I finally acquired a TC gauge that would allow me to evaluate the roughing pump candidates and did some testing over the weekend. The diaphragm pumps that I have hoped to use were only able to achieve an ultimate vacuum of about 6 Torr.

This is not horrible performance for a diaphragm pump, and it's also within the safe operating range for the Edwards EXT255H compound turbo pump, but there are a few reasons I'm not happy with it. Firstly, there just isn't much margin and working with such a high backing pressure will put more wear on the turbo pump than is necessary. Secondly, the Pirani gauges that I planned on using for monitoring rough-down and process control just don't operate at pressures that high. It would be much better to achieve a foreline pressure of at least 0.5 Torr so that the Pirani gauges can register it. To that end, I bought a Harbor Freight refrigeration service pump to act as my backing pump. I had hoped to keep the system entirely oil-free, but with some basic precautions, it should be very difficult for pump oil from the roughing pump to contaminate the rest of the system.

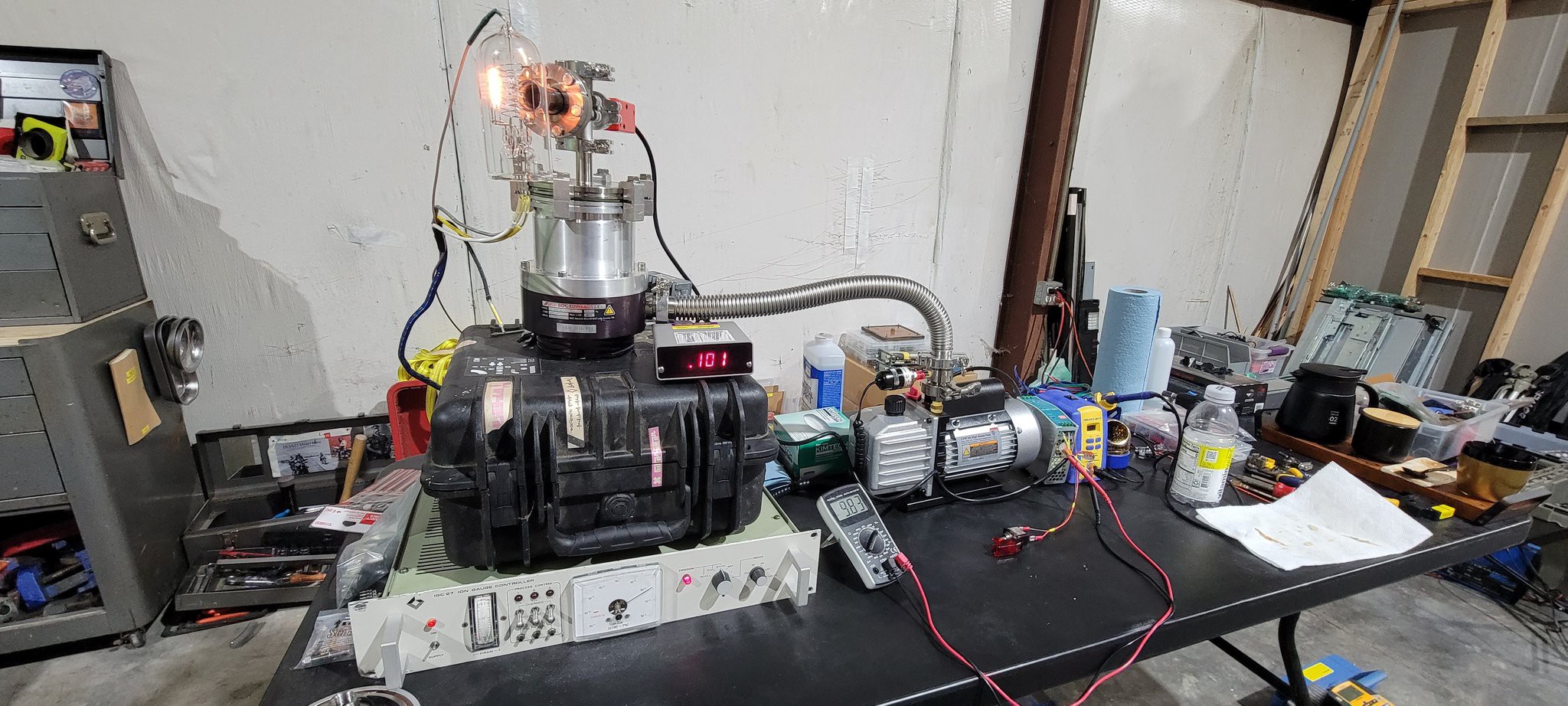

With the test manifold assembled, I fired up the new roughing pump and within a few minutes got the foreline pressure down below 0.1 Torr which is a massive improvement. With that settled, I wired up the Turbo and ion gauge, tightened everything down, and ran the whole system down for the first time.

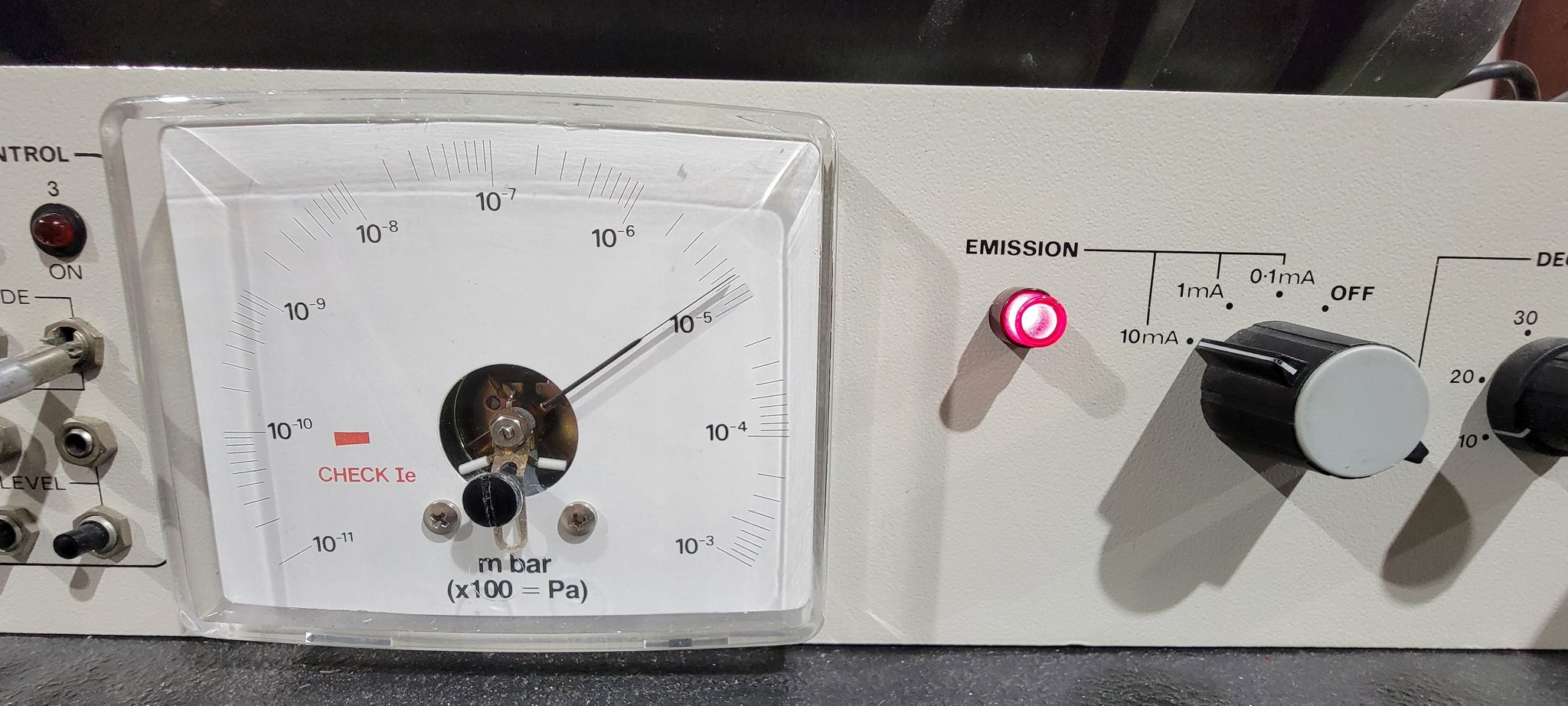

As you can tell from the glowing ion gauge, the system pumped down just fine and within about 20 minutes we were moving down through 10⁻⁵ mbar!

That's good enough. More performance can be squeezed out here by properly cleaning and drying the whole system and putting some Faraday Wax over the damaged purge valve port on the side of the turbo, but even if we never get into the 10⁻⁷ territory, a getter material in the sealed tubes will clean up the rest.

Nick Poole

Nick Poole

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.