The old incapable fume extractor

When I searched the internet for other solutions, it turned out that a tube fan could be a good alternative. And at about € 65 a lot more attractively priced. I bought one and then wondered how to make a good extractor out of it. I was looking for a compact design that would not take up too much desk space. When the extractor is placed above the soldering, it is much better at extracting all the smoke than if it is placed behind it. I still had a magnetic base lying around and after some experimentation I came up with a setup that worked amazingly well.

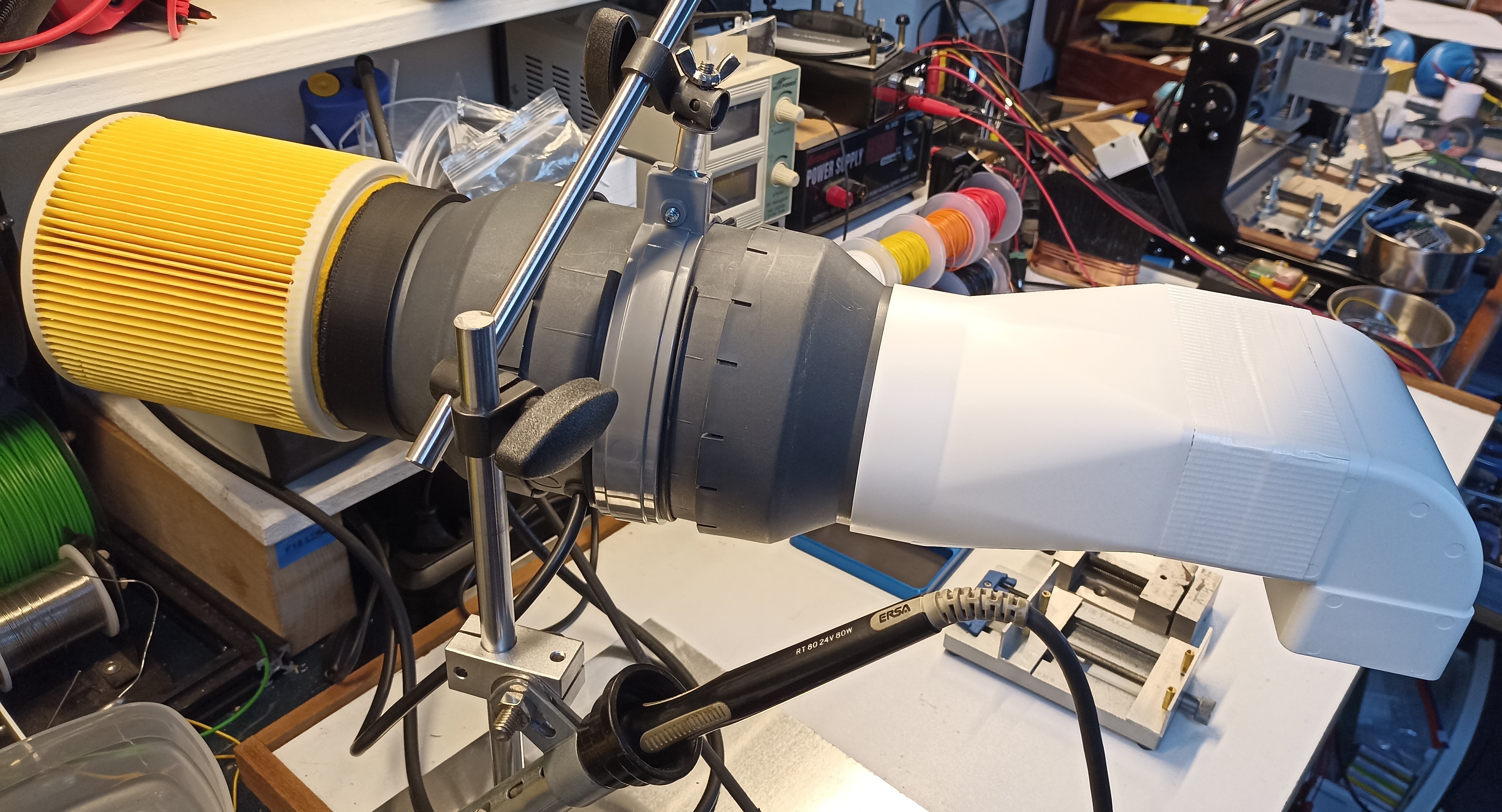

The finished soldering fume extractor

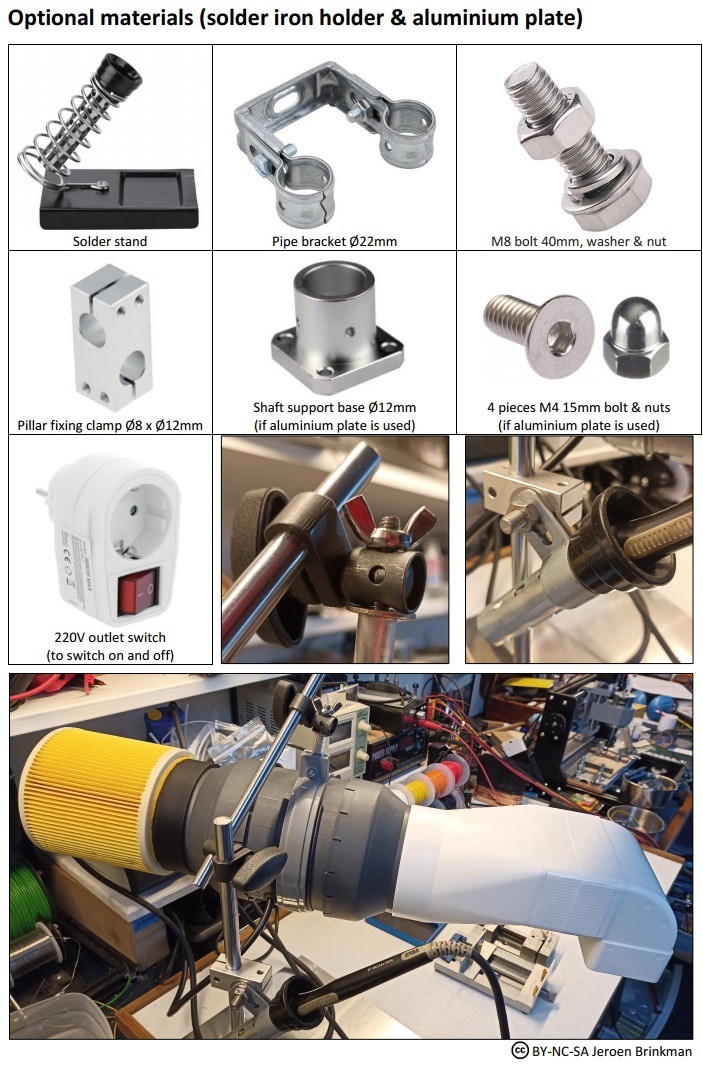

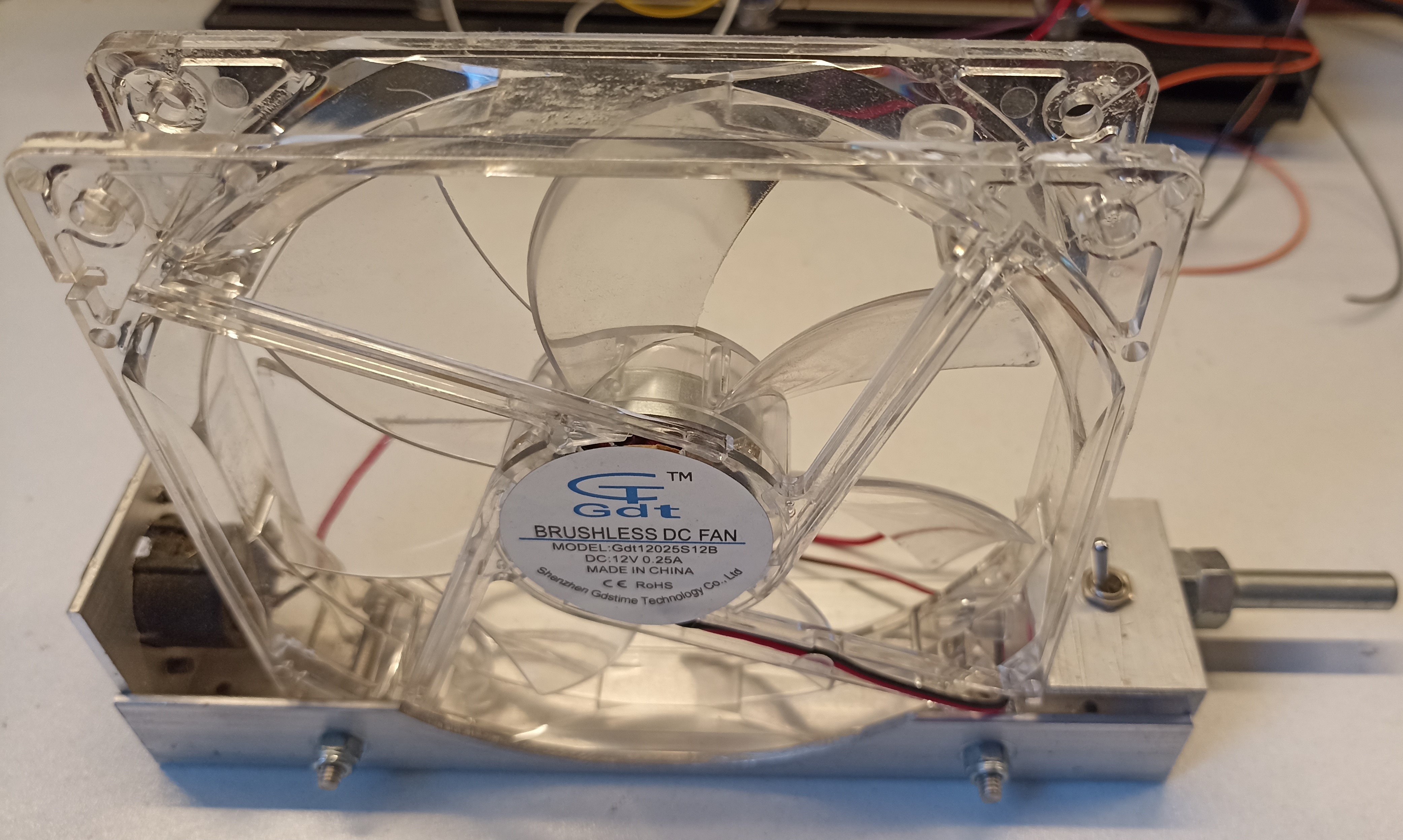

The pictures speak for themselves, the assembly is not very complicated. The bolt of the downpipe clamp has been shortened and an M6 thread has been tapped. A wingnut, a small 15mm piece of aluminium Ø10mm tube and a easher, mounts the clamp to the stand. A piece of the broken inner tube of a bicycle was cut off and placed between the downpipe clamp and the fan. I attached the white round to square pipe adapter to the white corner piece with duct tape. The reducer can be slid onto the fan easily. A plug is mounted to the power cable and can be turned on and off with an outlet switch. I chose to use an aluminum plate instead of an iron plate. The magnetic base does not work on this, instead a tube-base is used, mounted to the plate with four M4 bolts. Since it was very easy to implement, I also mounted a soldering bolt holder on the upright rod.

Finally, I placed a piece of 2mm felt under the metal plate, so that the desktop is protected and the vibrations of the fan are damped.

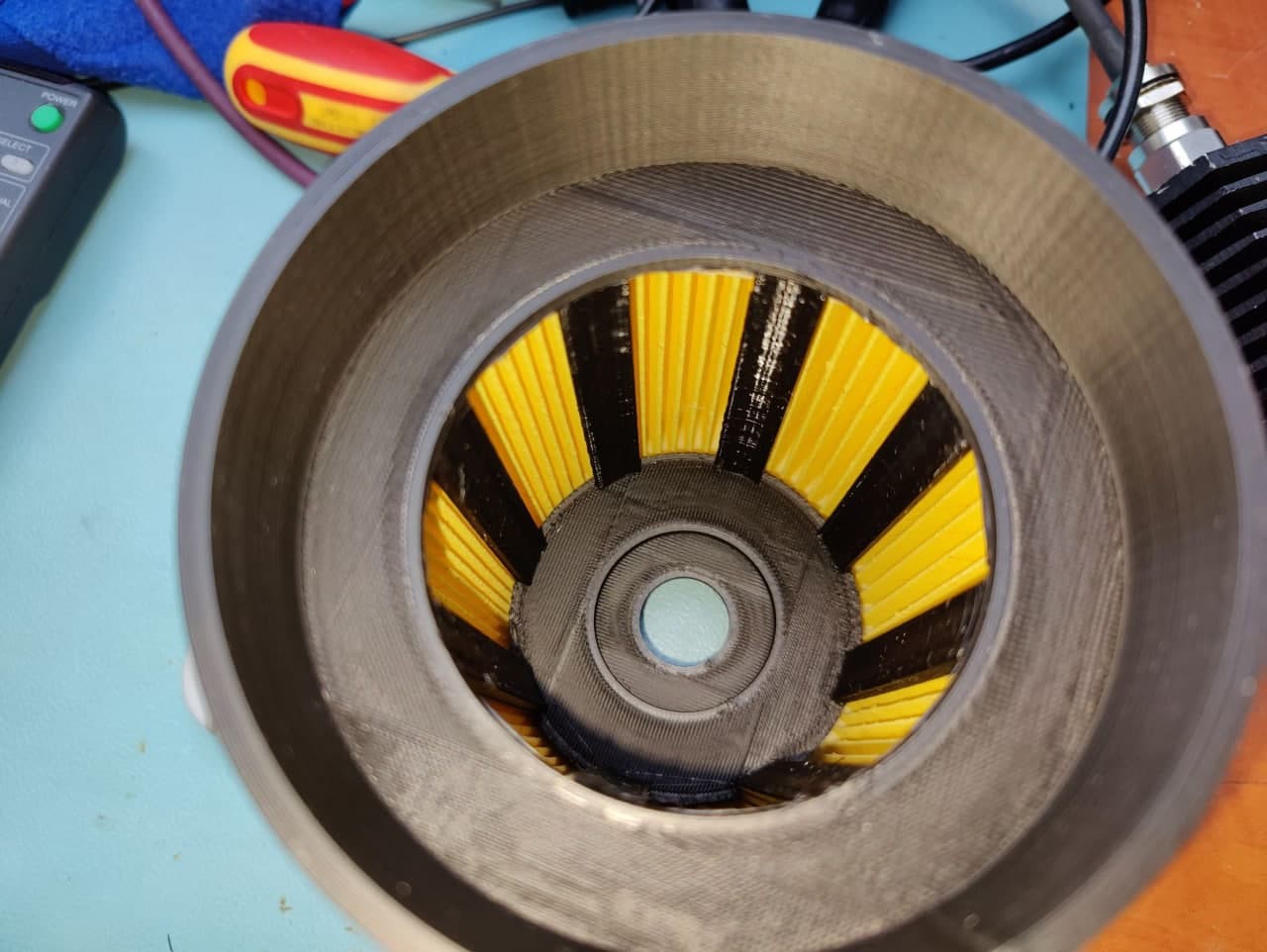

The used tree-support for the 3d-printed HEPA-filter holder

But then I started to wonder what happens to all the solder smoke that gets blown out the back. Surely that lingers in the room and is inhaled. It turned out that this smoke is made up of very small dust particles that only a HEPA (High Efficiency Particulate Air) can filter out. Kärcher uses such HEPA filters for its all-purpose vacuum cleaners and they are cheap (€10) and readily available. In addition, they are round in shape which is really handy when you want to mount one on a tube. But how, that was the key question.

I quickly figured out that a printed 3D reducer with filter holder would be the solution. This turned out not to be available on the web and I had to design it myself. That turned out to be more difficult than I thought, I could not work it out. Fortunately my friend Tjalling stepped in and designed a very nice filter holder and also printed it in PLA! To minimise material usage, the HEPA filter holder was printed upside down with a tree-support instead of a regular support to support the flange. This prints faster and uses less filament.

To ensure that the filter can be placed airtight on the holder, I cut a ring gasket from 2mm thick felt. This seals perfectly and the filter holder fits beautifully.

The 3d printed filter holder can be slid onto the tube by beveling the fan tube (outside) and the filter holder (inside) with a small bevel). Then the filter holder is placed in a pan containing 3cm of hot water. After a while the PLA material has softened somewhat and it can be pushed on the fan tube.

In short, with a cost of a little more than € 100, a high extraction capacity of 124m3/h and a low noise production of 58dB, it is a very attractive alternative to the commercially available fume extractors. The flexible mount makes it easy to place it in any position and it has a small footprint. I am very happy with it!

Solder fume extractor properties:

Maximum length: 55cm

Minimum width: 20cm

Minimum height: 30cm

Power consumption: 13watt

Extraction capacity: 124m3 per hour

Noise production: 58dB

Jeroen Brinkman

Jeroen Brinkman