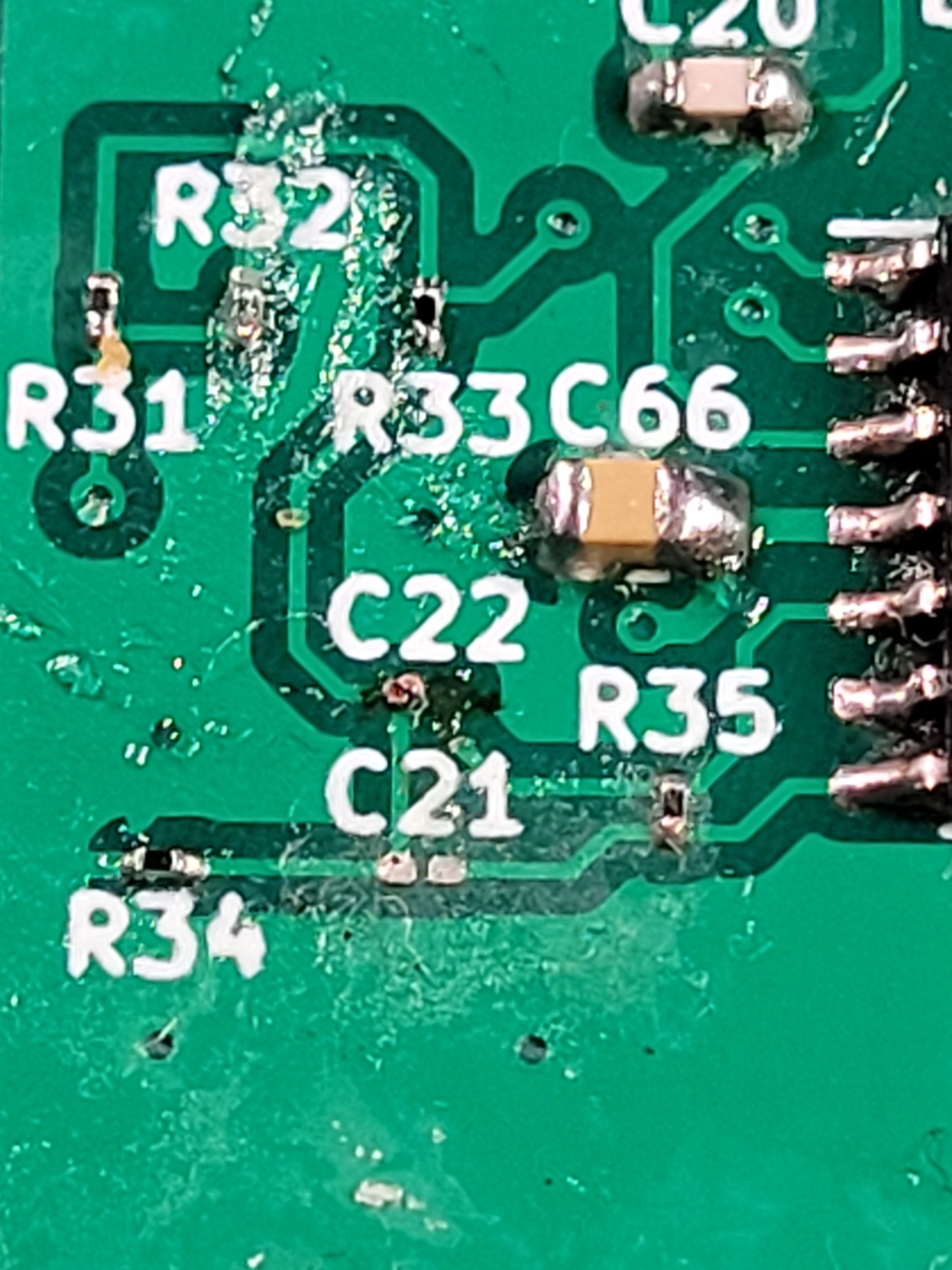

- Attempted to solder capacitor

onto area with broken pad by soldering to the trace after scrapping the

protection off

- Was able to scrape protection off, but was not able to get solder to stick to the exposed copper

- Ended up making the situation worse

- The whole point of soldering

myself was to:

- Save money

- To be accurately claim that I can solder surface mount devices

- The above two are no longer issues

- **SOLUTION: Redesign the board

- Don't use components smaller than 0402, use 0603 if space permits

- Fix negative voltage regulator output and feedback mistake (would have to cut 2 traces and connect 2 traces...)

- Re-check every other circuit for mistakes

- This works out as I can easily solder 0402 sized devices now, a lot of my 0201 components got damaged and have values that deviate greatly from the ideal value, so the filters were not gonna work properly anyway

- I have all of the tools I need this time, should be able to finish soldering aspect within a week

- I will spend the rest of this week and the weekend redesigning and working on the BOM, aim to order new board by Sunday or Monday

- ***Incorporate component availability into design - check if JLCPCB has component before selection, will use soldering

- Will buy new IC's as well, large chance of damaging components with hot air rework station, do not wanna take the time and risk with a board with this many components

![]()

Solder Progress 11

A project log for Music Spectrum and dB Visualizer

Receive input from a 3.5mm jack, divides the music into 7 frequency bands, shows the loudness of each frequency band in DB using LEDS.

Ghani Lawal

Ghani Lawal

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.