This page is devoted to explain the price of 1kg recycled PET bottle filament

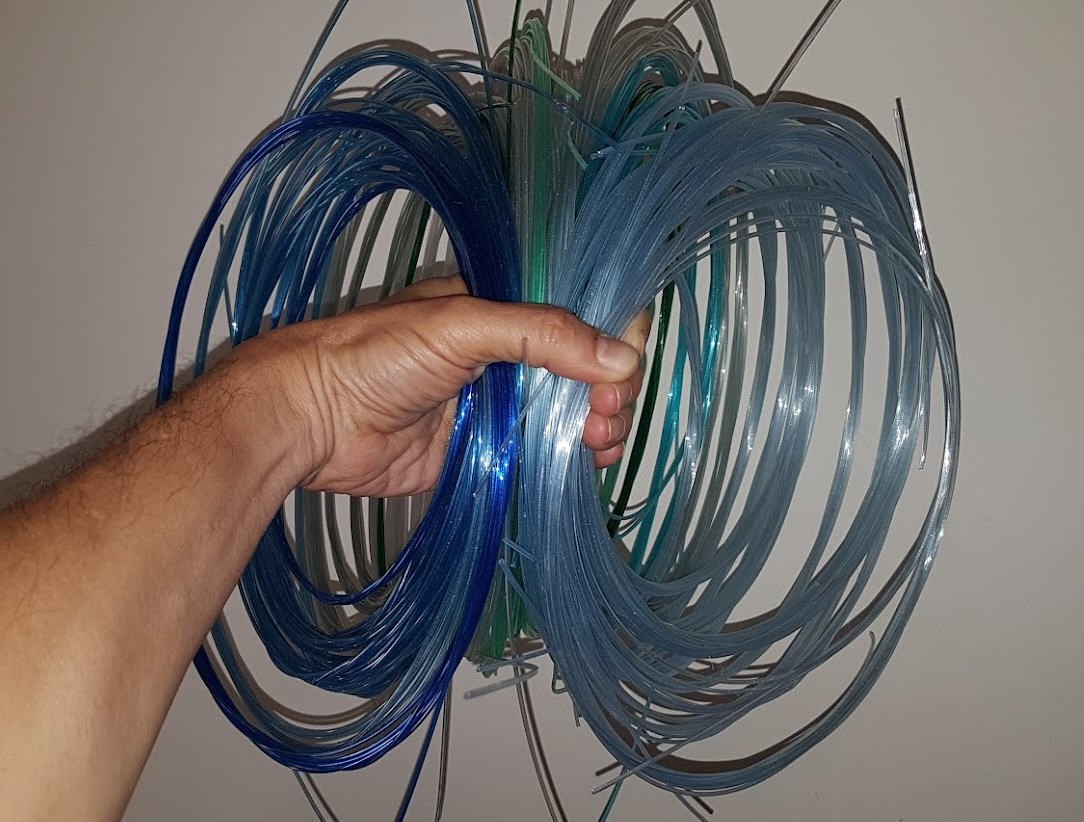

We will study the worst case : 1 small bottle producing only 5 to 6 m of filament. This is the blue one of my video !

To get these 5m we have a sequence divided into two steps

- pre heating the nozzle

- pullstruding the filament while the PID is regulating the temperature

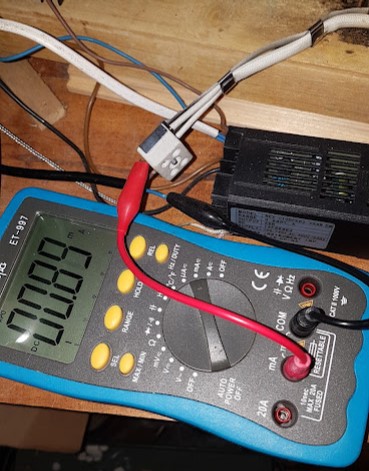

The heatband has a power of 200W (specified by the manufacturer) and this figure is consistant with the measurement done in situ. (230V * .89A = 204W)

The preheating phasis lasts 2 minutes and draws 2 * 200 /60 = 0.167 Wh of energy

The Pullstruding phasis lasts 10 minutes (for ~5 m ribbon) and draws :

- 5W during 10 minutes for the wiper motor (5V, 1A) = 5 * 10 /60 = 0.833 Wh of energy

- the PID regulates the temperature (1min 40s heating, 8min 20s Off). That is 200 W during 1 minute and 40s. 200 * 1.66/60 = 5.55 Wh of energy

Thus the final energy required to pullstrude one 5m bottle is : 0.167 + 0.833 + 5.55 = 6.553 Wh

Now 1kg of PETG filament has a lenght of 330 m it will require 330/5 = 66 bottles and will eat 66 times more energy to be produced than a single bottle.

So the total energy will be 66 * 6.553 = 433 Wh = 0.433 kWh

Knowing that 1kWh costs 0.18€ (here in France), we get our total cost of 0.433*0.18 = 0.078 €

In conclusion producing your own filament is really a cost saving solution

- 1kg of bottle recycled PET filament costs 0.08 €

- yes 8 cts €

- 250 to 300 times cheaper than buying it !

JP Gleyzes

JP Gleyzes

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.