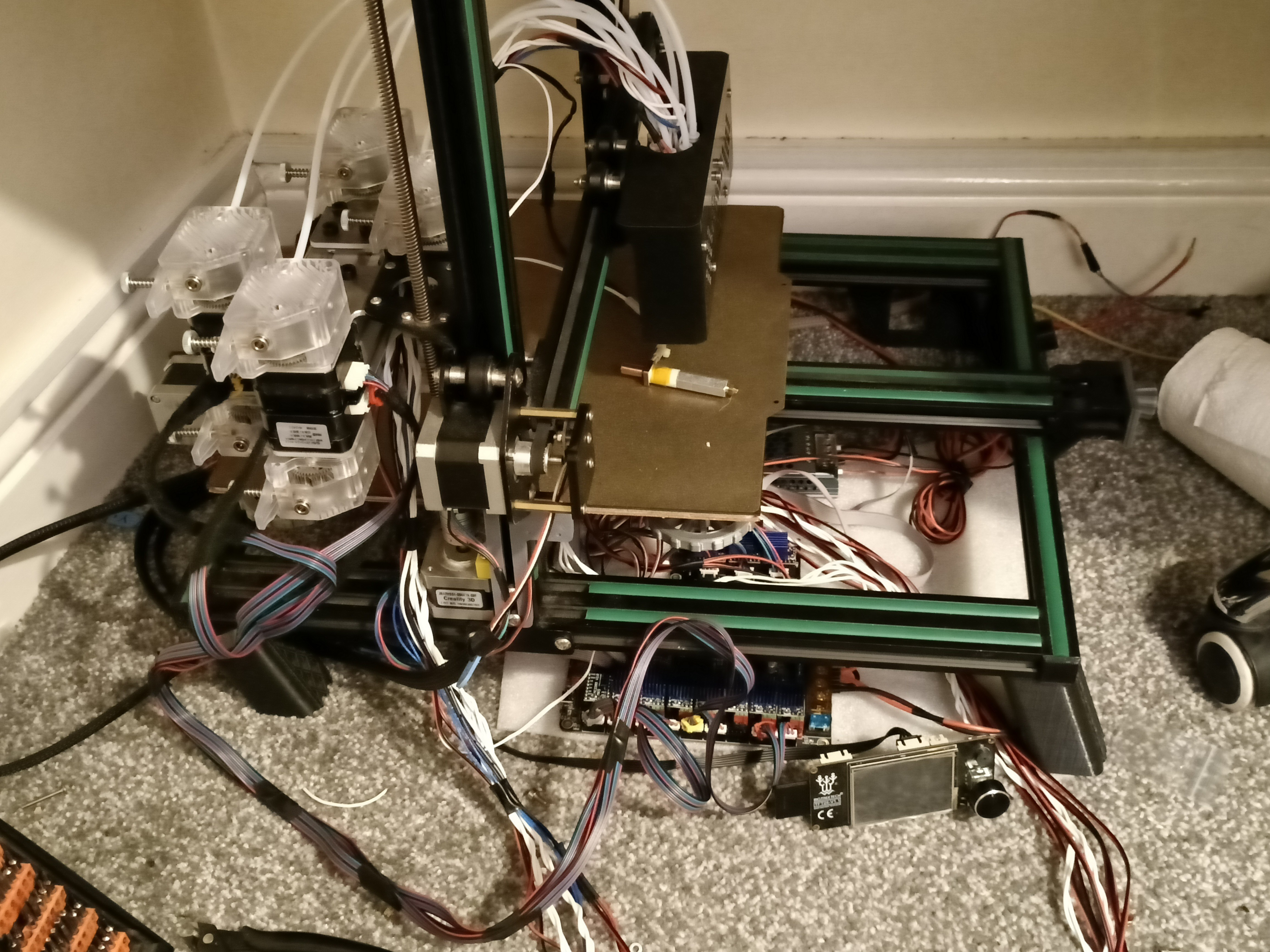

Surprisingly, even though the task was simple, it took 3h 20min to actually do the following:

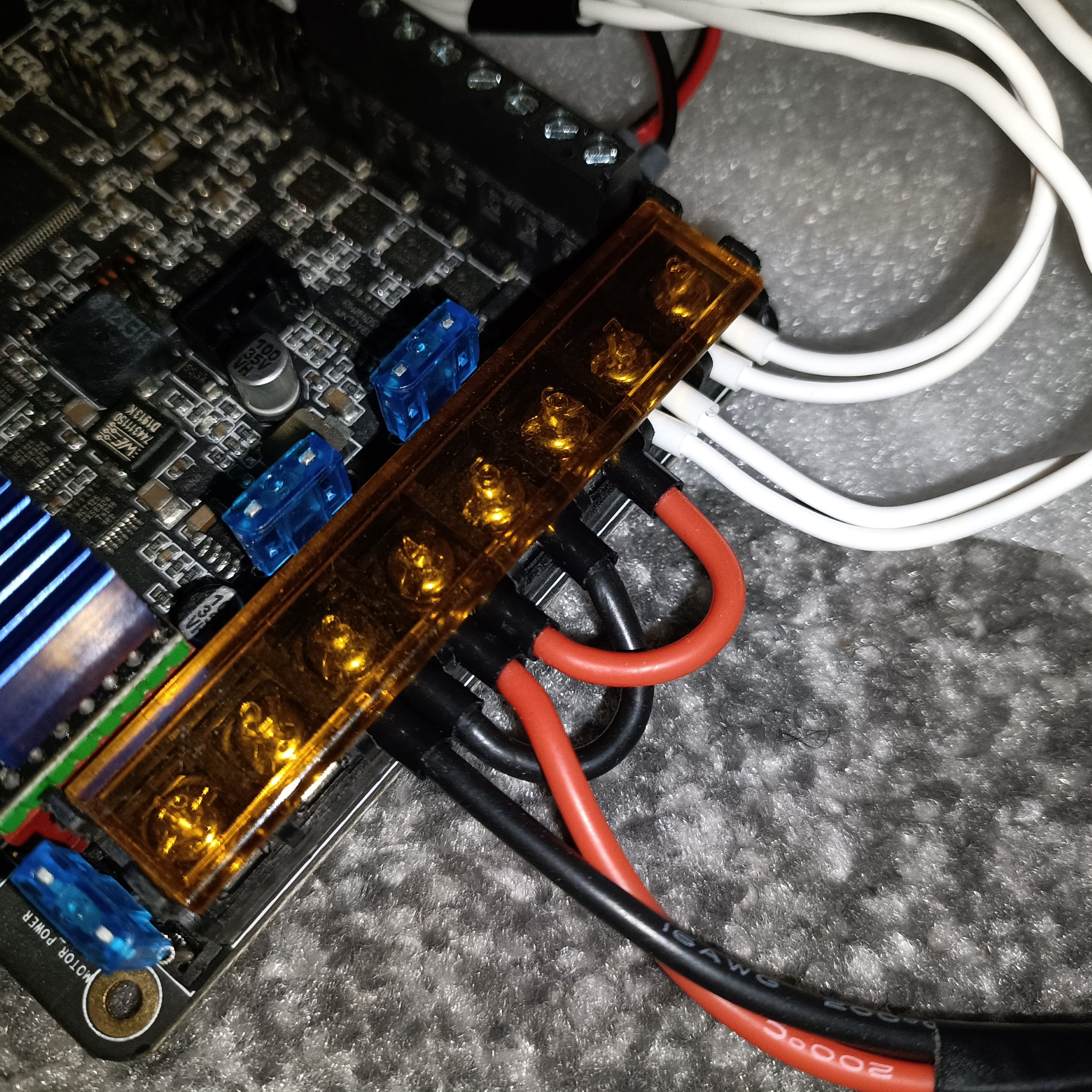

- Splice, crimp and connect the power cables to the PSU.

- It's a good thing that I took the advice from Me In The Past and got 16AWG (1.3mm^2) instead of 14AWG (which Me In The Past deduced was overkill and unweildly) as the jumper wires from the main power terminal to the bed power terminal barely fit.

- Stick electrical tape over the exposed metal tabs at the back of the mains socket for added safety.

- Open up the TMC2226s, stick on the heatsink

- Insert all steppers where they need to go. I've done XYZE0E1 as TMC2226 and the rest as TMC2209. I'm missing a heatsink for E7 but since I'm planning to only run these extruders at 300mA, it should be fine.

- Bundle up and electrical tape the wires for the X carriage.

- Replace the dupont-terminated Y axis motor cable with a XH like all the other ones.

I've used the packaging from the DDE (Dual Drive Extruders from SanBrother) as the testbench, which was a good idea as the PCBs have much more grip.

I haven't yet done the electrical system for the AC heated bed, as right now I've only got one question on my mind: Does the #Coaxial8or [gd0144] actually coaxialate?

Oh, right. I also had to get an extended Z axis endstop holder printed this morning. You can see it installed in the topmost image.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.