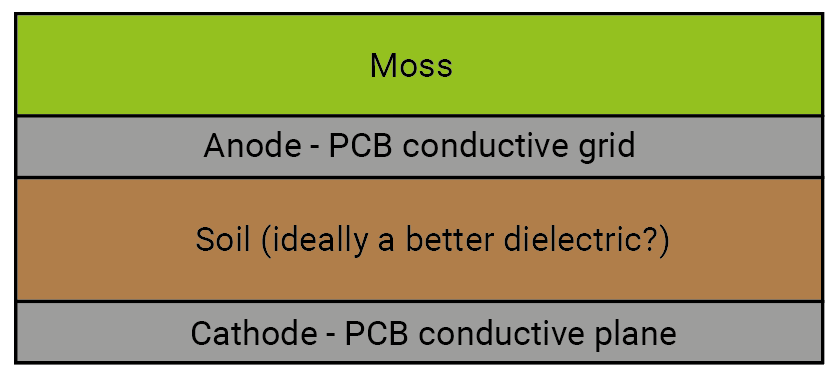

The construction of the container is fairly simple and consist of the following layers:

This is a very basic overview, but the parameters that seems to affect yield are:

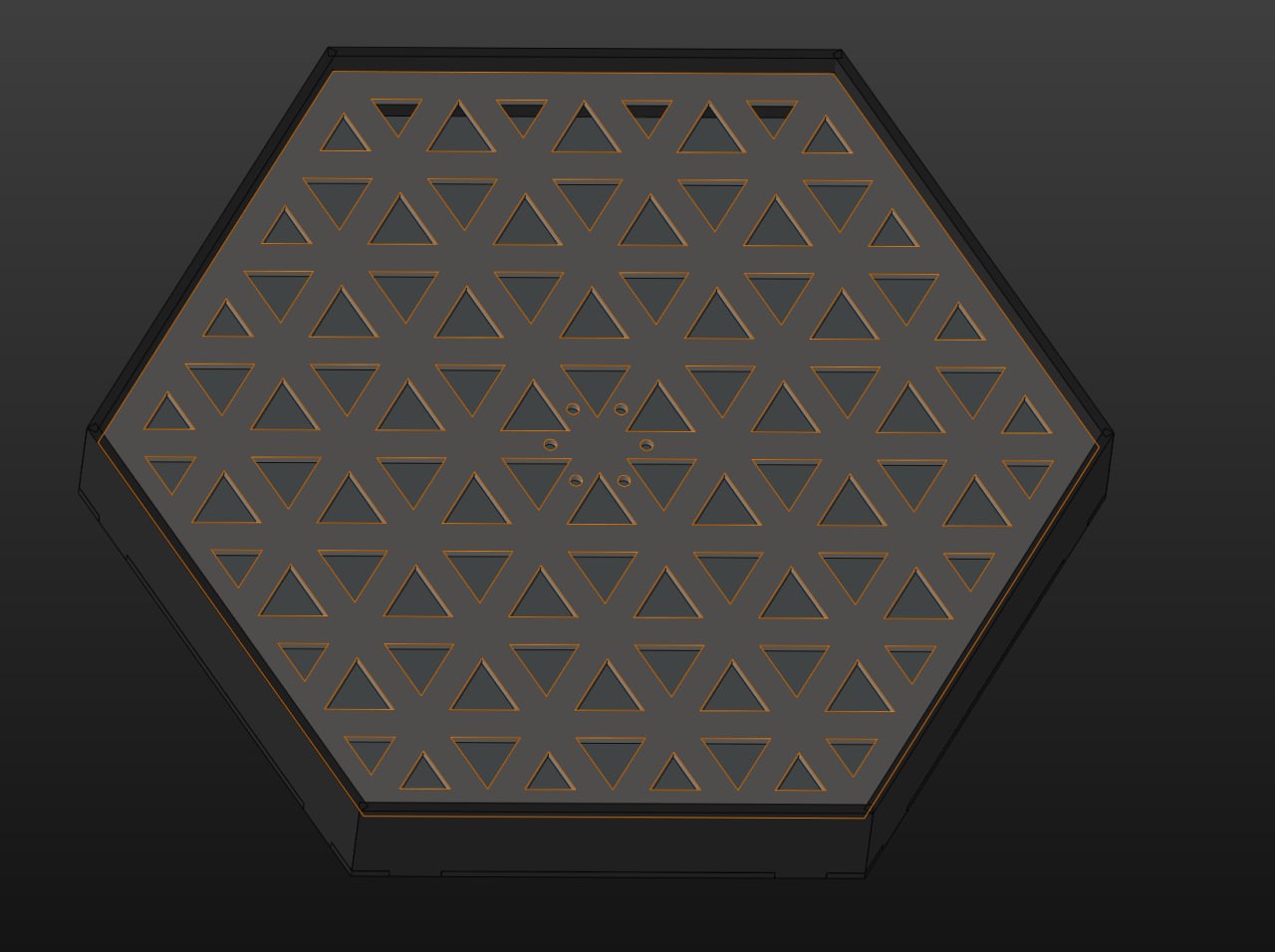

- The surface area of the anode, best results have been obtained with a conductive "matrix", which is not mentioned in the research paper. For the build I will try a grid to maximise the surface area while keeping it conductive.

- A large flat and even surface that can be a good conductor all across - for that I have a PCB in mind.

- Possibly a good dielectric and porrous material between the anode and cathode? there is little about this specifically so it will require some tests.

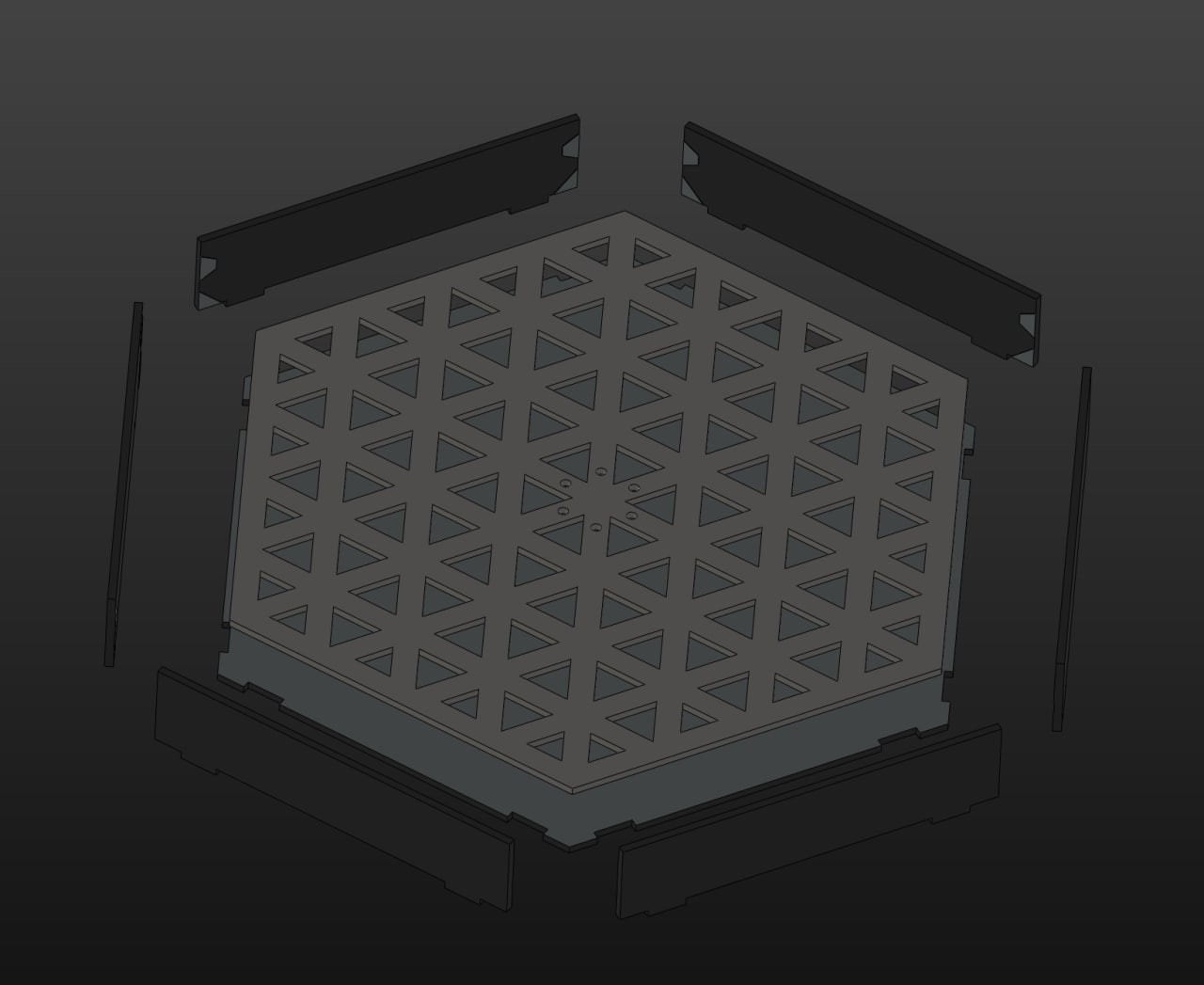

Following these constraints, this is the design to try next:

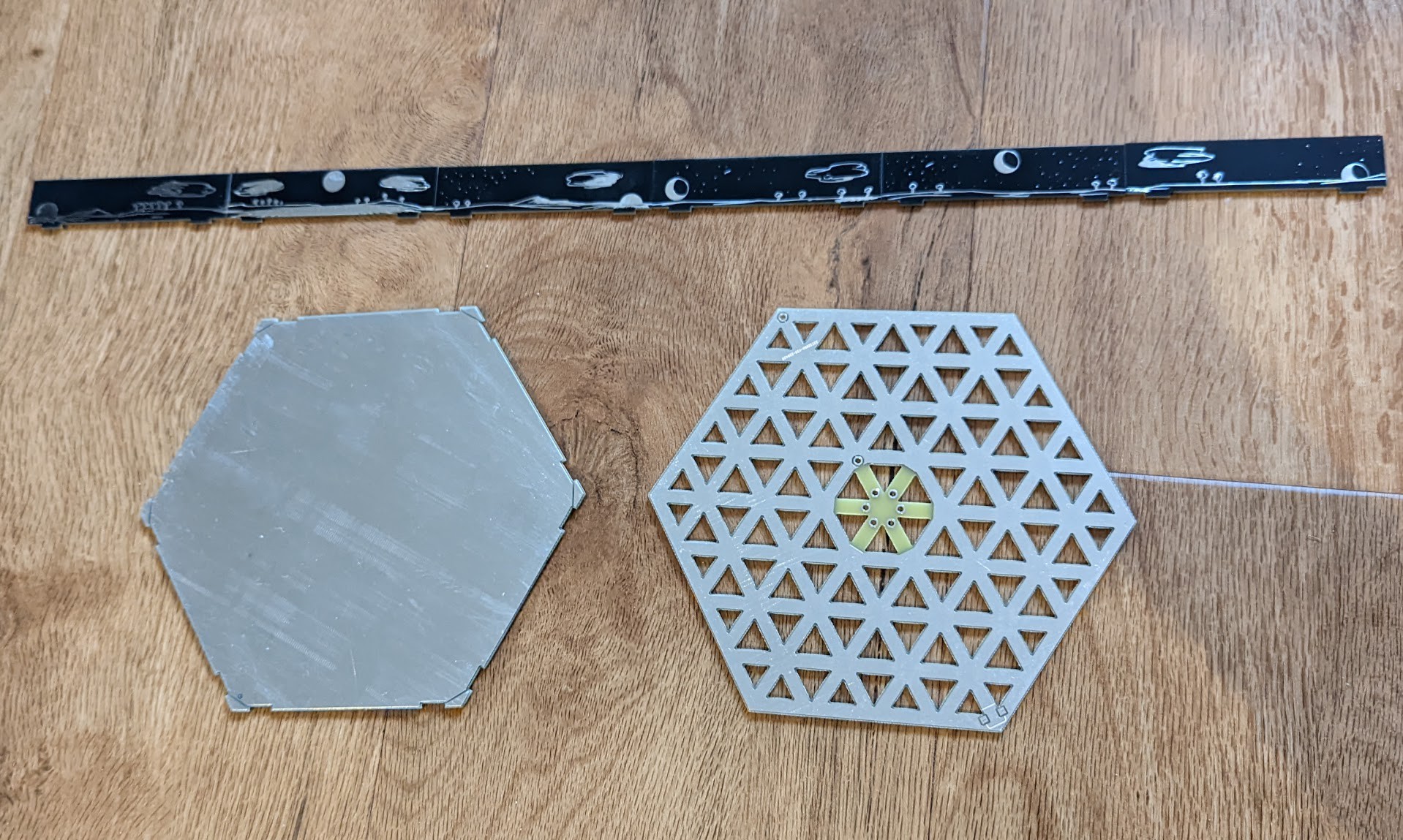

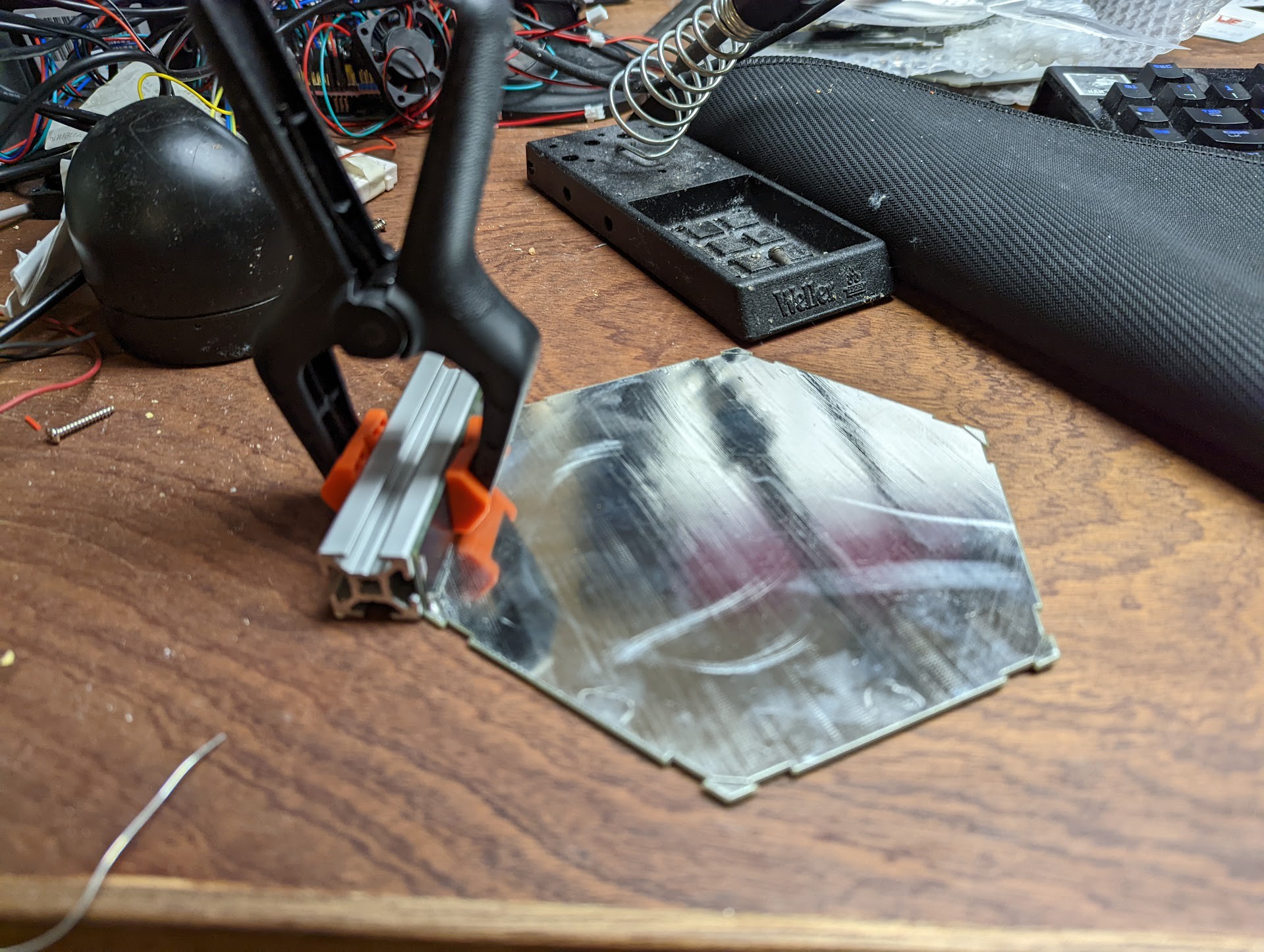

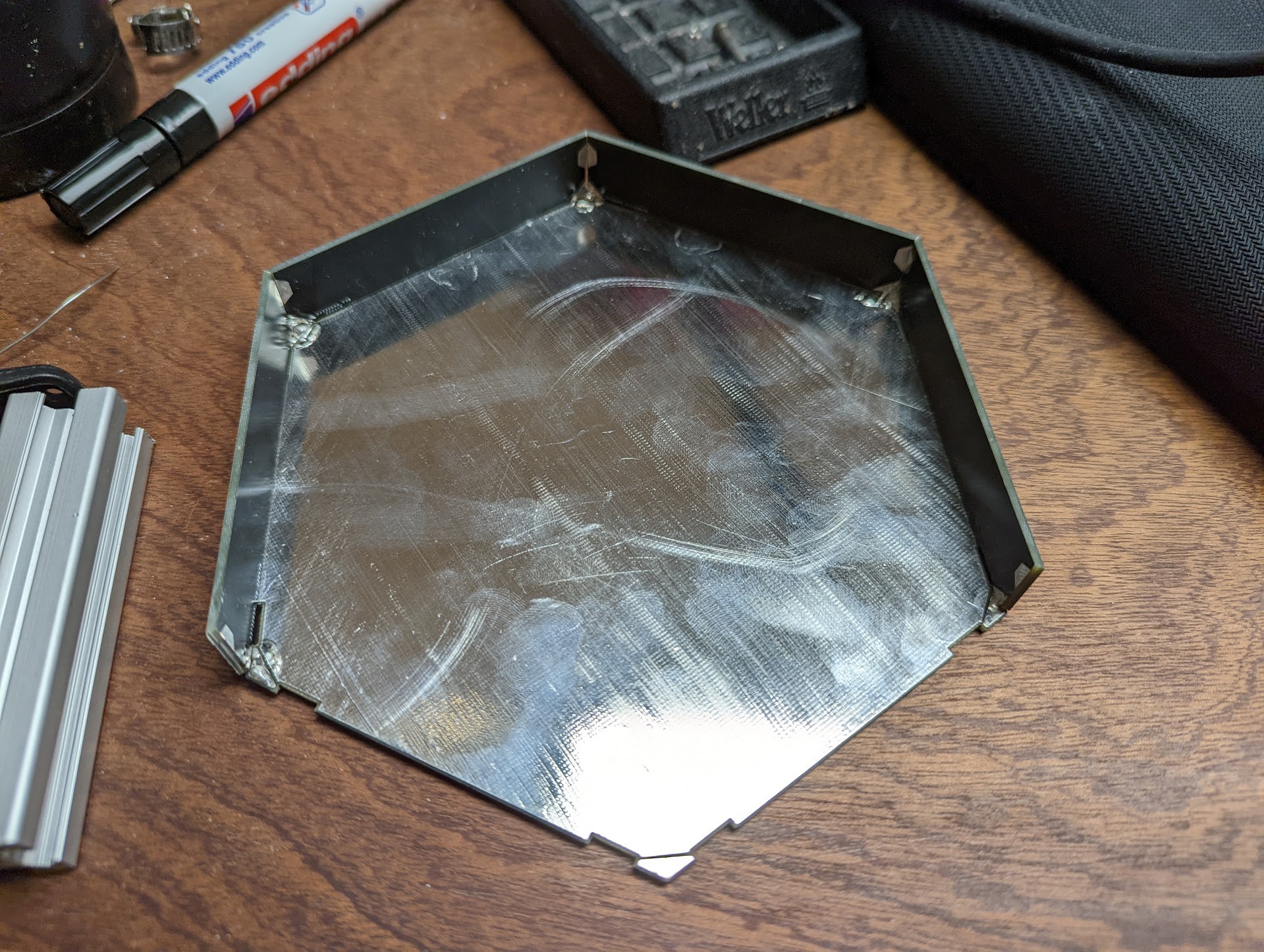

The top is a PCB grid, with plating on both sides, and the bottom is a large surface of copper. Since most of the container is made out of PCB, the sides to hold it together are made of FR4 too with little pads to hold it together. Here are some pictures of the assembly!

Next time!

Of course populating the new cell with moss! but also more test and datalogging on current fuel cells to understand how they work and perform better~

Guru-san

Guru-san

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.