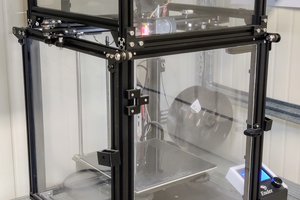

Attempts to make colorful, professional looking and informative membrane keyboards using an inkjet printer and a laminator.

The possibility of backlighting in the dark is considered a must-have functionality.

---------------------------------------------

I made four samples. Three years have passed. The text and contrasting images on three samples have blurred greatly. On one they remained in satisfactory condition. This indicates that this sample was well dried.

All the same, this home technology is not perfect. For example, for a black background you have to spend a lot of ink, as a result of which the lamination turns out to be fragile (weak adhesion).

Another critical drawback is the lack of tactile sensation of the center of the key.

Should we give up on the search? In no case. I think high-quality laminated prints can be made in a printing house. There they can also put drops of transparent rubber on the keys - the "Doming" technology.

Sl_Postmann

Sl_Postmann

Marius Taciuc

Marius Taciuc

Federico Virdia

Federico Virdia

Atte Linna

Atte Linna

Your definitely choosing a more professional medium, as to my means frustratingly molding clay into a upper(negative) and lower press in which to shape plastic bags(very difficult) into the key shapes. Plastering old gel cyanoacrylate into a grid to layer a sturdy flat plastic piece(thin enough to use over a smartphone screen). I have messed about and yielded an ugly solution, but would much rather see your almost origami effect yield a worthy keyboard.