-

Deployment Mechanism 3 - Third time, not the charm

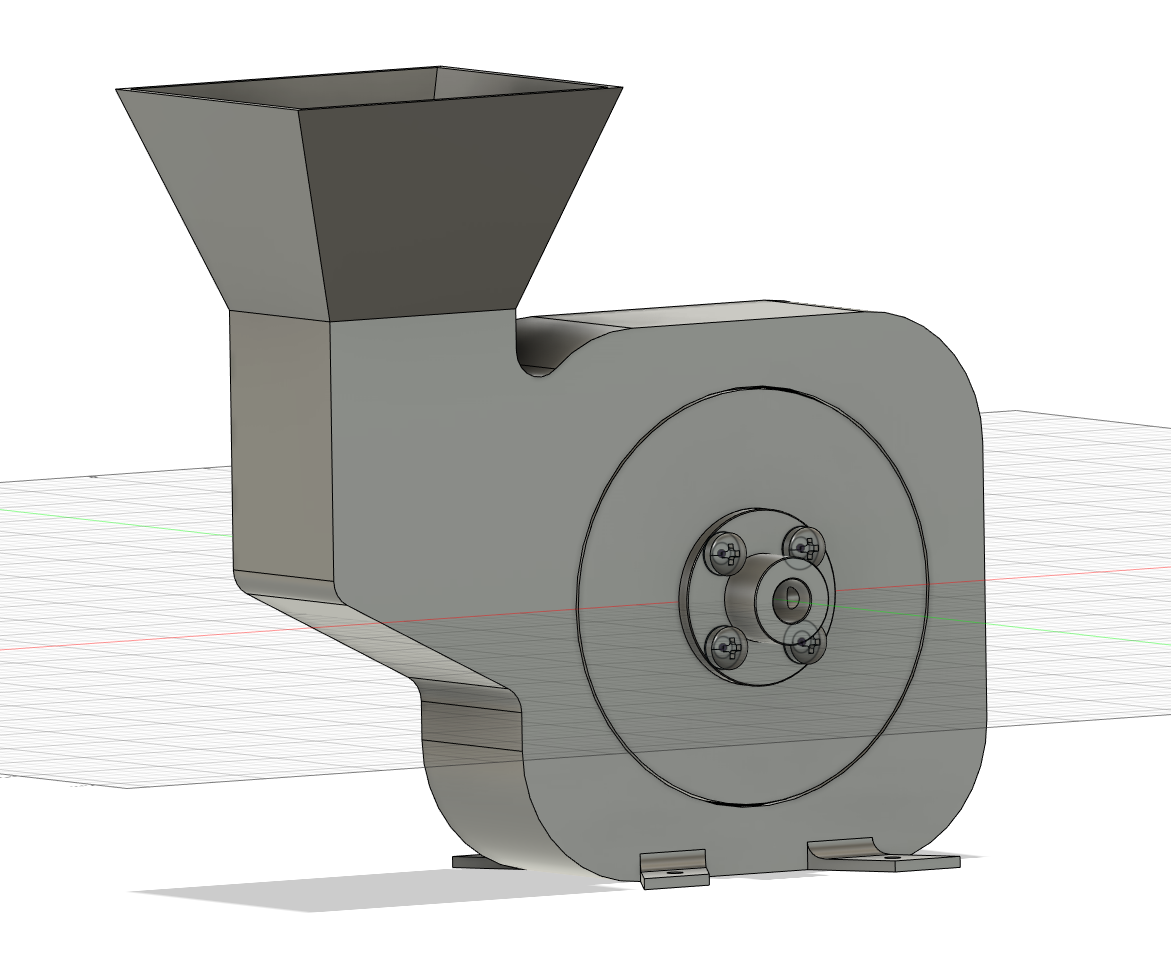

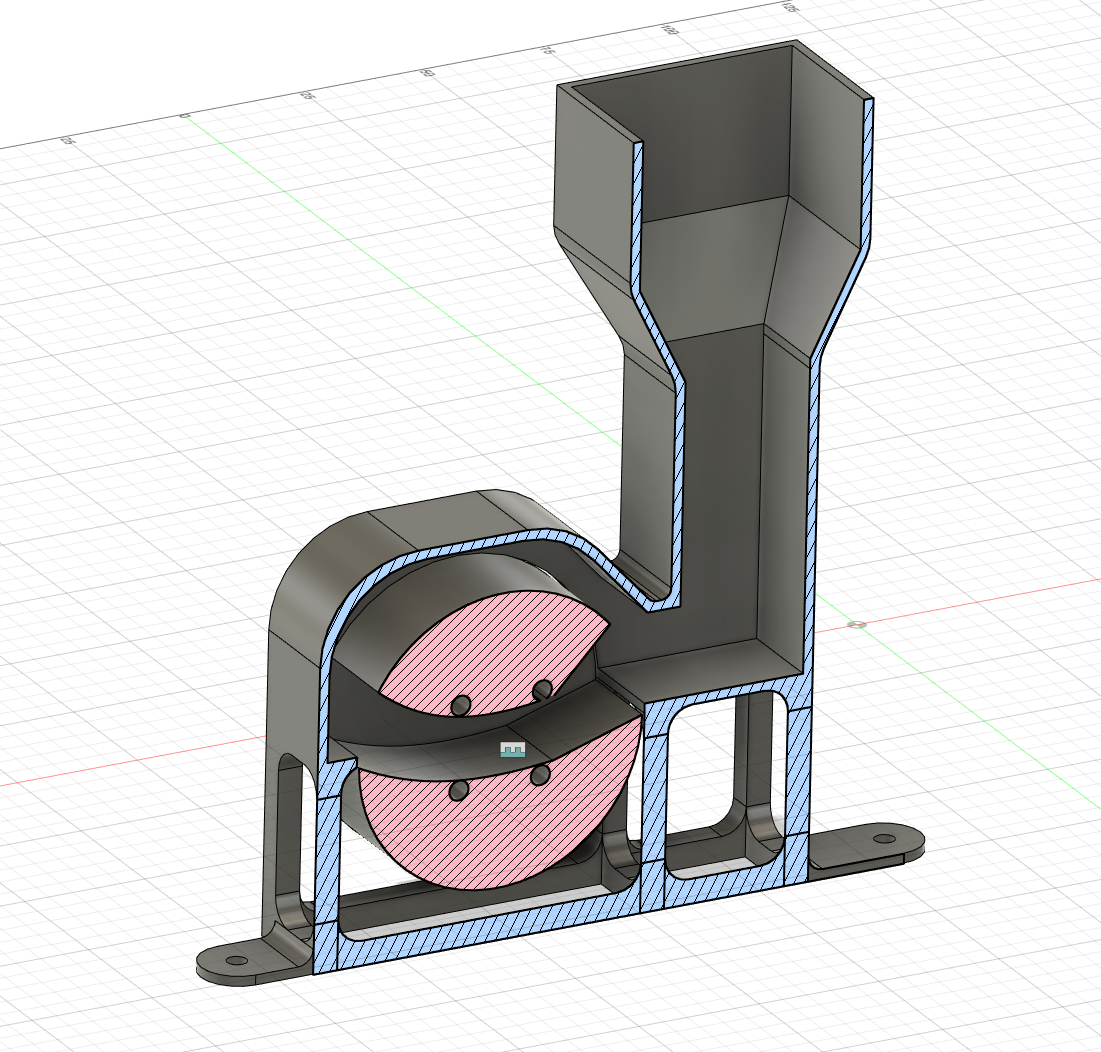

05/30/2022 at 01:32 • 0 commentsThe iterative process continues. Here's the latest attempt.

![]()

One nice addition: accurately sized screws, to ensure clearance is ok. Additionally, the model is scaled up to prevent jams. Here's the concept of operations:

![]()

Unfortunately, the baffle wall separating the chute from the wheel chamber extends too far down, and there is too much horizontal distance between the wheel and the chute. As a result, while the destructive jam problem remains fully fixed, the food get stuck in the chute and does not fall into the wheel chamber.

The wheel design and chamber work well as long as food reaches the wheel, so I'm going to leave the wheel and only rework the chute for the next iteration.

![]()

-

Deployment Mechanism 2 - A Cat Feeder For Ants?

05/26/2022 at 01:38 • 0 commentsAnother design has come and gone. I think this one has some potential though! Biggest issue with this one is that I just made it way too small!

I have been trying to minimize size of test components to reduce printer filament usage, but it really bit me this time. The conveyances were so small that food got jammed up even not going anywhere!

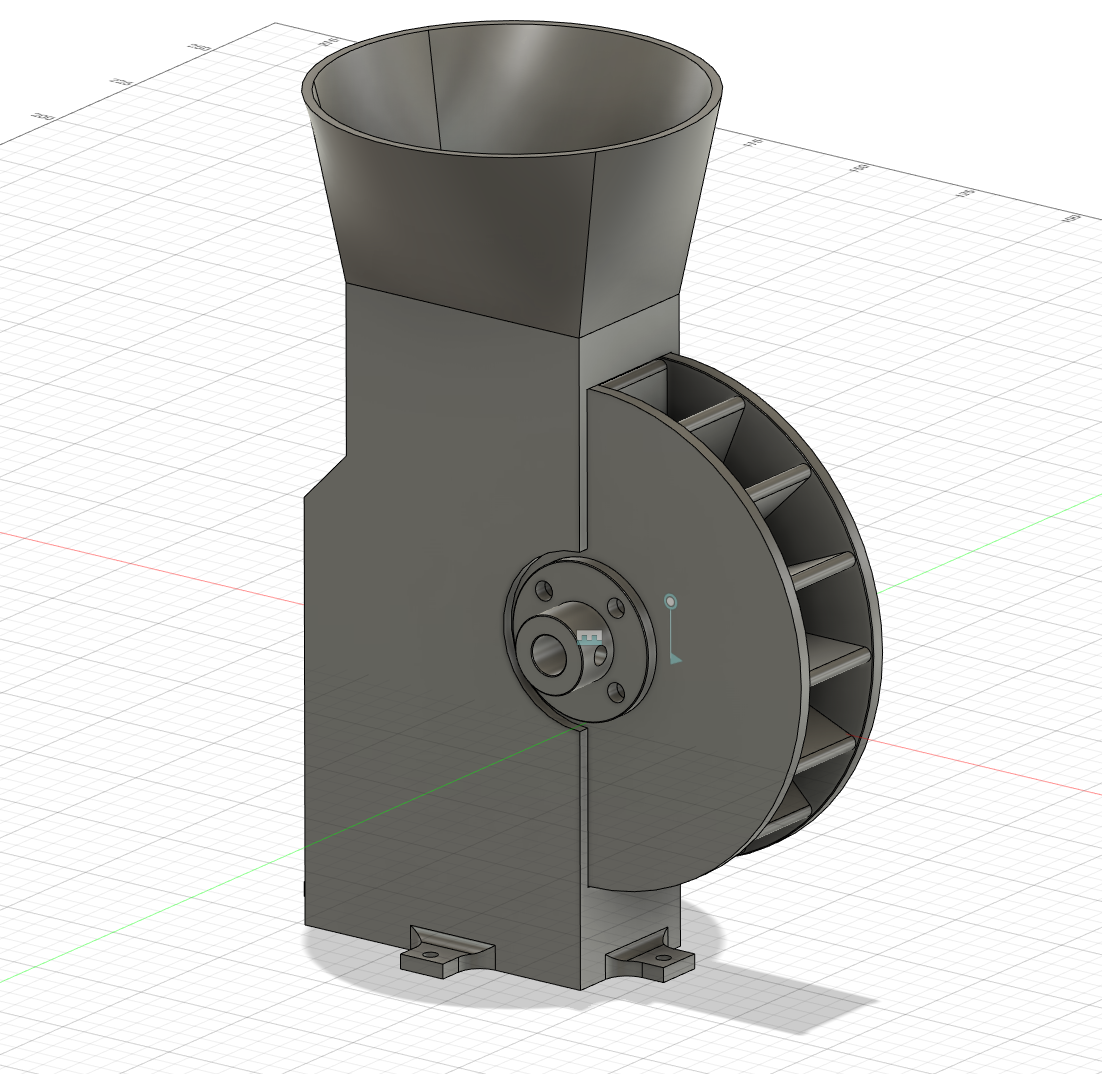

Anyway, here's the design.

![]()

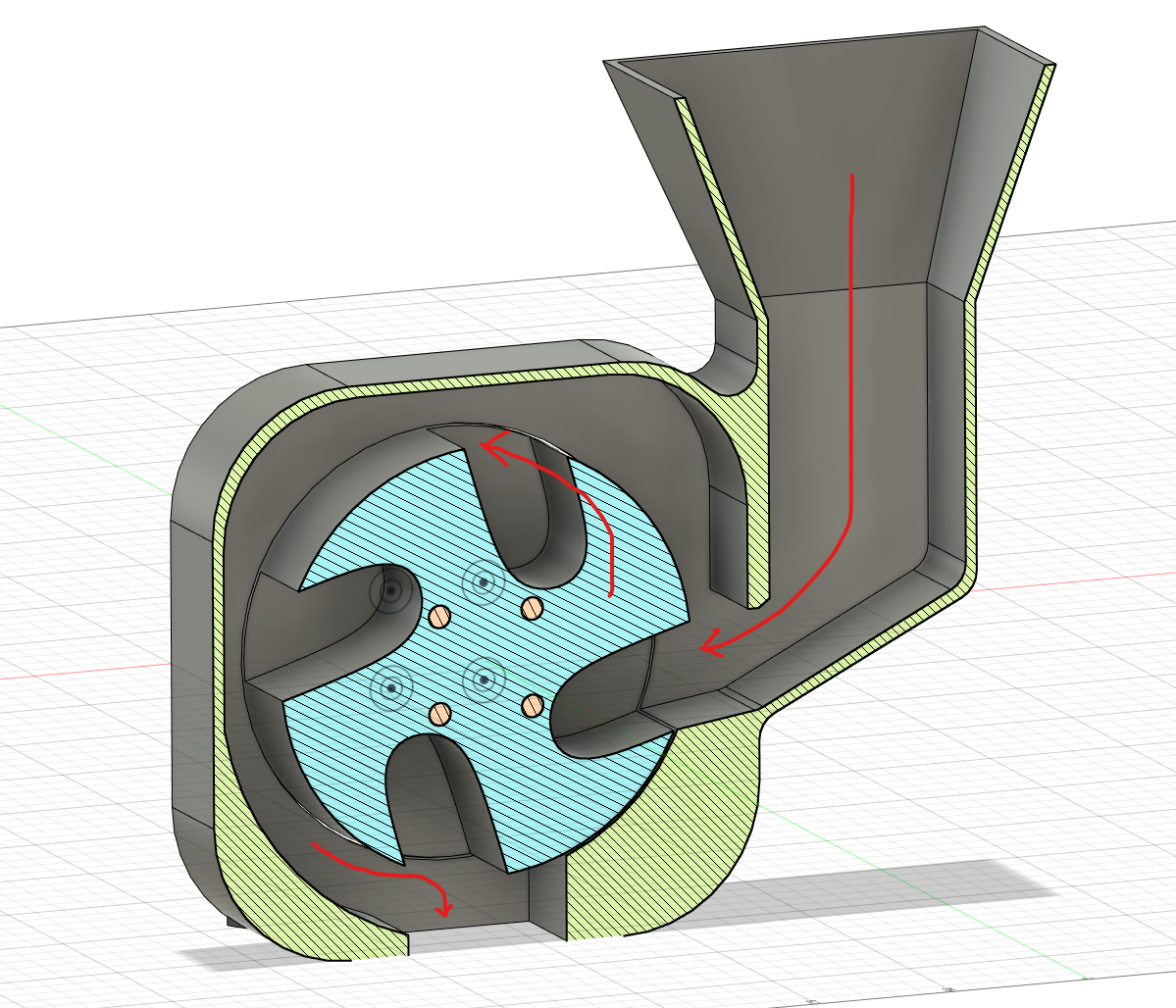

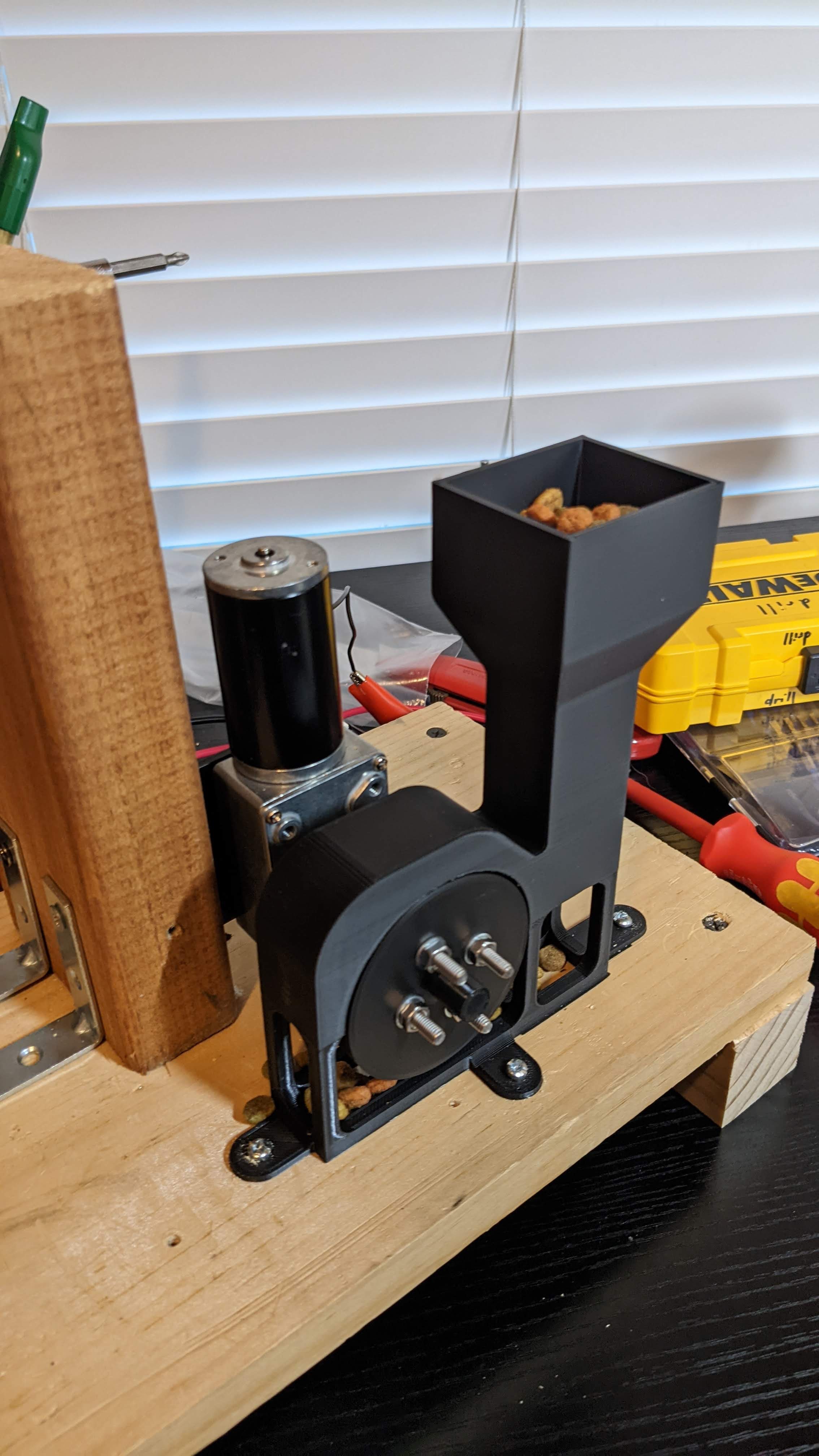

The concept of operation becomes much clearer when viewed cross-section.

![]()

The wheel turns counterclockwise. Food flows from the bottom of the hopper into the wheel. The wheel continues to rotate and is deposited underneath the wheel. Note that it is not necessary to actually have a slot all the way through the wheel - a water wheel design would work perfectly fine as well.

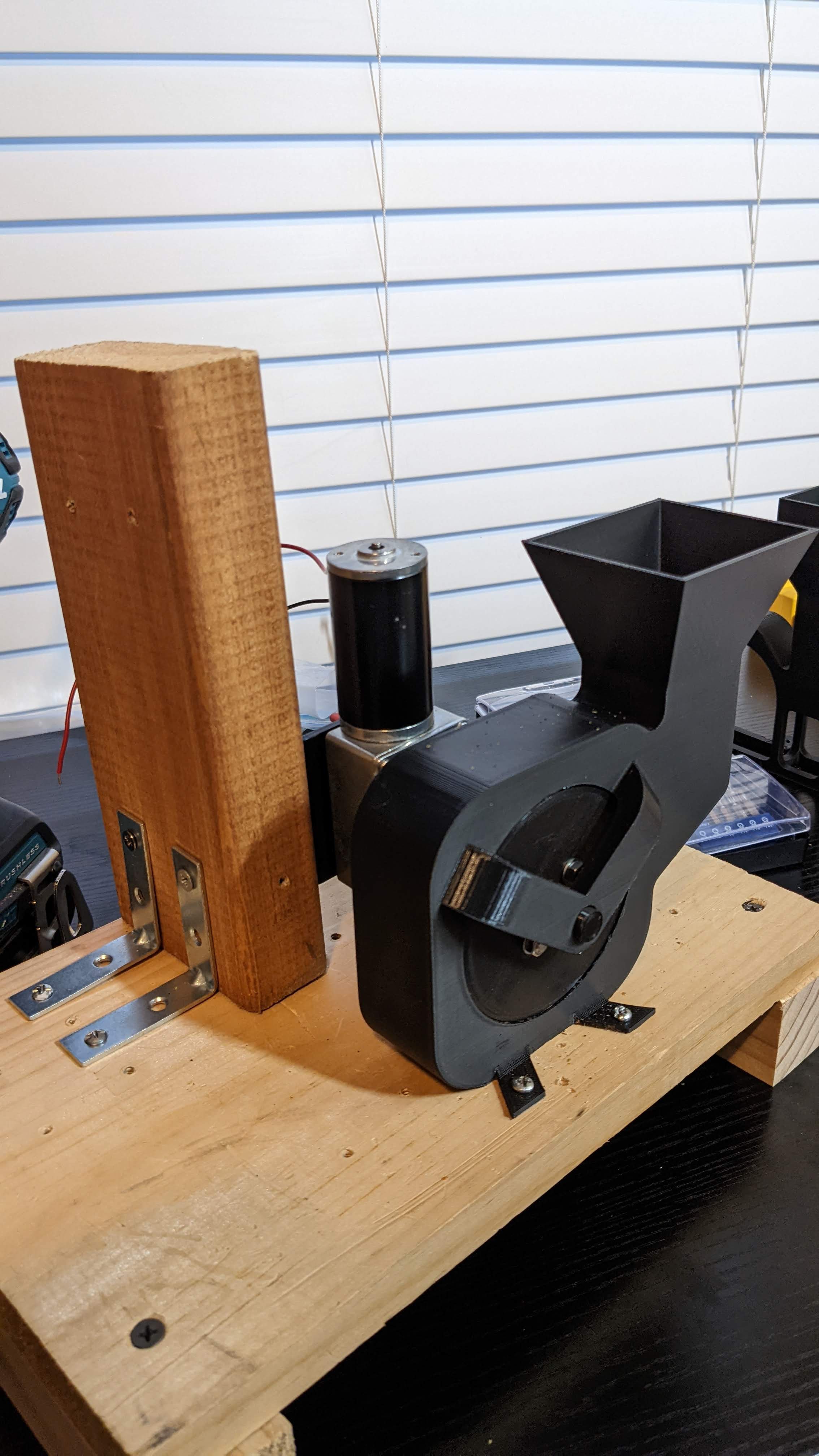

Here's the assembled mechanism.

![]()

![]()

As you can see, really quite a bit too small. I had to tap the hopper repeatedly to get food to flow like a liquid out of the hopper downshaft and into the "loading zone" for the wheel. But as long as I did so food deployed successfully with no destructive jams.

I am encouraged enough by the performance of this model that I am going to do a second revision of it. Planned tweaks:

- Increase size in all three dimensions

- Fix an issue where at one point in the wheel's rotation, food can slip out in an unintended manner.

- Increase room in the wheel chamber to further buy down risk of destructive jams

- Add a slight angle to the bottom of the food downshaft to prevent a "deadzone" where food could get stuck for long periods of time.

-

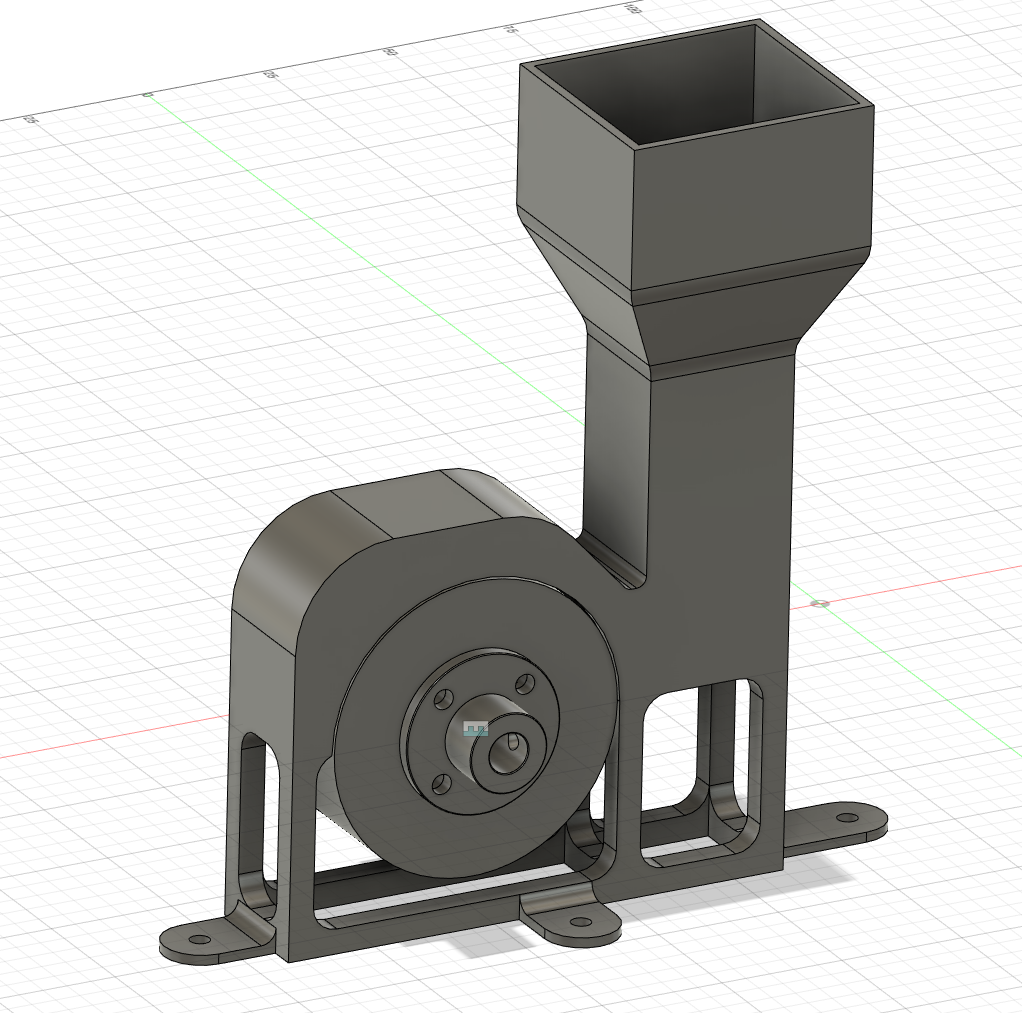

Deployment Mechanism 1 - Fail

05/21/2022 at 21:02 • 0 comments![]()

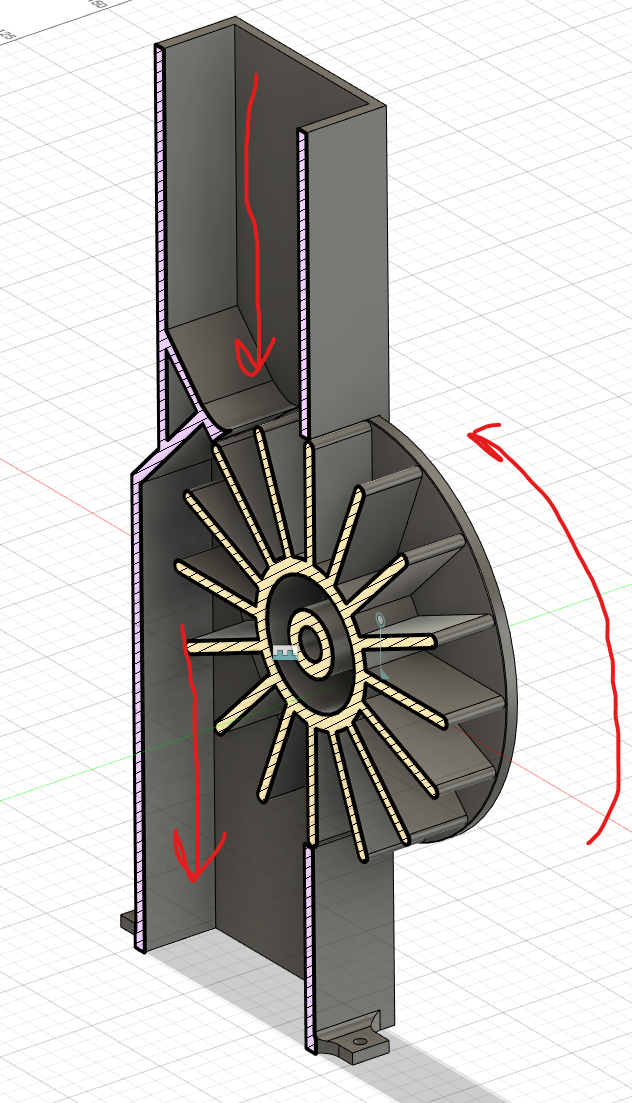

Learning from my mistakes of last time, I decided to actually test the food deployment mechanism before designing the final product. Pictured above was my first attempt. The concept of operations is simple, as illustrated below. The "water wheel" is turned by a worm-gear DC motor connected via a flange coupler. Food drops from the hopper into the water wheel, which turns, dropping the food into the chute where it would be flowed to a food bowl for consumption.![]()

My biggest problem to solve is to preventing kibbles from getting jammed in whatever mechanism I use and jamming up deployment. This model is specifically designed to prevent these jams with the curved lip at the bottom of the chute intended to block falling kibbles from getting stuck.

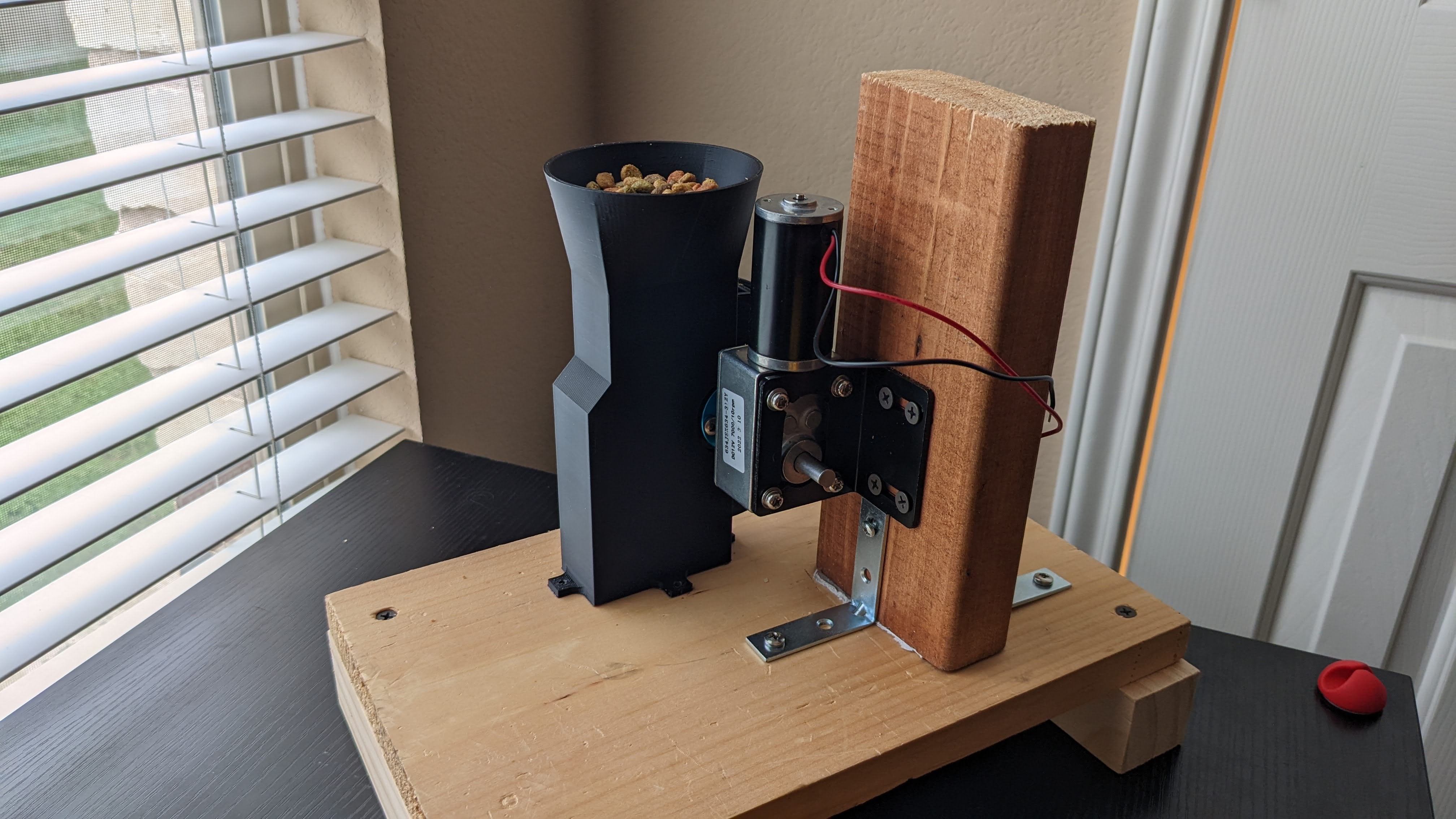

After designing and printing the wheel and hopper/chute parts, I designed the test fixture.

![]()

![]()

This uses the following parts:

Other materials included M4-7 bolts/nuts/washers, drywall screws, scrap wood, and L braces.

Finally, I connected it to a power supply and set it going!

Sadly, the results were disappointing. Although the fixture delivered food consistently and reliably, jammed kibbles was a big problems.

Roughly every ten seconds during active feeding, a kibble would become trapped between the wheel and the hopper chute. This would cause current to spike to 500mA (nominal 100mA), and more importantly, caused the entire fixture to jolt violently after the kibble got crushed or the jam cleared.

After only a minute of operation, there was significant damage to the lip of the hopper, which was specifically designed to prevent jams.

Sadly, I'm going to put this design in the bucket of unsatisfactory results.

Joseph Marlin

Joseph Marlin