "fatigue limit" Here it is snapped around a 500 bottle.

@Evilamblonyx I can increase the clamping force by closing the diameter, or thickening the whole flexure.

Spring steel inserts would be a great idea. I'll dig into Mcmaster Carr

Spring steel inserts would be a great idea. I'll dig into Mcmaster Carr

Maybe you can also play with just how much travel you actually need on the jaw. If the parts you are clamping are super consistent, maybe that can save all your flexures a lot of travel.

Maybe you can also play with just how much travel you actually need on the jaw. If the parts you are clamping are super consistent, maybe that can save all your flexures a lot of travel.

Also might help you up your clamping force.

Also might help you up your clamping force.

ahh

ahh

![]() @Chris Thompson I have made realy good experiences with PA (Nylon) for 3D Printed compliant mechanisms. But PP works also really well, but has a much lower tensile strength.

@Chris Thompson I have made realy good experiences with PA (Nylon) for 3D Printed compliant mechanisms. But PP works also really well, but has a much lower tensile strength.

PETG is in my experience not the best choise for this job

May be a band of spring steel like from a constant force spring or a tape measure is better than a wire. You could roll up the ends and slip it into a hole with a slit.

May be a band of spring steel like from a constant force spring or a tape measure is better than a wire. You could roll up the ends and slip it into a hole with a slit.

How would you make sure it didn't move around or deform the plastic?

How would you make sure it didn't move around or deform the plastic?

tape measure is a great idea, you could even drill holes in it to constrain it to the plastic. And it's wider so distributing a forces against the plastic more evenly.

tape measure is a great idea, you could even drill holes in it to constrain it to the plastic. And it's wider so distributing a forces against the plastic more evenly.

![]() Another thought. Print from elastomer, and then put in rigid inserts, or in-situ cast epoxy into prepared voids.

Another thought. Print from elastomer, and then put in rigid inserts, or in-situ cast epoxy into prepared voids.

hmm, I would need to do some actual prototyping to work it out, but maybe you actually want the compression forces going through all the plastic chunks, and the spring steel or tape measure is just for keeping everything the same distance apart.

hmm, I would need to do some actual prototyping to work it out, but maybe you actually want the compression forces going through all the plastic chunks, and the spring steel or tape measure is just for keeping everything the same distance apart.

I'd try to basically roll the ends of the strip into a spring pin and press that into a hole.

I'd try to basically roll the ends of the strip into a spring pin and press that into a hole.

![]() Piano wires. Another springy material.

Piano wires. Another springy material.

Dan Gelbart has a good video on flexures, and he mixes nitinol springs with sheet metal frames:

Dan Gelbart has a good video on flexures, and he mixes nitinol springs with sheet metal frames:

https://www.youtube.com/watch?v=PaypcVFPs48

He's on a different level than the average hobbyist, but still a lot of good tips

He's on a different level than the average hobbyist, but still a lot of good tips

![]() @Dan Maloney I can highly recommend this video, in fact all of his videos are fantastic.

@Dan Maloney I can highly recommend this video, in fact all of his videos are fantastic.

+1 on that!

+1 on that!

so great!

so great!

And now I see that our time is about up. Everyone's welcome to stay and continue the chat, but for now we'll just say our official "Thanks!" to Amy for dropping by today. Good chat, I really enjoyed it. And thanks to everyone for participating -- good questions!

And now I see that our time is about up. Everyone's welcome to stay and continue the chat, but for now we'll just say our official "Thanks!" to Amy for dropping by today. Good chat, I really enjoyed it. And thanks to everyone for participating -- good questions!

Thank you!

Thank you!

Thanks Amy!

Thanks Amy!

Thanks, Dan, Dusan, and team for organizing!

Thanks, Dan, Dusan, and team for organizing!

Thanks @Amy Qian

Thanks @Amy Qian

![]() I designed a 3D printed button (for the prusa contest) with a compliant mechanism ratchet, that could change its color by turning it. Is just a toy to fiddle with, but it turned our really nice.

I designed a 3D printed button (for the prusa contest) with a compliant mechanism ratchet, that could change its color by turning it. Is just a toy to fiddle with, but it turned our really nice.

Would you like to see it and is it appropriate to poste the link here?

![]() Thank you so much @Amy Qian

Thank you so much @Amy Qian

I wanna see it, post the link @Evilamblonyx !

I wanna see it, post the link @Evilamblonyx !

https://www.prusaprinters.org/prints/124195-color-click-button

We clearly should do a show your compliant mechanism section. May be after all other questions are done.

We clearly should do a show your compliant mechanism section. May be after all other questions are done.

Sounds good, go ahead. I'll wait a bit to pull the transcript

Sounds good, go ahead. I'll wait a bit to pull the transcript

Thanks @Amy Qian

Thanks @Amy Qian

Ok, I have some latches at the bottom half of https://hackaday.io/project/10649/log/177879-new-boxes-for-your-electronics-projects

Ok, I have some latches at the bottom half of https://hackaday.io/project/10649/log/177879-new-boxes-for-your-electronics-projects

They work reasonably well even made out of plywood.

looks cool, @Florian Festi ! I imagine if they don't bend a lot and you don't bend them too often, they will work really well

looks cool, @Florian Festi ! I imagine if they don't bend a lot and you don't bend them too often, they will work really well

Yeah, they are basically just for a hand full of uses during assembling.

Yeah, they are basically just for a hand full of uses during assembling.

I got this conventional hinge and a compliant one layer latch as a feature request but have not done one myself yet: https://www.jarkman.co.uk/catalog/cnc/hotwirebox.htm

I got this conventional hinge and a compliant one layer latch as a feature request but have not done one myself yet: https://www.jarkman.co.uk/catalog/cnc/hotwirebox.htm

![]() Snap-in joints on a lasercut thingy. https://www.improwis.com/projects/hw_TestTubeRack/

Snap-in joints on a lasercut thingy. https://www.improwis.com/projects/hw_TestTubeRack/

The latch is super neat IMHO.

The latch is super neat IMHO.

![]() I came late to the Hack Chat so I will read later. I just want to thank

I came late to the Hack Chat so I will read later. I just want to thank

Dan Maloney

Dan Maloney

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.