Quick introduction

So I'm thinking of any new possible features that the Slime could do and I realised that I could have 1 Slime at 0 degrees and the other at 90 degrees to use the extruder motor of the second on as a 6th axis. That reminded me of the ribbon nozzle I talked about a few logs ago and looked around for internet mentions and other variable nozzles. Quickly, I found the first variable nozzle I ever knew: the SmartNozzle.

"While I'm here at this site, I might as well look to see what the 2022 entries are." I thought, and there I found the tube printing hotend.

Printing in tubes

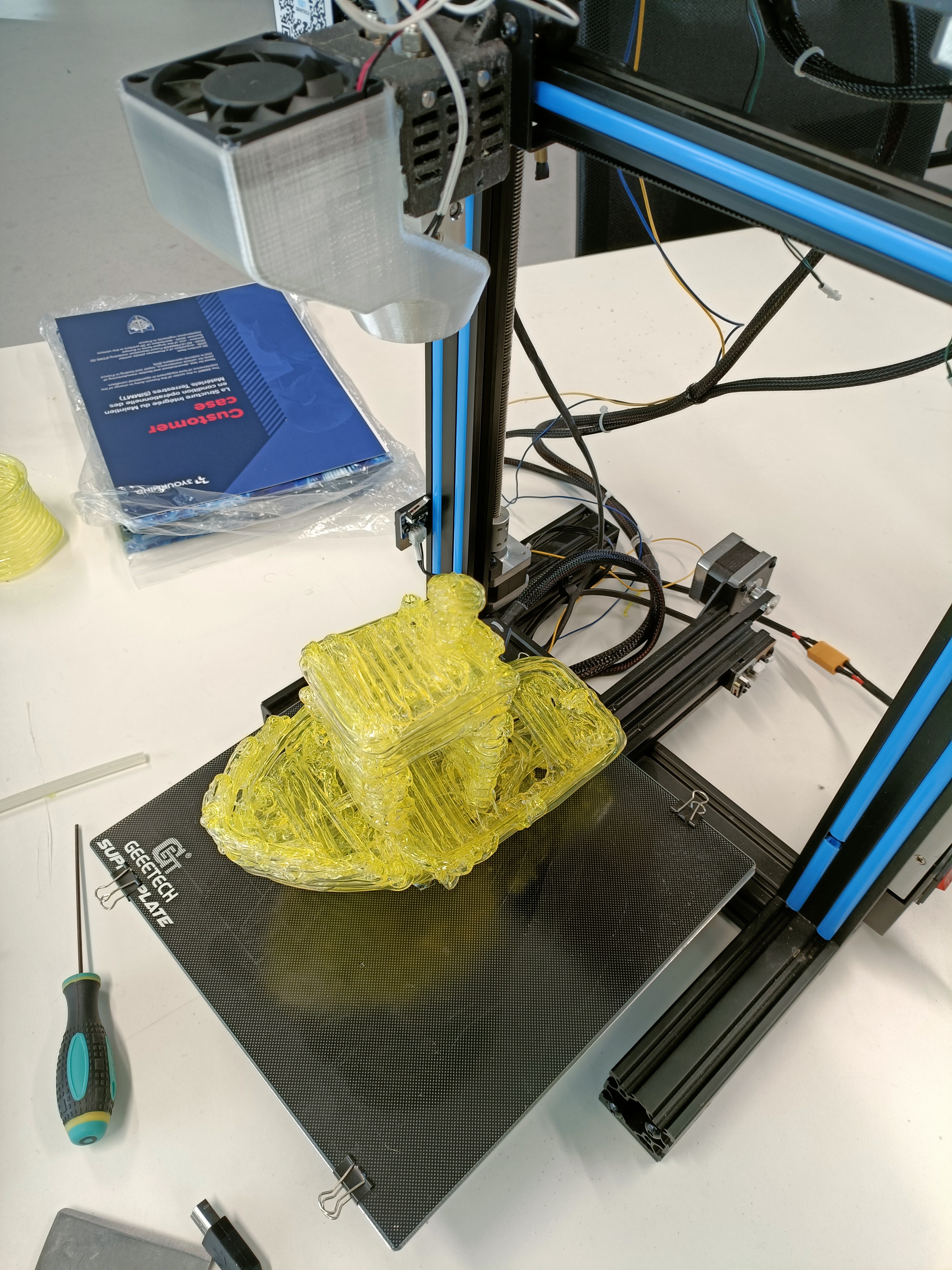

So my university just happens to have a tube 3D printer that I've known about for months but didn't know if it was some secret prototype so never said much about it. I could never quite work out how it worked until now, but I have seen it printing and the prints it's made:

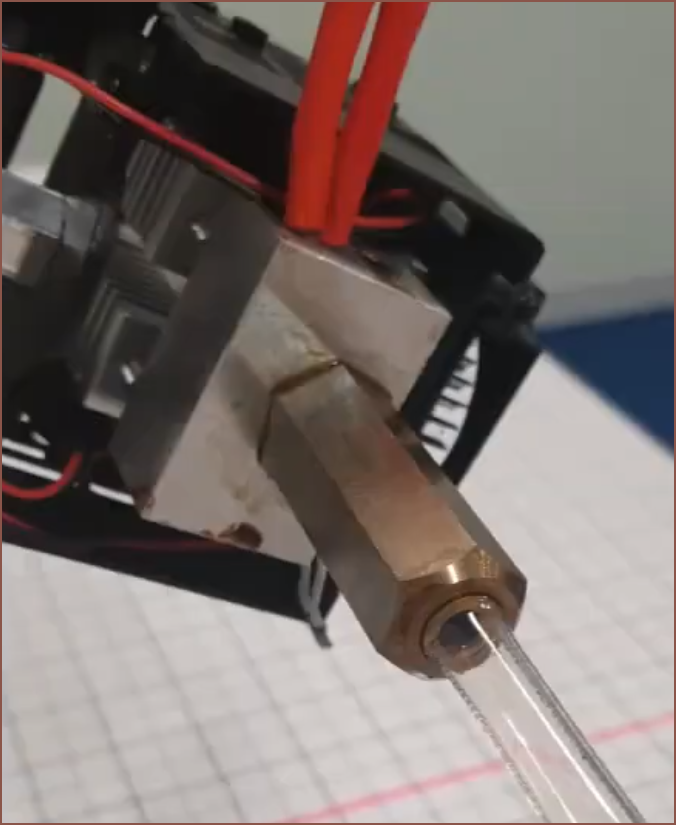

I didn't notice that there was a gap between the inner hole and the edge of the face, and now it makes sense how the walls stay solid and without voids.

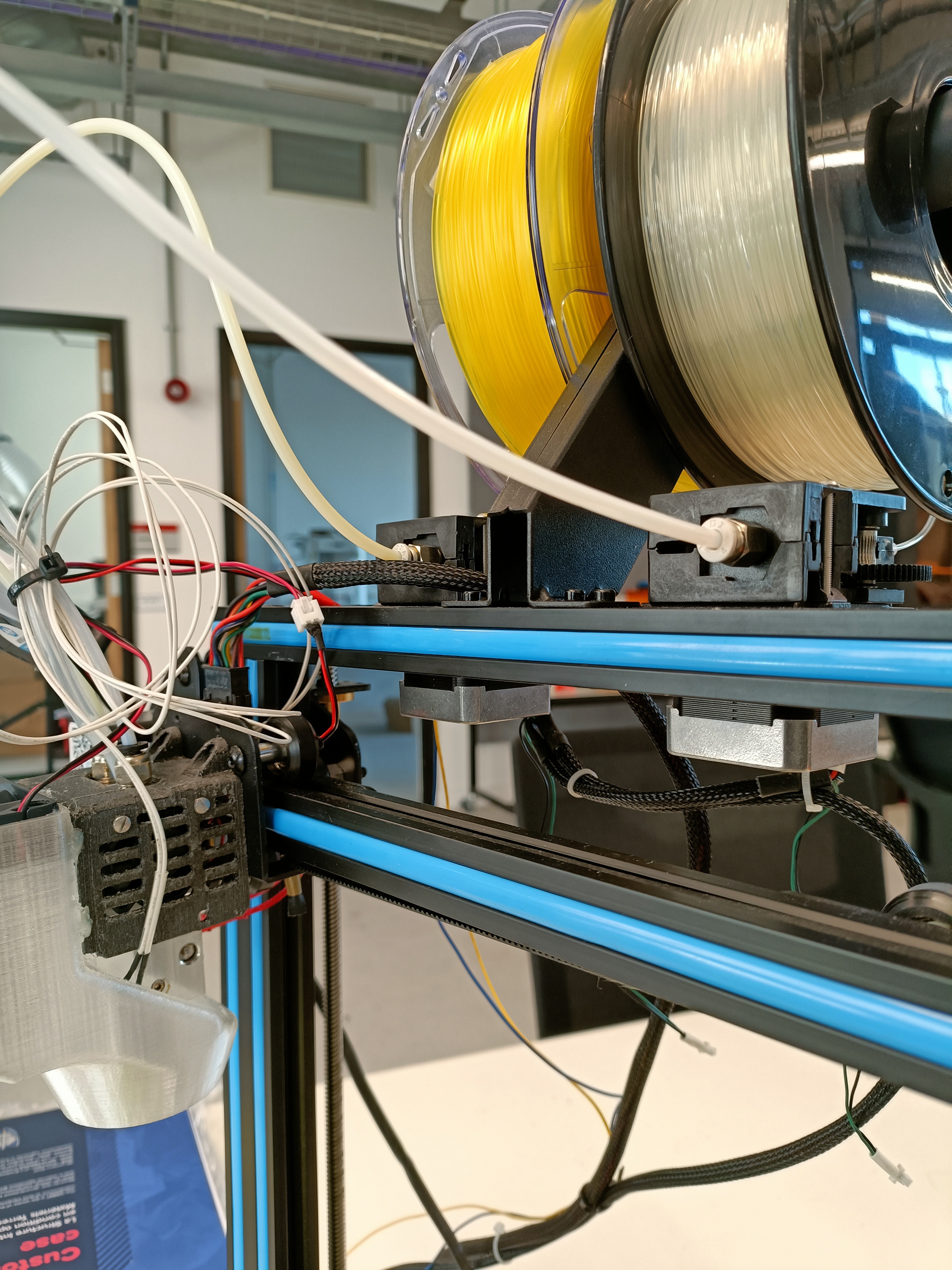

I didn't notice that there was a gap between the inner hole and the edge of the face, and now it makes sense how the walls stay solid and without voids. As you can also see from the image, the hotend takes in 2 spools of filament, so I was happy to realise that I could create a tool that used both Slimes a few logs ago because it meant that the potential of printing tubes was possible. The tubes almost freeze in place so some really extreme overhangs are possible. I wonder if it would be suitable for a 5 axis version of wire printing, or perhaps used as tree supports.

As you can also see from the image, the hotend takes in 2 spools of filament, so I was happy to realise that I could create a tool that used both Slimes a few logs ago because it meant that the potential of printing tubes was possible. The tubes almost freeze in place so some really extreme overhangs are possible. I wonder if it would be suitable for a 5 axis version of wire printing, or perhaps used as tree supports.Most recently, it seems that they're trying different colours instead of 2 sets of clear filament to colour the parts

I do wonder what an opaque material would look like, but a more immediate question would be "How would I manufacture it?"

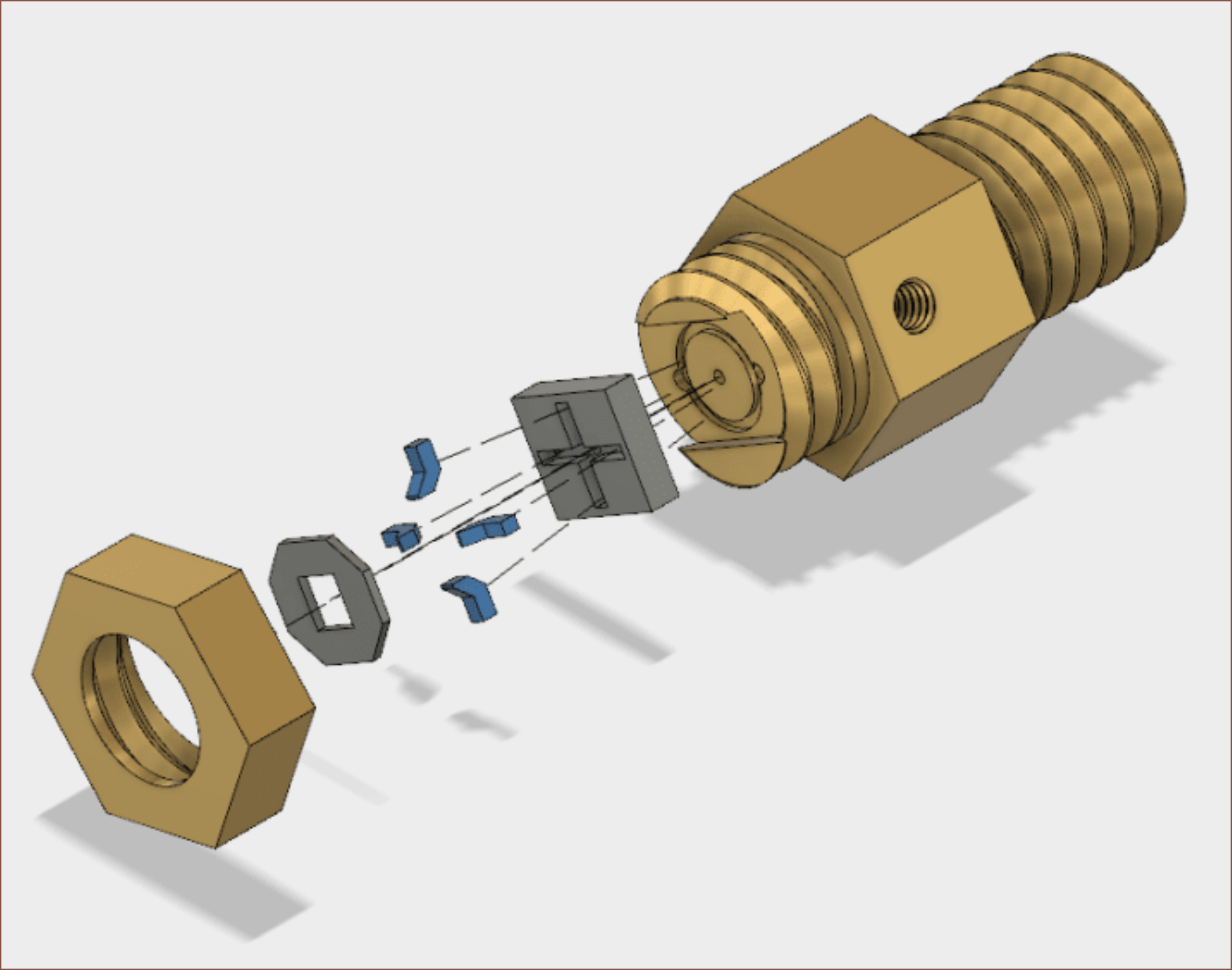

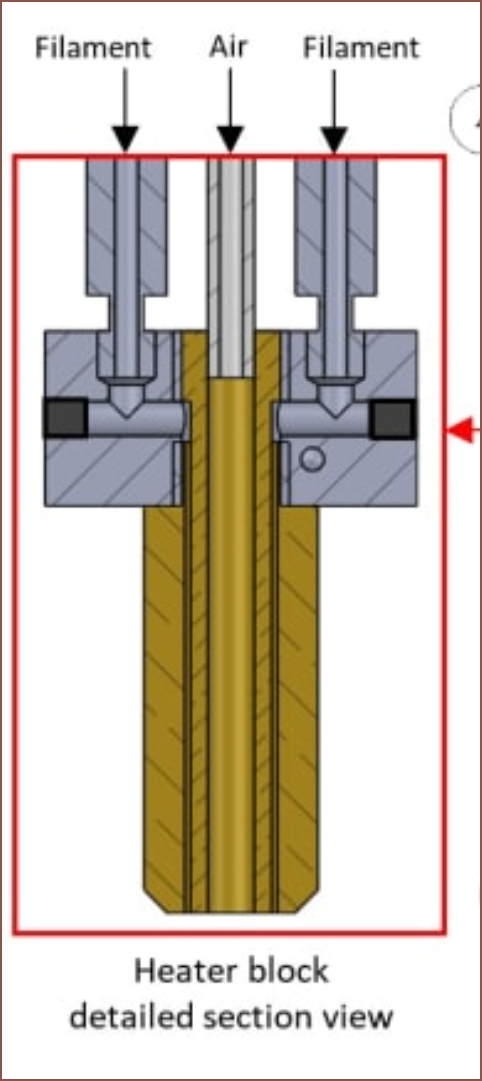

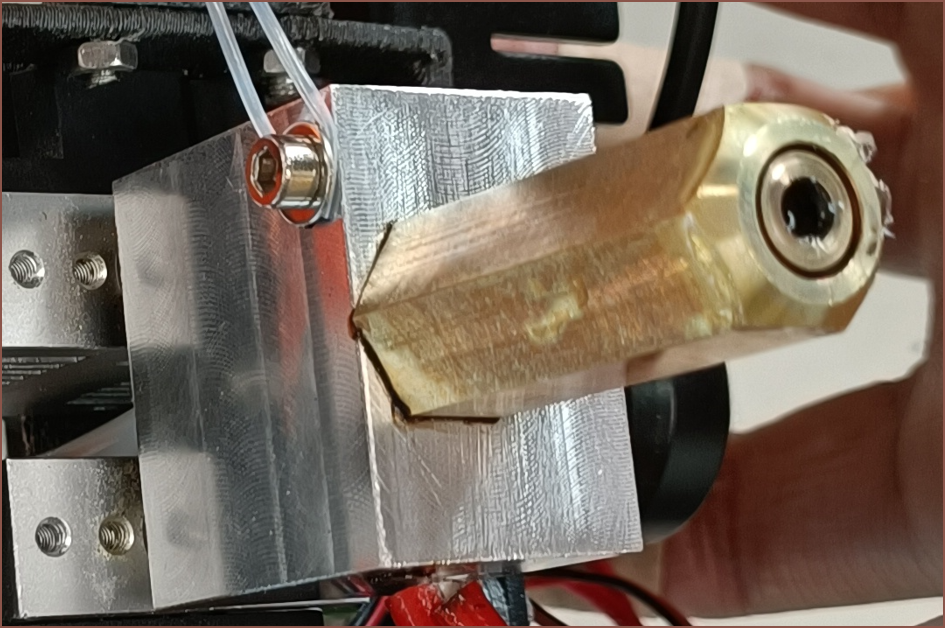

I do wonder what an opaque material would look like, but a more immediate question would be "How would I manufacture it?" This diagram gives some ideas, but I'm not sure how the outer brass looking block attaches to the aluminium looking block.

This diagram gives some ideas, but I'm not sure how the outer brass looking block attaches to the aluminium looking block.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.