As written on my blog and meant here before have been still facing some troubles with the recoater. Therefore, I decided, even I really didn't want to, to change its design.

Main problems are with the roller part. Unfortunately, I have made its diameter of 38mm, which implies high rotating speeds and causes layer shifts. I spent some time to come up with the solution how to incorporate roller with smaller diameter into the current printer design. But due to space constrains it's not easily possible.

Another issue is that once the roller, being from PTFE, starts to warm up, it starts to deform a bit due to nonsymmetrical heating of it. I eliminated this by "grilling" the roller during the printer heat up, but I cannot be sure that it is perfectly circular and concentric with the axels. As we are speaking about the hundredths of millimeter which plays a role, it is a problem.

It is not all. Last problem is related to smooth rods which are approx. 550mm long. I thought it will be OK without support, but it is not. And again, you cannot ensure layer thickness precision which is needed.

Here are intended changes:

1) Replace smooth rods with the linear guides

2) Change the recoater from roller to blade. I will come back to the roller in v2.

3) Change the drive train, to be able to worh not only with the steel rope but also to test special heat resistant GT2 belts.

4) Change the cover of linear technics parts to be comfortably accessible for maintenance.

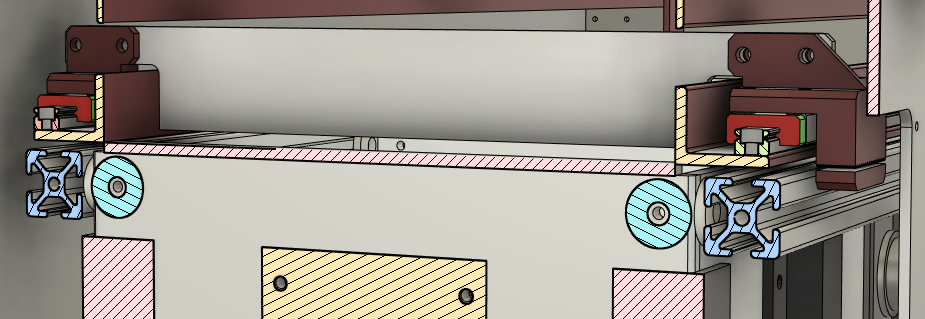

I have proposed this design:

It consists of MGN9R rails with the MGN9H trolleys. Aluminum wiper will have precisely flat bottom (will be CNC machined). I read research papers related to the blade shape and I was really surprised that flat bottom is better than symmetric, asymmetric or rounded. But it has some logic.

You can see the design in deep detail here: https://sls4all.com/fusion360-model/

I would like to rebuild printer in this way in two weeks or so. Hopefully, it will work as intended. There is one thing which makes me worried - I can't pull the trolley exactly on the axis direction of the rail... will see.

I expect from this change to be able to focus on the sintering parameters and be sure that there is one layer like each other.

Tomas Starek

Tomas Starek

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.