Every product starts with a concept, an idea.

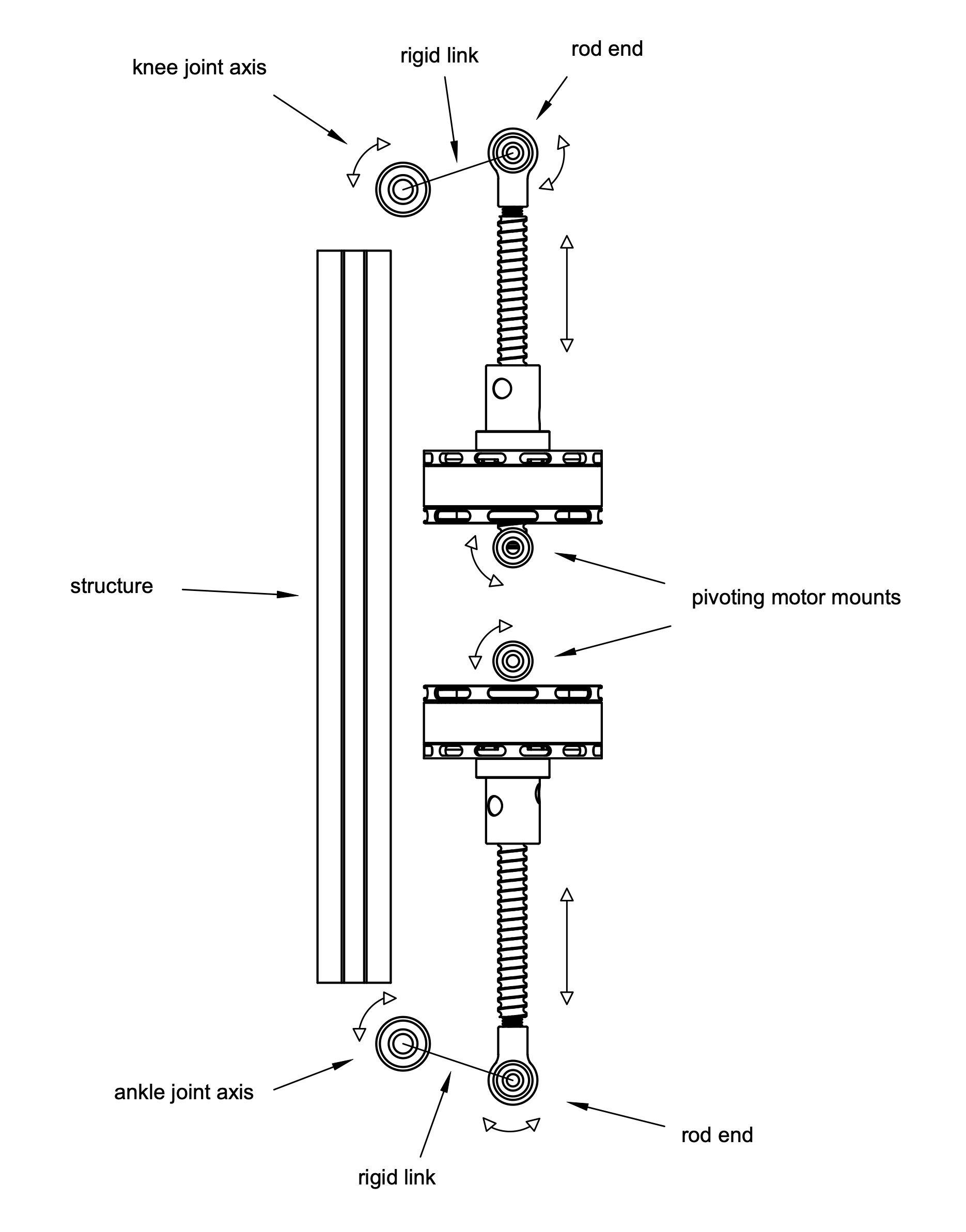

This was the case for the mechatronics design. Taking the actuation principle observed from MIT TF8, the concept shown in the following picture was conceived.

Another video of a similar actuator is attached here.

It is important to mention that for this project, elastic elements are excluded for simplicity and components minimization.

Motors on their own are unable to provide the required specifications. Combined with ball screws, the resulting actuators enable tuning to accomplish the needed properties. The actuators are mounted over pivoting mounts, and the screws pass through the motors' axes. These screws exert a linear force over a lever mechanism, which translates linear motion into torque at the joints' origin. This lever mechanism is what allows for reduction tuning, by modifying the properties of the rigid link portrayed on the image.

There is a structure, represented by an aluminum profile on the image, which holds everything together including the electronics.

The exclusion of elastic elements enables the system to know its position by using a forward kinematics model, thus without the need for joint encoders.

Maximiliano Palay

Maximiliano Palay

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.