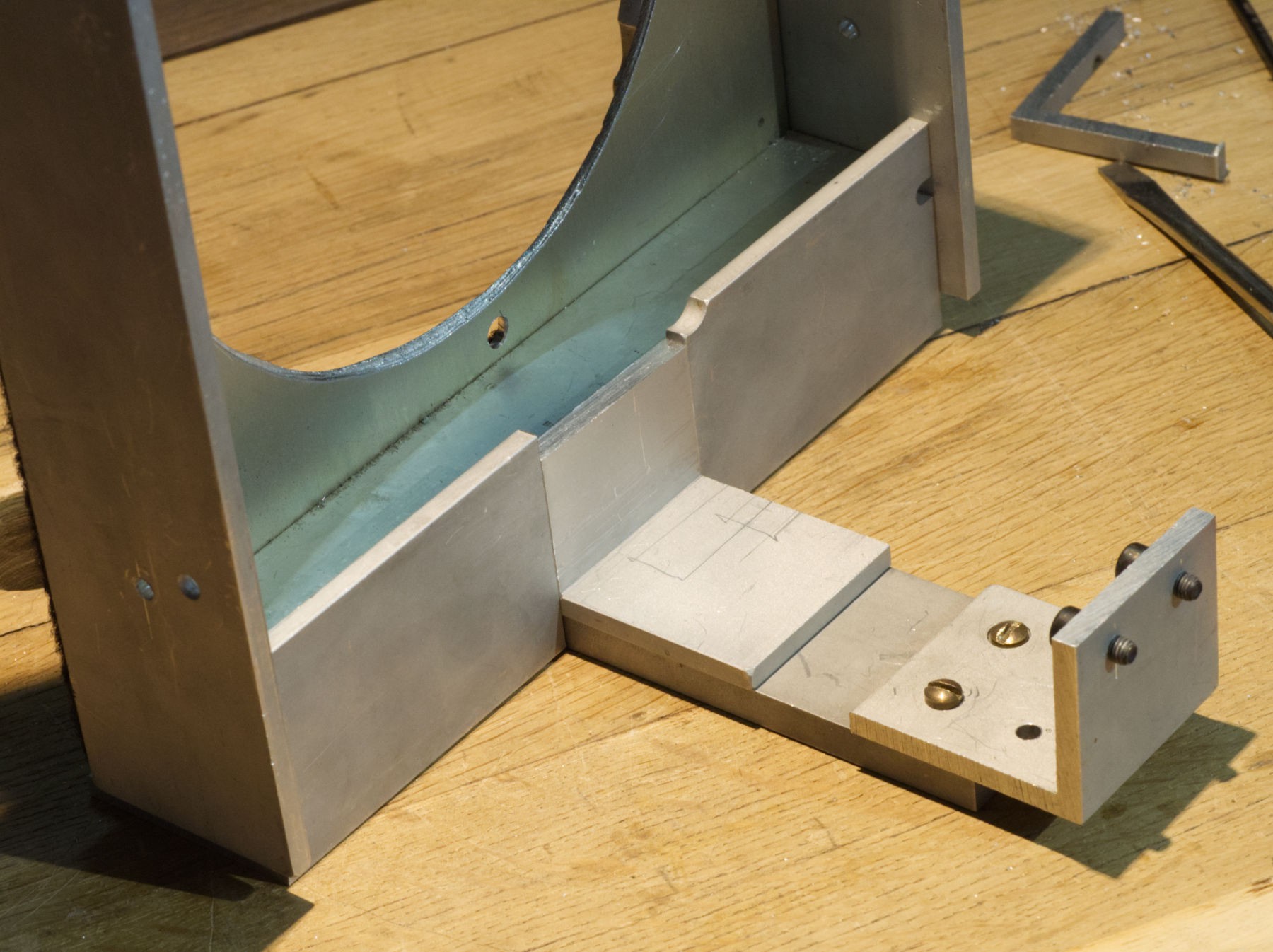

Another of these 5 mm thick aluminium L is going to be used, cut in two halves.

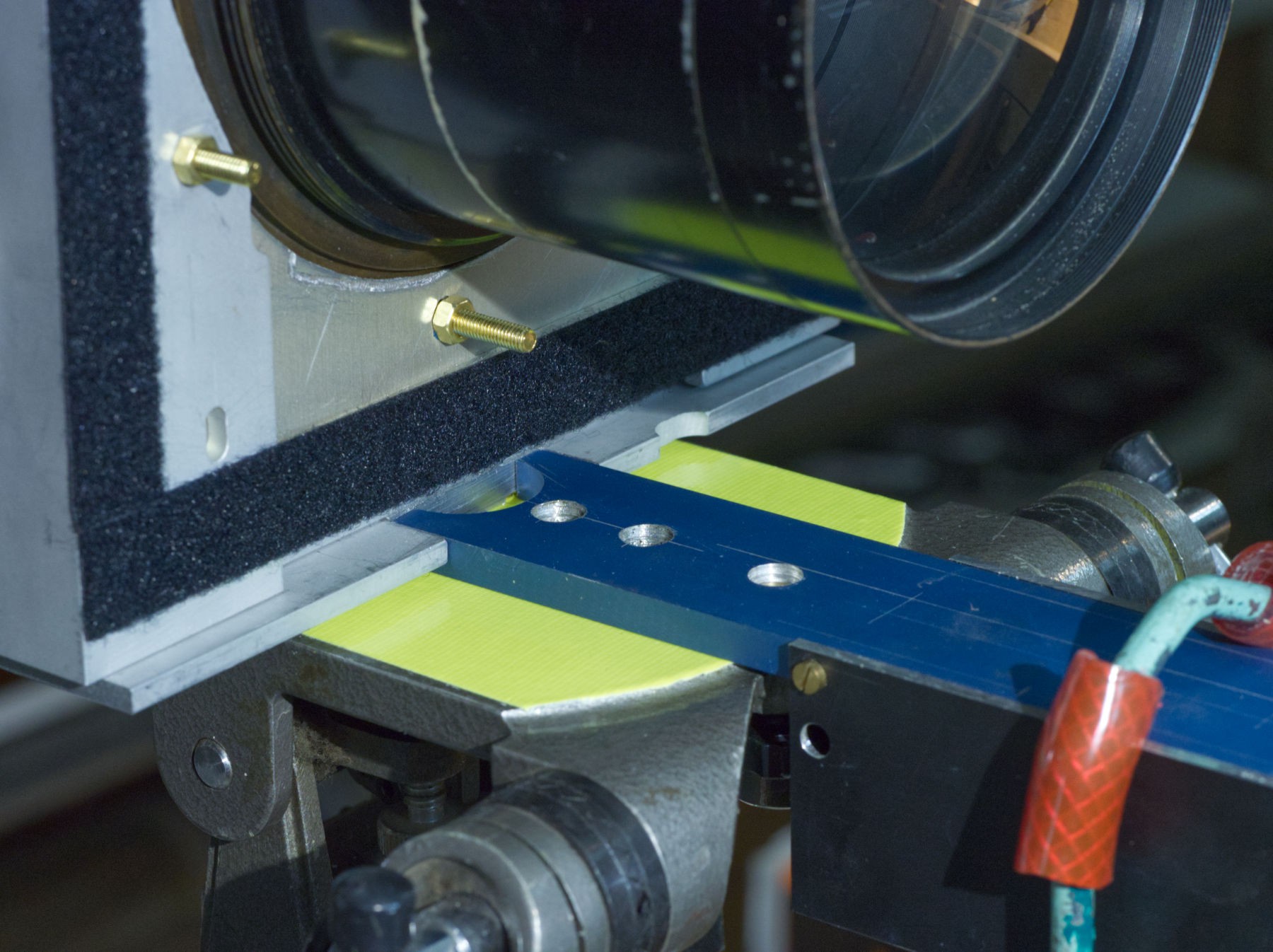

The 2 mm square tube is too weak. That'll be stronger.

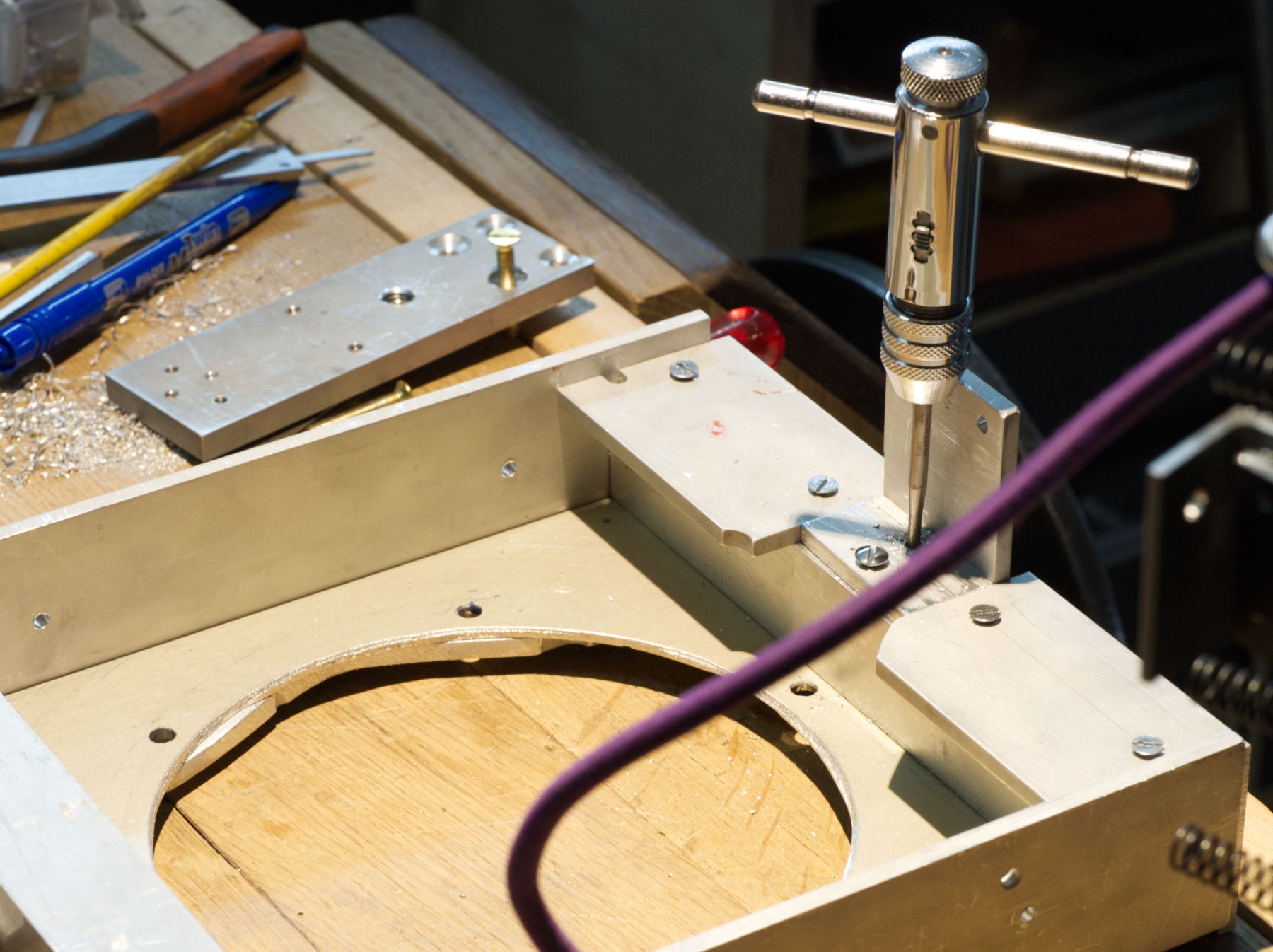

Drilling, taping, as you can see, stainless steel screws are used.

It's nice to have a big jaws vise on the bench.

M3 screws in an 5 mm thick plate, it'll do, but it was close to the disaster.

As the L shape are bigger than the 30 mm square tube, the alignement with the rear part of the build is perfect and easy now.

[zit] Olivier Gade

[zit] Olivier Gade

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.