Not sure why it took a year of this project sitting in the back of my mind and working on an unrelated project (#Tetent Timespy [gd0136]) , but I just realised that "Timing belts are made of rubber, right? Wouldn't a big enough one be as wear resistant as a regular tyre?"

I wouldn't be suprised if I thought about it briefly but then dismissed it because I was worried about stones and dirt touching the drive gear(s). With a roller scrubber, I doubt it'll be an issue.

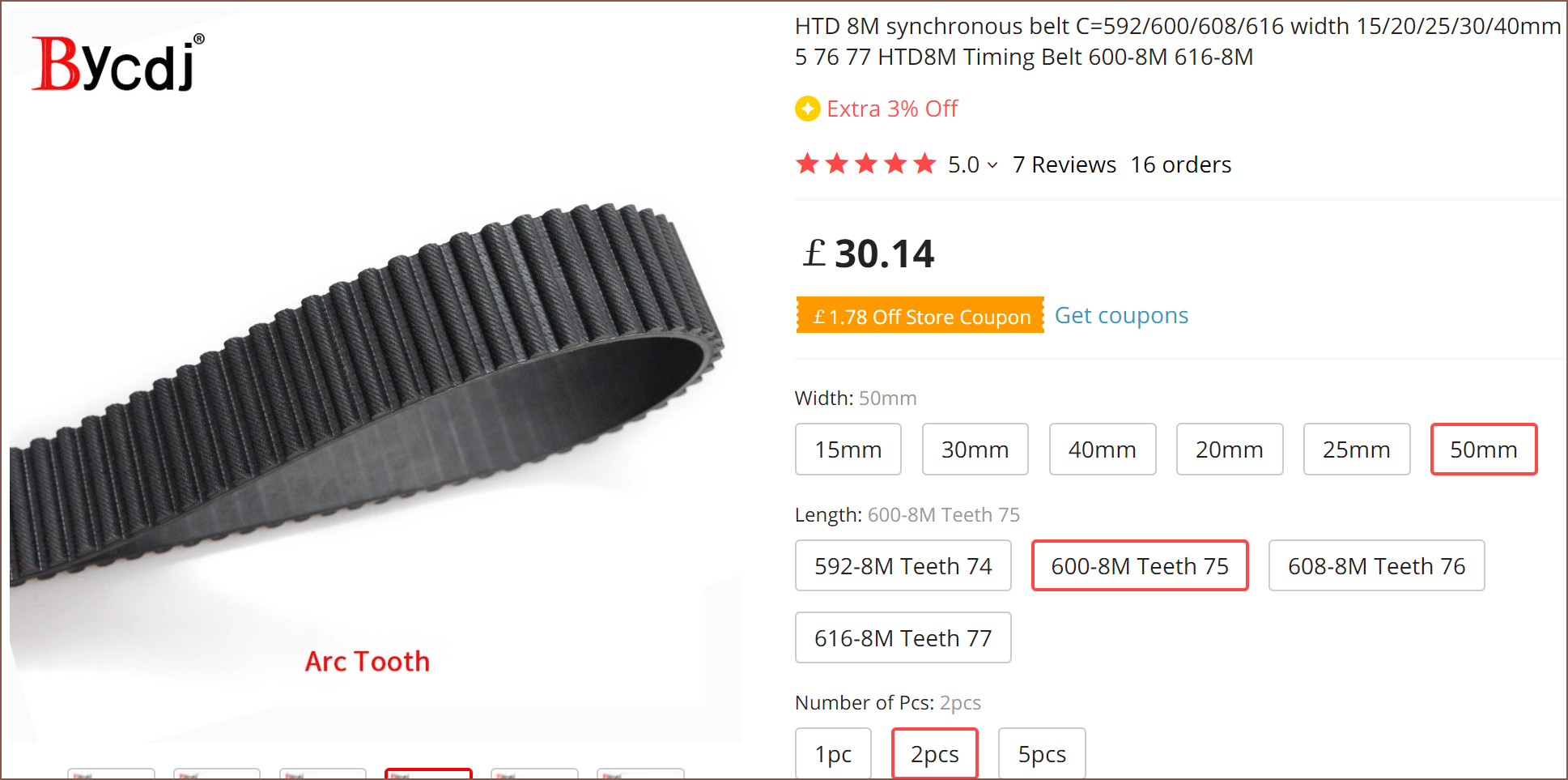

They come in a variety of different widths and (more importantly) lengths and they're much cheaper than I was expecting. In the concept, the belt was 100mm. That might be a bit wide. There's always the optiion to go dual 40mm belts for a 80-90mm track, but considering that bike tyre's are nowhere near that, I wonder if a wide track could bring in issues with turning and obstacle avoidance. On the other hand, the thinner the track, the harder it is to balance when stationary or emergency-dodging an obstacle. Since a thin sole reminds me of the shoes below and reduces both cost and complexity for the prototype, I'm going to opt for a 50mm belt.

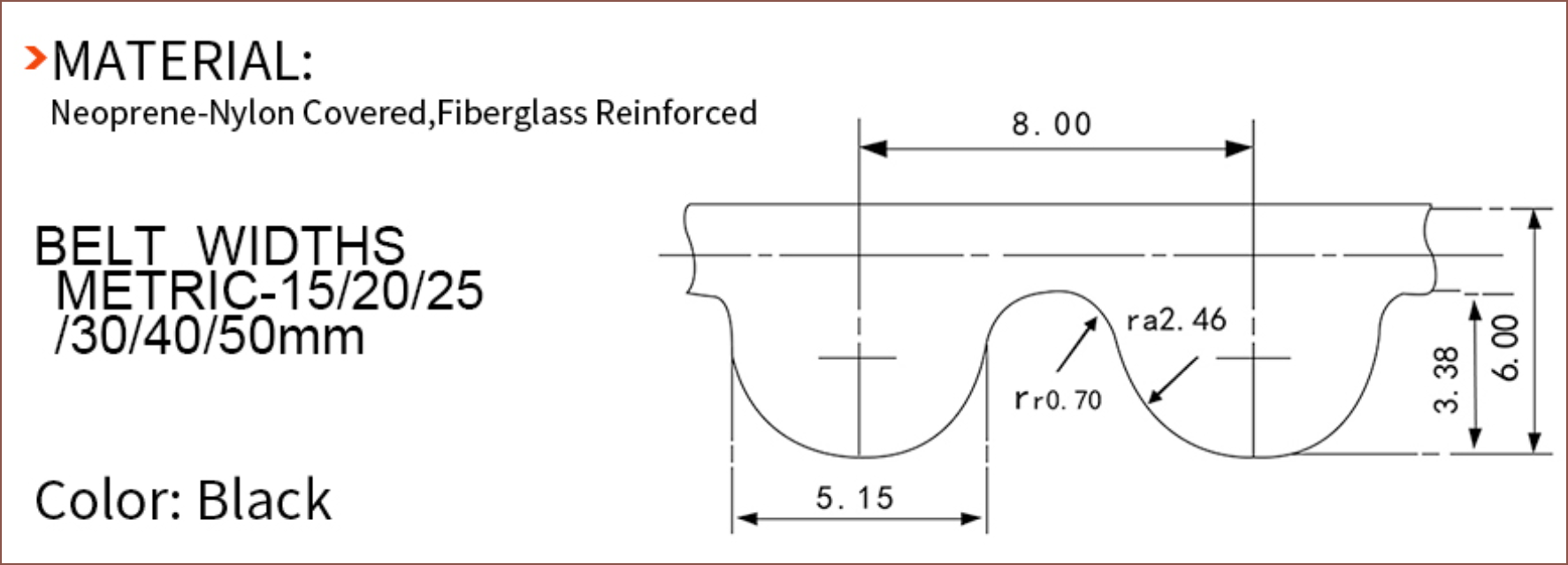

Next, I looked at the technical specifications of the 8M belt:

All I could tell from the internet is that the UK legal limit for a motorcycle is a tread depth of 1mm (unless it's under 49CC, then as long as it's visible). so I assume >3mm treads when new is good enough for science. Next, I searched for "Neoprene tyre" and the results look promising.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.