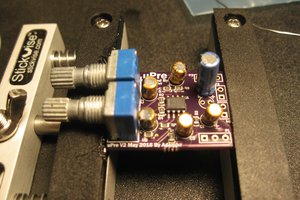

The TSAL circuit includes a NE555 timer to control the flash rate and a few discrete MOSFETs to perform switching operations. New members simulated their circuits in LTSpice, and picked component values to meet the specifications. Next the circuits were realized as printed circuit boards in Altium Designer. Once the PCBs were designed and checked by senior members on the team, they were ordered, assembled and tested. Two examples are shown here; in lieu of a full TSAL light, discrete LEDs are used to represent the red and green indicator lights on the TSAL. The members that complete this training are now well equipped to help out and contribute to the design and manufacturing efforts of the team.

Over the past 3 years we have sourced our PCBs through JLC PCB. As designs for the car change often, we need a supplier who can react with our needs and supply PCBs on short notice so we can get back to testing and racing. JLC PCBs are high quality and of solid construction. They arrive quickly and are always made with precision. We are grateful for the support of JLC in the production of our racecar!

FormulaUFSM

FormulaUFSM

Madaeon

Madaeon

DIY GUY Chris

DIY GUY Chris

AVR

AVR