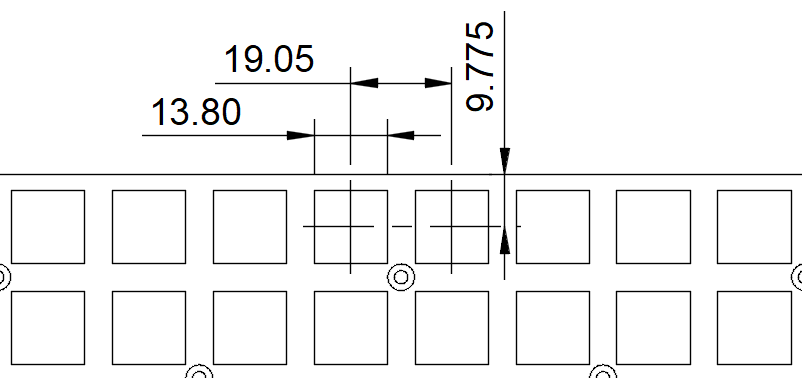

The positioning of keycaps and switches on the plate follow the keyboard unit u, which is usually 19.05 mm. Your letter and number keys have a width of 1u, while others use multiples of that (1.25u, 1.5u, 2u, ...). Since this unit is so ubiquitous in keyboard plate design, I saw it as a perfect opportunity to set it as a user parameter in Fusion 360.

The final model files for both plate and case can be found under the project files or in my Github repository. Here are some pictures of the prints:

Switch Dimensions

Plate

The spacing between keys is simply 1u if both keys have a width of 1u. In the general case, the equation below calculates the distance between two keys, with the widths being multiples a and b of u. I included an example for a = 1.5 and b = 1.25. Since I already had u stored as a parameter, Fusion 360 calculated the exact value for me.

Armed with a caliper, I set out to get the dimensions of the switch sockets for the perfect fit. That was easier said than done, because a bit too loose and the switch would come out easily, slightly too tight and plate would bend after fitting all the switches. A hole size of 13.8 mm gave the best result.

Around the edge of the plate I added a margin 0.5 mm to the usual u-spacing. This also determined the space between key caps and case. But I then had to offset the edge around the plate inwards by 0.25 mm for better assembly, resulting in the 9.775 mm as shown in the drawing below. The thickness of the plate is 1.5 mm.

Case

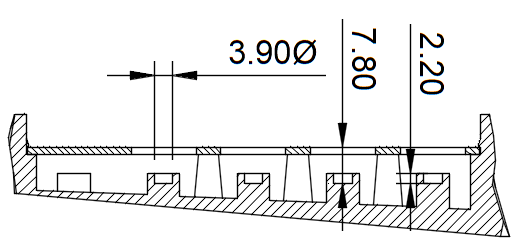

Having switches suspended by a thin sheet of printed plastic made the keys flex with every stroke. To prevent that and give the keyboard more stability in general, each switch has a socket it sits in. That is a hole with a diameter of 3.9 mm and a depth of 2.2 mm, which receives the thick cylindrical pin on the bottom side of the switch. The distance between the top of the plate and the bottom of the socket is 7.8 mm. That is shown in the following cross section of the case and plate.

Stabiliser Dimensions

Stabilisers are mounted onto the plate from below. The plate has a cut-out as shown in the drawing below. The stab wire is under the the narrow side of the cut-out.

Screw Dimensions

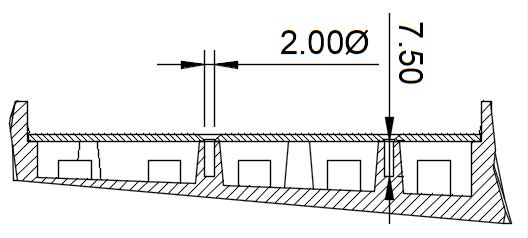

The plate sits on a 2 mm wide ledge along the inner edge of the case and is held in place by bumps protruding from the side. In the middle, there are numerous self-tapping screws of gauge 2 and with a length of 3/8" (= 9.5 mm). A hole diameter of 2 mm gave the screw a good grip, while not splitting the plastic. The hole is 7.5 mm deep.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.