I only got one 3/8" screw that's adapted to the vintage Gitzo tripod head system, and there's the need for two more.

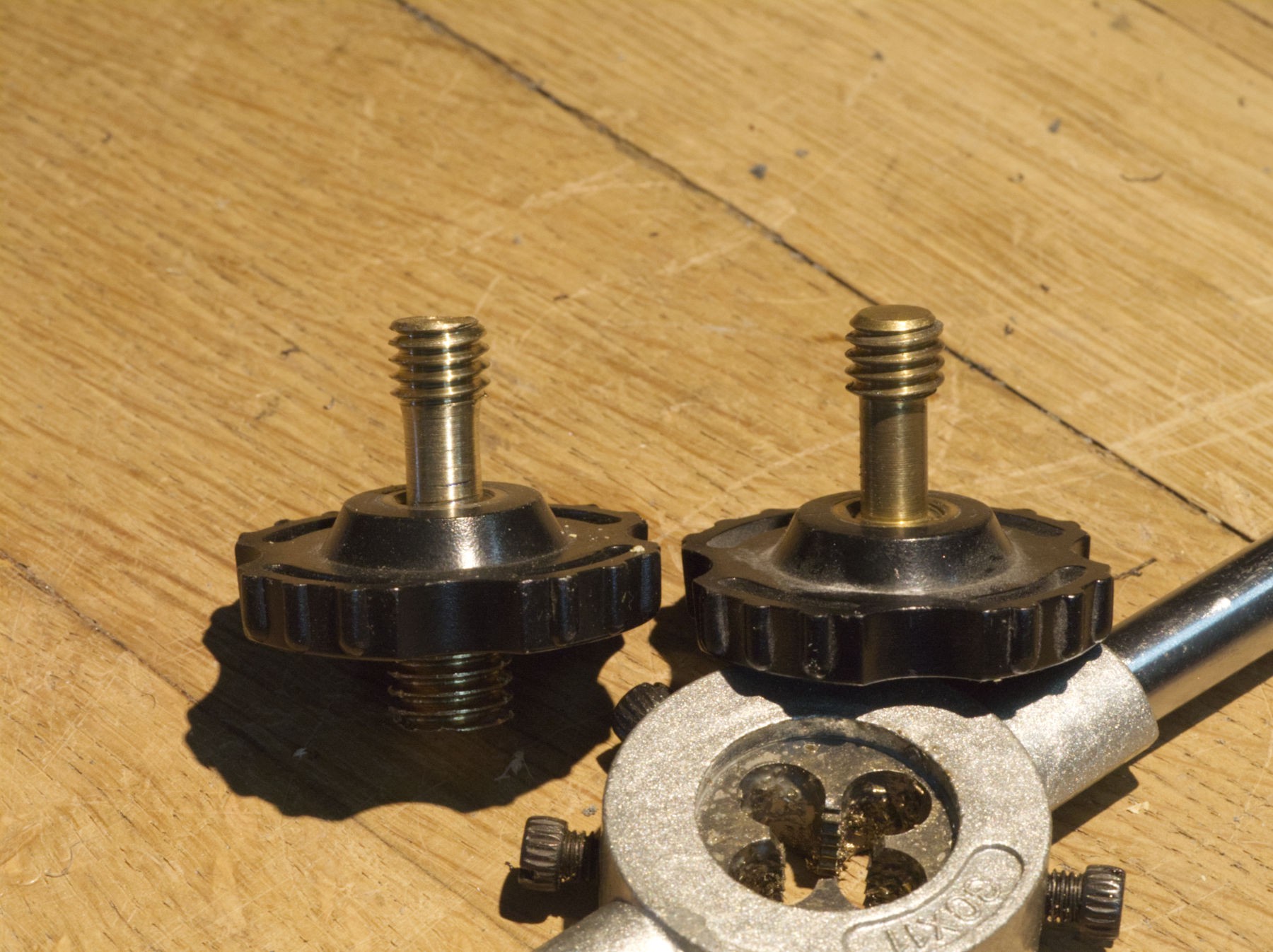

The first try's been made with some 1/4" screws with 3/8" adapters, I want full 3/8" screw, more strong.

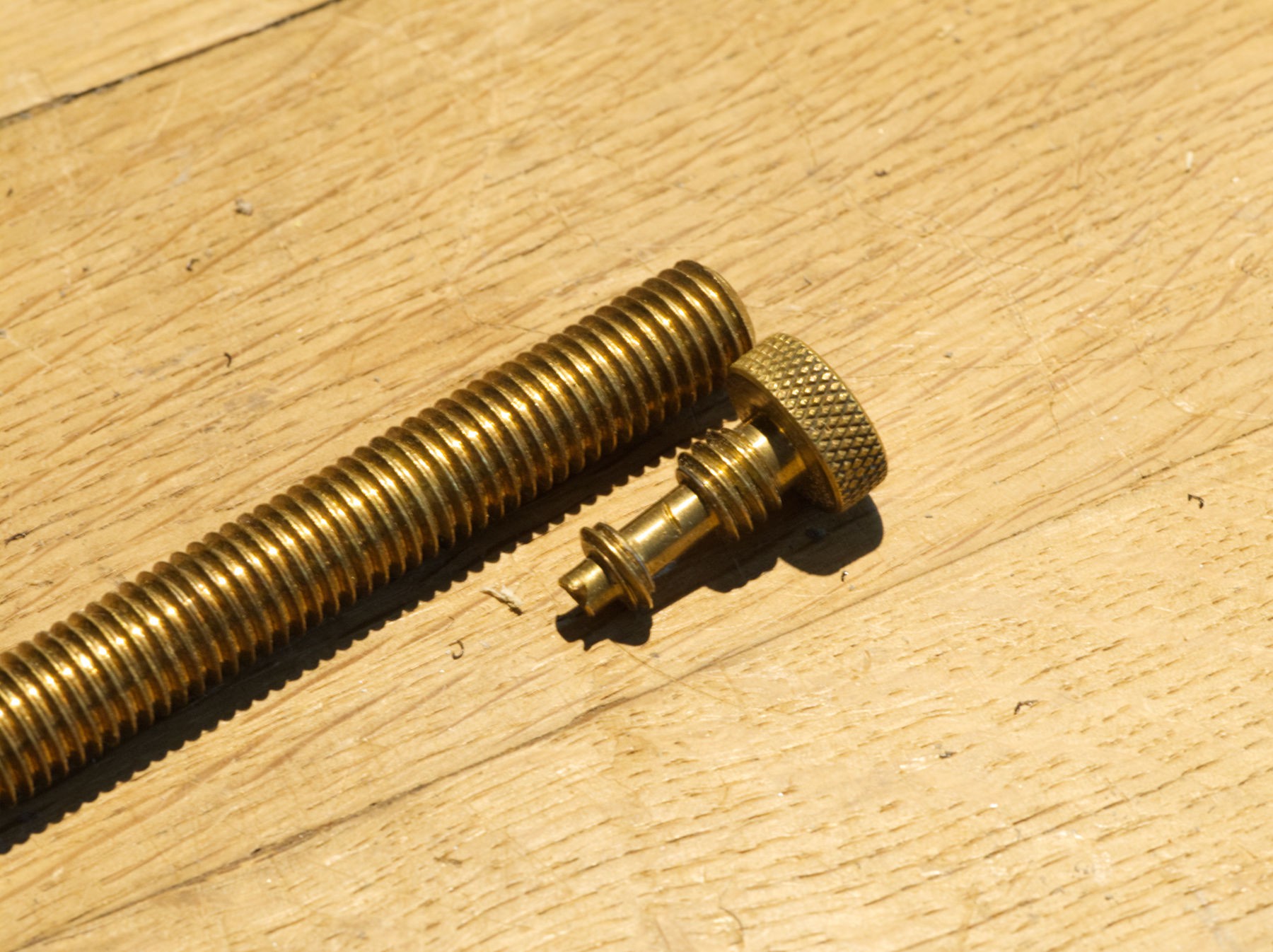

That M 12 brass screw brought on the cheap at a vide grenier (garage sales) will be perfect.

The drill press is another time used as a metal lathe, the tool is just handheld and the vibrations are tiring, as the fastest speed is around 2500 RPM, it takes time.

Finished with sandpaper, it's nice, but too short ! the model used has a worn end...

Next I've used a clamp to help holding the tool, like a with a wood lathe, it was much better, less tiring and more accurate.

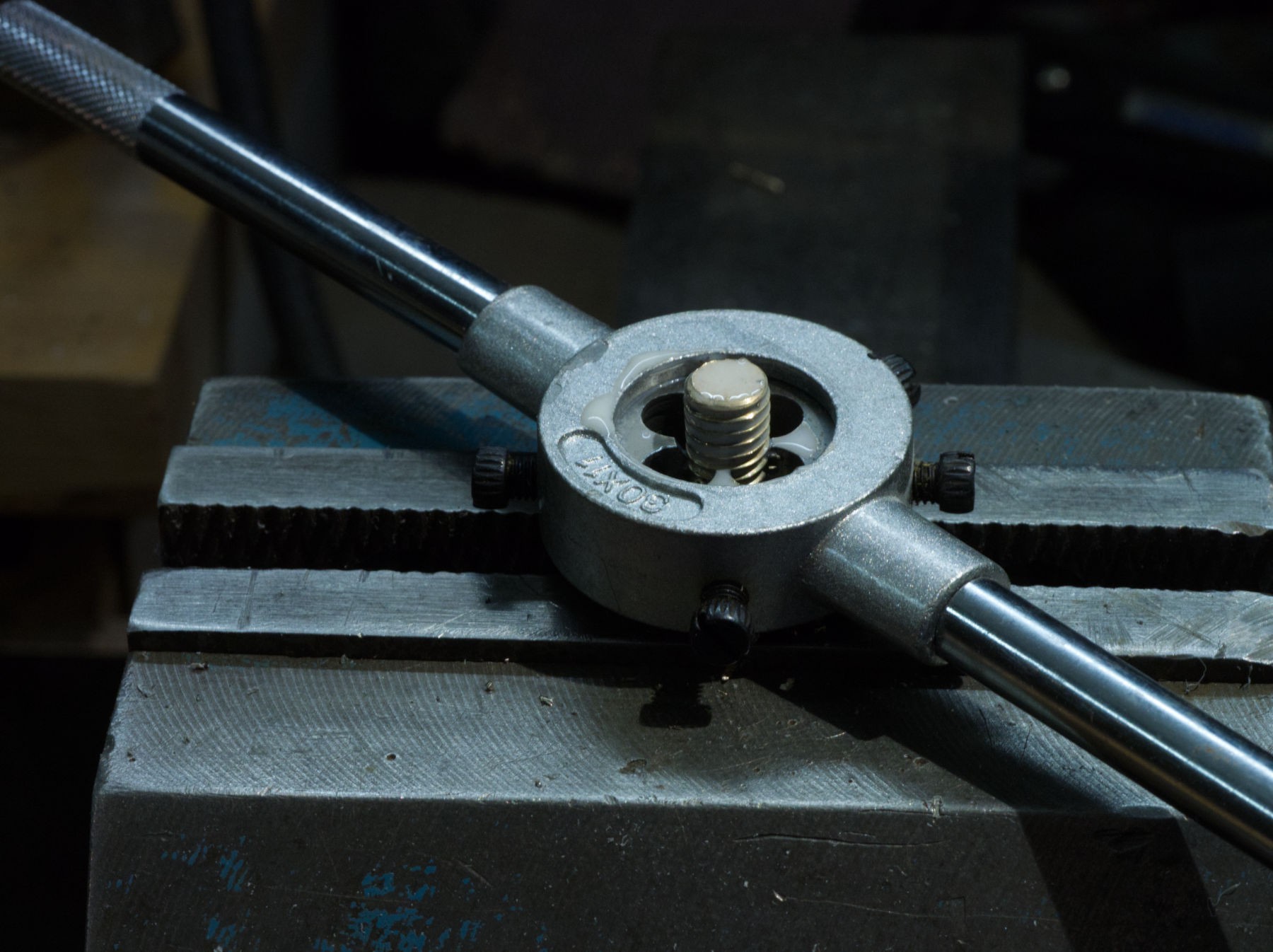

Threading with the appropriate 3/8 " filière (die), I like that holding tool with those 5 adjusting screws, precise and sturdy, both where brought on order in a specialized shop, big price for unusual stuff (anything that's not metric around here is some exotic thing, hence expensive).

The first and only time I asked for a 3/8 " threaded hole in a photographic workshop, the price for that only hole was close to the expensive die and tool holder.

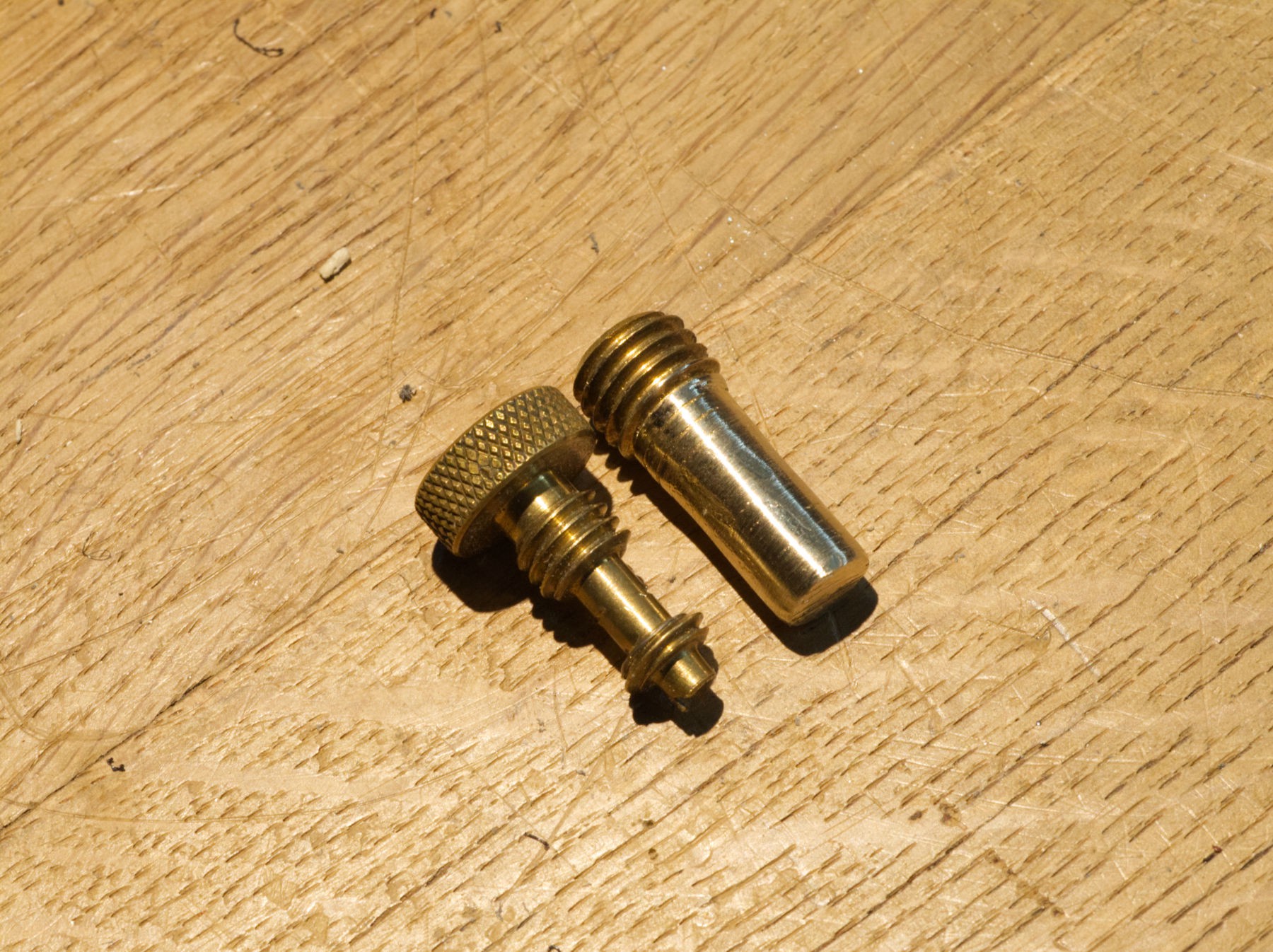

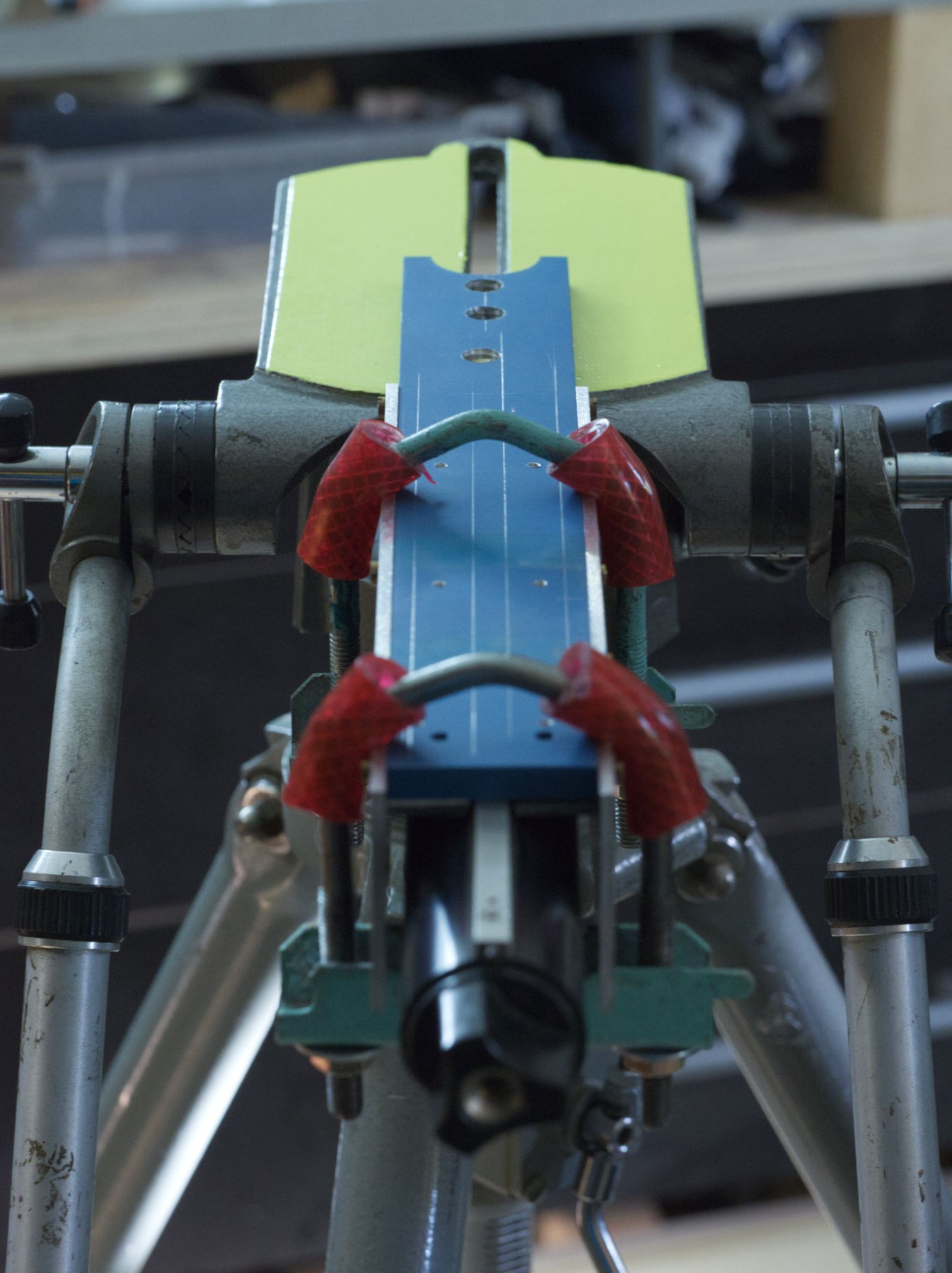

After threading the whole screw, it must have un épaulement (a shoulder) in the middle, to be able to move slightly in the slot.

It's not perfect but it works.

Very proud of the second one : mine on the left, the Gitzo one on the right.

Taping M 2 threads in an M 12 nut to have a big head with a good grip.

Very good.

Well, not so much, the closest hole isn't aligned at all ! but the clearance of the screws shoulders in the slot is enough to have a good alignment with the lens.

[zit] Olivier Gade

[zit] Olivier Gade

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.