One of the issues I'm finding with the continuous fibre feature implementation is that the fibres on Aliexpress like basalt and carbon are sold in something that more resembles a ribbon than thread.

While scrolling around, reading what industrial 3d printing companies have been getting up to, I found out that there's some rivalry between Desktop Metal and Markforged, and that Desktop Metal was making a continuous fibre 3D printer that could compete with Markforged's offering.

While scrolling around, reading what industrial 3d printing companies have been getting up to, I found out that there's some rivalry between Desktop Metal and Markforged, and that Desktop Metal was making a continuous fibre 3D printer that could compete with Markforged's offering.Seems that Desktop Metal has engineered a way to use the fibre's ribbon stock to their advantage.

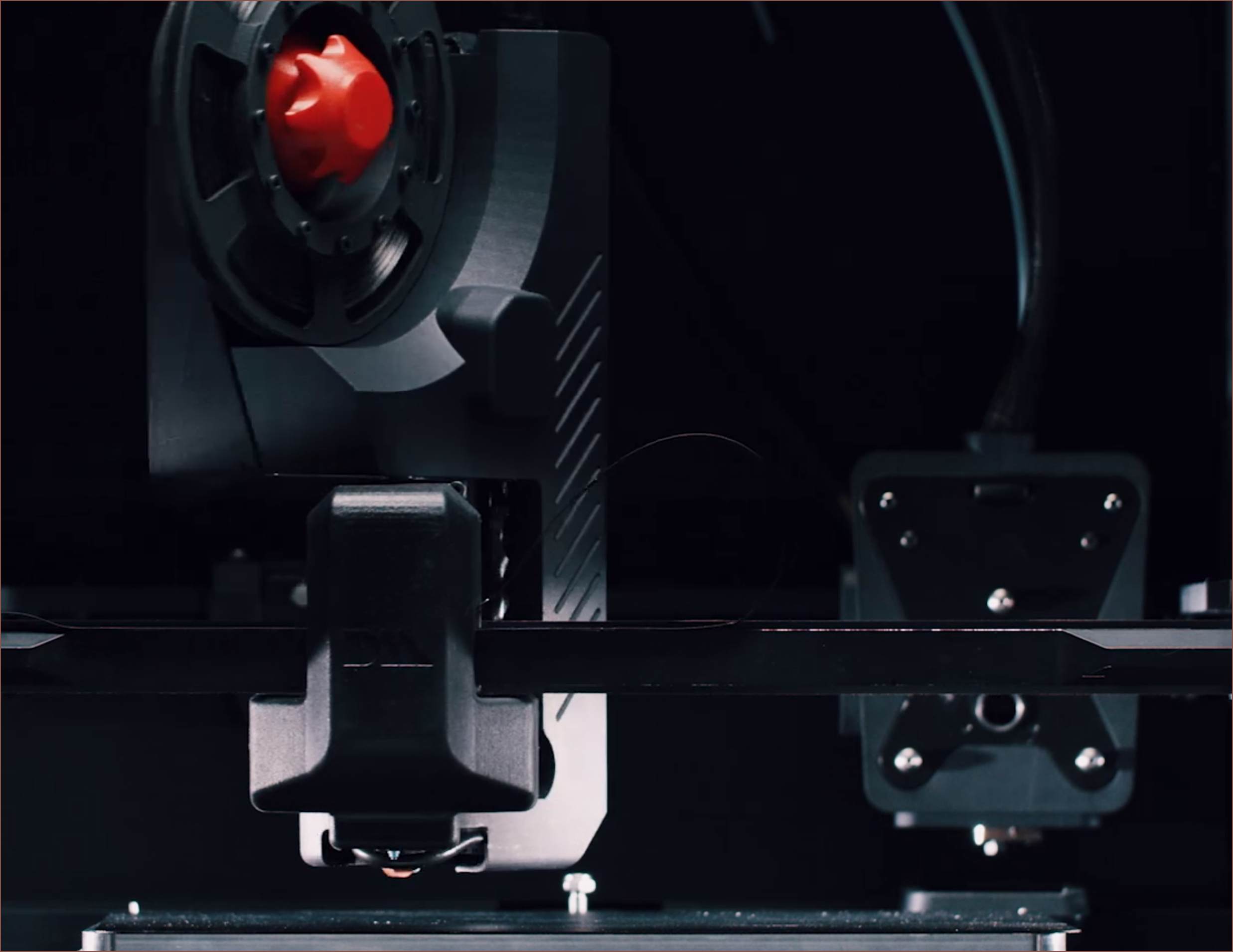

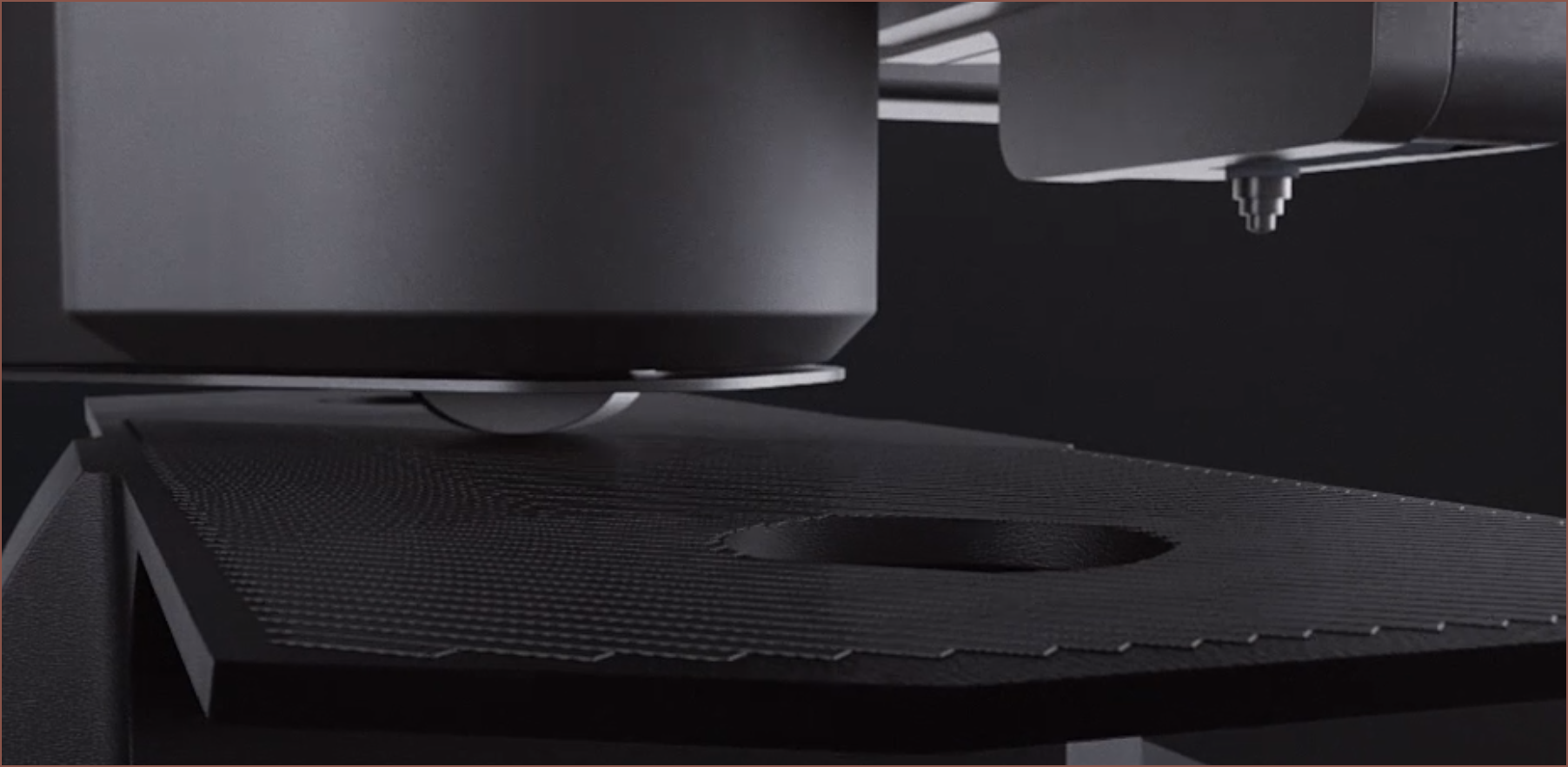

It very much seems to be a 2 tool toolchanger with the fibre tool being able to rotate 90 degrees, which would be able to get the fibre in any orientation. This reminds me of the rotating nozzle I found earlier.

It very much seems to be a 2 tool toolchanger with the fibre tool being able to rotate 90 degrees, which would be able to get the fibre in any orientation. This reminds me of the rotating nozzle I found earlier. It likely uses a heated roller (that seems spring loaded in the animation) to apply the continuous fibre.

It likely uses a heated roller (that seems spring loaded in the animation) to apply the continuous fibre.Why is this a nice solution? For starters, I believe that it could be easier to do this instead of accurately aligning a thread under a nozzle to print a fibre infused extrusion line. Another thing is that it sounds much easier to feed to the Slime, easier to cut and I can use the free extruder gear as the 6th axis, unlocking the ability to have fibre reinforced prints not just on the Rotary Bed, but on all the beds like the Long Bed (because parts that use this bed would likely benefit the most from fibre reinforcement) and 5 axis support.

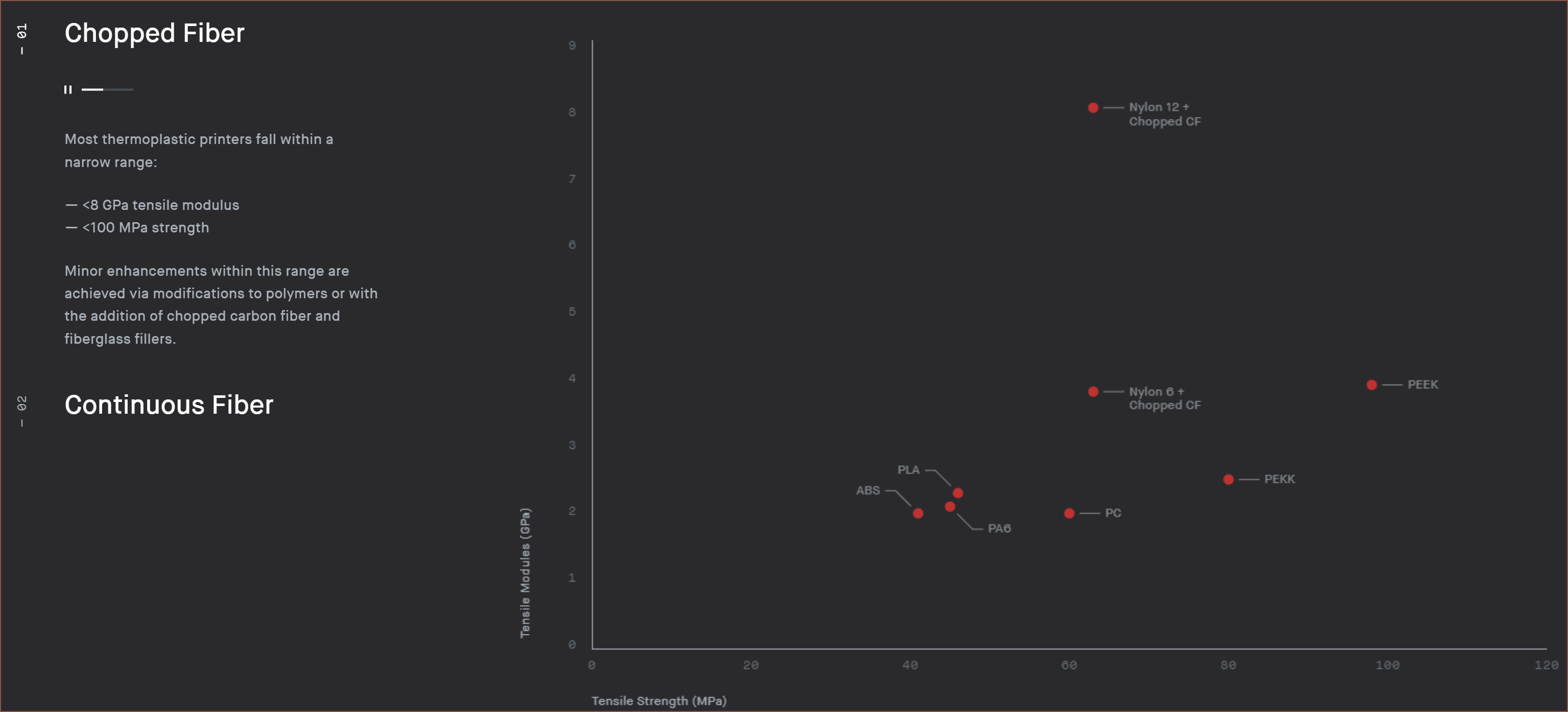

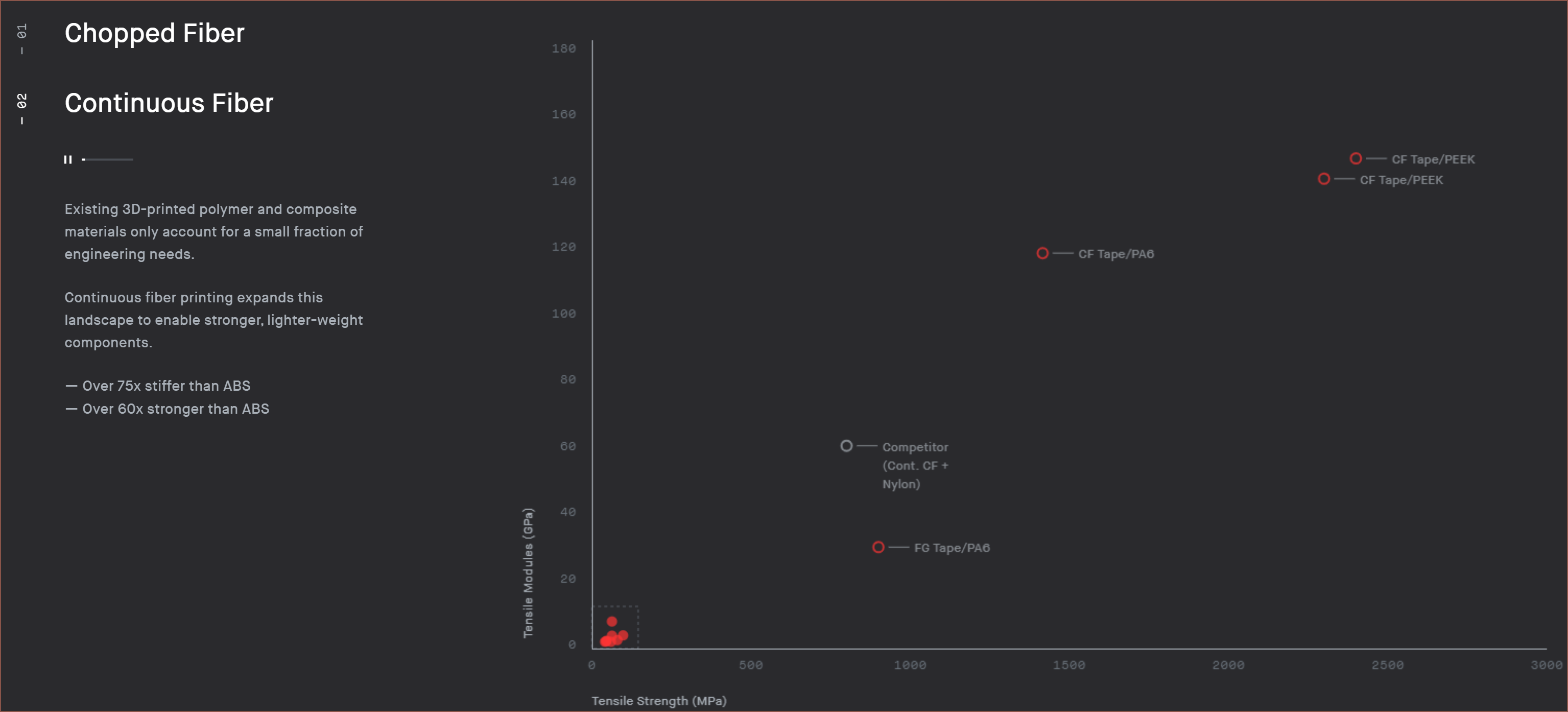

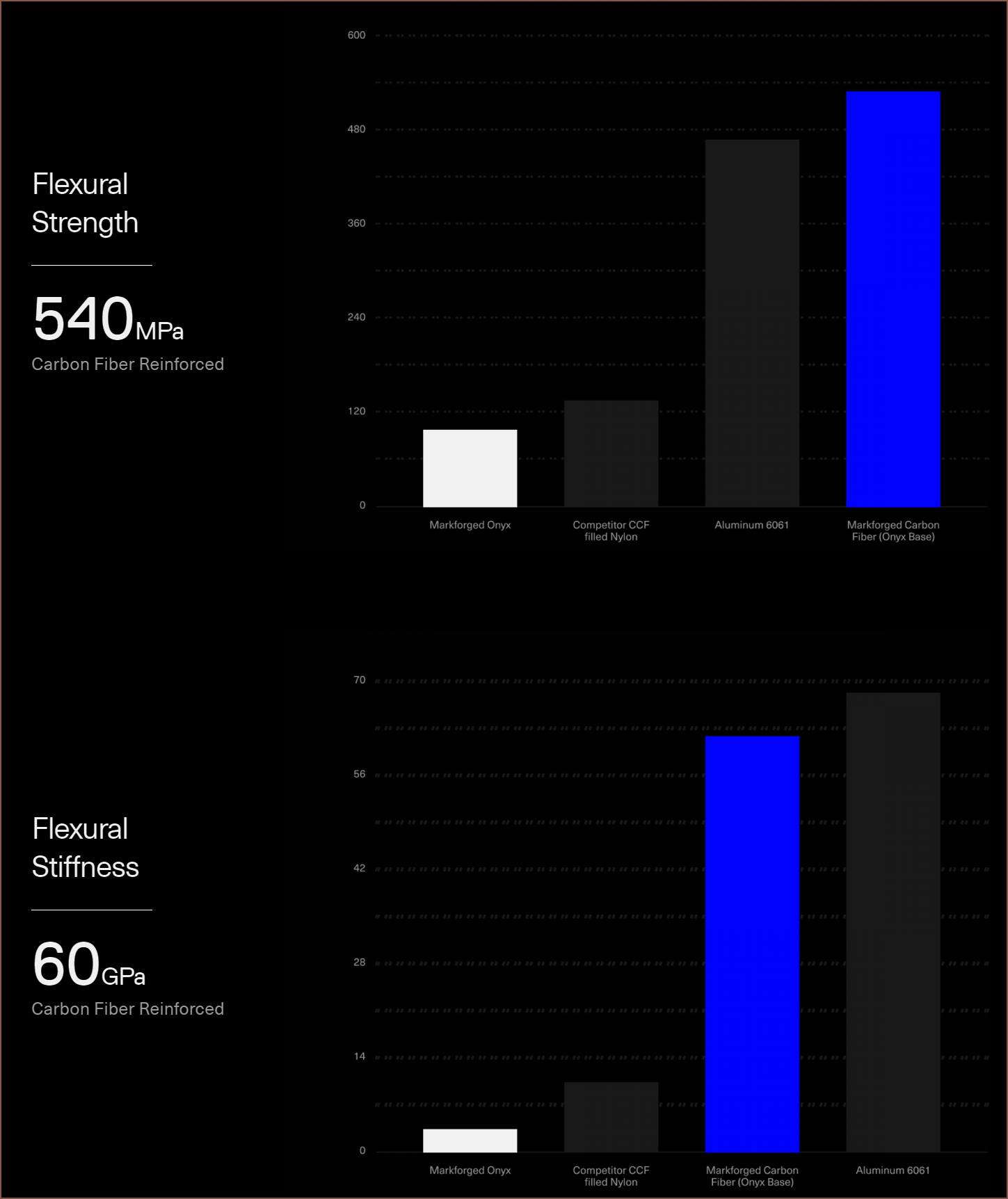

Then there's these 2 graphs:

The grey dot is likely Markforge's flagship continuous carbon fibre:

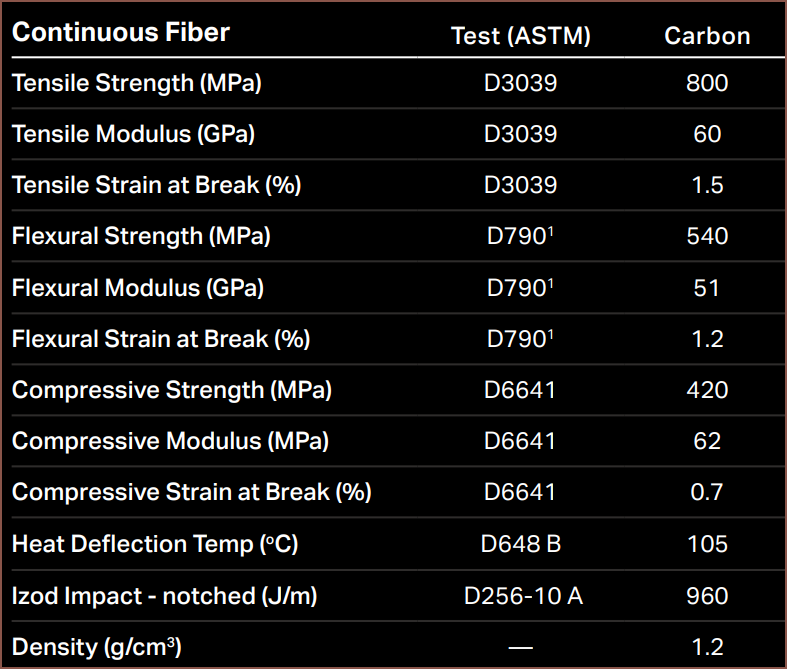

The grey dot is likely Markforge's flagship continuous carbon fibre: The carbon fibre tape is nearly 2x the tensile strength and is 2x the modulus. I'm more interested in the cheaper glass fibre tape (for which basalt should be a bit better). 30GPa modulus and a strength inbetween 800 and 1000MPa, according to Markforge's datasheet:

The carbon fibre tape is nearly 2x the tensile strength and is 2x the modulus. I'm more interested in the cheaper glass fibre tape (for which basalt should be a bit better). 30GPa modulus and a strength inbetween 800 and 1000MPa, according to Markforge's datasheet: I just hope that I can just press the basalt fibre into a printed channel similar to using a soldering iron to embed steel wire into a print. If that plan fails, I'd imagine extruding a thin bead of filament on one side of the fibre for a stronger bond between the fibre and the bottom of the channel could provide a solution.

I just hope that I can just press the basalt fibre into a printed channel similar to using a soldering iron to embed steel wire into a print. If that plan fails, I'd imagine extruding a thin bead of filament on one side of the fibre for a stronger bond between the fibre and the bottom of the channel could provide a solution. kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.