We monitored our chiller power and temperature with the open source monitor extraAC, based on the excellent IotaWatt. We attached the monitor to our glycol chiller, a coolwine.com labeled G&D Chiller. 3 Ton / 10 kW. Data is forwarded to the open source emoncms.org for offsite viewing.

When the tank temperature needs to be lowered during cold crashing, a lot of cooling power is needed from the chiller. However when the tank temperature is stable, only a moderate amount of chilling power is needed to keep the temperature stable. For moderate cooling power, the compressor cycles on and off, and the circulating pump still runs. This wastes pumping energy, and energy keeping the glycol loop cool.

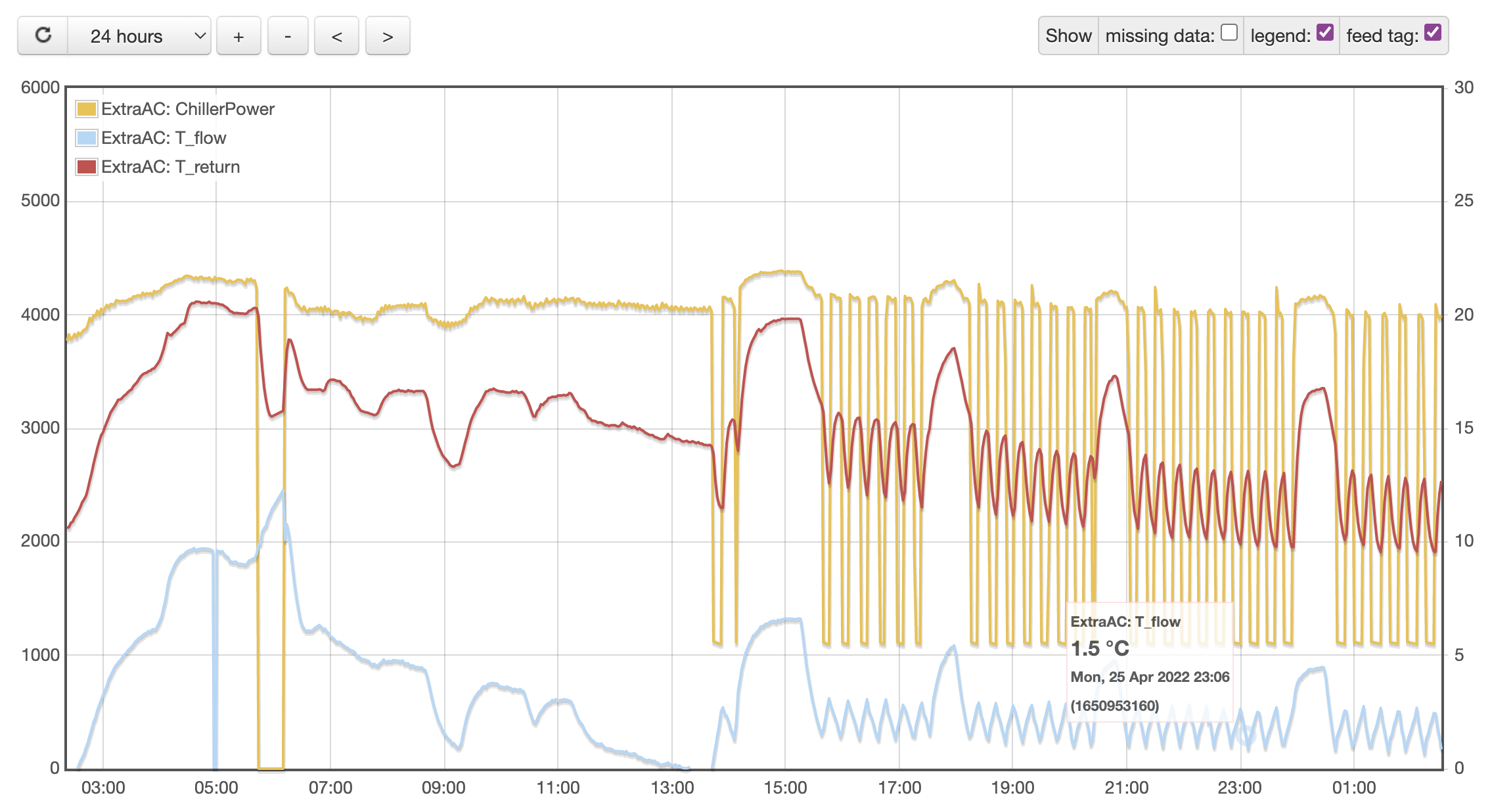

Before adding the chiller control, below we can see the tanks cooling at full chiller power as of 6:00am until 13:30, then the chiller runs on partial power, PWM-ing the compressor, for the rest of the chart. By adding an IoT switch, we can largely eliminate this second PWM part of the chart, simply by running the chiller less often by scheduling it with the IoT switch.

Tim Bishop

Tim Bishop

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.