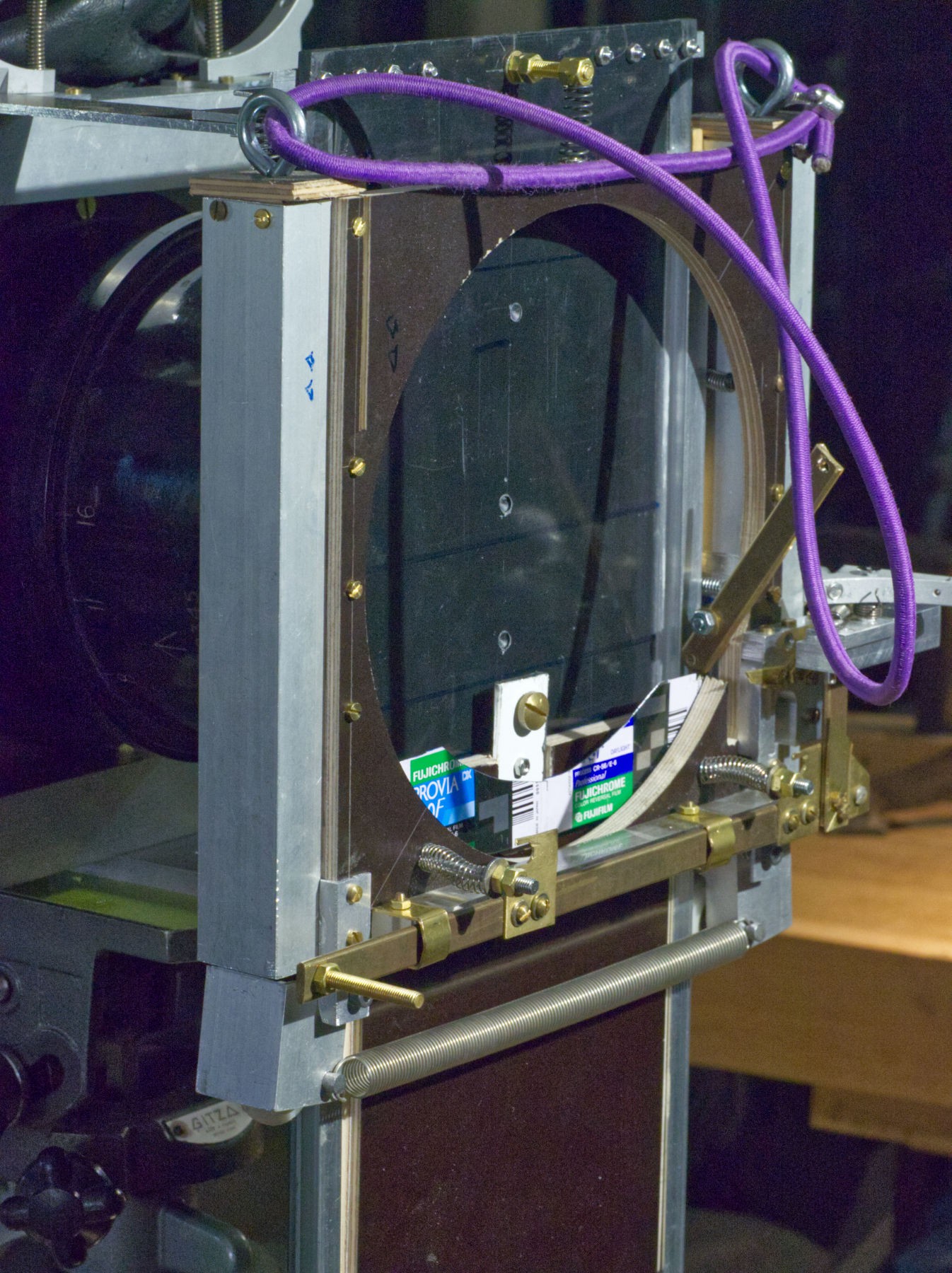

The blade has an square aperture of 160 mm, and the sliding blind can make half of it to have two times faster shutter speed, and again, and again. The smaller the slot, the faster the time.

It must be fastened to the blade at the chosen place, that M 6 brass screw will do the job (the small aluminium part is finally not going to be used).

Sharpening the tip with a lathe tool using the drill press.

Some 3 mm thick Dibond is going to hold it.

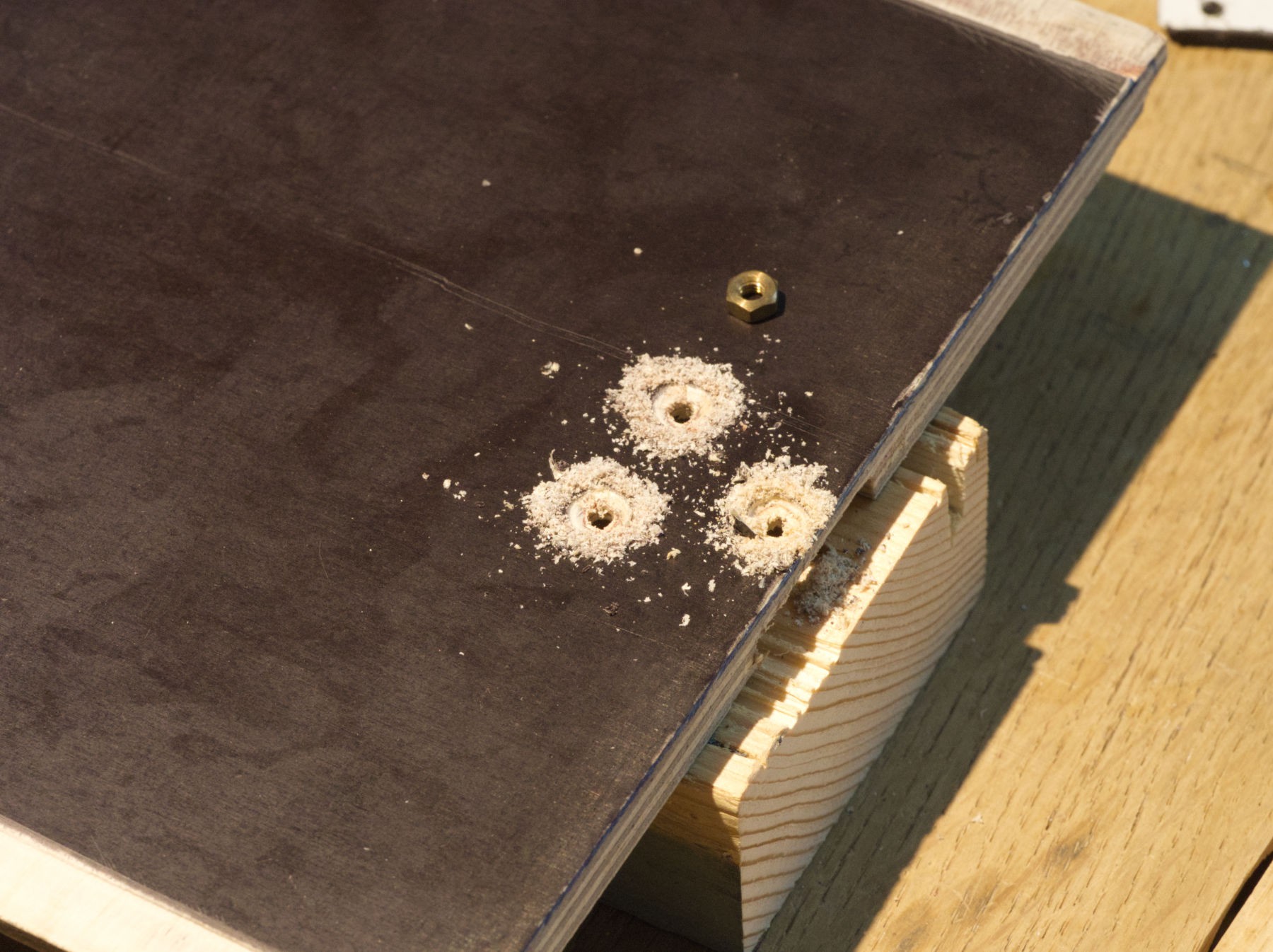

After milling the shape in the blind, drilled en place.

Largers (but not too deep !) holes on the back, so the nuts don't scratch the blade surface.

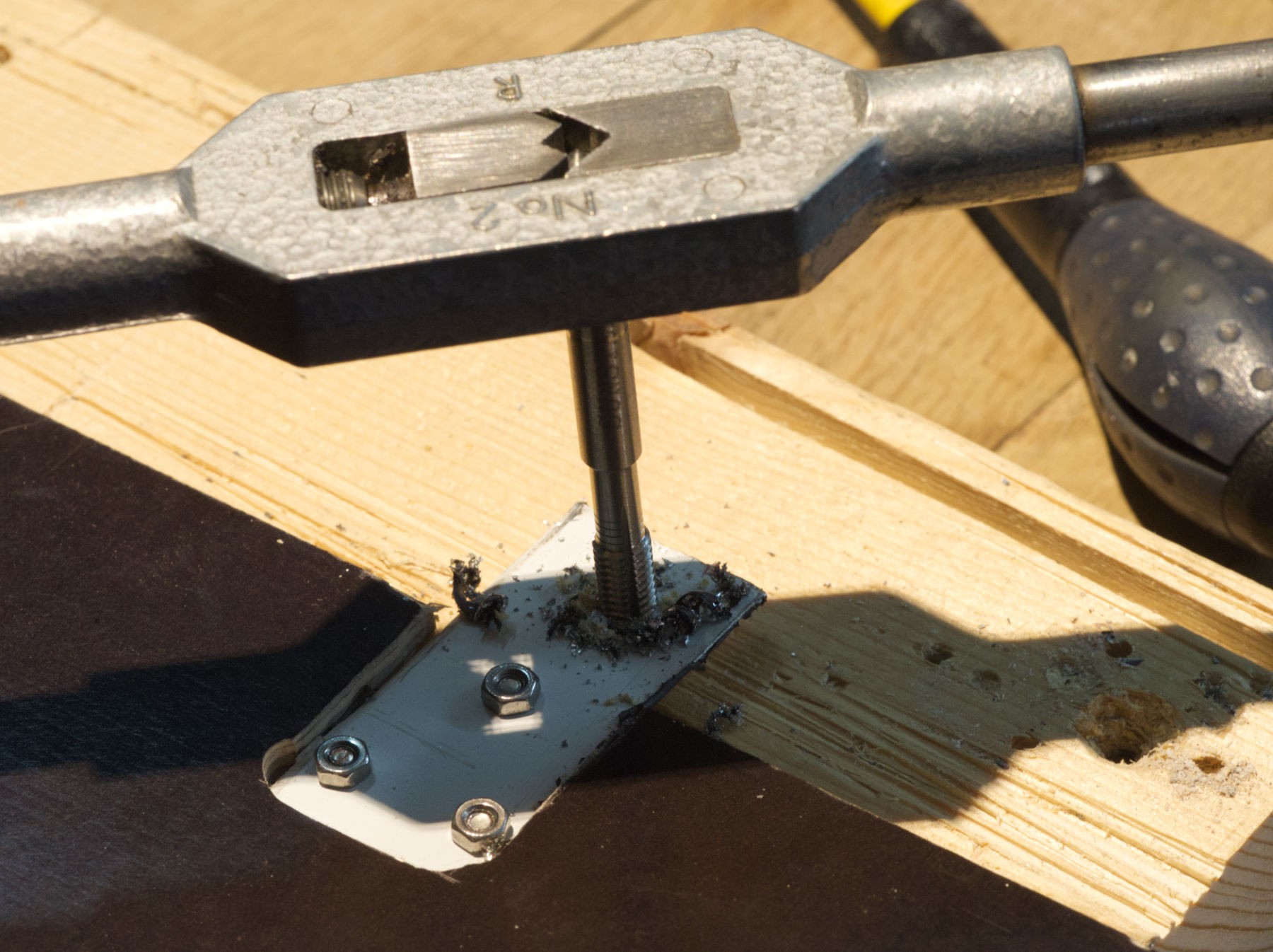

Drilling 5 mm, taping M 6 threads.

Carefully drilling holes (NOT TOO DEEP) in the blade.

Ok, let's try it.

Does not hit the flap.

But the screw's head is too slippery to be turned easily with the finger tips, and I don't want th need any tool to take a picture, so it must be molletée (knurled), starting on the small vise, with a triangular file.

The small vise isn't strongly fixed on the bench, the bigger one is.

Nice, it's now easier to use.

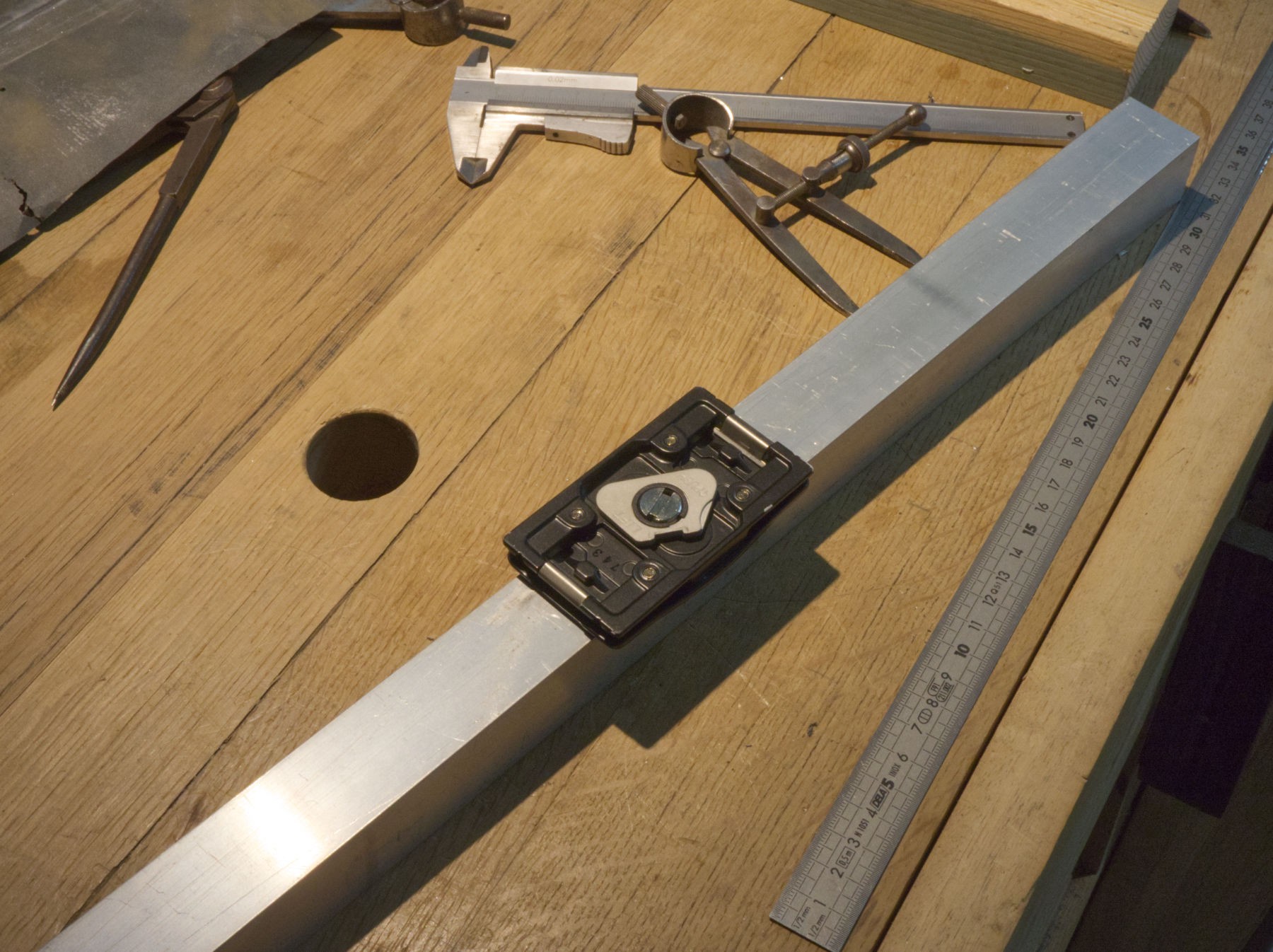

A last 5mm hole and taping 3/4 " threads.

To adapt the tube on a tripod, it will help holding the weight of the camera.

[zit] Olivier Gade

[zit] Olivier Gade

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.