You may have noticed that "water resistant" has started showing up on Tetent projects:

This is because I'm going to "double or nothing" and pursue water resistance.

Part of the reason is because I read somewhere that waterproofing had to be implemented "at the design stage", part of the reason is the "#showerthoughts" phenomenon, part of the reason is the BOM price and the largest share of the reason is because the market is quite dry when it comes to water-resistant options (pun intended). Oh, and I watched the following video where an Apple executive mentioned how failure rates dropped substantially when they started adding water resistance to the iPhone.

I believe there is something called a "feature parity threshold", under which there was little reason to invent a custom solution because something else already exists and is accessible. Water resistance crosses this threshold when compared to the vast amount of input peripherals and instruments. It also puts it on parity to a bluetooth keyboard in a plastic bag, which is not possible to do with Tetent.

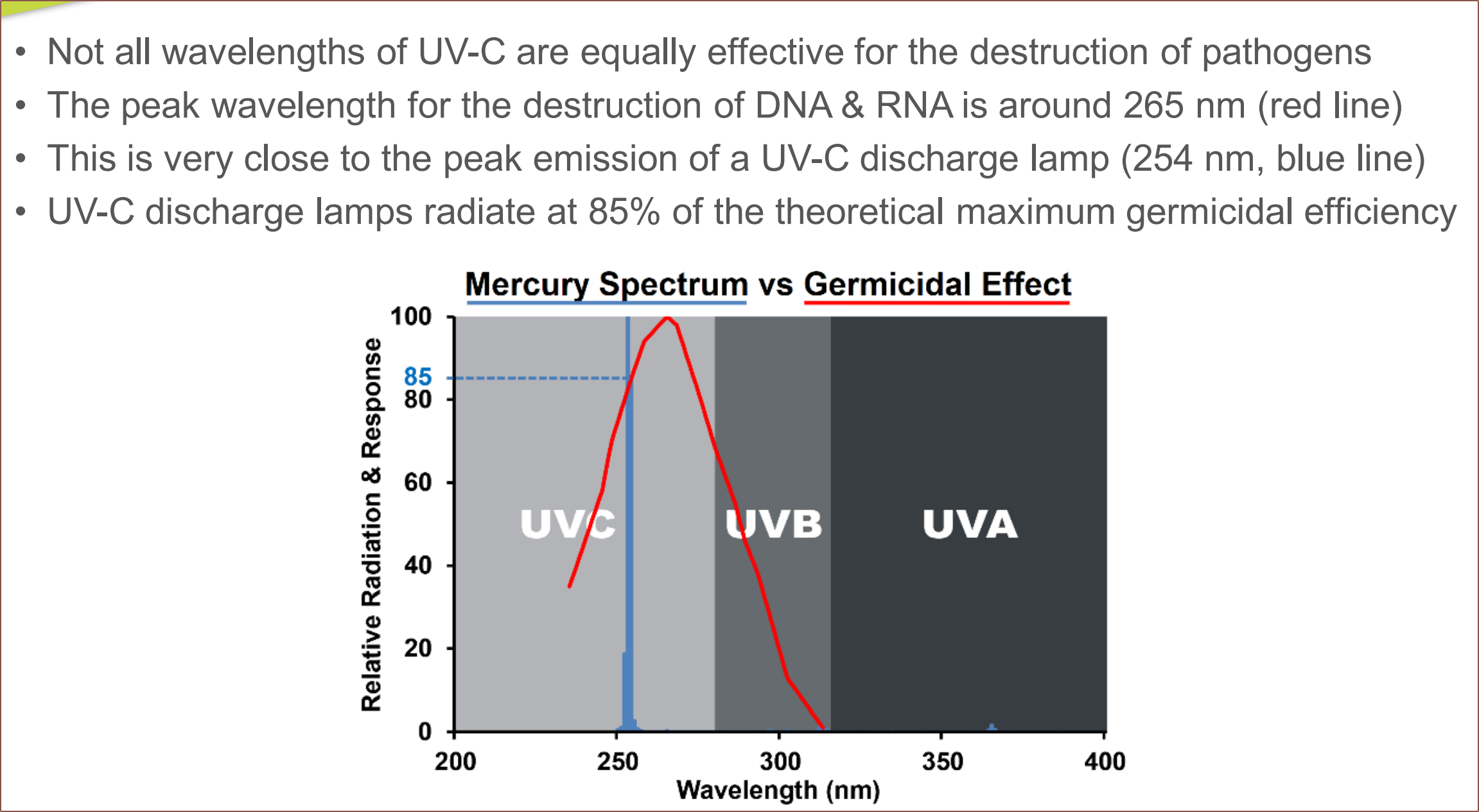

It also means that it's much easier to clean and can be deployed in more real-world environments, though UV-C sterilisation might be more difficult to achieve. This is because virtually all plastics are opaque under 300nm, and the ideal range for germicidal efficiency is around 265 - 275nm:

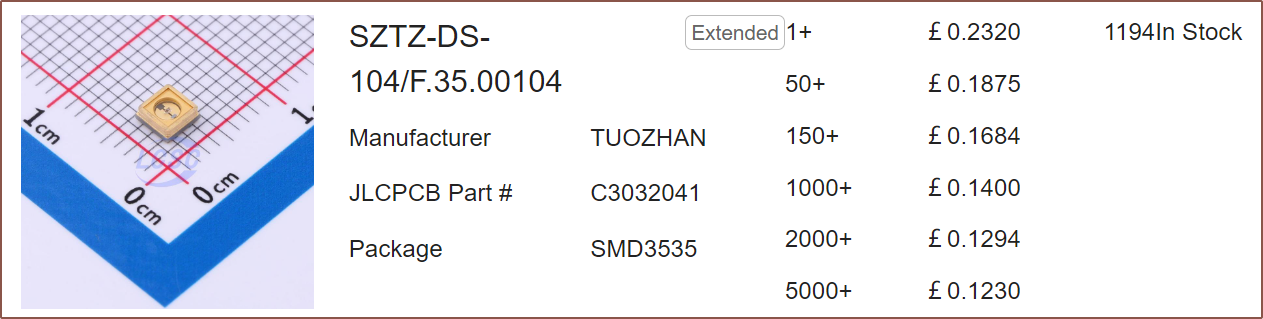

On JLC, it seems that the best (and cheapest) UV-C LED is 275nm. It also seems every LED in this category uses 6V.

The waterproof UV-C lamps use quartz as the transparent medium. There's also "UV Grade Fused Silica".

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.